Cloth-rolling device of weaving machine

A loom and cloth rolling technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high price, high tension of cloth rolling, slow speed of cloth rolling roller, etc., and achieves simple structure, convenient installation and maintenance , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

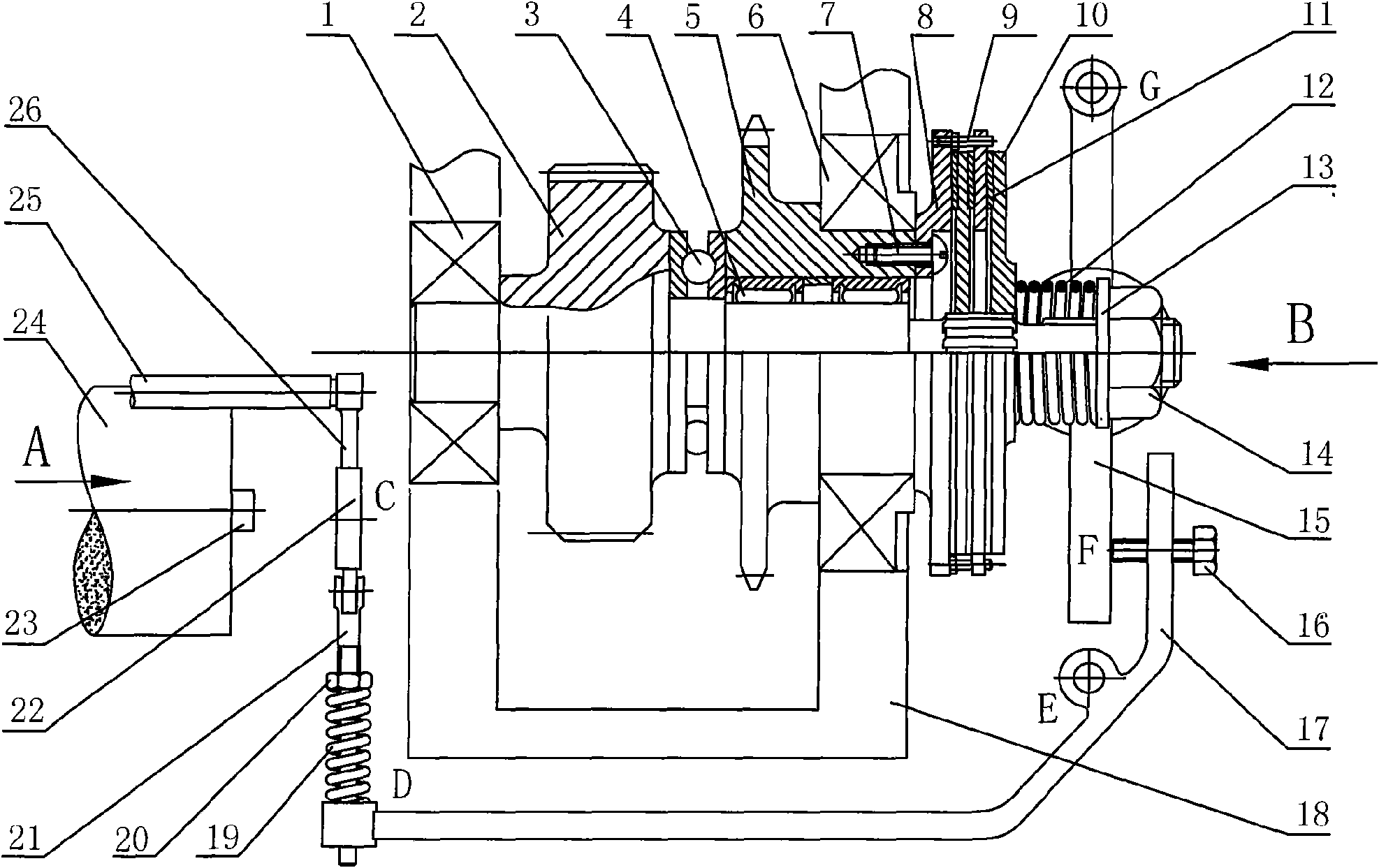

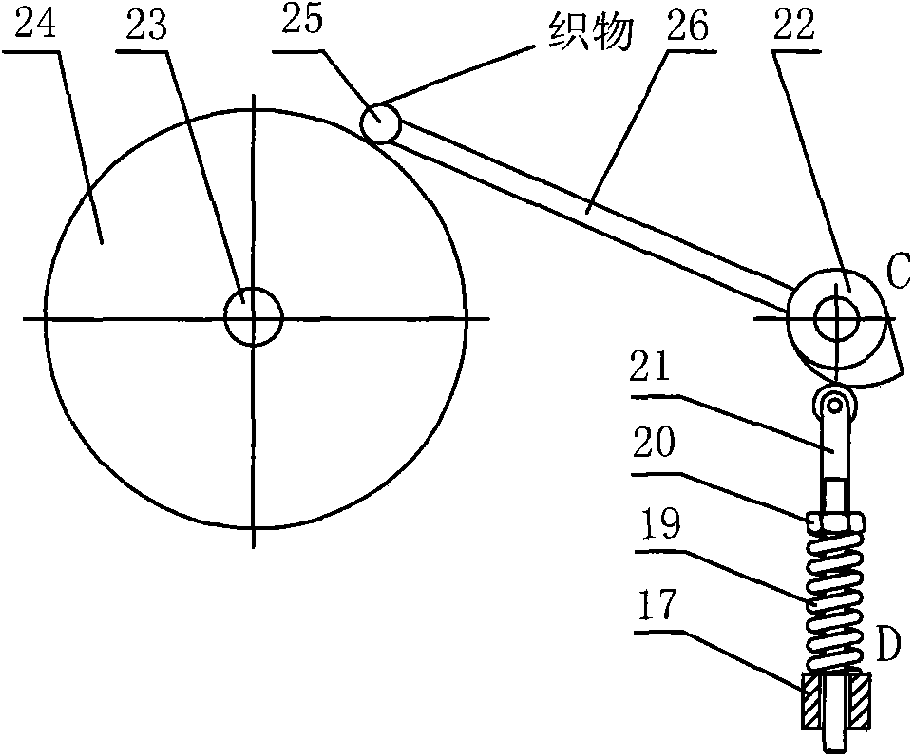

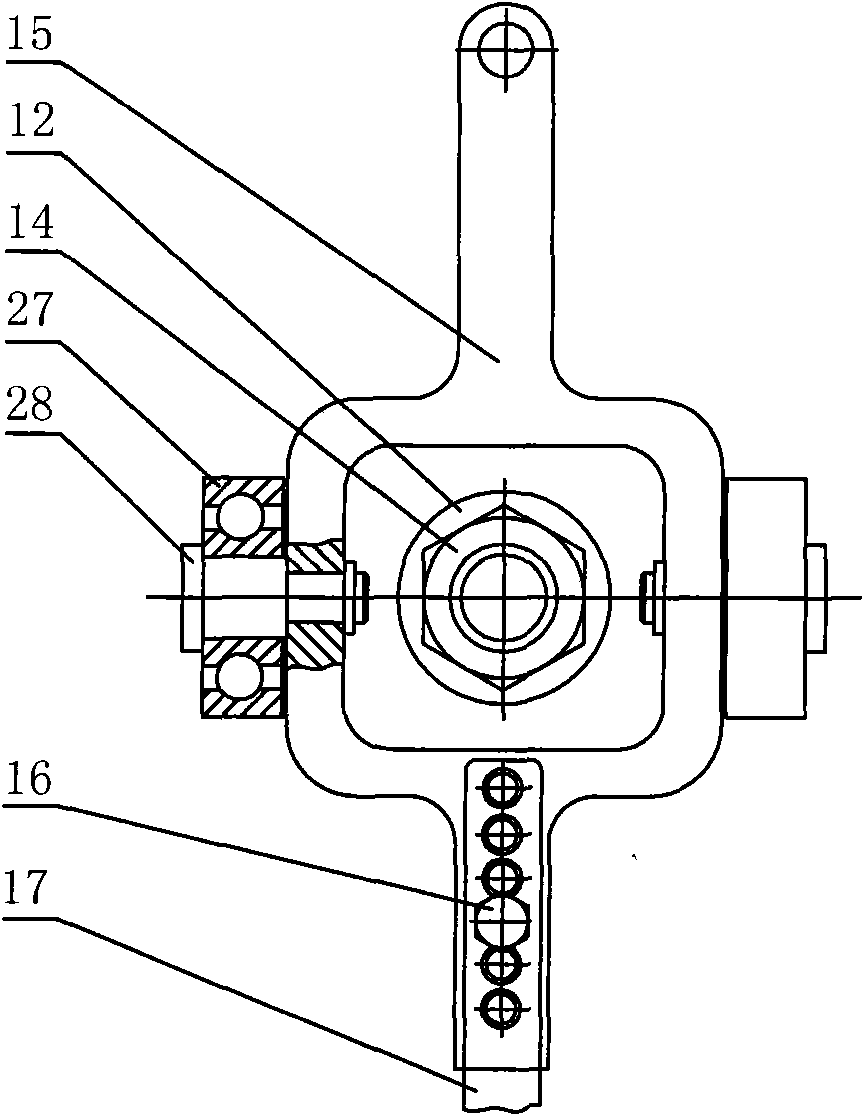

[0025] See attached figure 1, the specific embodiment of the input shaft, the output shaft and the friction clutch between the two shafts in the present embodiment is as follows: the input shaft 2 is driven by the main shaft of the loom; not shown) and other drives; the hollow output shaft 5 is looped on the input shaft 2 through the needle roller bearing 4, and the axes of the two shafts coincide and can rotate relatively; the active friction disc 10 of the friction clutch is connected with the input shaft 2 through a spline, It can move axially on the input shaft 2; the driven friction disc 8 of the friction clutch is fixedly connected with the output shaft 5 with the connecting screw 7, and the rest of the driven friction discs are fixed circumferentially relative to the driven friction disc 8 through the guide pin 9, but can be moved along the The guide pin 9 moves axially; the friction plate 11 is clamped by the main and driven friction discs, and the friction force is tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com