Method and equipment for liquid-solid continuously separation for slurry state bed reactor

A reactor and slurry bed technology, which is applied in the field of liquid-solid continuous separation and equipment for slurry bed reactors, can solve the problems of complicated operation, complex equipment structure, and occupied reaction space, so as to improve the settlement efficiency and improve the Separation efficiency, the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

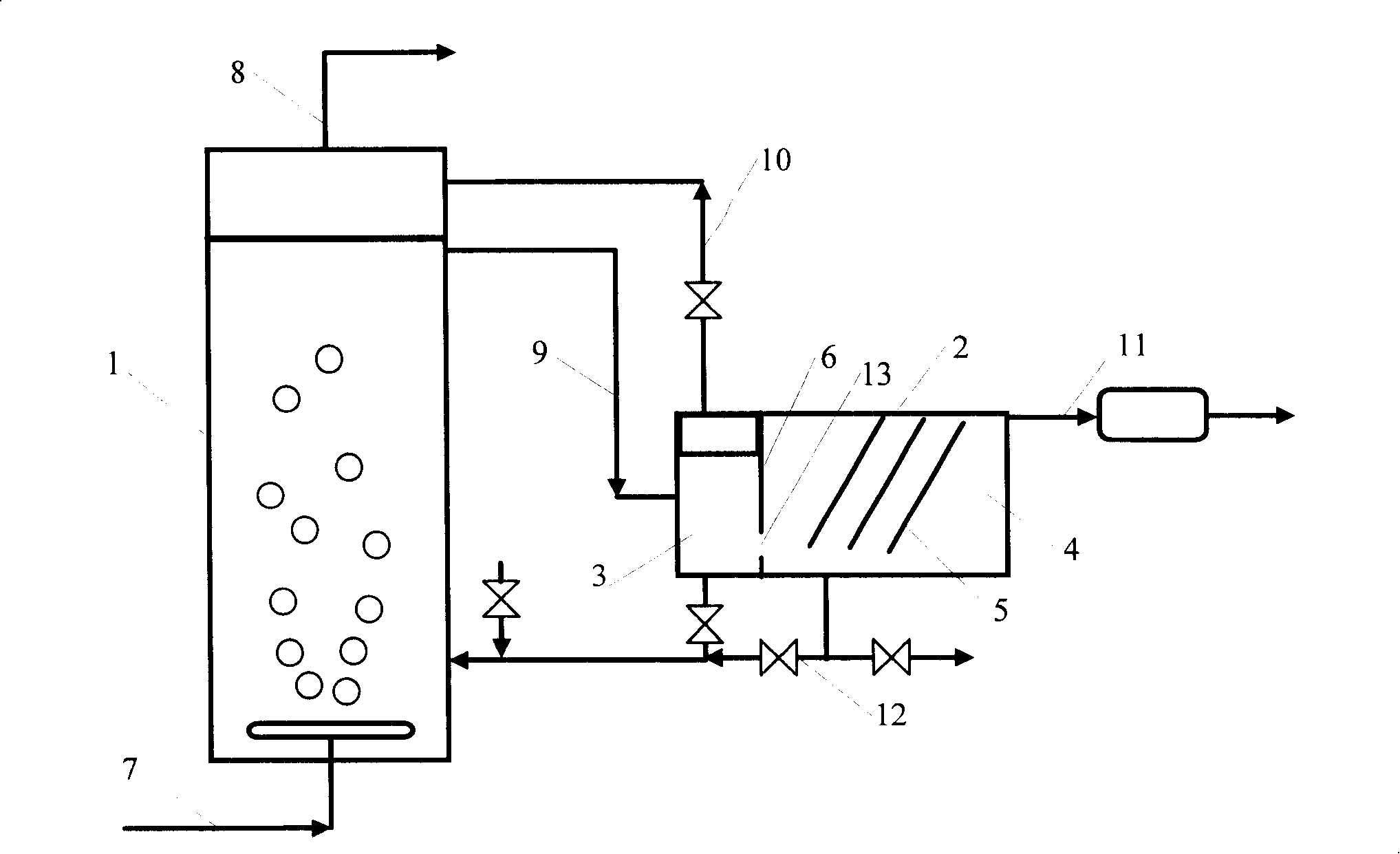

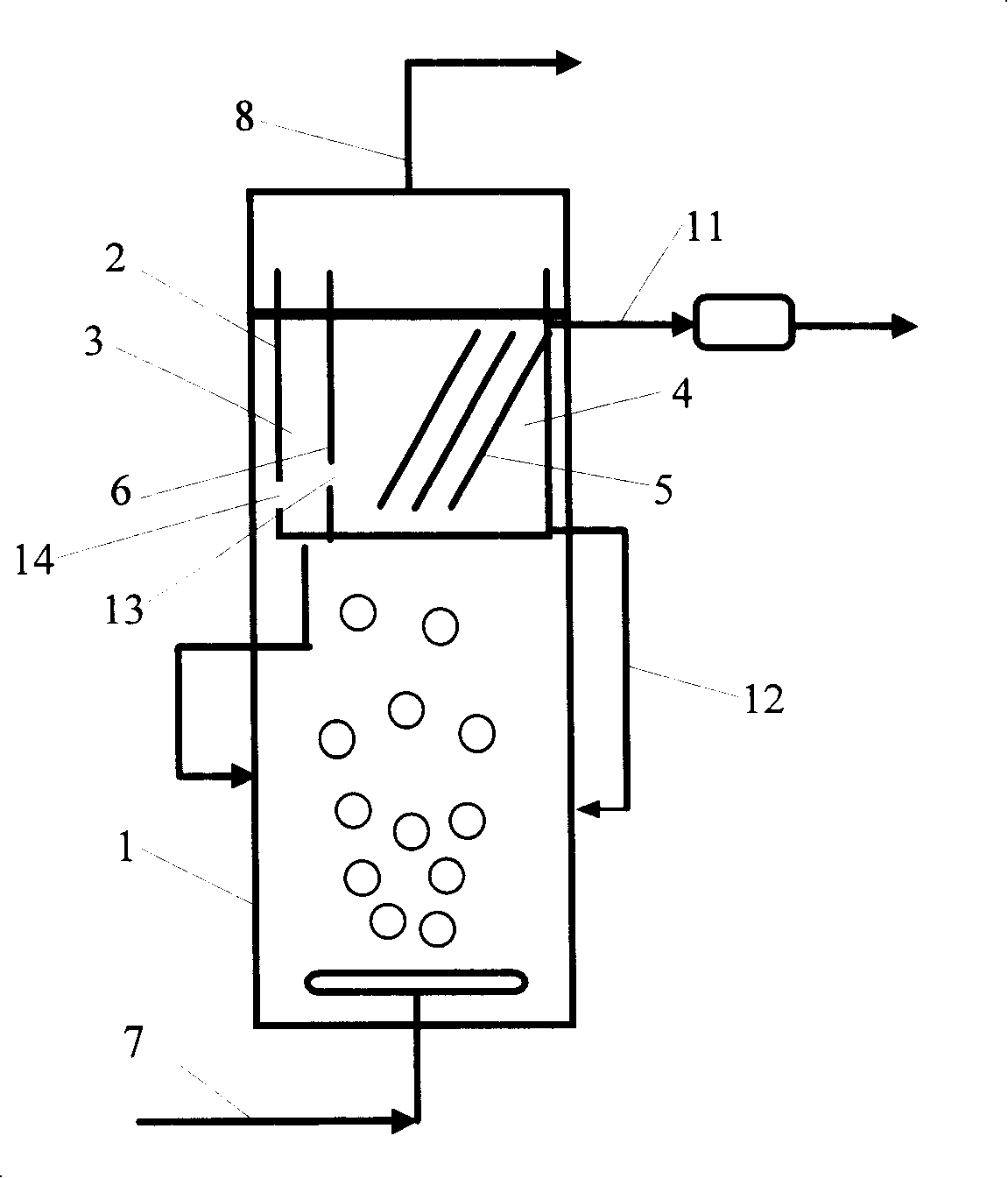

[0035] The process of continuous solid-liquid separation in the slurry bed reactor is shown in the attached figure 1As shown, the inclined plate settler adopts a group of parallel flat plates with a plate inclination angle of 50°, and the vertical distance between the plates is 0.05m. The suspended slurry discharged from the reactor is introduced into the pre-separator of the separation unit, the catalyst with larger particle size settles at the bottom of the preprocessor, the separated thicker slurry returns to the reactor to continue to participate in the reaction, and the separated gas returns to the upper part of the reactor , the rest of the suspended slurry flows into the inclined plate settler at the lower part of the preprocessor for further separation; the clear liquid separated in the inclined plate settler is a liquid product. Analysis by weighing method: the solid mass percentage in the clear liquid is less than 0.1%, the cutting particle size is 5 μm, and the sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com