Loop control method and rolling method of hot rolling mill

A control method and technology for a hot rolling mill, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of production rhythm impact, operation stability impact, rolling rot, etc., to improve production stability performance, improve The effect of product quality

Active Publication Date: 2014-07-09

PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

View PDF4 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to keep the final rolling temperature, it can be solved by increasing the exit temperature of rough rolling. However, increasing the exit temperature of rough rolling will bring about problems such as the decrease of strip surface quality and the increase of energy consumption, which has a certain limit.

Improving the strip threading speed of hot strip rolling will have

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

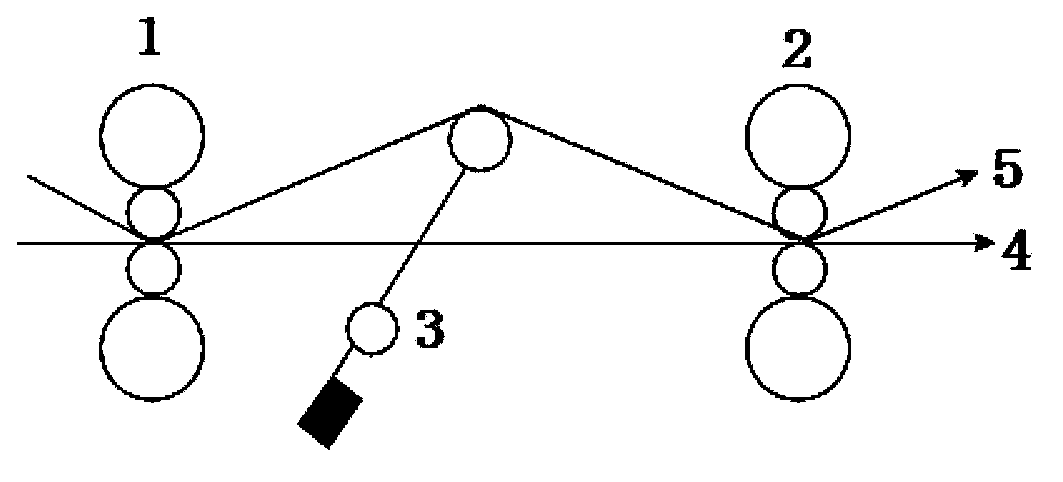

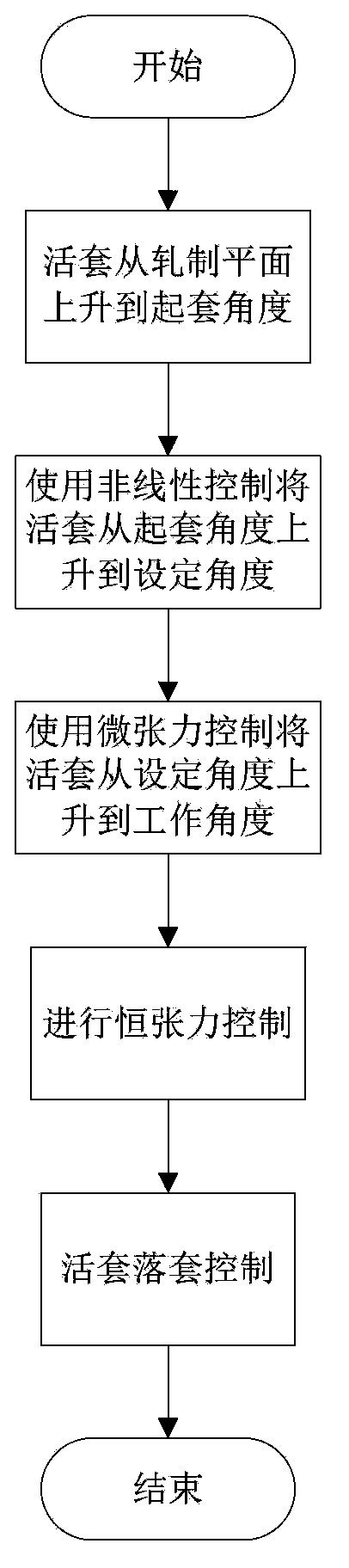

The invention discloses a loop control method and a wide and thin specification rolling method of a hot rolling mill. The loop control method comprises performing a loop raising process of a loop after the frame adjacent to the downstream of the loop bites steel; after the loop raising process is completed, performing a constant-tension control process of the loop; before the frame adjacent to the upstream of the loop releases the steel, performing the looping process of the loop. The loop-raising process of the loop comprises, after the frame adjacent to the downstream of the sleeve bite the steel, adjusting the angle of the loop to a loop raising angle; through non-linear control, adjusting the angle of the loop from the loop raising angle to a set angle which is greater than the loop raising angle; through micro-tension control, adjusting the angle of the loop from the loop raising angle to a working angle which is greater than the set angle.

Description

technical field [0001] The invention relates to a looper control method of a hot rolling mill and a rolling method for the hot rolling mill. Background technique [0002] The finishing looper of the hot rolling mill is the key equipment to keep the strip rolled stably in the finishing stand. Due to the large amount of deformation and the rolling force close to the limit of the equipment, the thin gauge is more likely to be affected by small changes in the rolled piece or the small disturbance of the rolling mill itself, and the untimely regulation and other damages to the rolling stability. The instability of the looper may cause the strip to deviate , Narrowing, crushing, rolling waste, and tailing phenomenon, so stricter requirements are put forward for the rolling control production process between each stand of the finish rolling. [0003] For traditional hot-rolled strip mills, Kawasaki Steel Corporation of Japan is the first in the world to develop a set of fully cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B37/00B21B41/00

Inventor 罗许翁建军谭继云王海云左军邹小波李俊洪任守斌黄徐晶李卫平

Owner PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com