Tensometer for simultaneously evaluating polymerization stresses, shrinkage and modulus development

a technology of polymerization shrinkage and modulus, which is applied in the direction of measurement devices, instruments, scientific instruments, etc., can solve the problems of increased patient pain, anxiety, and economic burden, and the cavities usually do not fully regenerate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

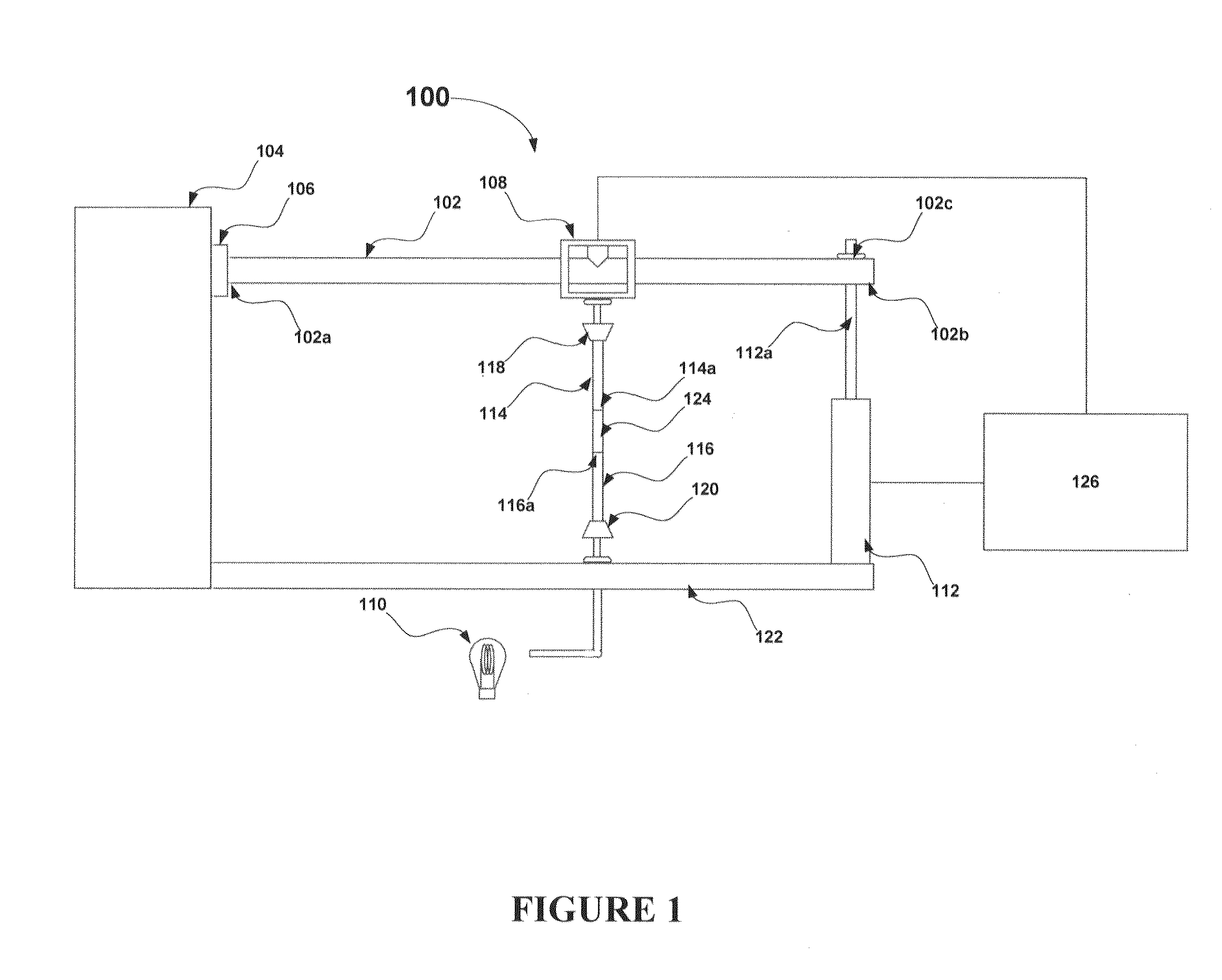

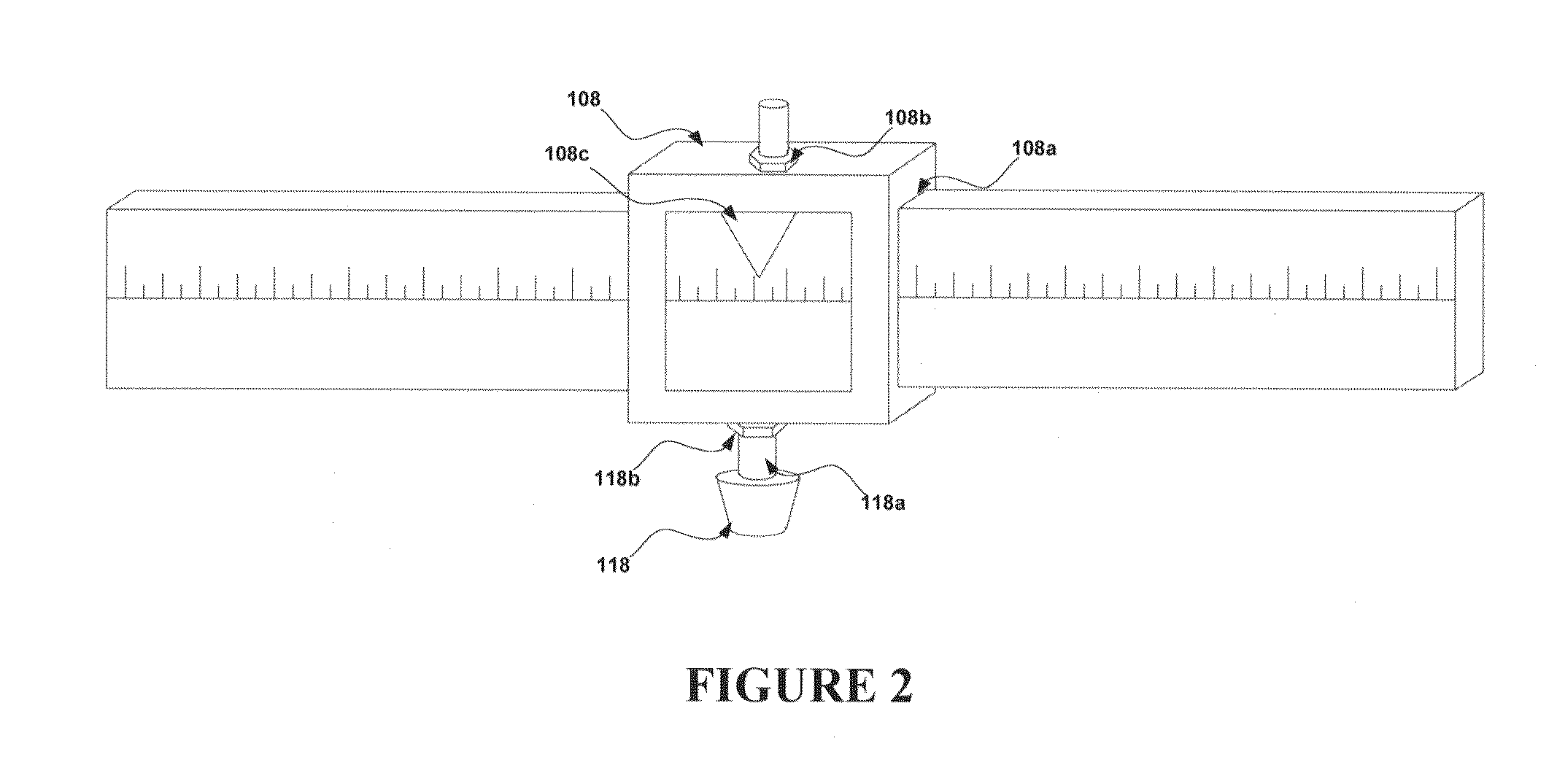

[0064]Evaluation of the development of polymer stresses in TPH Micro Matrix Restorative: lot #070403, shade A1, Dentsply-Caulk.

[0065]In this investigation, a commercial composite (TPH Micro Matrix Restorative: lot #70403, shade A1, Dentsply-Caulk, Milford. Del., USA) was used as a test material to demonstrate the validity of our newly designed tensometer in the evaluation of PS. TPH is based on a visible-light activated, urethane-modified Bis-GMA and TEGDMA (1:1 mass ratio) filled primarily with a barium boron aluminum silicate glass at 78% mass fraction (filler volume fraction is approx. 57%). The specimen / rod diameter was 6.0 mm. The visible-light curing pen light (Spectrum Curing Unit, Denstply-Caulk, Milford, Del.) was attached to the lower quartz rod with an opaque flexible light guide. The faces of quartz rods connected to the specimen were silanized to promote adhesion between the composite sample and rods. The silanization process was conducted by applying a 1% by mass aceto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| mass fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com