Stretch bending-straightening machine

A technology of stretching, bending, straightening and straightening rolls, which is applied in the direction of bending workpieces, metal rolling stands, metal rolling mill stands, etc. problems, to achieve the effect of prolonging the service life, ensuring the straightening quality and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

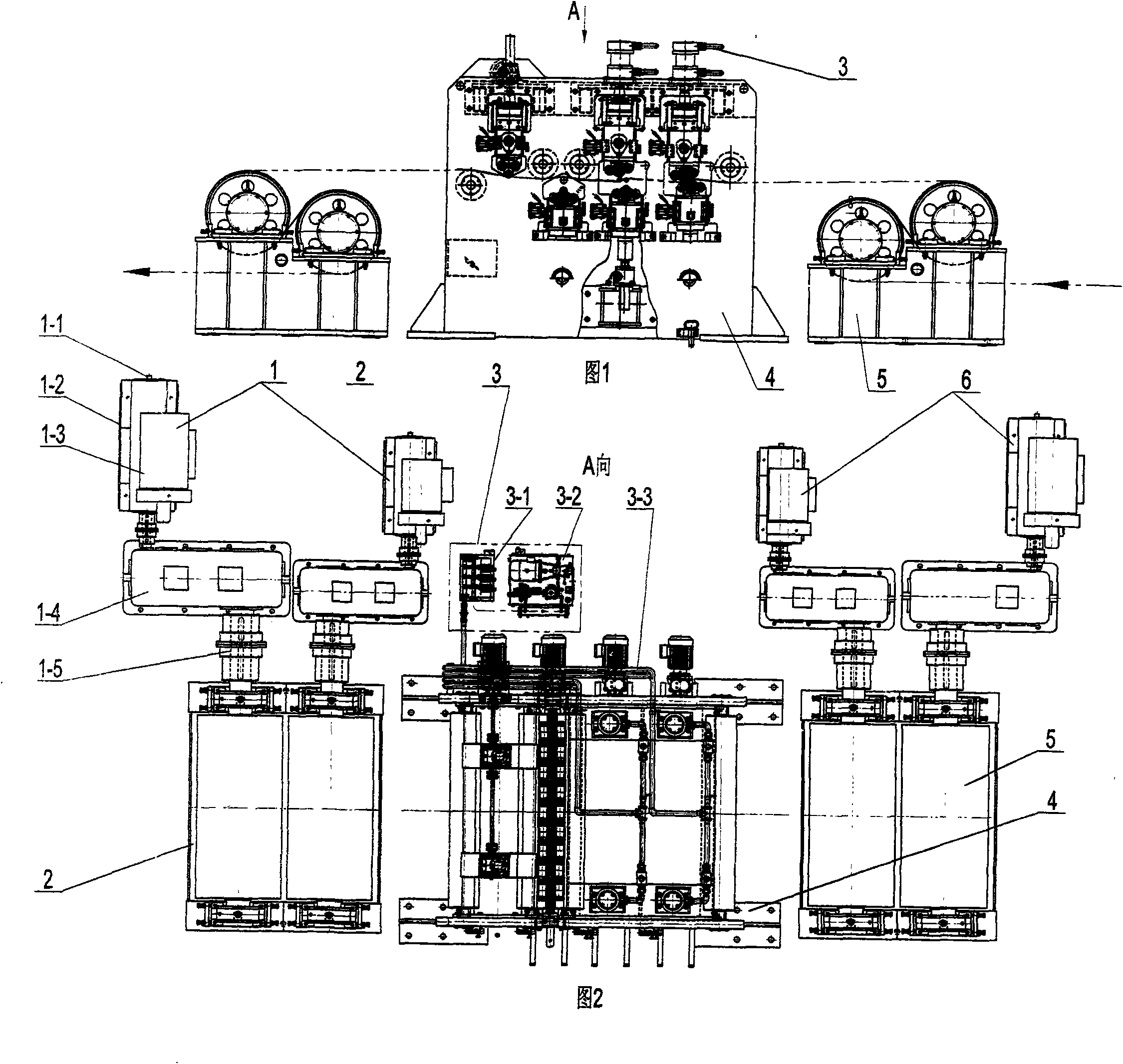

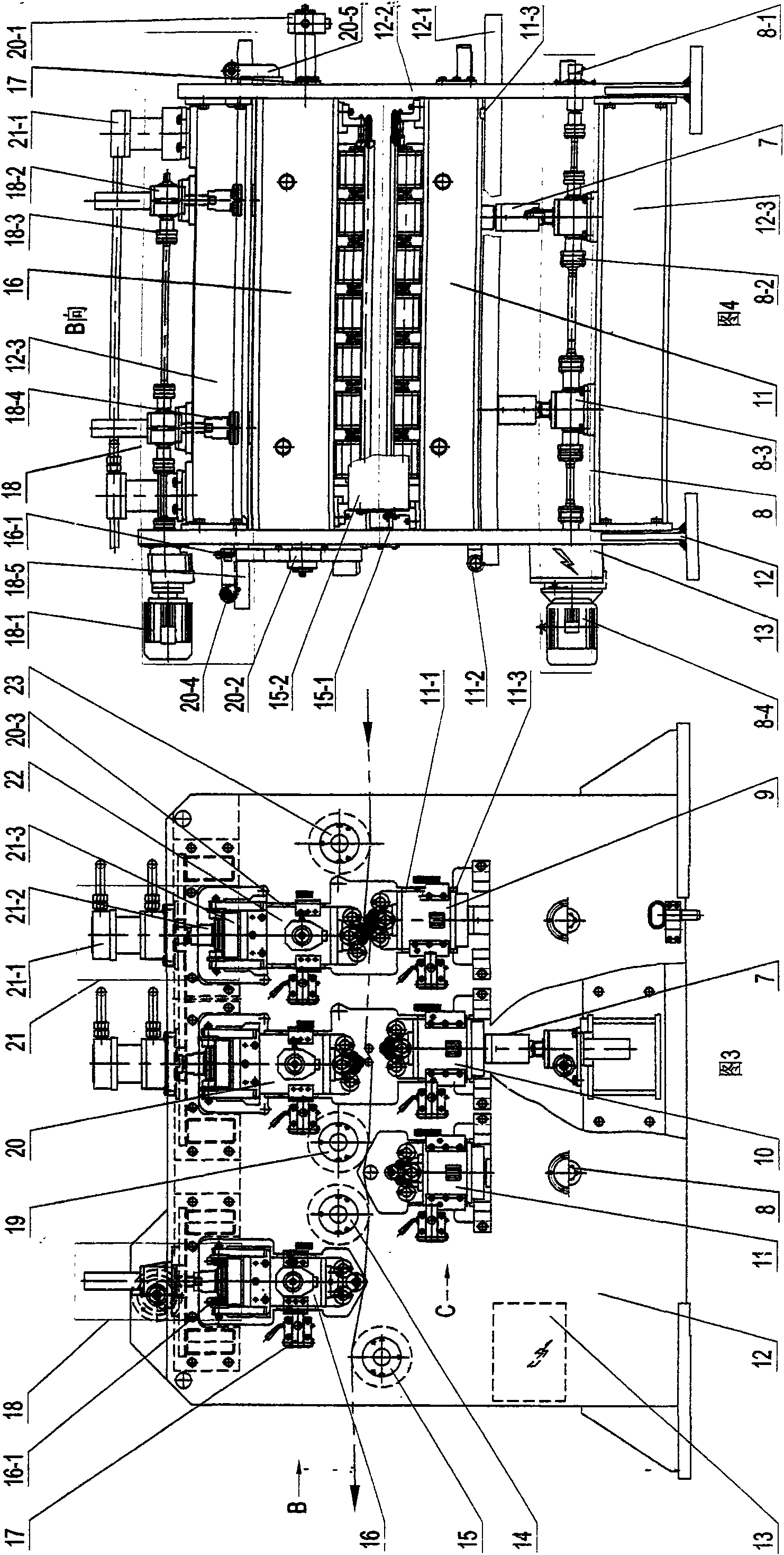

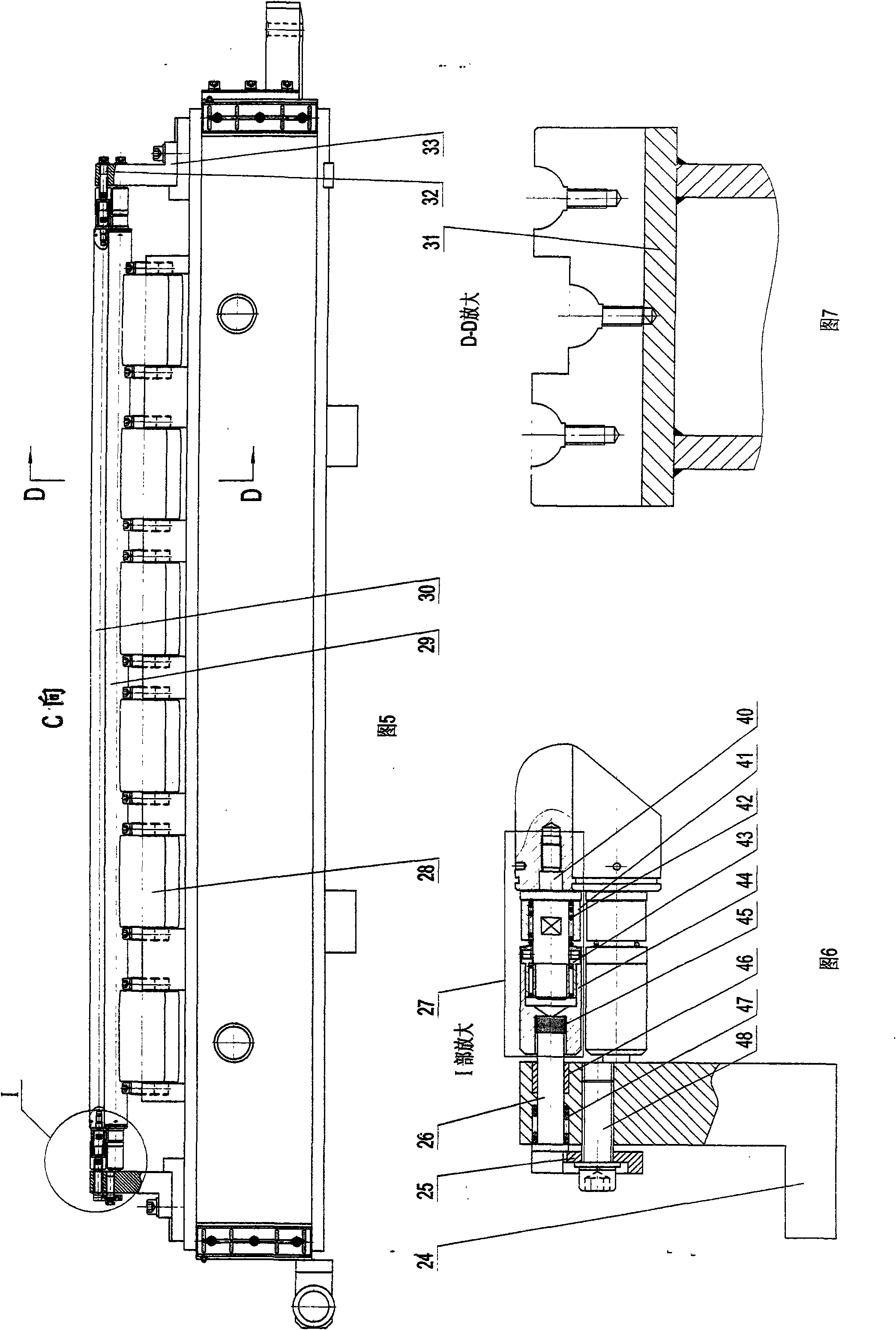

[0028] There are three forms of the series of tension-bending straightening machines of the present invention: two bending and two straightening, two bending and one straightening, and one bending and one straightening. The structural difference is reflected in the straightening machine body. The structure diagram of the body 4 with two bends and two corrections is as follows image 3 , Figure 4 As shown (right feeding form); two bends and one straightening image 3 , Figure 4 In contrast, the upper straightening roller box 16, the upper lifting device 18, and the steering roller device 15 are reduced; one bending, one straightening and image 3 , Figure 4 Contrast reduced turning roll device 15, upper straightening roll box 16, upper lifting device 18, upper bending roll box 20, fast depressing device 21, lower bending roll box 10. The series of stretch bending straightening machines of the present invention also have a left-feeding form.

[0029] The series of stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com