Method for testing bond strength of materials

A technology of bonding strength and testing method, which can be used in analyzing materials, measuring devices, instruments, etc., and can solve problems such as difficulty in grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

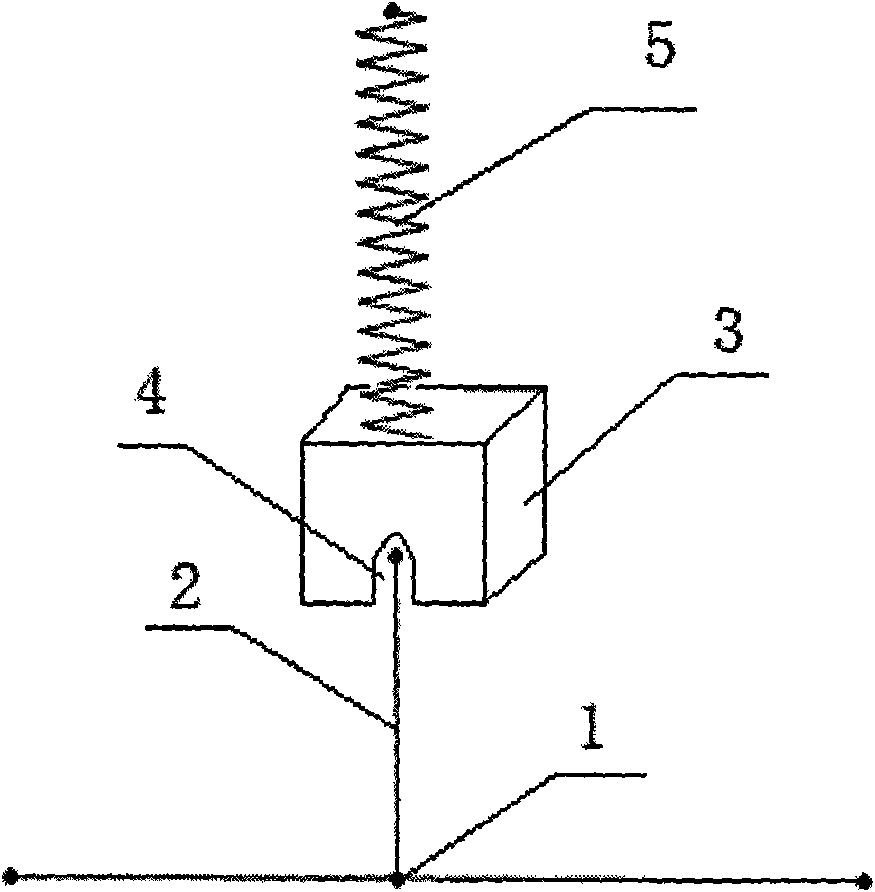

[0023] Embodiment 1: see image 3 , the present invention adopts the method of single bonding point wire bonding tension test, that is, the bonding test lead 2 perpendicular to the surface where the bonding point 1 is located is fastened on the clamping fixture 3, and the lower end of the clamping fixture 3 is provided with a Groove 4, the bonding test lead 2 is pasted in the groove 4 of the clamping fixture 3 by glue, and the clamping fixture 3 is pulled by the stress sensor or tension meter 5 on the bonding point 1 at a rate of no more than 2g per second Pull up vertically at a constant rate to directly read the tension value on the tension meter to obtain the bonding strength of the bonding point, and obtain the bonding strength of another bonding point in the same way. Let the tensile force displayed by the tension meter be F 1 , and assume that the tensile strength of the bonding test lead and bonding point is the same everywhere as F 2 , and once the force on the lead ...

Embodiment 2

[0024] Example 2, see Figure 4 In this embodiment, there is a small hole in the clamping fixture 3, and the bonding test lead 2 is tightened and fixed by the rubber nut after passing through the small hole. The test method is the same as that of the first embodiment.

Embodiment 3

[0025] Embodiment 3: see Figure 5 , the present embodiment utilizes frictional force, and the clamping fixture 3 adopts two aluminum plates with rubber, and the bonding test lead 2 is clamped by two aluminum plates with rubber, and then the two aluminum plates with rubber are fixed, and the test method is the same as the implementation example 1.

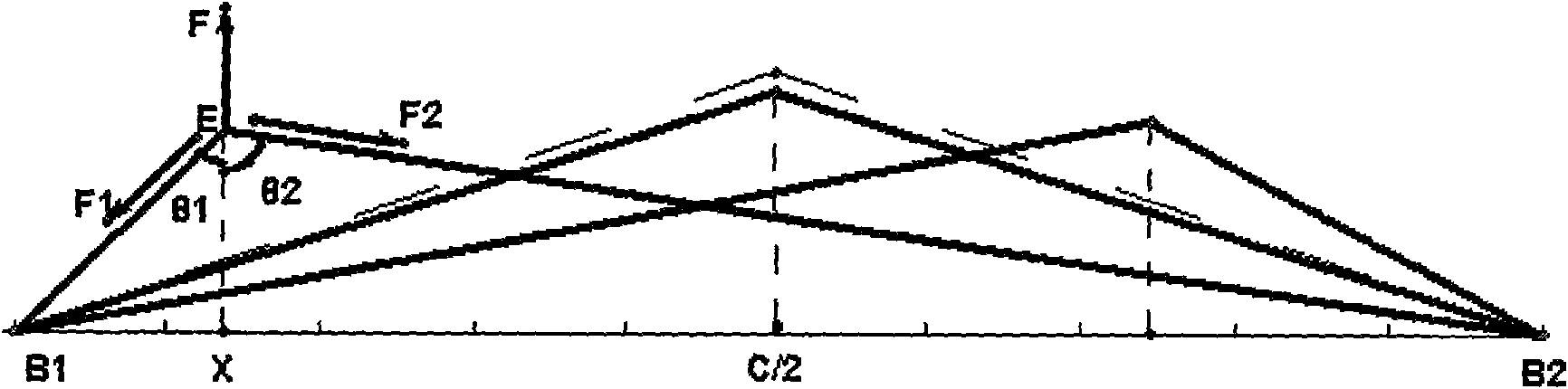

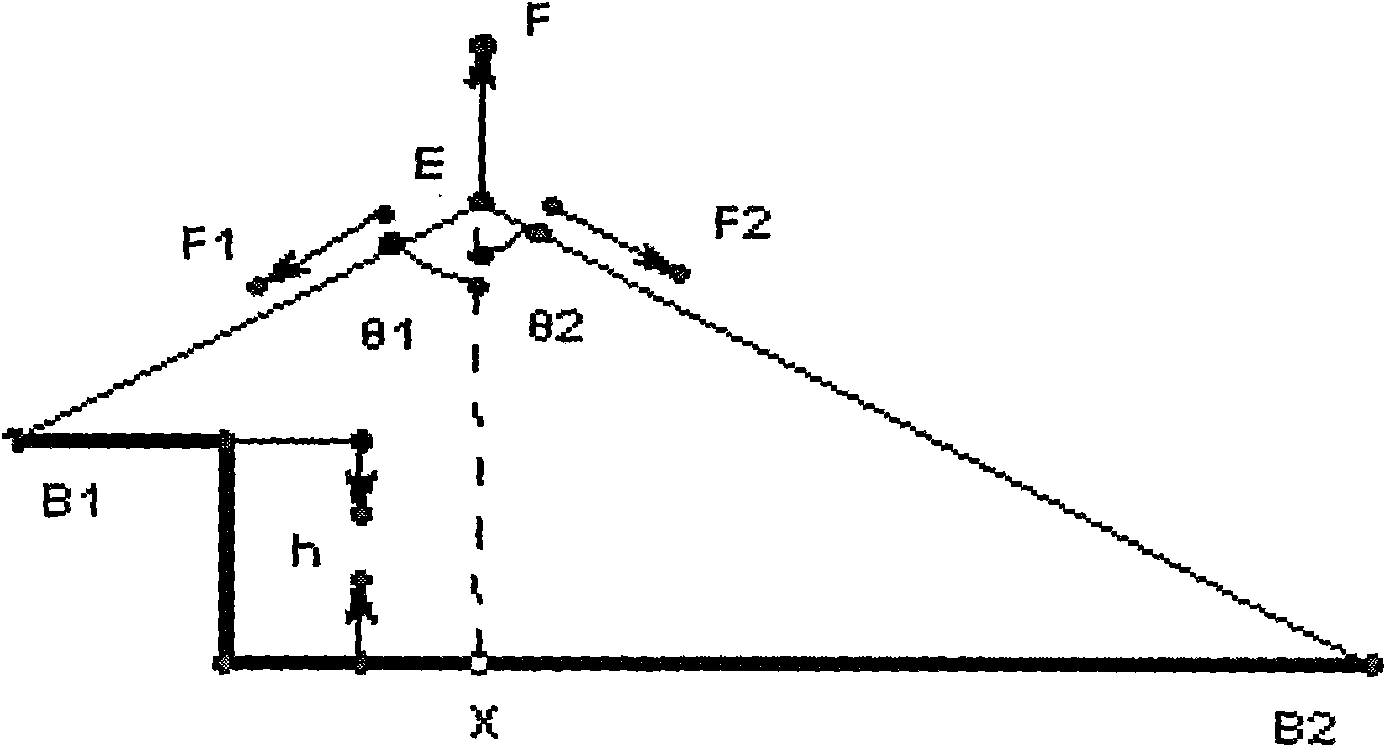

[0026] The present invention starts from the tensile force of accurate measurement of bonding strength. For the destructive wire bonding tensile test of double bonding points, the ideal situation is that the hook and the leads on both sides are all at 120 degrees. The force received is the same, so the value read by the spring is the accurate bond strength value. In actual operation, it is necessary to visually check the position of the hook by the operator so that the angle between the spring and the two leads is 120°, that is, it is difficult to obtain accurate bonding strength. The test method of the wire bonding tensile test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com