Electrode of lithium sulfur battery and preparation method thereof

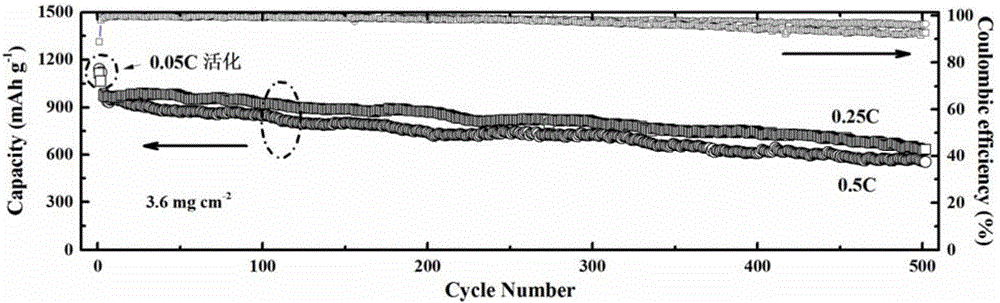

A lithium-sulfur battery and electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of low sulfur utilization rate, low sulfur loading area density, short cycle life, etc., to improve discharge capacity and quality Great effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

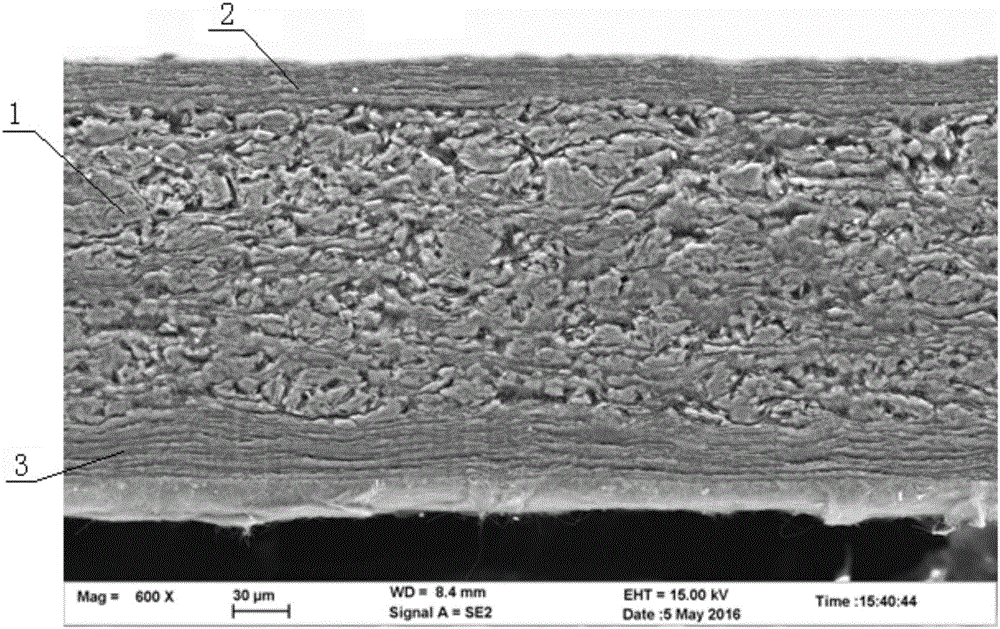

[0044] The first layer of conductive hydroxyl or carboxy-based layer uses nanocellulose as a support material, carbon nanotubes as a conductive material, the mass ratio of nanocellulose and carbon nanotubes is 1:1, and isopropanol is used as a solvent, and it is used after uniform dispersion The method of vacuum filtration quickly forms a film, and the density of the first layer of conductive layer is 2mg / cm 2 The active material layer uses sulfur-carbon composite positive electrode powder, nanocellulose and carbon nanotubes, sulfur-carbon composite positive electrode powder is used as active matter particles, nanocellulose is used as a support material, and carbon nanotubes are used as a conductive carbon material. The mass ratio of the three is 80:10:10, use isopropanol as a dispersion solvent, and use vacuum filtration to form a film after uniform dispersion, and the layer density of the prepared middle layer active material is 5mg / cm 2 ; The last layer of conductive layer ...

example 2

[0046] The first layer of conductive hydroxyl or carboxyl layer uses aramid fiber and Ketjen black, aramid fiber is used as the support material, Ketjen black is used as the conductive material, the mass ratio of aramid fiber and Ketjen black is 1:1, and N-methylpyrrolidone is used As a solvent, after uniform dispersion, use vacuum filtration to quickly form a film, and prepare the first layer of conductive layer with a density of 1mg / cm 2 The active material layer uses sulfur-carbon composite positive electrode powder, aramid fiber and Ketjen black. The sulfur-carbon composite positive electrode powder is used as the active particle, aramid fiber is used as the support material, and Ketjen black is used as the conductive carbon material. The mass ratio of the three is 90: 5:5, use ethanol as the dispersion solvent, and use vacuum filtration to form a film after the dispersion is uniform, and the layer density of the prepared middle layer active material is 20mg / cm 2 ; The las...

example 3

[0048] The first conductive layer uses aramid fiber and conductive carbon black. The mass ratio of aramid fiber and conductive carbon black is 2:1. Deionized water is used as the dispersion solvent. After the dispersion is uniform, the vacuum filtration method is used to quickly form a film. Prepare the first layer of conductive layer with a density of 0.5mg / cm 2 ; The active material layer uses sulfur cathode powder, nanocellulose and carbon nanotubes, and the mass ratio of the three is 85:10:5. Deionized water is used as the dispersion solvent. After the dispersion is uniform, the vacuum filtration method is used to form a film. The prepared The layer density of active material in the middle layer is 10mg / cm 2 ;The last layer of conductive layer uses the same ratio and surface density as the first layer, uses deionized water as the dispersion solvent, and after the dispersion is uniform, the vacuum filtration method is used to form a film on the basis of the first two layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com