Membrane viscosity measurement method

A measurement method and viscosity technology, applied in the field of integrated circuit semiconductor packaging and testing, can solve the problems of high cost, complex equipment and operation, high precision, and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0013] Measure the viscosity of UV film with adopting LINTEC system (RAD-2500 series) laminating machine as example, the concrete operating steps of the inventive method are as follows:

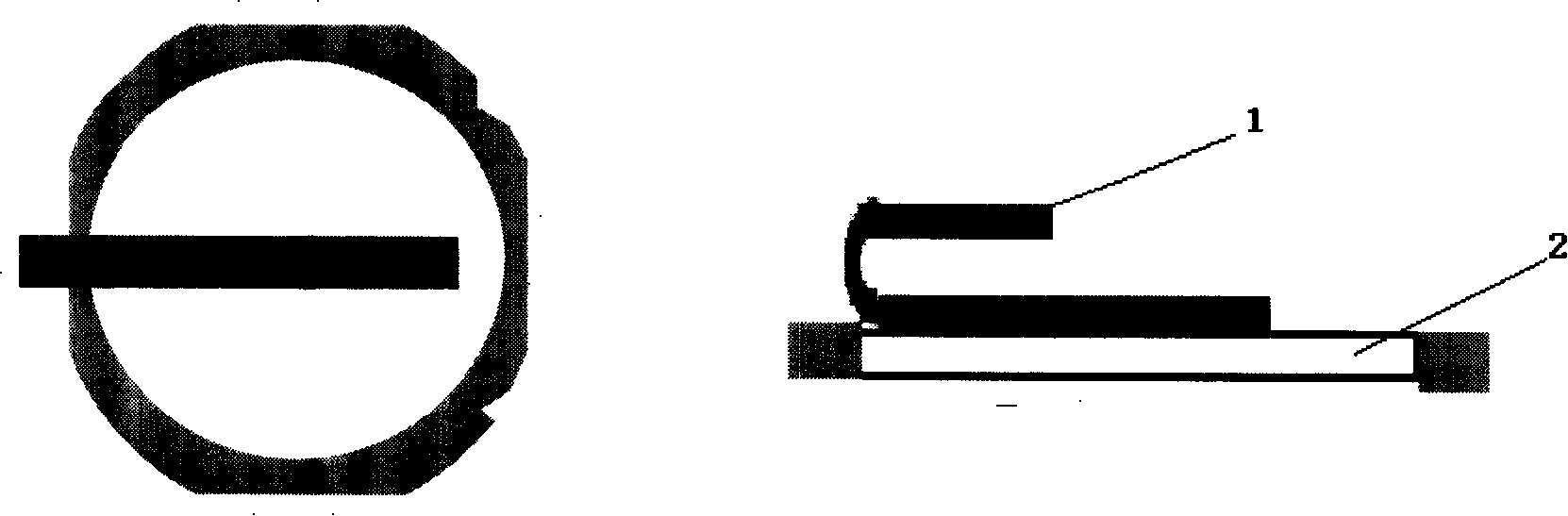

[0014] 1. If figure 2 As shown, use the film lamination machine made by LINTEC (RAD-2500 series), and use the fixed roller attachment pressure on the equipment to attach a fixed-size rubber belt 1 (length: 10-200cm, width: 2-15cm) to the UV film. 2's fixed position.

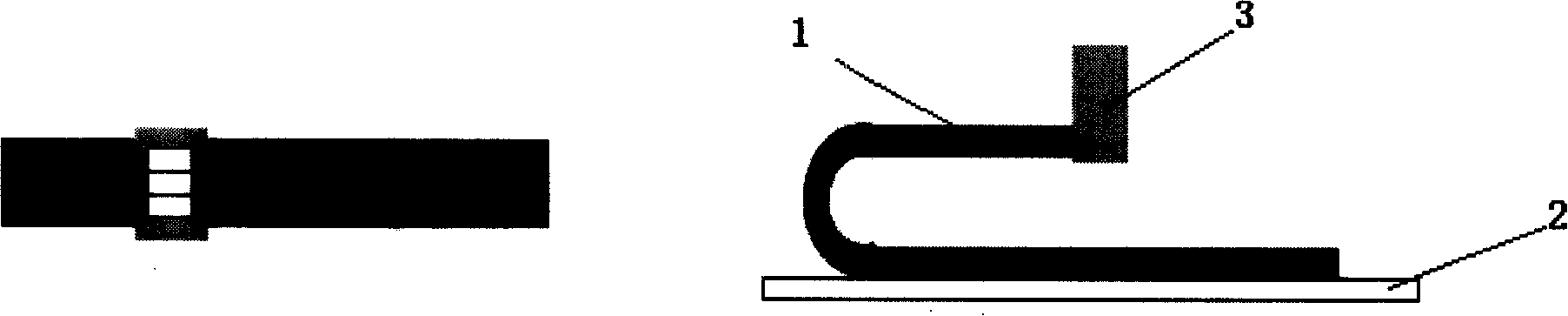

[0015] 2. If image 3 and Figure 4 As shown, fix the pasted film 2 on the working platform 4 of the film laminating machine with the adhesive side facing upwards. One end of the rubber belt 1 is connected to the tension gauge 3, and the tension gauge 3 is fixed on the film laminating machine in reverse. 4 same height.

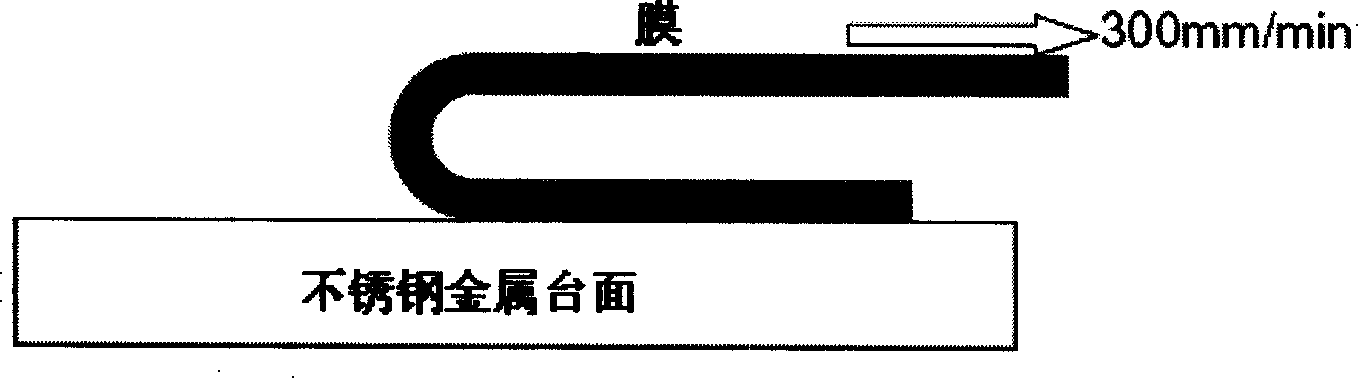

[0016] 3. If Figure 5 As shown, the rubber belt 1 is peeled off fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com