Coriolis mass flowmeter

A mass flow, measuring instrument technology, used in mass flow measuring devices, direct mass flow meters, measuring flow/mass flow, etc., can solve problems such as changing installations, not significantly avoiding measurement signal deterioration, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

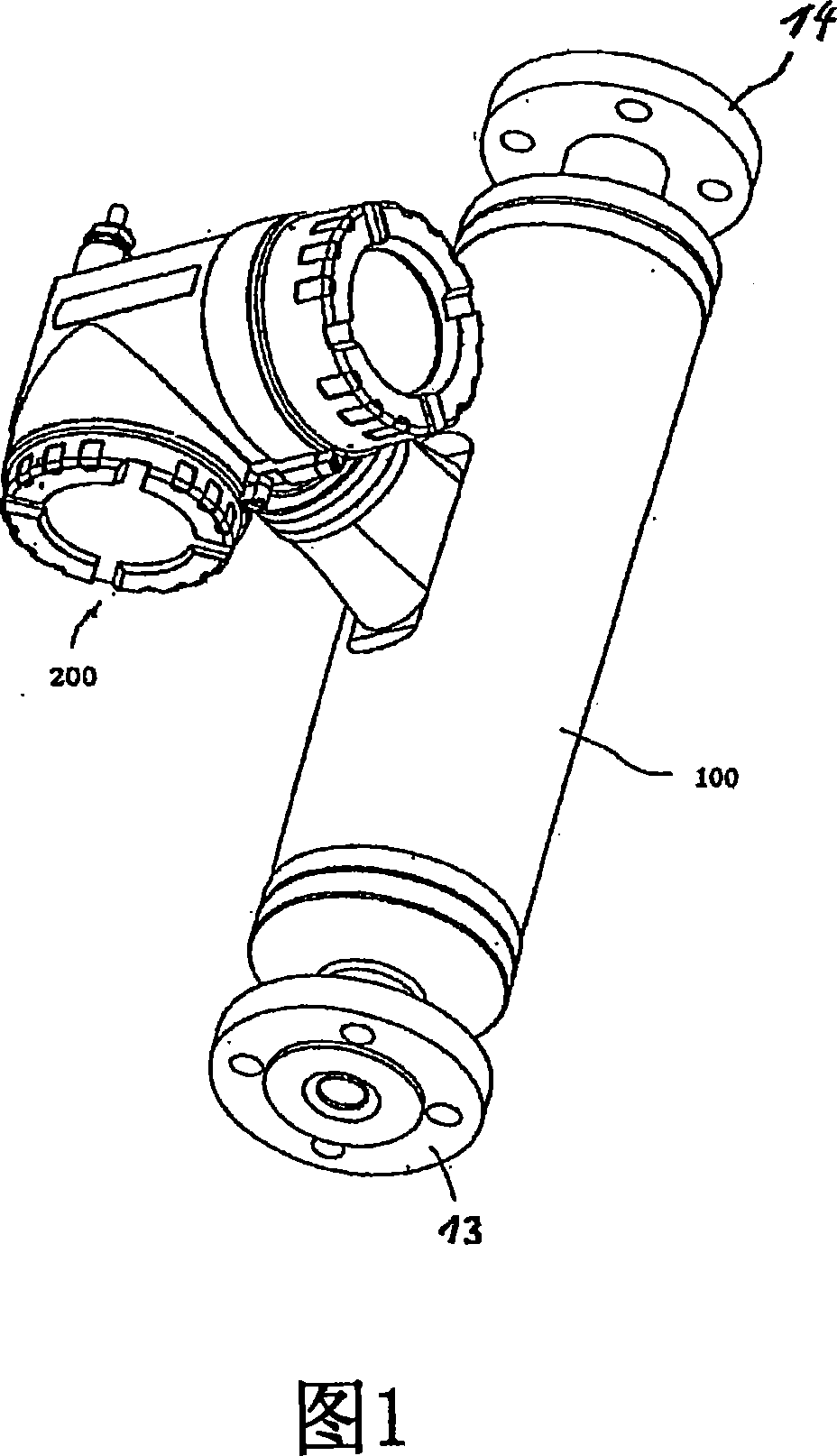

[0057] Fig. 1 is a perspective view of a Coriolis mass flow measuring instrument 1, which is used to detect the mass flow rate m of a medium flowing in a pipeline (not shown) and convert it into a mass flow measurement value X representing the mass flow rate instantaneously. m form of expression. The medium can be virtually any flowable material, such as liquid, gas, vapor, etc. In addition, the Coriolis mass flow measuring instrument 1 can also be used to measure the density ρ and / or viscosity η of the medium.

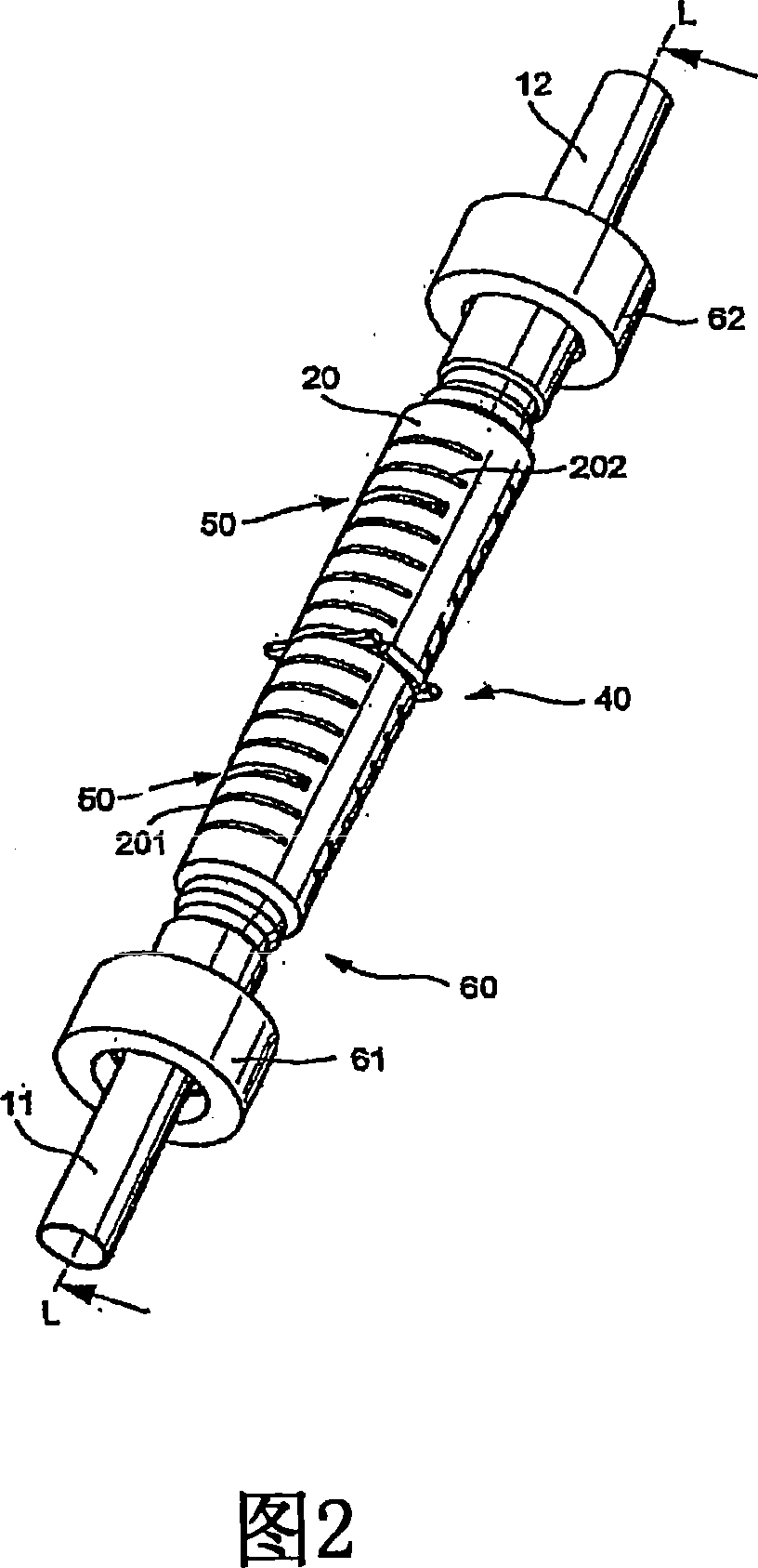

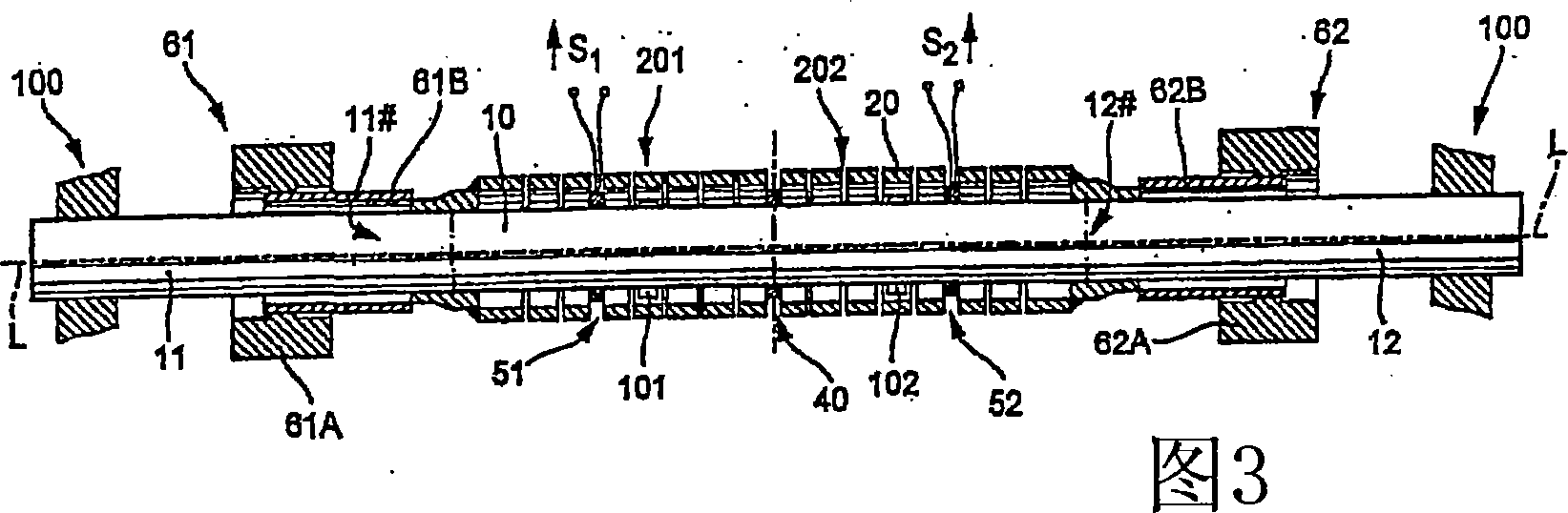

[0058]To this end, the Coriolis mass flow measuring device 1 comprises a vibrating-type measuring transmitter 10 through which the medium to be measured flows during operation, and a measuring device electronics 50 which communicates with the measuring device. The measuring transducer 10 is electrically connected. Figures 2-6 show transmitter embodiments and developments, while Figure 7 is a schematic example of the meter electronics. Preferably, the measuring inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com