Polyimide film and its producing process

A technology of polyimide film and manufacturing process, which is applied in flat products, other household appliances, applications, etc., and can solve the problems that polyimide film products cannot meet the needs of microelectronics and information industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

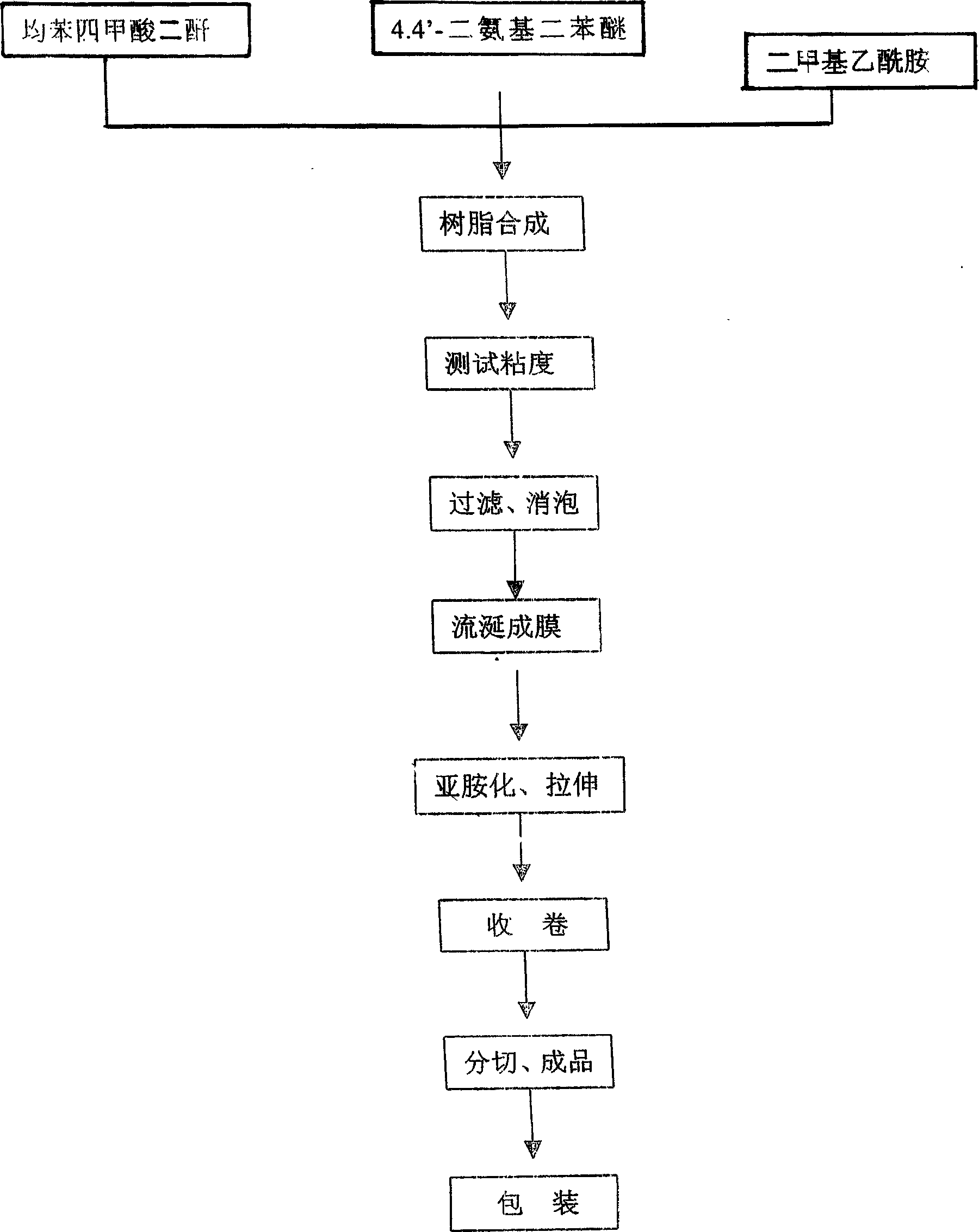

[0007] The present invention uses pyromellitic dianhydride as the main raw material, 4.4'-diaminodiphenyl ether and dimethylacetamide as auxiliary materials, pyromellitic dianhydride, 4.4'-diaminodiphenyl ether, dimethyl The weight ratio of acetamide is 0.6-0.7%, 0.55-0.65%, 3.5-4.0%, respectively, the thickness of the polyimide film is 0.25-0.35mm, and the width is 1250-1500mm; its manufacturing process mainly It includes resin synthesis, viscosity test, filtration, defoaming, salivation film formation, imidization treatment and stretching process, winding, slitting in sequence; Put the amide solvent into the dissolution kettle, put the weighed 4.4'-diaminodiphenyl ether into it, start the corresponding mixer to stir and dissolve, the dissolution time is not less than one and a half hours, and wait until the 4.4'-diaminodiphenyl ether is completely dissolved Finally, stop stirring, use compressed air to press the 4.4'-diaminodiphenyl ether solution through the filter into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com