A basalt fiber winding composite pipe forming device

A basalt fiber and tube forming technology, which is applied in the direction of tubular articles, household appliances, other household appliances, etc., can solve the problems that the uniformity of tension has a great influence on the quality of filament winding products, the tension is not constant, and the overall strength is affected. The effect of saving labor and cost, stable fiber tension fluctuation, and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

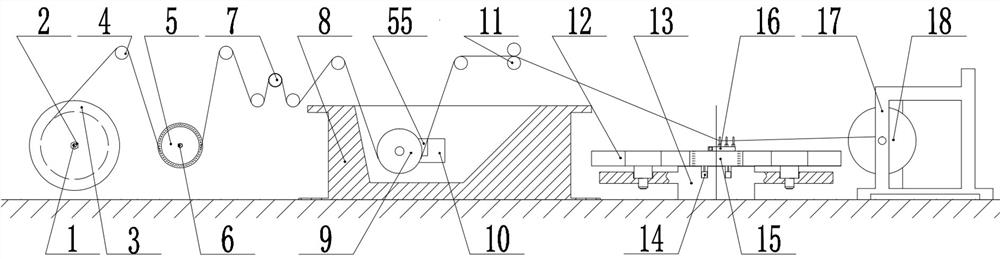

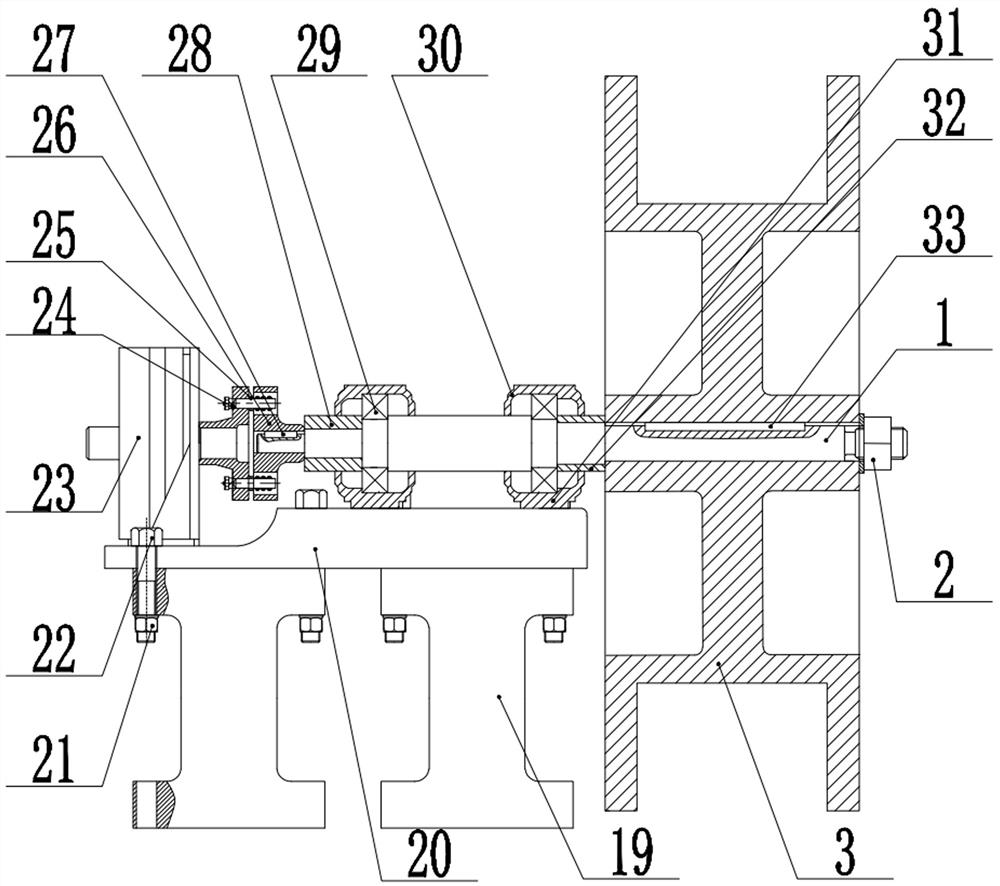

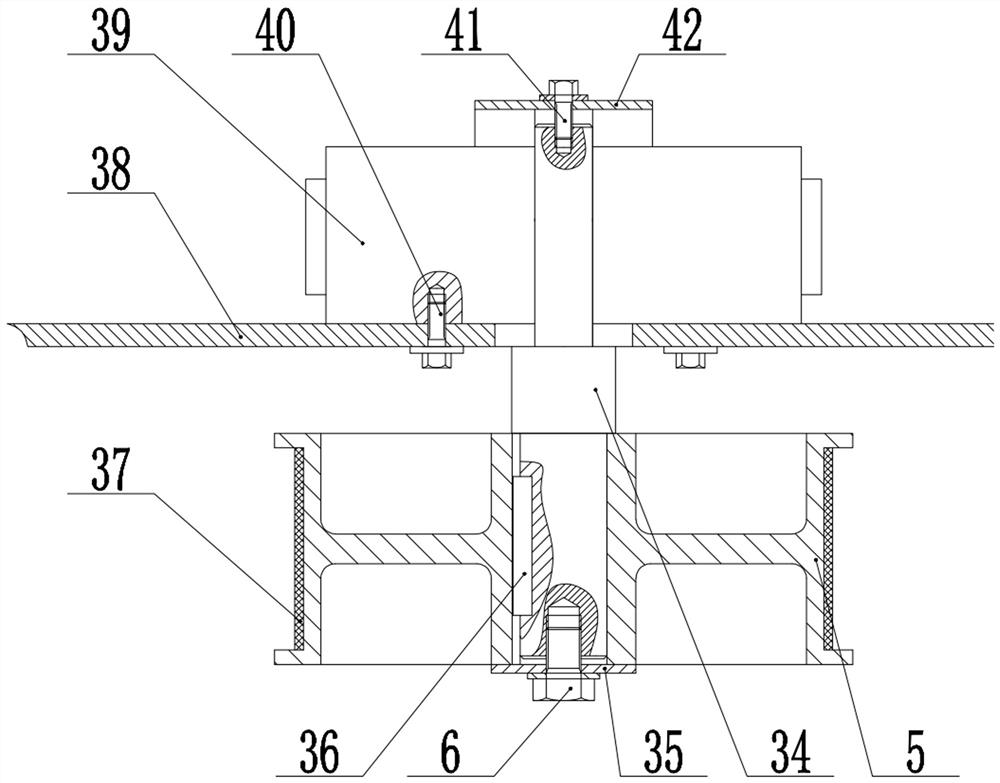

[0035] Such as figure 1 As shown, the present invention is a kind of winding forming device for basalt fiber composite pipe, comprising unwinding roller 3 and composite pipe 18, between which unwinding roller 3 and composite pipe 18 are provided with idler roller 4, main speed roller 5, The tension detection roller 7, the dipping mechanism and the linear reciprocating mechanism, the composite tube 18 are driven by the pulley to rotate in the forward direction, and the unwinding roller 3 is driven by the torque motor to rotate in the reverse direction, so that a certain amount of pretension is generated on the fiber. The idle roller 4 is arranged between the unwinding roller 3 and the main speed roller 5, between the main speed roller 5 and the tension detection roller 7, between the tension detection roller 7 and the rubber dipping roller 9, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com