Photochemical oxidation method for increasing oilfield sewage prepared polymer solution viscosity

A technology for preparing polymers and photochemical oxidation, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of long process, short life, expensive filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

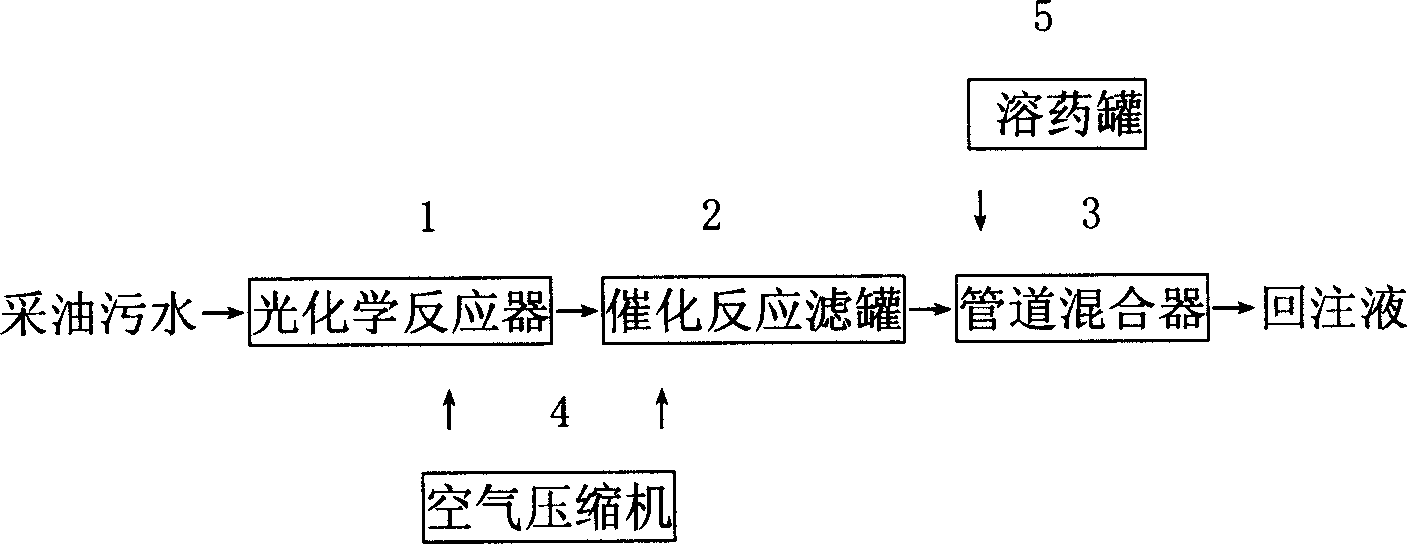

Method used

Image

Examples

Embodiment 1

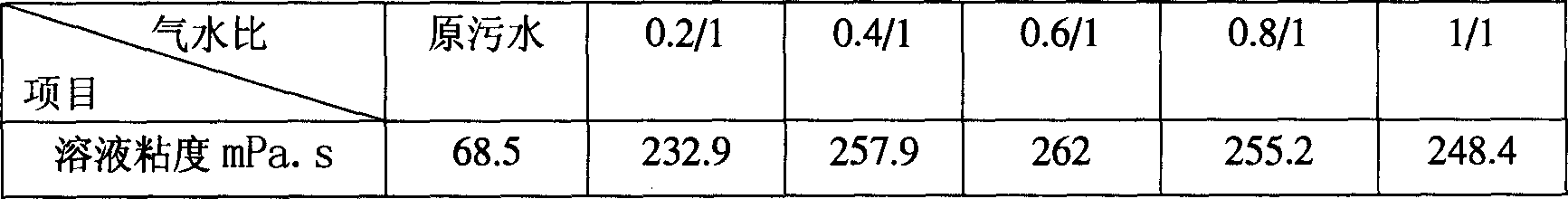

[0032] Effect of Aeration on Viscosity of Polymer Solution Prepared from Sewage

[0033] In the photochemical reactor made of stainless steel, 3 partitions with holes are placed in parallel, and two layers of UV254nm and UV185nm lamps with a height of 350cm are installed, and water is fed by a water pump. When the ratio of aeration gas to water is 0.2~1 / 1, the photochemical reaction time is 5min, the reaction temperature is 45℃, the injection water quality is petroleum 14.1mg / l, pH6.8, volatile phenol 2.6mg / l, sulfide 2.2mg / l , SS 14.6mg / l and Fe2+2.5mg / l, the photochemical reaction treatment was carried out under different aeration rates respectively. After the treatment, 1500mg / l PAM was added to the treated sewage to make a polymer solution, and the viscosity of the injected liquid was detected in 15 minutes. The results are listed in Table 1.

[0034] Table 1. The effect of aeration on the viscosity of polymer solution prepared in sewage

[0035]

...

Embodiment 2

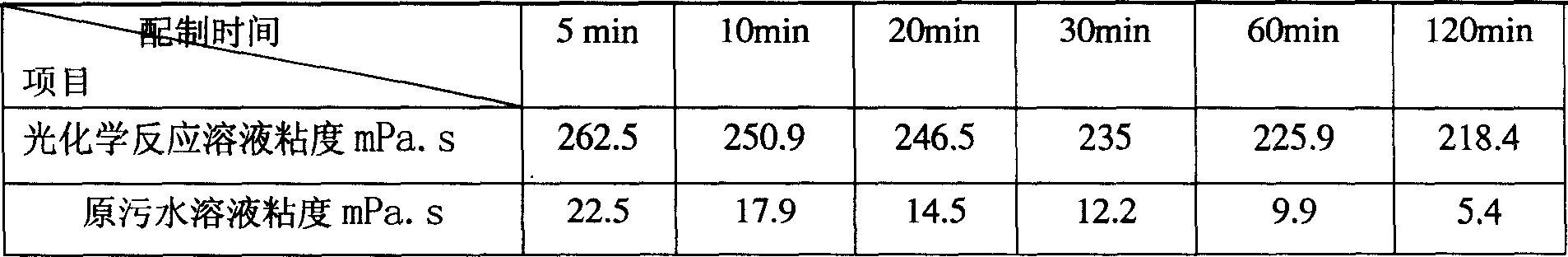

[0038] Effect of Injection Time on Viscosity of Polymer Solution Prepared from Sewage

[0039] In the photochemical reactor made of stainless steel, 3 partitions with holes are placed in parallel, and two layers of UV254nm and UV185nm lamps with a height of 350cm are installed, and water is fed by a water pump. The ratio of aeration gas to water is 0.6 / 1, the photochemical reaction time is 5min, and the reaction temperature is 45°C. The injection water quality is petroleum 14.1mg / l, pH 6.8, volatile phenol 2.6mg / l, sulfide 2.2mg / l, SS 14.6 mg / l and Fe 2+ Under the condition of 2.5mg / l, the aeration photochemical reaction treatment experiment was carried out. After the photochemical reaction treatment, 1500mg / l PAM was added to the sewage to prepare the polymer solution, and the viscosity of the injected liquid was detected at different preparation injection times.

[0040] Table 2. The effect of injection time on the viscosity of polymer solution prepared in ...

Embodiment 3

[0044] Effect of Photochemical Reaction Time on Viscosity of Polymer Solution Prepared from Sewage

[0045] In the photochemical reactor made of stainless steel, 3 partitions with holes are placed in parallel, and two layers of UV254nm and UV185nm lamps with a height of 350cm are installed, and water is fed by a water pump. The aeration gas water ratio is 0.6 / 1, the photochemical reaction time is 3-15min, the reaction temperature is 45°C, the water quality is petroleum 14.1mg / l, pH 6.8, volatile phenol 2.6mg / l, sulfide 2.2mg / l, SS 14.6mg / l and Fe 2+ Under the condition of 2.5mg / l, the aeration photochemical reaction treatment experiment was carried out, and 1500mg / l PAM was added to the treated sewage with different photochemical reaction time to prepare polymer solution, and the change of viscosity of the injection liquid was detected. The results are listed in Table 3.

[0046] Table 3. Effect of photochemical reaction treatment time on viscosity of polymer sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com