Hot continuous rolling mill loop control method and used controller

A hot tandem rolling mill and control method technology, applied in metal rolling, metal rolling, tension/pressure control and other directions, can solve the problems of inaccurate compensation, deviation of compensation value, aggravated looper fluctuation, etc., to improve control accuracy, The effect of improving control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

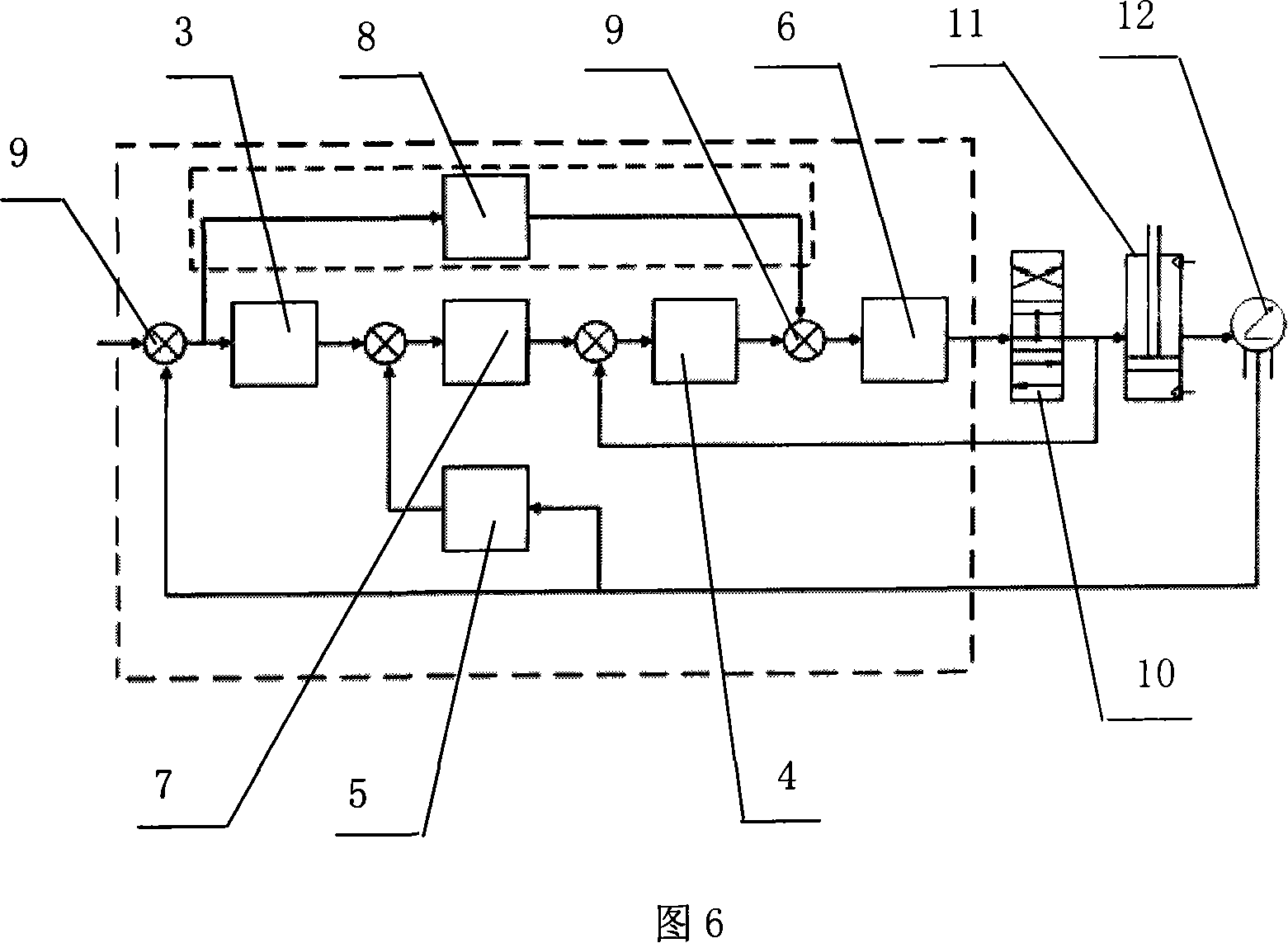

[0051] As shown in Figure 5, a kind of looper control method of hot rolling mill, this method comprises the following steps:

[0052] a. Set the parameters in the looper controller in advance, that is, set the angle intervals of at least two looper devices 2, and make the looper devices 2 correspond to different compensation coefficients in different angle intervals;

[0053] b. The hot rolling mill starts to run, and the angle decoder 12 feeds back the angle signal of the looper device 2 to the looper controller;

[0054] c. The looper controller compares the angle signal of the looper device 2 fed back with the set angle range to determine the compensation coefficient of the looper device 2;

[0055] d. The looper controller determines the output compensation value according to the looper compensation coefficient and outputs the compensation value to the looper servo valve

[0056] 10, used to compensate the looper device 2.

[0057] During the working process of the hot r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com