Method and apparatus for inspecting optical filter adhesion in lens mould set

A technology of lens module and detection method, which is applied in measurement devices, optics, power metering, etc., can solve the problem of insufficient glue dispensing, uneven dispensing of filters and spacers, and insufficient adhesion between filters and spacers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

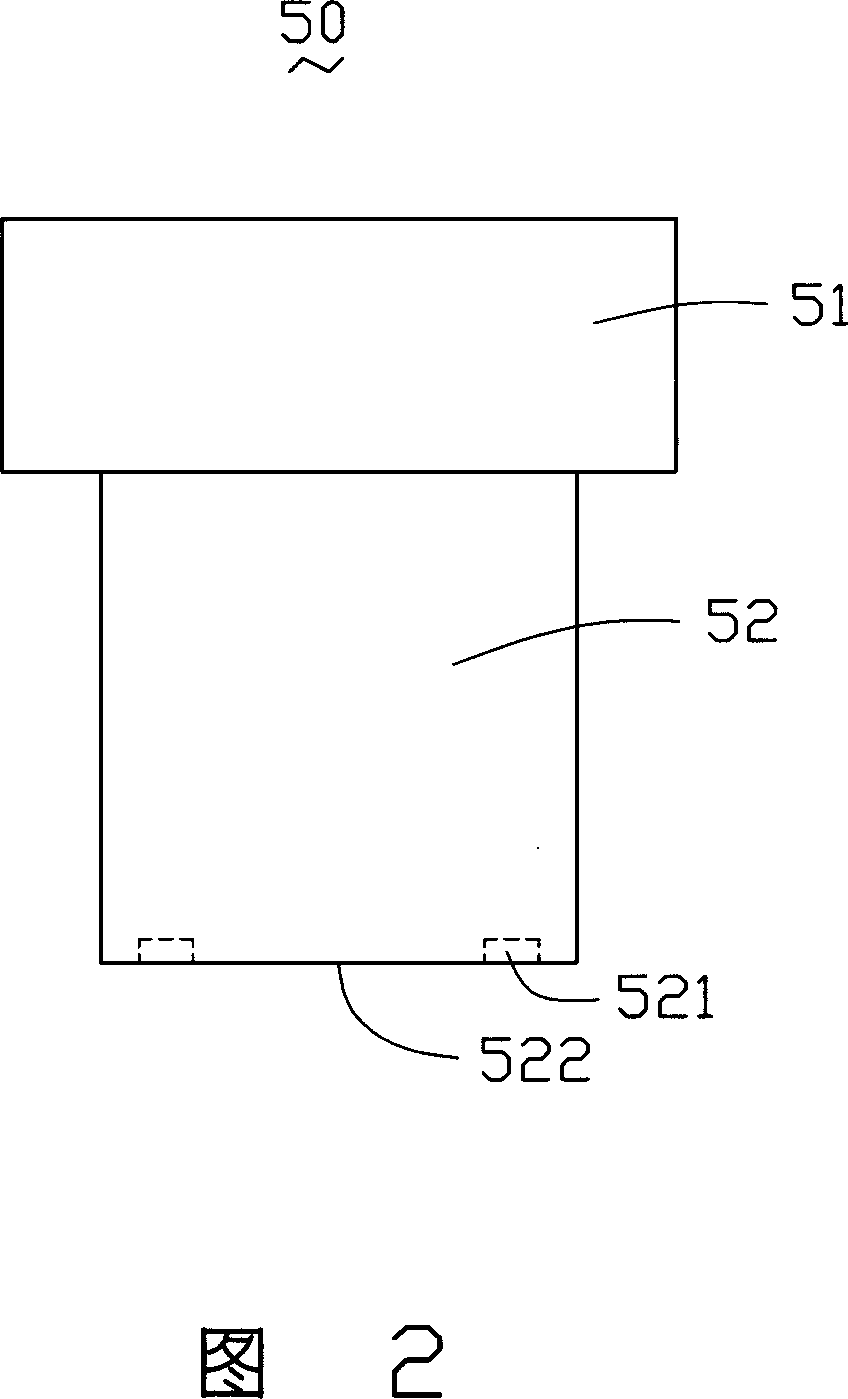

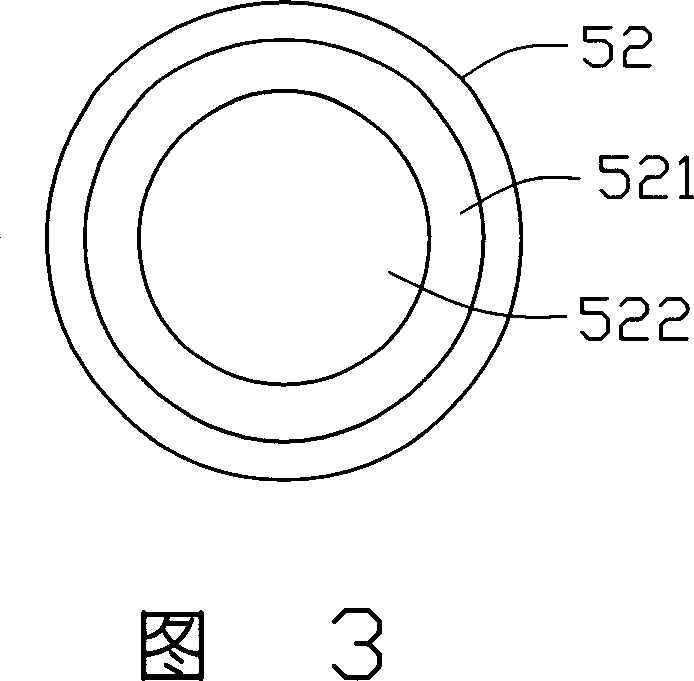

[0014] Please refer to Fig. 1 to Fig. 3, the method for detecting the adhesion of the optical filter in the lens module provided by the embodiment of the present invention includes the following steps:

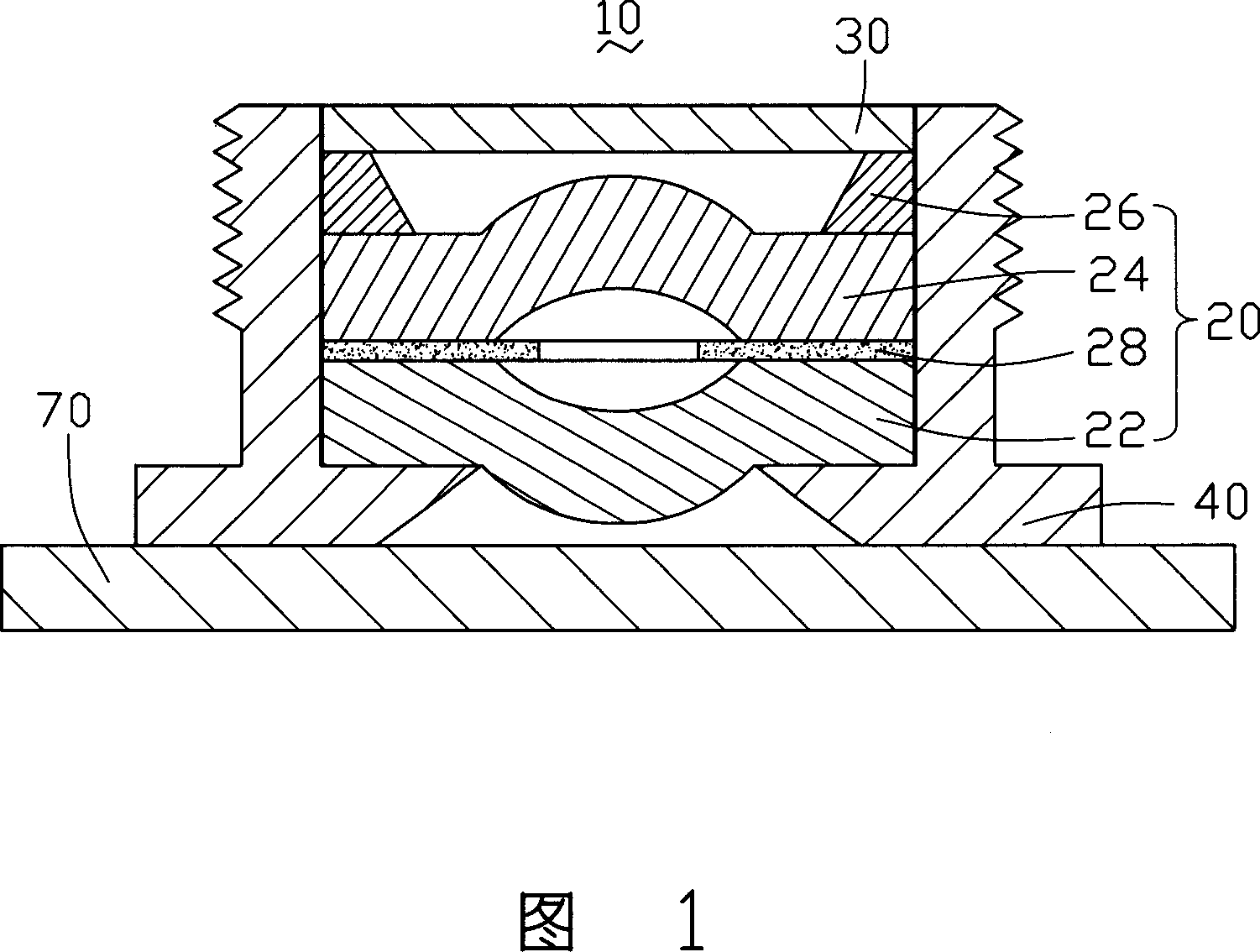

[0015] (1) As shown in FIG. 1 , a lens module 10 is provided, which includes a lens assembly 20 , a filter 30 and a lens barrel 40 . The lens assembly 20 and the filter 30 are housed in the lens barrel 40 sequentially from the object side to the image side.

[0016] The lens assembly 20 may include various optical elements such as lenses 22 , 24 and spacers 26 . The lens 22 and 24 can be made of glass or plastic. The peripheral surfaces of the lenses 22 and 24 are fixed in the lens barrel 40 by glue. The spacer 26 is ring-shaped and is used to form a space between the lens 24 and the filter 30 to avoid damage to the elements due to conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com