Inner-furnace tension compensation control method suitable for continuous rolling horizontal type annealing furnace

A horizontal annealing furnace, compensation control technology, applied in heat treatment process control, furnace, heat treatment furnace, etc., can solve problems such as tension fluctuations in the furnace, improve production efficiency and product quality, reduce abnormal downtime, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

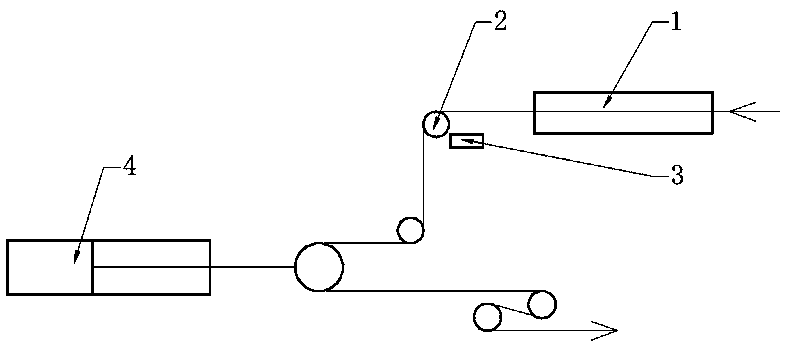

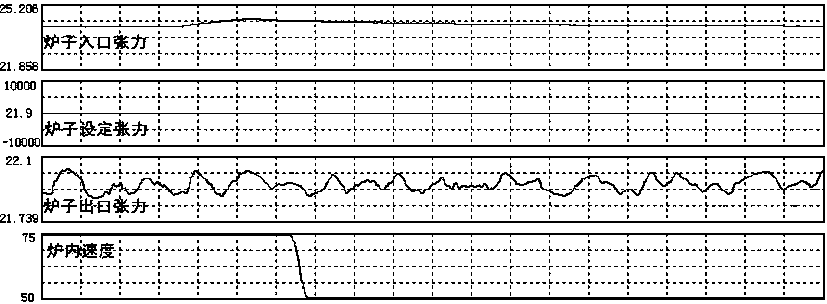

[0032] In this embodiment one, the ultra-pure ferritic steel 441 with a size specification of 1.1×1250mm is taken as an example, as figure 1 The bouncing roller device and the bouncing roller movement closed-loop control system are installed as shown, when the steel strip of the same specification passes through the annealing furnace, the influence of the acceleration and deceleration process in the furnace area on the tension in the furnace:

[0033] Before the steel coil goes online, the width of the ferritic steel 441 is measured by the on-site sensor in the program, and the given value of the thickness gauge at the exit of the rolling mill is collected through the rolling mill. Calculate ΔW=|1252mm-1249mm|=3mm, Δh=|1.098mm-1.105mm|=0.007mm, determine the compensation coefficient n as 0.5,

[0034] Ultra pure ferritic steel 441

previous volume

next volume

width

1249mm

1252mm

thickness

1.105mm

1.098mm

[0035] Such as fi...

Embodiment 2

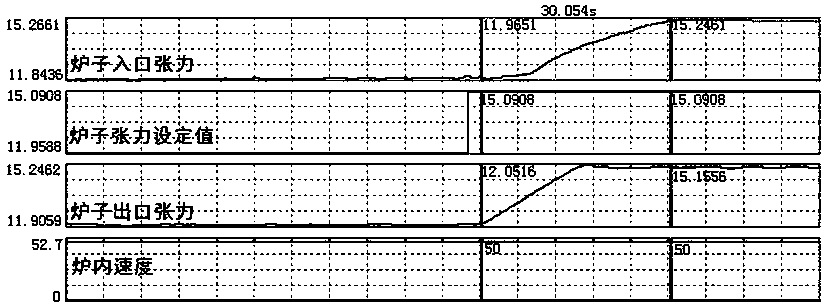

[0038] In the second embodiment, the ultra-pure ferritic steel 441 with a size specification of 1.1×1250 mm is changed into an ultra-pure ferritic steel 441 with a size specification of 1.5×1500 mm as an example, such as figure 1 The bouncing roller device and the bouncing roller motion closed-loop control system are installed as shown in the figure. Under the same strip speed, the influence of the specification change process on the tension in the furnace is as follows:

[0039] Ultra pure ferritic steel 441

[0040] The speed of the steel strip in the annealing furnace is fixed at 50m / min, and the program selection is used to calculate ΔW=|1505mm-1248mm|=257mm, Δh=|1.498mm-1.102mm|=0.396mm, and the compensation coefficient n is determined to be 1.1, such as image 3 , Dimensions and specifications change, the program calculates that the set value of tension in the furnace is changed from 11.96kN to 15.09kN. During the rolling process, through the spring roller tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com