Method for evaluating etching forms of surface of rock plate in acid etching physical simulation test

A technology of etching morphology and physical simulation, which is applied in the fields of earthwork drilling, electrical digital data processing, and special data processing applications, etc. It can solve the problems of complex etching morphology, strong randomness of etching, and difficulty in describing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The steps of the present invention will be described in detail below.

[0048] The evaluation method of the etched form on the rock slab surface in the physical simulation experiment of acid etching includes the following steps in turn:

[0049] (A) Use a three-dimensional laser scanner to scan the rough surface of the rock slab after acid etching to obtain three-dimensional data on the rock slab surface;

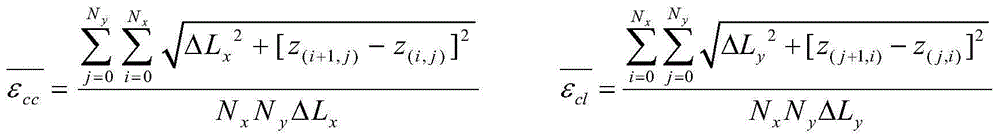

[0050] (B) Using the 3D data obtained in step (A) to calculate the transverse tortuosity ratio of the rock slab surface and longitudinal tortuosity two parameters;

[0051] (C) Utilize the obtained in step (B) and Two parameters, classify the etched morphology of the slab surface as follows:

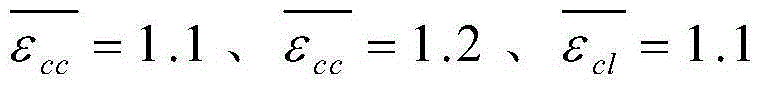

[0052] (1) when When the slab surface is uniformly etched,

[0053] (2) when When , the surface of the slab is in the form of point-like etching,

[0054] (3) when When , the surface of the slab is in the form of nail bed etching,

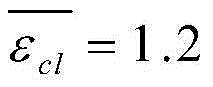

[0055] (4) when When , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com