Rolling construction monitoring system and rolling construction monitoring method

A construction monitoring and rolling machine technology, applied in general control systems, control/regulation systems, and comprehensive factory control, etc., can solve the problems of pauses in the middle, insufficient rolling times, and high randomness, avoiding undervoltage and Overvoltage, time saving, manpower reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

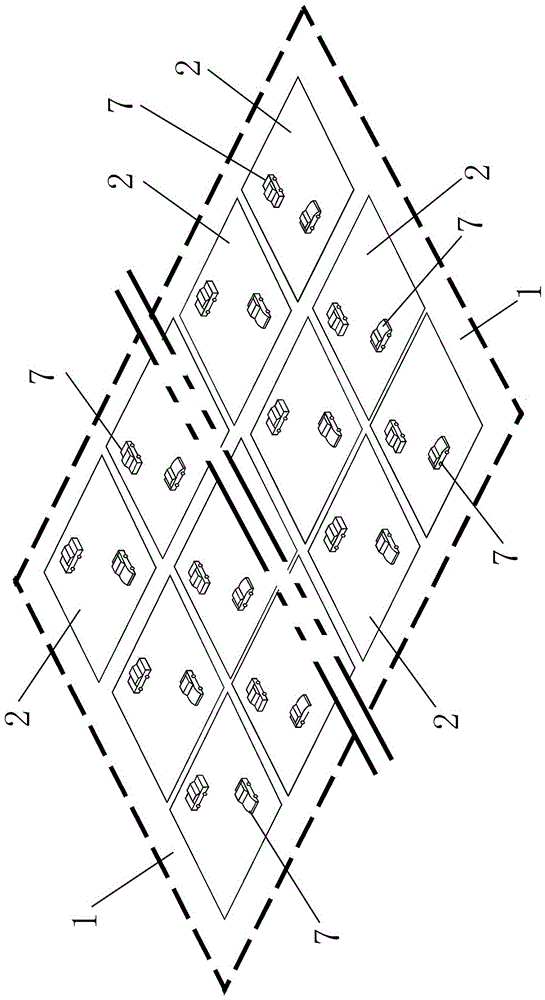

[0050] In the construction area (1), divide the construction tenders (2) according to the design requirements, set up at least one construction tender (2) according to the design requirements, and configure the construction rolling machine (7) in each construction tender (2), Configure at least one construction rolling machine (7) according to the design requirements, install RTK base station (5) and construction data processing mechanism (10) in the construction area (1), and install a vehicle on each construction rolling machine (7) GPS mobile station (6), RTK base station (5), vehicle-mounted GPS mobile station (6) and GNSS satellites (4) constitute the positioning system (3), and the vehicle-mounted GPS mobile station (6) in the overall positioning system (3) implements continuous , Real-time data collection, the vehicle-mounted GPS mobile station (6) collects the three-dimensional position information of the construction rolling machine (7), and the vehicle-mounted GPS mob...

Embodiment 2

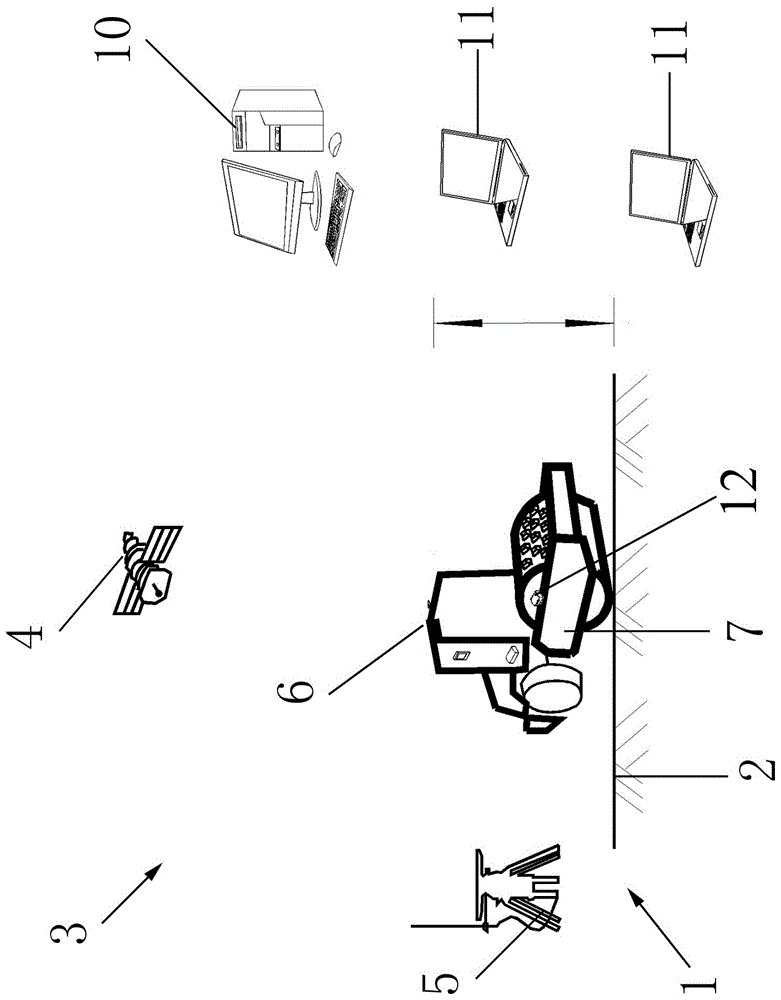

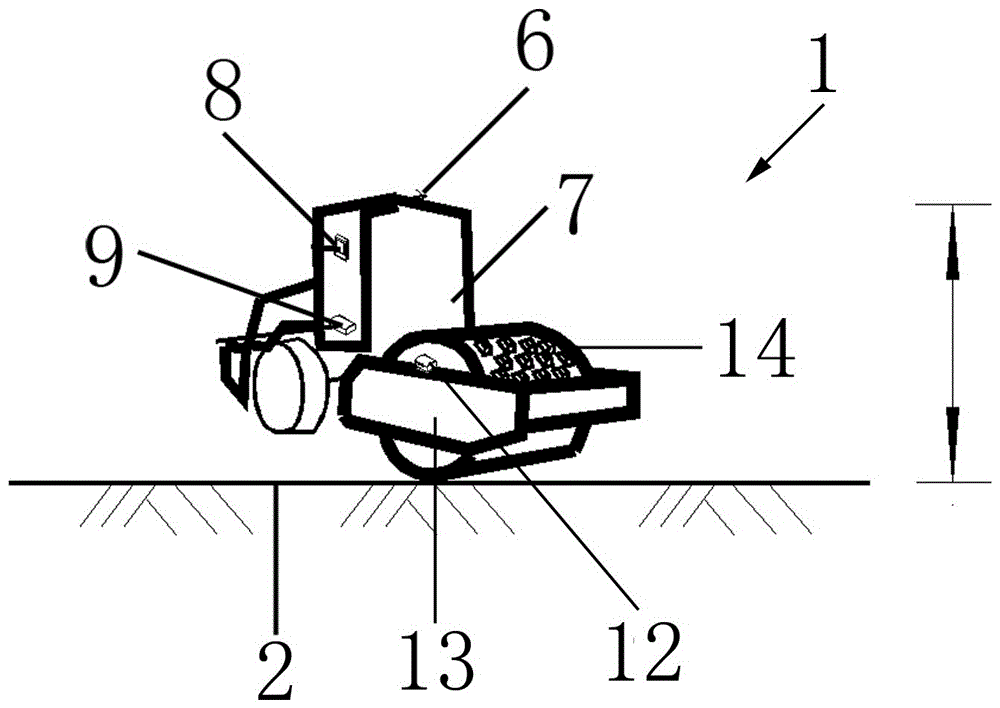

[0052] The rolling construction monitoring system consists of a positioning system (3), a construction rolling machine (7), a vehicle-mounted display (8), a vehicle-mounted controller (9), a construction data processing mechanism (10), an operation monitoring client (11) and a rolling mill The pressure detector (12) is composed, and the positioning system (3) is composed of GNSS satellites (4), RTK base stations (5) and vehicle-mounted GPS mobile stations (6).

[0053] The vehicle-mounted GPS mobile station (6) is connected to the vehicle-mounted controller (9) through a line, and the vehicle-mounted GPS mobile station (6) receives the data information of the RTK base station (5) in real time, as well as the walking track and rolling path of the construction rolling machine (7). The number of times of pressing and the thickness of the rolling layer are transmitted to the on-board controller (9), the rolling degree detector (12) is connected with the on-board controller (9) thro...

Embodiment 3

[0056] The RTK base station (5) searches for GNSS satellites (4) and receives the data information of the GNSS satellites (4). The RTK base station (5) sends differential data to the vehicle-mounted GPS mobile station (6) in real time through the radio station, improving the vehicle-mounted GPS mobile station (6). ) positioning accuracy.

[0057] Install vehicle-mounted GPS mobile station (6), rolling degree detector (12), vehicle-mounted display (8) and vehicle-mounted controller (9) on construction rolling machine (7), vehicle-mounted GPS mobile station (6), rolling The pressure detector (12) and the vehicle-mounted display (8) are connected to the vehicle-mounted controller (9) through a line, the vehicle-mounted GPS mobile station (6) receives data information from the RTK base station (5), and the vehicle-mounted GPS mobile station (6) continuously Accurate and real-time collection of rolling data information of the construction rolling machine (7), the vehicle-mounted GP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com