Method measuring inter-batch stability of latex paint by using rotational rheometer

A technology of rotational rheometer and latex paint, applied in the direction of flow characteristics, instruments, measuring devices, etc., can solve the problems of inability to obtain experimental results, inability to fully inspect product quality fluctuations, and large manpower, and achieve the effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

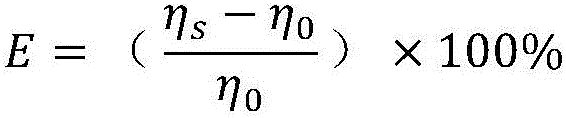

[0028] Step 1: Select a standard latex paint sample A, and use a rotational rheometer to measure the sample at 0.01s -1 , 0.001s -1 、1000s -1 、5000s -1 Viscosity values at 4 preset shear rates within the shear rate range;

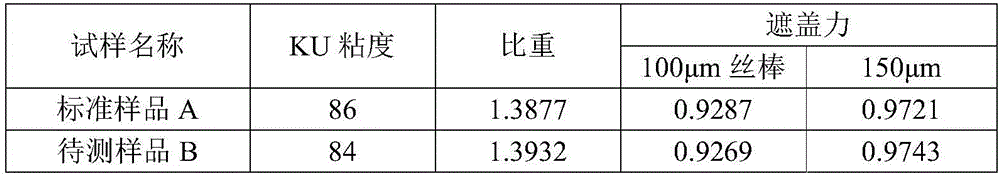

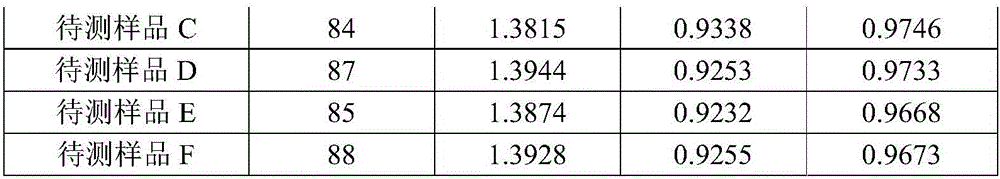

[0029] Step 2: According to the experimental method stipulated in the national standard, measure the factory routine inspection performance of the standard latex paint sample: KU viscosity, specific gravity, hiding power (150μm wet film preparation device, 100μm wire rod);

[0030] Step 3: Select 5 batches of latex paint samples B, C, D, E, and F to be tested, and use a rotational rheometer to measure the sample at 0.01s -1 , 0.001s -1 、1000s -1 、5000s -1 Viscosity values at 4 preset shear rates within the shear rate range;

[0031] Step 4: According to the experimental method stipulated in the national standard, measure the factory routine inspection performance of the latex paint samples B, C, D, E, and F to be tested: KU viscosity, specific gr...

Embodiment 2

[0042] Step 1: Select a standard latex paint sample A, and use a rotational rheometer to measure the latex paint sample to be tested at 0.1 to 1000s -1 Viscosity values at 4 preset shear rates within the shear rate range.

[0043] Step: 2: According to the experimental method stipulated in the national standard, measure the factory routine inspection performance of the standard latex paint sample: KU viscosity, specific gravity, hiding power (150μm wet film preparation device, 100μm wire rod)

[0044] Step 3: Select 5 batches of latex paint samples B, C, D, E, and F to be tested, and use a rotational rheometer to measure the temperature of the samples at 0.1S -1 ~1000S -1 Viscosity values at 4 preset shear rates within the shear rate range

[0045] Step 4: According to the experimental method stipulated in the national standard, measure the factory routine inspection performance of the latex paint samples B, C, D, E, and F to be tested: KU viscosity, specific gravity, hidi...

Embodiment 3

[0054] Step 1: Select a standard latex paint sample G (recipe information is shown in Table 5), and use a rotational rheometer to measure the temperature of the sample at 0.1-1000s -1 Viscosity values at 4 preset shear rates within the shear rate range;

[0055] Table 5 Sample G Formulation Information

[0056]

[0057]

[0058] Step 2: According to the experimental method stipulated in the national standard, measure the factory routine inspection performance of the standard latex paint sample G: KU viscosity, specific gravity, hiding power (150 μm wet film preparation device, 100 μm wire rod);

[0059] Step 3: increase the consumption of cellulose 1 in the formula of standard latex paint sample G, and prepare latex paint sample H to be tested; reduce the consumption of cellulose 1 in the formula of standard latex paint sample G, and prepare latex paint sample I to be tested; use Cellulose 2 completely replaced cellulose 1, and the latex paint sample J to be tested wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com