Smokeless odorless bleaching agent for die-casting aluminum and preparation method and application of smokeless odorless bleaching agent

An odorless, bleaching agent technology, applied in the field of bleaching agent, can solve the problems of environmental pollution, irritating smell, aeration, etc., and achieve the effect of strong bleaching ability, less damage and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

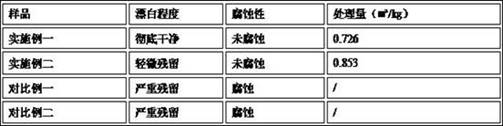

Examples

Embodiment 1

[0021] In the present embodiment, each raw material and percentage by weight in the bleaching agent:

[0022] Citric acid 8%;

[0023] Potassium fluoride 20%;

[0024] Ammonium bifluoride 6%;

[0025] Sodium thiosulfate 6%;

[0026] Pure water 60%;

[0027] The above raw materials are mixed and prepared according to the weight percentage. First add pure water to the reaction kettle, then add citric acid and stir for 30 minutes, then add potassium fluoride and stir for 30 minutes, then add ammonium bifluoride and stir for 30 minutes, and finally add sodium thiosulfate Stir for 30 minutes until it is completely dissolved, then open the valve of the reactor and fill it.

[0028] The bleaching agent is applied to the bleaching agent after alkaline de-anodizing film of die-casting aluminum and aluminum alloy combination parts, and has good effect.

Embodiment 2

[0030] In the present embodiment, each raw material and percentage by weight in the bleaching agent:

[0031] Hydroxyethylidene diphosphate 6%;

[0032] Potassium fluoride 22%;

[0033] Ammonium bifluoride 9%;

[0035] Pure water 55%;

[0036] The above raw materials are mixed and prepared according to the weight percentage. First add pure water to the reaction kettle, then add hydroxyethylidene diphosphoric acid and stir for 30 minutes, then add potassium fluoride and stir for 30 minutes, then add ammonium bifluoride and stir for 30 minutes, and finally add hydrogen peroxide Stir for 30 minutes until it is completely dissolved, then open the valve of the reactor and fill it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com