Lining viscosity measurement instrument

A measuring instrument and viscosity technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of unsuitable viscosity measurement of inner wall lining of pipelines, unsuitable for lining viscosity measurement, inaccurate positioning of viscometers, etc., and achieve a simple structure. , fast measurement, low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

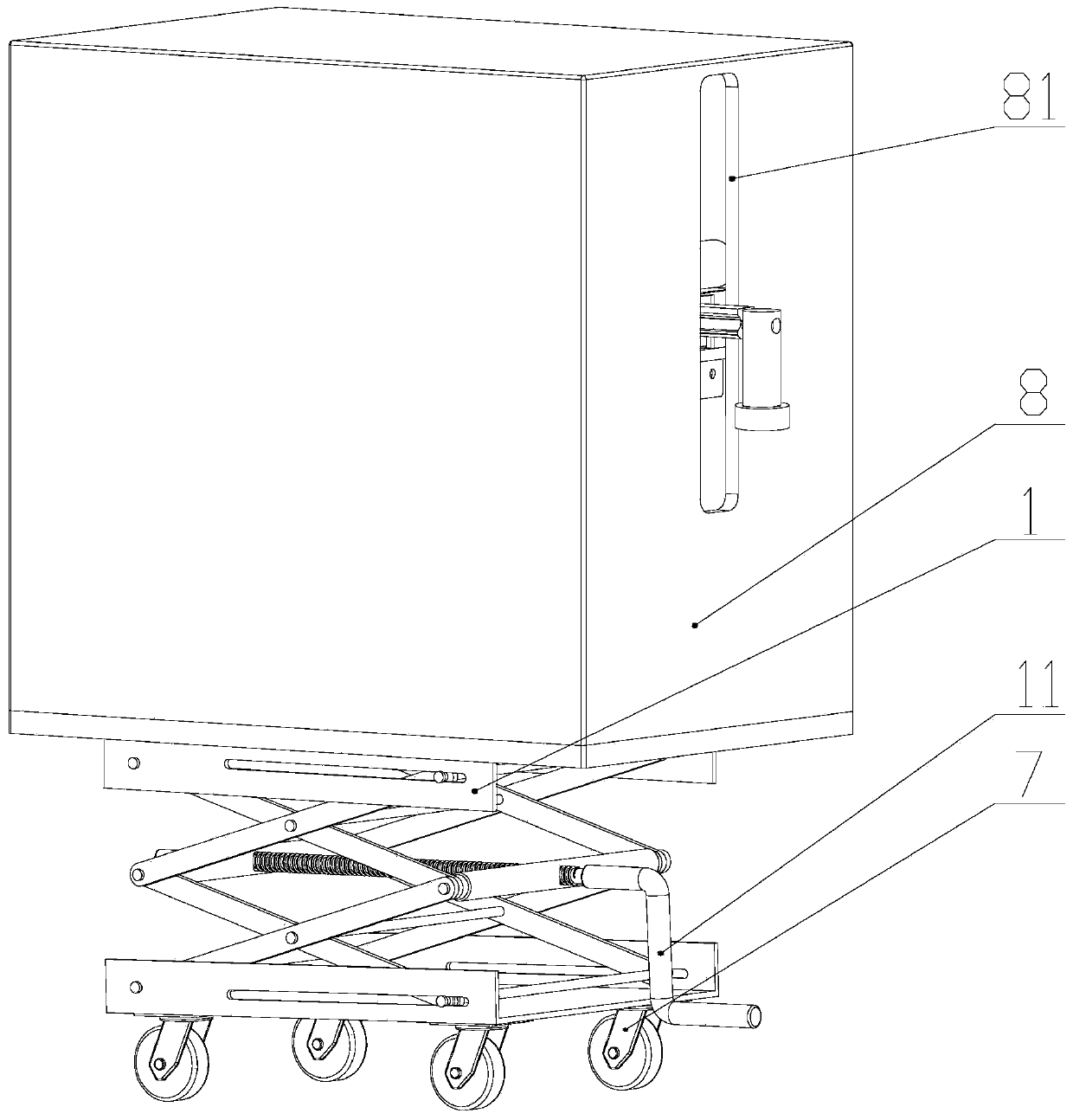

[0026] Such as figure 1 As shown, each transmission mechanism of the lining viscosity measuring instrument is in the box body 8, and each transmission mechanism includes a light guide rod 3, a ball screw nut pair 4, a platform 5, a first motor 21, and the like. Casing 8 is fixed on the scissor lift platform 1, and the scissor lift platform can be selected as the manually controlled lift platform of 200*200*280 produced by Beijing Zhongxing Company. The lifting of scissor lift table 1 adopts handle 11 hand control, and universal wheel 7 is equipped with at the bottom. The shell of casing 8 has a vertical groove 81, and pressure head 54 can move up and down, left and right, and linear guide rail 53 passes groove 81, and pressure head 54 is positioned at outside casing 8.

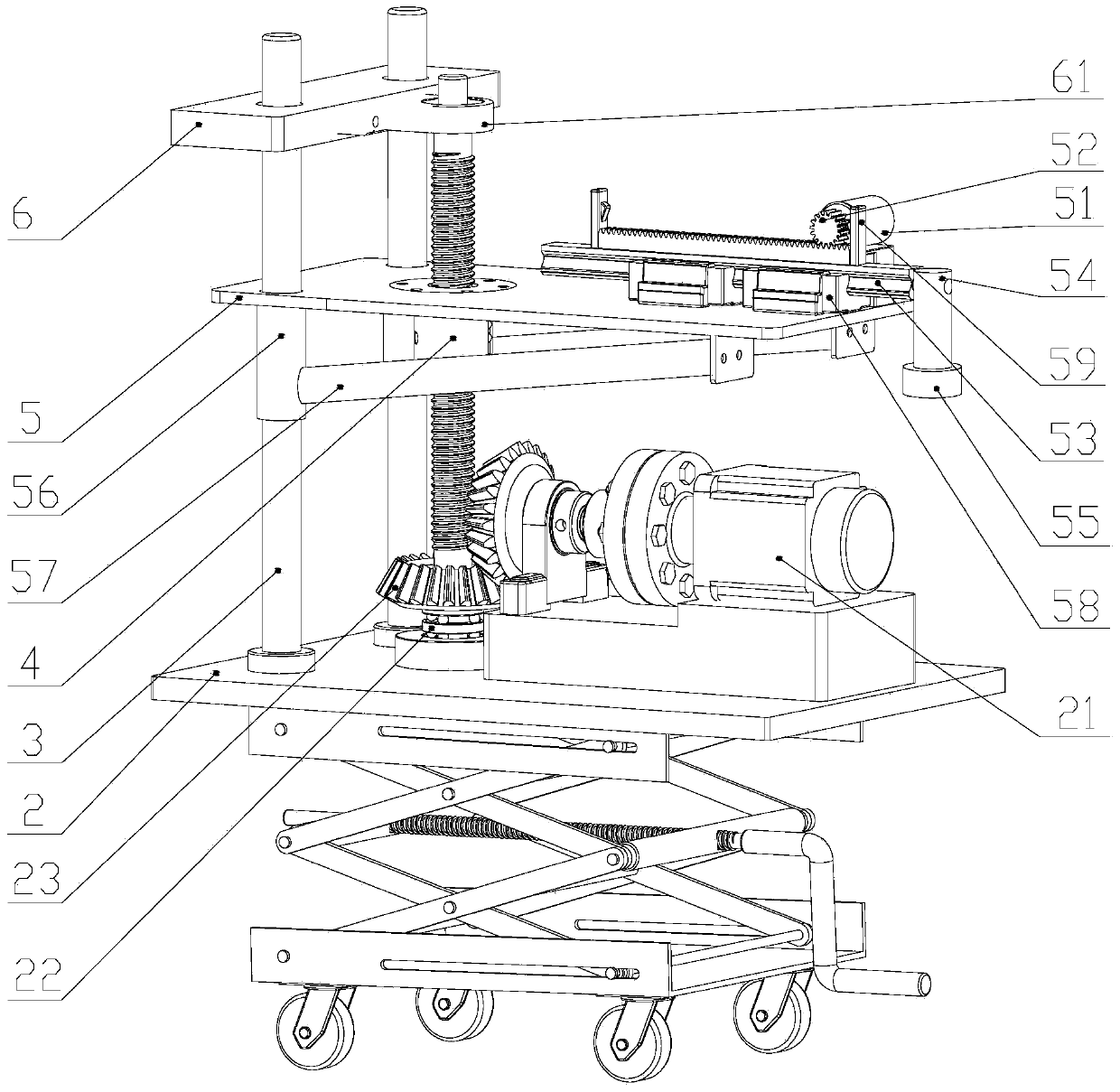

[0027] Such as figure 2 As shown, the top of the scissor lift table 1 has a bottom plate 2 on which two light guide rods 3 and one ball screw nut pair 4 are vertically arranged, and a fixed block 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com