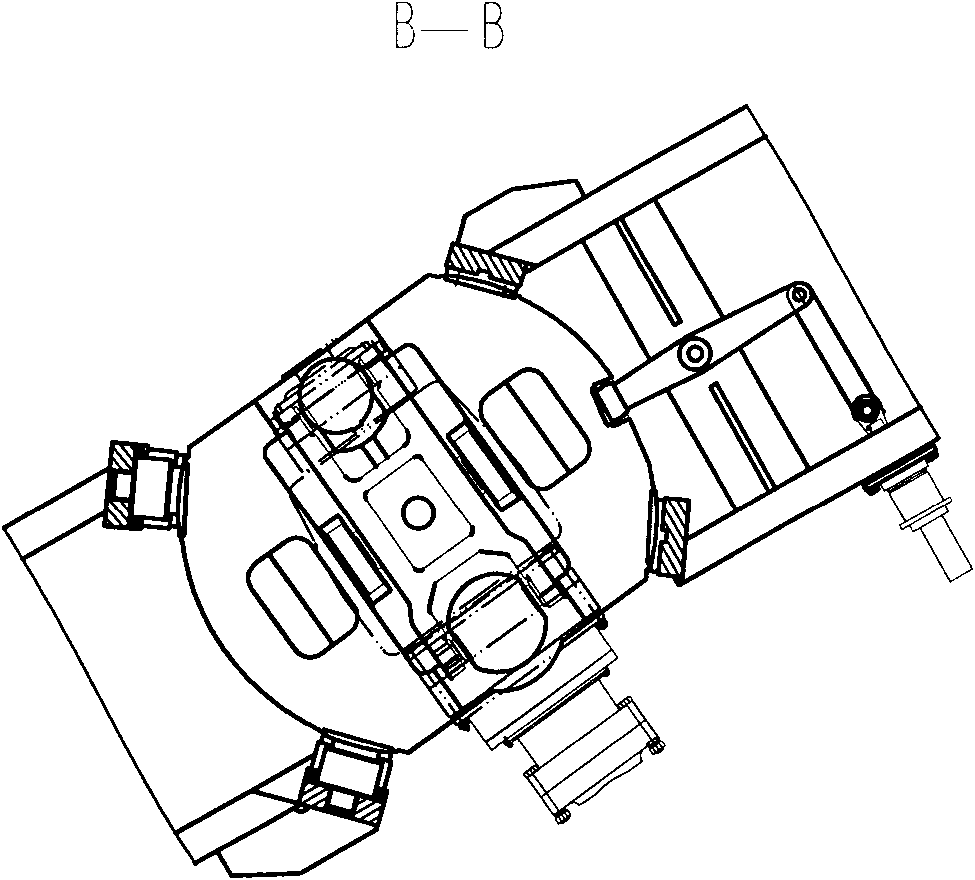

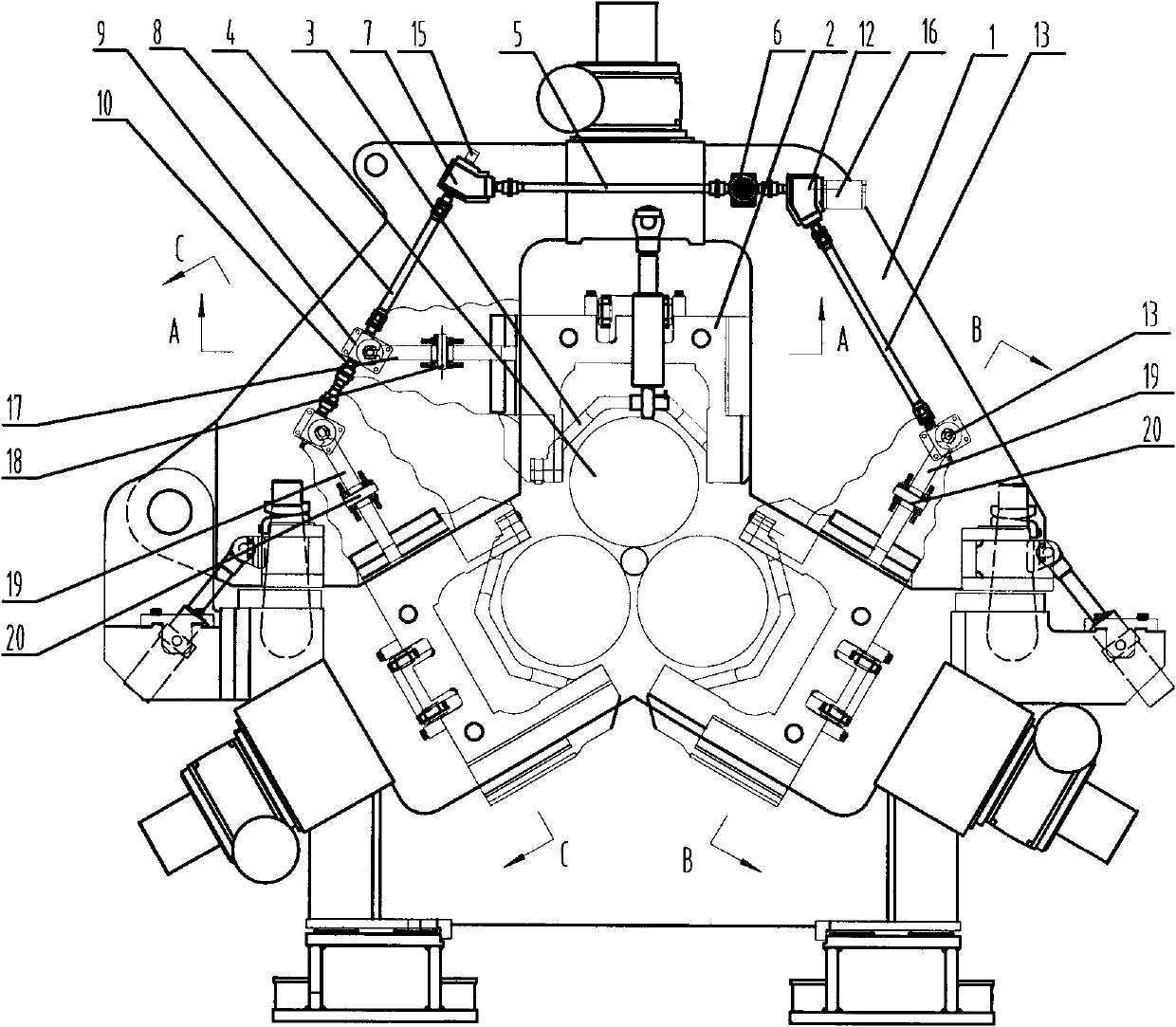

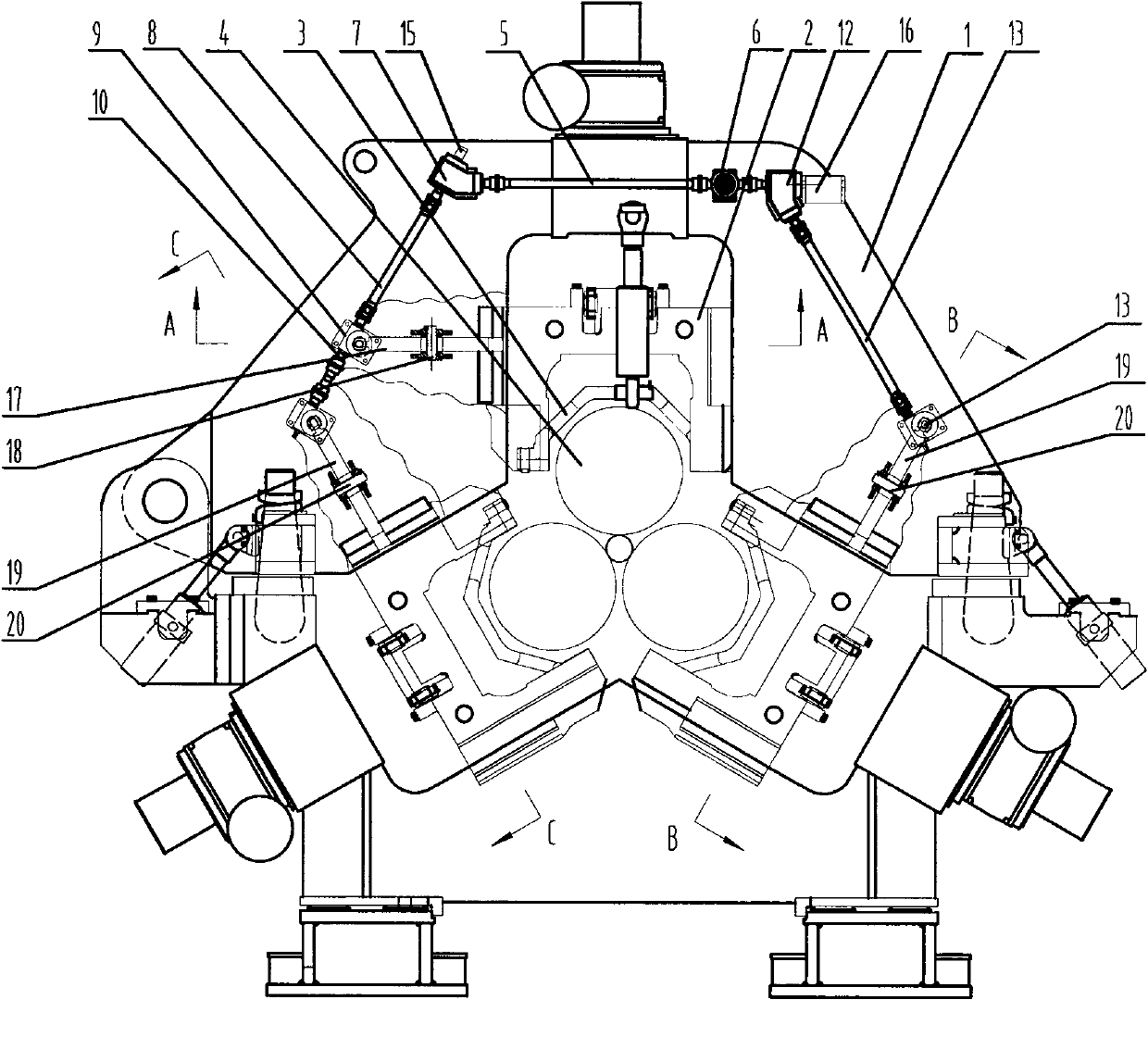

Feeding angle adjusting device of three-roller skew rolling mill

An adjustment device, a technology of skew rolling mill, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc. Synchronize the same precision and other problems to achieve the effect of improving the rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A feeding angle adjustment device for a three-roller cross-rolling mill, comprising an upper frame 1, an upper drum device 2, an upper roll box 3 and an upper roll assembly 4, and the upper frame 1 is respectively fixed with double output shafts Drive motor 6, the first worm gear lifter 9, the second worm gear lifter 11 and the third worm gear lifter 14, an output shaft of the double output shaft drive motor 6 passes through the first coupling and transmission rod 5 and the first commutator 7 and The second shaft coupling and transmission rod 8 are connected together, and the second shaft coupling and transmission rod 8 are connected together with one end of the input shaft of the first worm gear elevator 9, and the other end of the input shaft of the first worm gear elevator 9 passes through the first The three couplings and the transmission rod 23 are connected with the input shaft of the second worm gear lifter 11, and the other output shaft of the double output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com