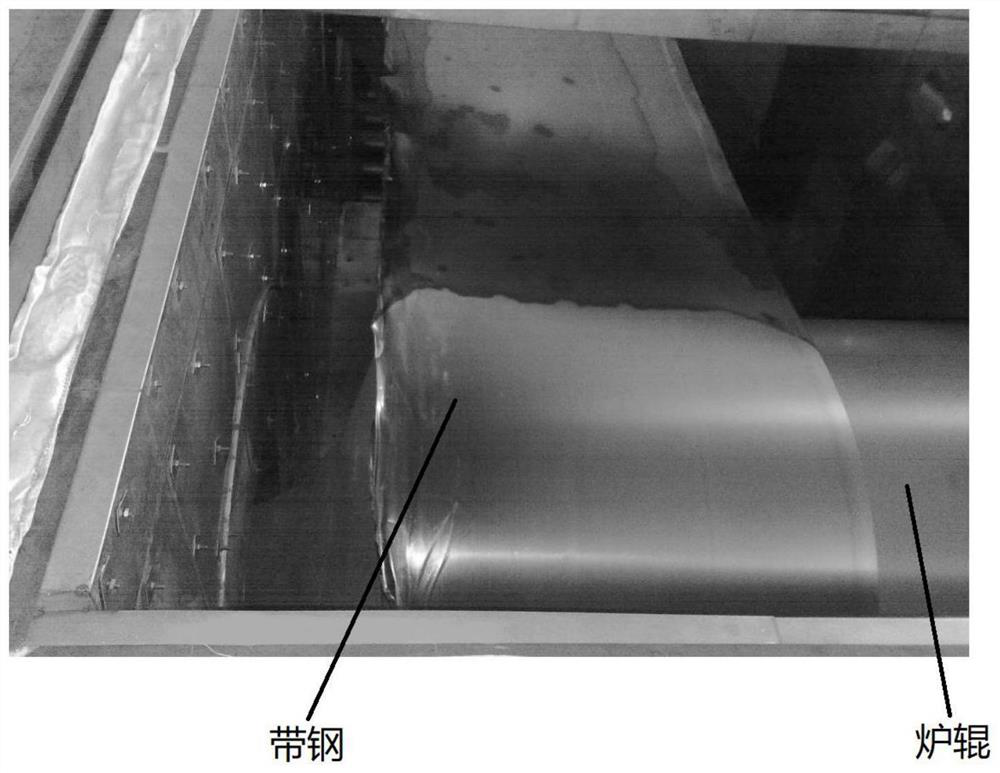

Strip steel deviation simulation system of continuous hot galvanizing unit annealing furnace and control method

A technology of strip deviation and control method, applied in the field of cold rolling, to achieve great economic benefits, avoid deviation, and reduce the effect of deviation and edging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

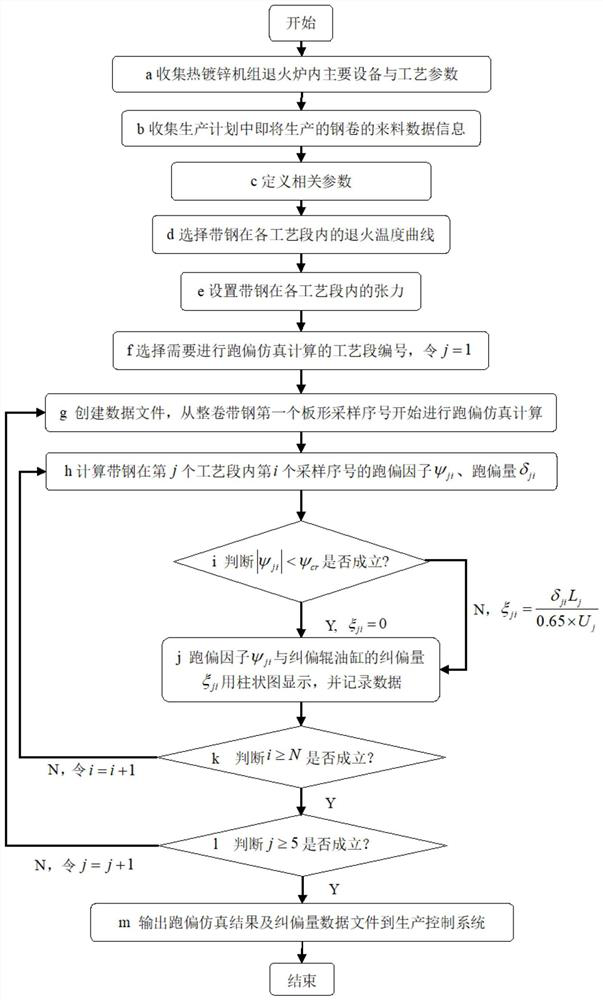

Method used

Image

Examples

Embodiment 1

[0073] In this embodiment, a product with a steel grade of 590DP and a coil number of 9459940500 is taken as an example.

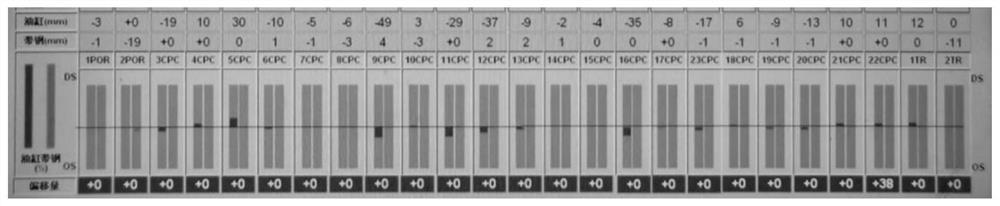

[0074] First, in step (a), the main equipment and process parameters in the annealing furnace of the hot-dip galvanizing unit are collected, mainly including: the process sections in the annealing furnace are numbered in sequence RTF section=1, SF section=2, SCF section=3, JCF1 section = 4, JCF2 section = 5, critical unit deviation factor ψ cr =18, furnace roll body length L 1 =2100mm, L 2 =2100mm, L 3 =2100mm, L 4 =2100mm, L 5 =2100mm, furnace roll diameter D 1 =1000mm, D 2 =1000mm, D 3 =1000mm, D 4 =1000mm, D 5 =1000mm, straight section length S 1 =600mm, S 2 =700mm, S 3 =700mm, S 4 =2100mm, S 5 =2100mm, furnace roll crown γ 1 =0.8mm, γ 2 =2.5mm, γ 3 =2.5mm, γ 4 = 0 mm, γ 5 = 0mm, the distance H between the centerlines of adjacent furnace rollers j =20800mm, the distance U between the deviation correction roller and the last furnace r...

Embodiment 2

[0104] In this embodiment, a product with a steel type of DU6232A1 and a coil number of 550449000 is taken as an example.

[0105] First, in step (a), the main equipment and process parameters in the annealing furnace of the hot-dip galvanizing unit are collected, mainly including: the process sections in the annealing furnace are numbered in sequence RTF section=1, SF section=2, SCF section=3, JCF1 section = 4, JCF2 section = 5, critical unit deviation factor ψ cr =18, furnace roll body length L 1 =2100mm, L 2 =2100mm, L 3 =2100mm, L 4 =2100mm, L 5 =2100mm, furnace roll diameter D 1 =1000mm, D 2 =1000mm, D 3 =1000mm, D 4 =1000mm, D 5 =1000mm, straight section length S 1 =600mm,S 2 =700mm, S 3 =700mm, S 4 =2100mm, S 5 =2100mm, furnace roll crown γ 1 =0.8mm, γ 2 =2.5mm, γ 3 =2.5mm, γ 4 = 0 mm, γ 5 = 0mm, the distance H between the centerlines of adjacent furnace rollers j =20800mm, the distance U between the deviation correction roller and the last furnace r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com