Edge shape control method

A control method and shape technology, applied in contour control and other directions, can solve the problem of inability to adjust and eliminate broken edge waves, and achieve the effect of improving rolling stability and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The edge shape control method provided by the embodiment of the present invention can realize the online control of the edge shape by using the single-tapered work roll equipped with the last stand rolling mill and its online roll shifting. In view of the characteristics of edge breaking, that is, there is edge breaking at about 70mm of the width, corresponding to the detection channels of the ABB shape meter, there are 3 channels for the working side and the driving side of the width respectively. The three channels refer to the part of the edge of the strip corresponding to the three detection channels of the ABB shape meter.

[0032] The invention provides a method for controlling the edge plate shape, including:

[0033] Use the shape meter to detect the shape value of the three effective channels on the working side and driving side of the strip;

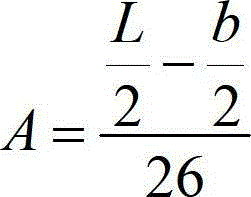

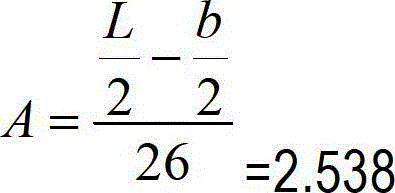

[0034] Correct the shape value to obtain the comprehensive shape value of the working side of the strip, that is:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correction factor | aaaaa | aaaaa |

| correction factor | aaaaa | aaaaa |

| correction factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com