Fully-automatic intelligent heat insulation paper cup production line

An intelligent, fully automatic technology, applied in cardboard items, external support, transportation and packaging, etc., can solve the problems of low degree of automation, difficult humidity control, unfavorable in-line production of paper cups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

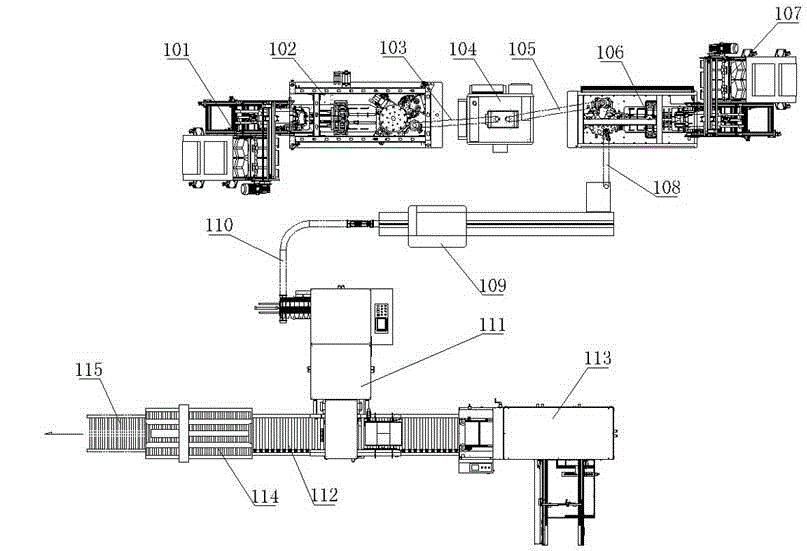

[0014] As shown in the figure, the fully automatic intelligent heat-insulating paper cup production line of the present invention consists of an inner cup forming machine 102, an inner cup testing machine 104, a heat-insulating cup outer sticking machine 106, an automatic bagging machine 109 and an automatic boxing machine connected in sequence. machine 111, the inner cup forming machine 102 and the inner cup testing machine 104 are connected through the first connecting conveying pipe 103, the inner cup detecting machine 104 and the heat-insulated cup external sticking machine 106 are connected through the second connecting conveying pipe 105, and the heat-insulating cup outer Sticker 106 and automatic bagging machine 109 link to each other by the 3rd connection conveying pipe 108, automatic bagging machine 109 and automatic cartoning machine 111 link to each other by the 4th connecting conveying pipe 110, automatic cartoning machine 111 links to each other with carton conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com