Horizontal loop device with support vehicles

A looper device and support car technology, applied to bending workpieces, metal processing equipment, metal rolling, etc., can solve problems such as difficult maintenance, deformation and instability of the looper and the looper fixed frame, and achieve stable operation, Easy control and maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

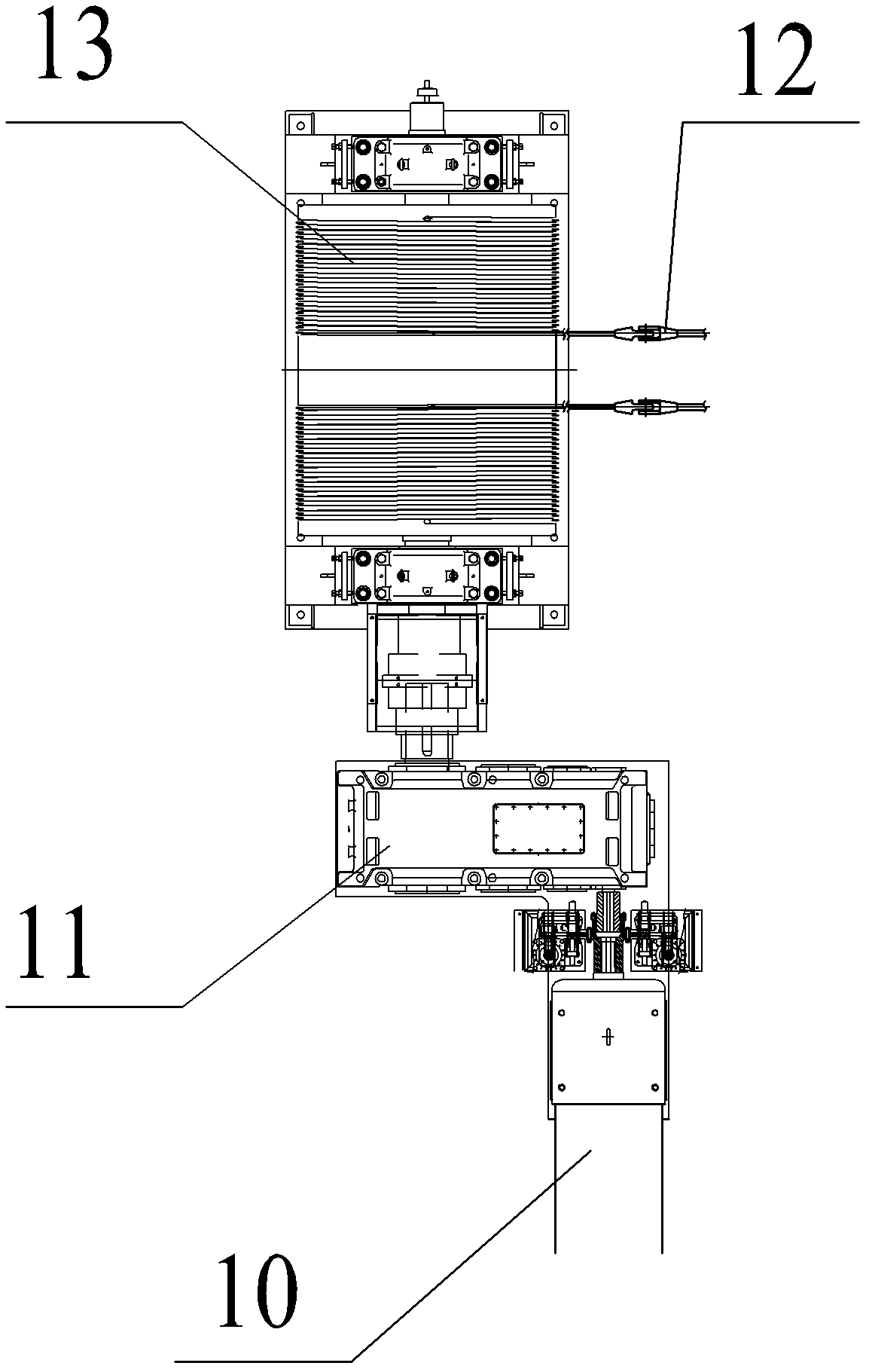

[0031] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

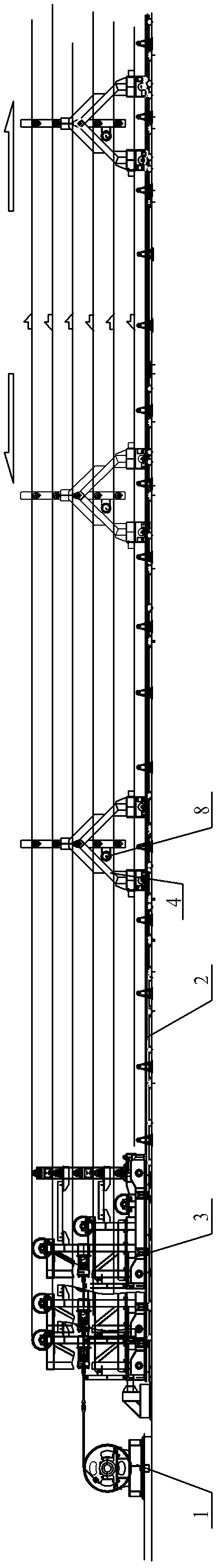

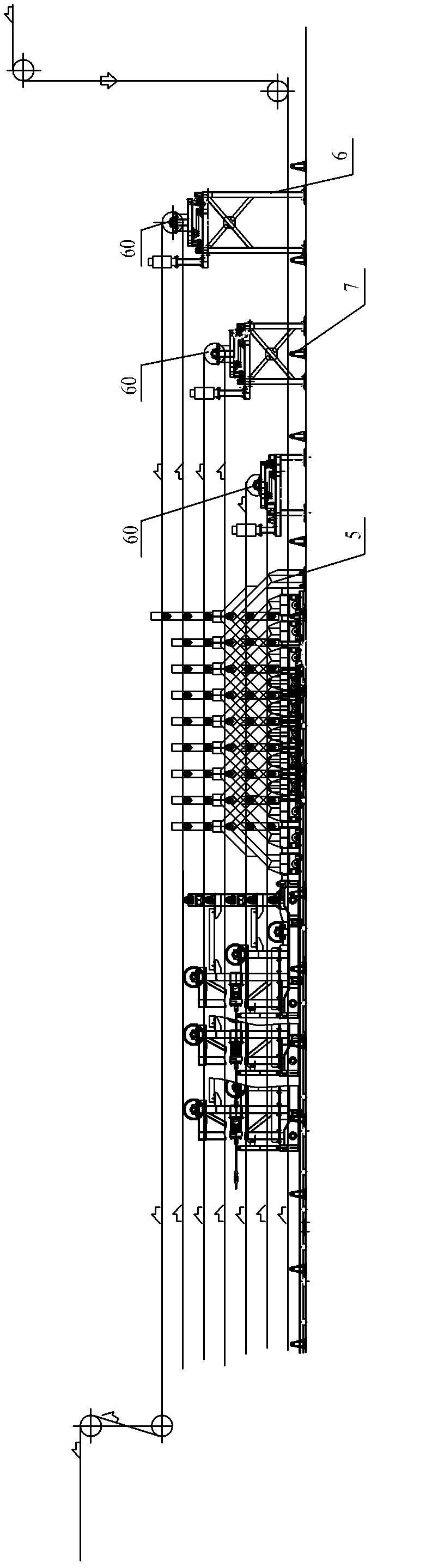

[0032] Such as Figure 1a and Figure 1b As shown, the support car horizontal looper device of the present invention includes a transmission device 1, a track device 2, a looper car 3 capable of running along the track device and a plurality of support cars 4, and a fixed track fixed on the looper base platform. Support device 5, steering deviation correction device 6 and a plurality of ground support rollers 7, the support car 4 and the fixed support device 5 are equipped with a looper and a support car, a support car and a support during the looper charging and releasing process. There is a torque reel device 8 with a uniform scaling distance between the cars. Figure 1a The middle left cutting head is the direction of filling the sleeve, and the right arrow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com