Magnetic separation device

A technology of magnetic separation device and separation chamber, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high energy consumption and low separation efficiency, and achieve the effect of reducing energy consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

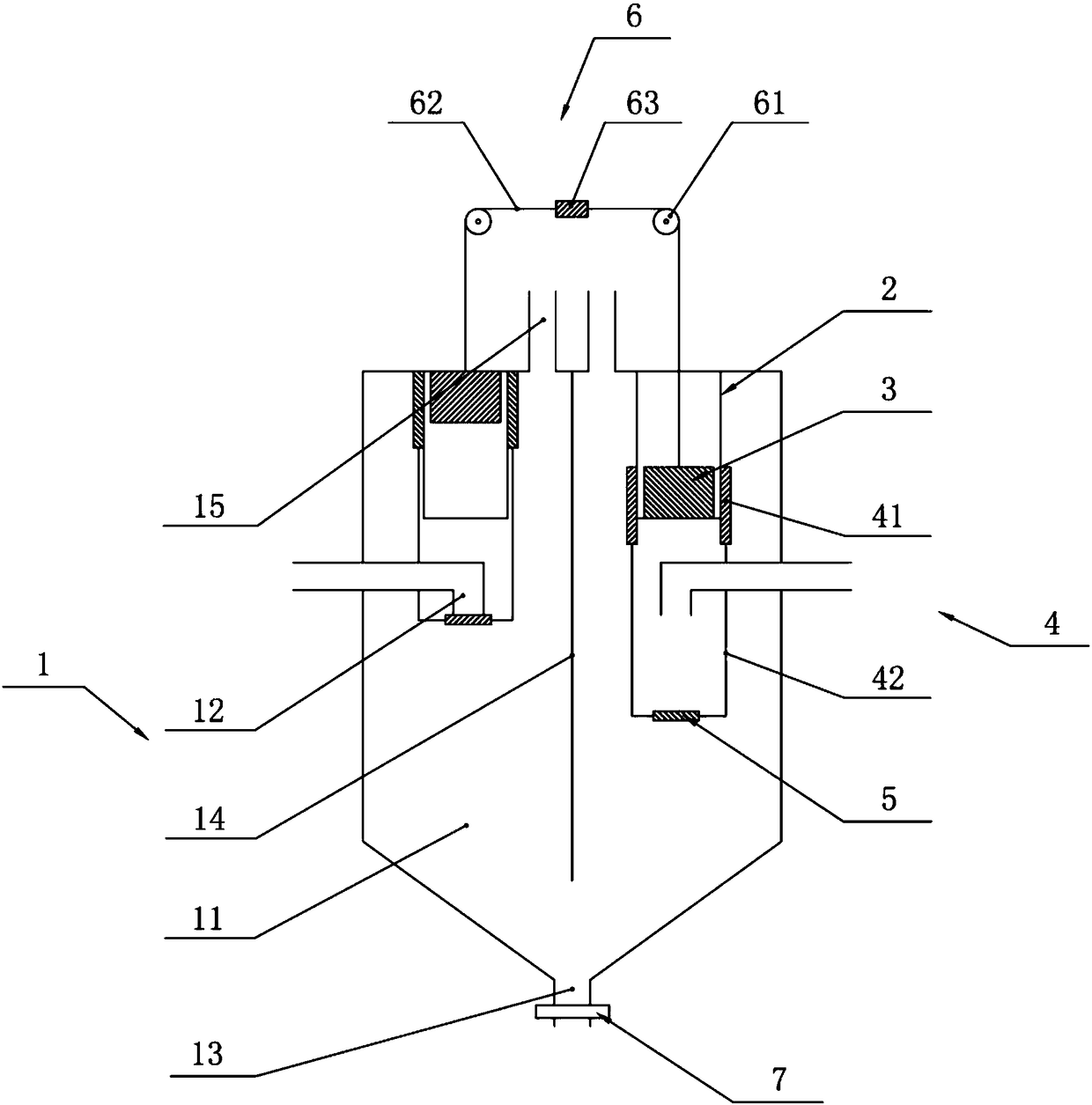

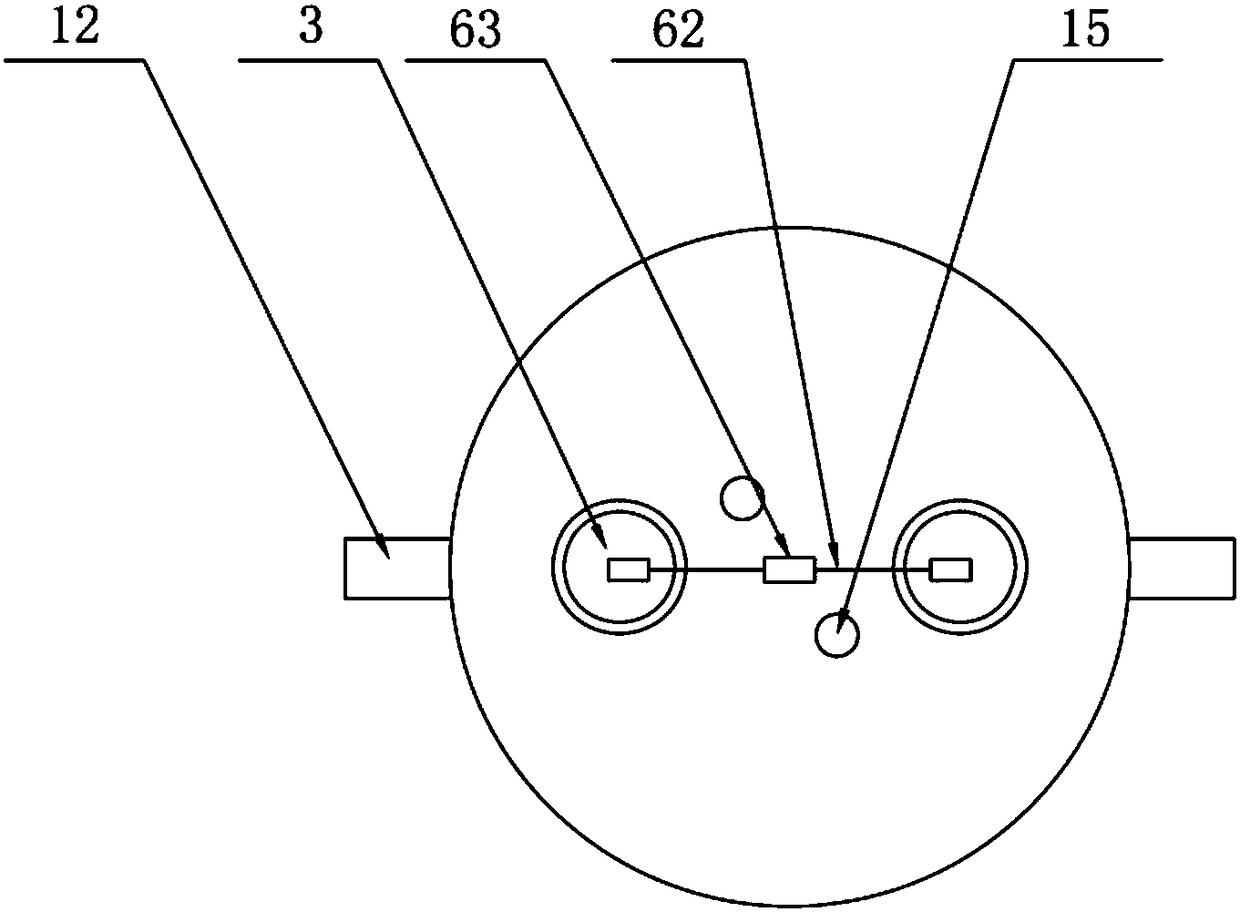

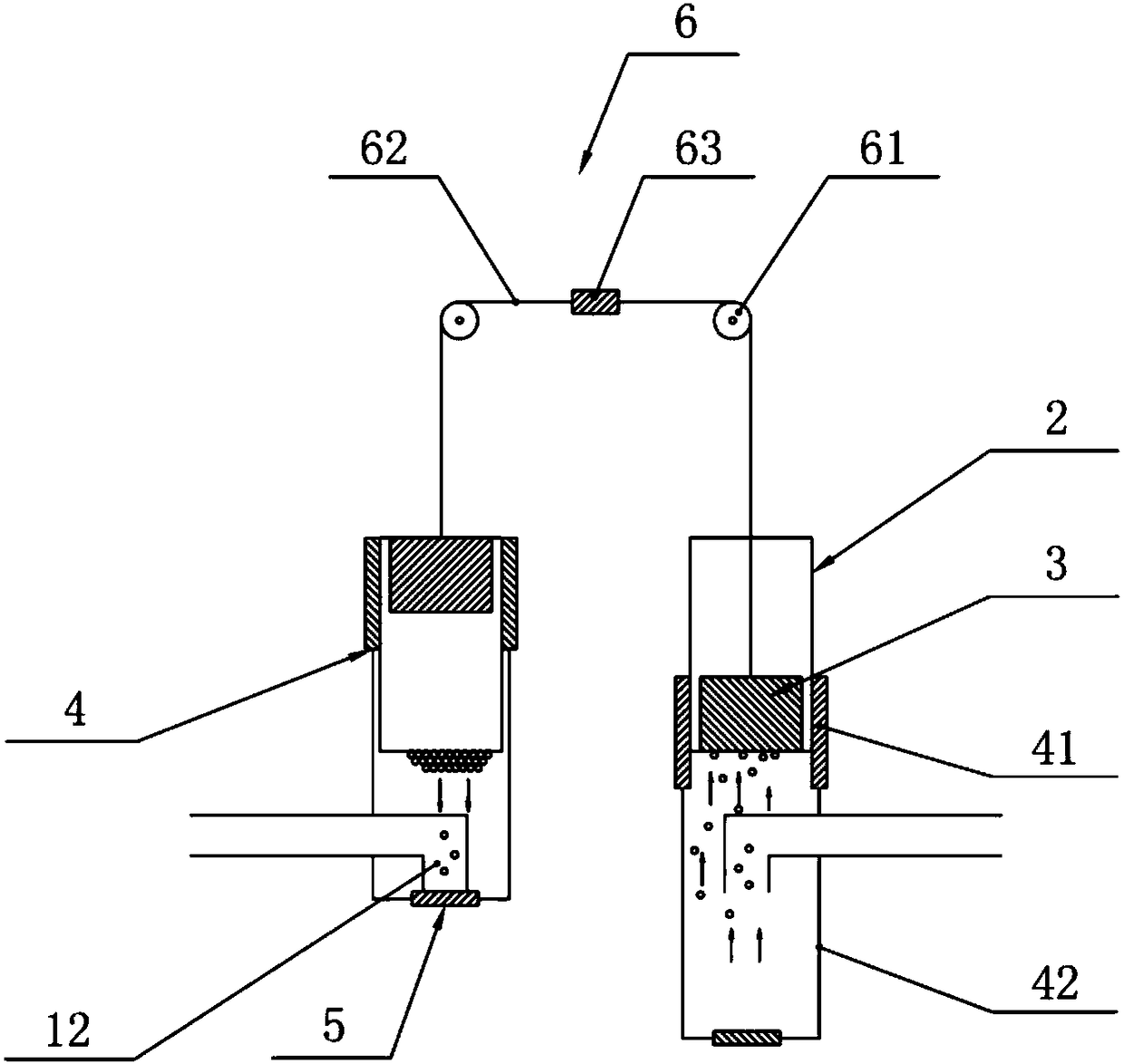

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0037] The invention provides a magnetic separation device, such as Figure 1-5 As shown, the magnetic separation device includes a separation chamber 1, a cylinder 2, a magnet 3, a bracket 4, a tray 5, a drive assembly 6 and a water seal assembly 7, wherein:

[0038] The above-mentioned separation chamber 1 has a cylindrical structure with an overall height of 3 meters, and its upper part is a cylindrical structure with a diameter of 2 meters. The bottom of the separation chamber 1 is a conical structure, and a dividing plate 14 with a length of 2.8 meters and a width of 2 meters is fixed in the middle of the separation chamber. One side of each separation chamber 11 is provided with a feed liquid inlet 12, specifically, the feed liquid inlet 12 is connected with an external pipeline, and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com