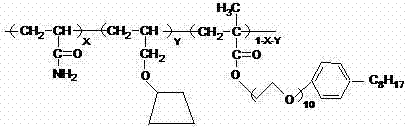

Temperature and salt-resistant AM/ACD/AE copolymer and its preparation method

A temperature-resistant, salt-resistant, copolymer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as increasing the viscosity of the injection liquid, and achieve enhanced hydrophobic association, mild reaction conditions, and simple preparation methods. workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1 The preparation method of AM / ACD / AE copolymer.

[0011] First use 140mL of deionized water to mix 7.1g of acrylamide AM, 13.1g of allyl cyclodextrin ACD and 0.698g of octylphenol polyoxyethylene methacrylate AE into three monomers with a monomer concentration of 15%. Solution, add this solution to a 250mL three-necked flask; then add 0.11mL of potassium persulfate with a concentration of 0.8g / mL and 0.11mL of sodium bisulfite with a concentration of 0.7g / mL in sequence, and stir the above mixed solution evenly, Fill it with nitrogen for 20 minutes to remove oxygen, and react at 45°C for 5 hours to obtain a colloidal product, which is washed 3 times with absolute ethanol until white precipitation appears. After drying in an oven at 50°C for 24 hours, an AM / ACD / AE copolymer is prepared.

[0012] Measure the intrinsic viscosity of the AM / ACD / AE copolymer according to the standard described in GB12005.1-89, and then measure the molecular weight of the copolymer accor...

Embodiment 2

[0013] Example 2 The temperature resistance effect of AM / ACD / AE copolymer.

[0014] In order to evaluate the temperature resistance of the AM / ACD / AE copolymer, the following experiment was done to prove it. The obtained product AM / ACD / AE copolymer and the purchased acrylamide polymer are respectively prepared into a salt solution with a concentration of 2000 mg / L. The specific process is as follows: First, prepare a NaCl solution with a concentration of 3000 mg / L with deionized water; Then use the prepared salt solution to make the above product AM / ACD / AE into a 2000mg / L copolymer aqueous solution; the purchased acrylamide polymer is also made into a 2000mg / L solution; finally, the two prepared above A solution, the change of apparent viscosity of the solution was measured at different temperatures, which proved that the AM / ACD / AE copolymer prepared by this invention has better temperature resistance than ordinary acrylamide polymers;

Embodiment 3

[0015] Example 3 The salt resistance effect of AM / ACD / AE copolymer.

[0016] In order to evaluate the salt resistance of the AM / ACD / AE copolymer, the following experiment was done to prove it. The obtained product AM / ACD / AE copolymer and the purchased acrylamide polymer are respectively formulated into a salt solution with a concentration of 2000mg / L. The specific process is as follows: Use deionized water to prepare a series of salt solutions with a concentration of NaCl. Different concentrations of salt solutions were prepared by mixing acrylamide polymer and AM / ACD / AE copolymer into a copolymer solution with a concentration of 2000mg / L. At a temperature of 25°C, the apparent viscosity changes of the two were measured. It is proved that the AM / ACD / AE copolymer prepared by this invention has better salt resistance than ordinary acrylamide polymers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com