Cylinder-less paper winder

A paper machine and roll technology, applied in the field of paper product processing equipment, can solve the problems of low production efficiency, long production process, waste, etc., and achieve simple and convenient rolling operation, good coreless roll quality, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

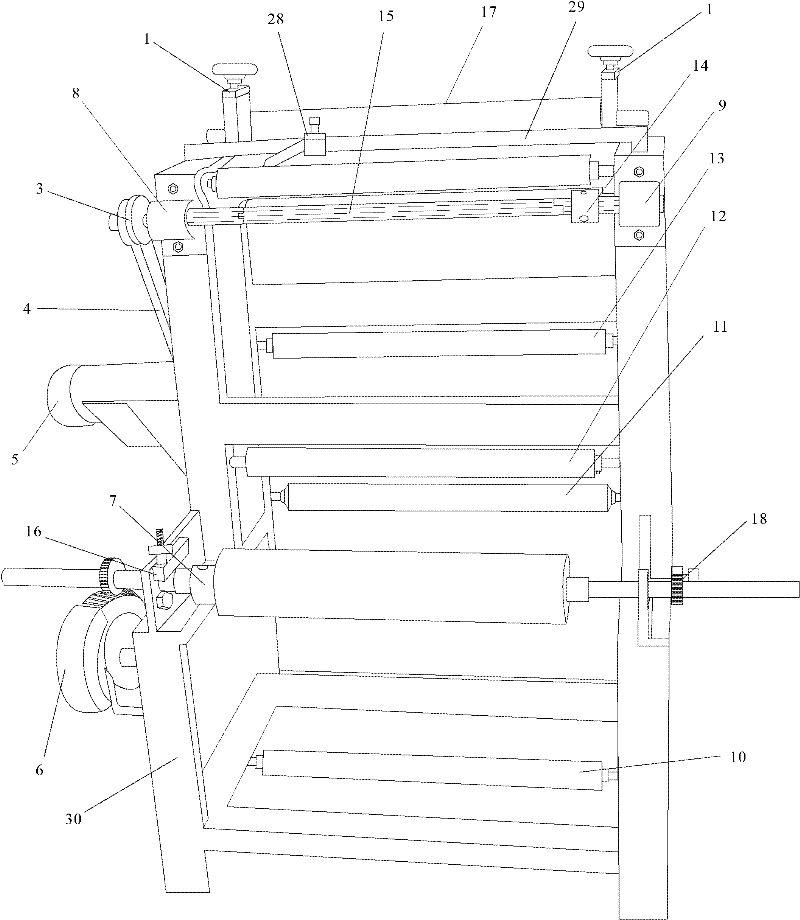

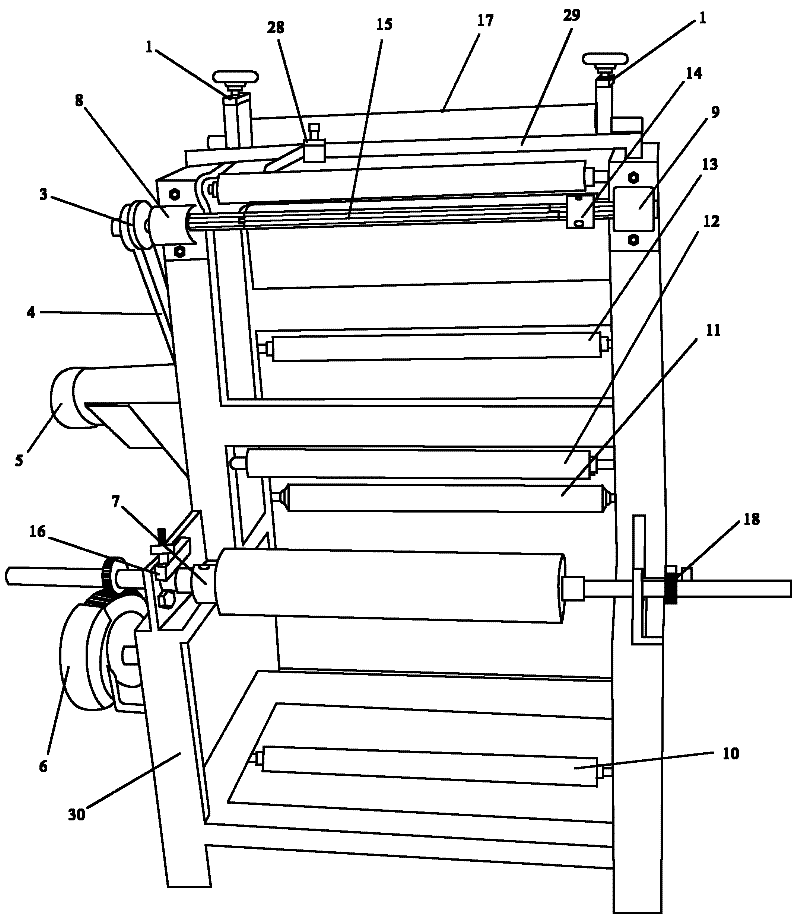

[0017] Embodiment: a kind of drumless winding machine of the present invention, as shown in accompanying drawing 1, accompanying drawing 2, it comprises frame 30, driving motor 5, transmission mechanism, several rollers and control device that are arranged in parallel in pairs, machine The frame 30 is provided with a feeding device 7 for placing the paper roll to be rolled, and the paper roll to be rolled can be rotated on the feeding device 7 to unfold its outer layer of paper webs sequentially to form a paper release action, so that the paper roll to be rolled The peripheral paper webs are unfolded and unloaded sequentially; the top front of the frame 30 is provided with a reel shaft 15, and the driving motor 5 drives the reel shaft 15 to rotate through a transmission device.

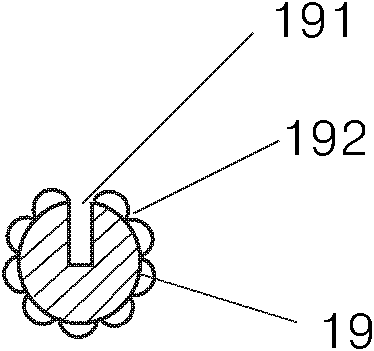

[0018] The reel shaft 15 is a three-section type, which is a three-section structure that can be connected as a rotating shaft to roll the paper tube and can be disconnected to unload the paper tube th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com