Sodium-calcium-silicate glass composition, its manufacturing method and use

A technology of glass composition and sodium calcium silicate, which is applied in the manufacture of said glass composition and the field of manufacturing glass plates for solar cells, and can solve problems such as easy crystallization of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

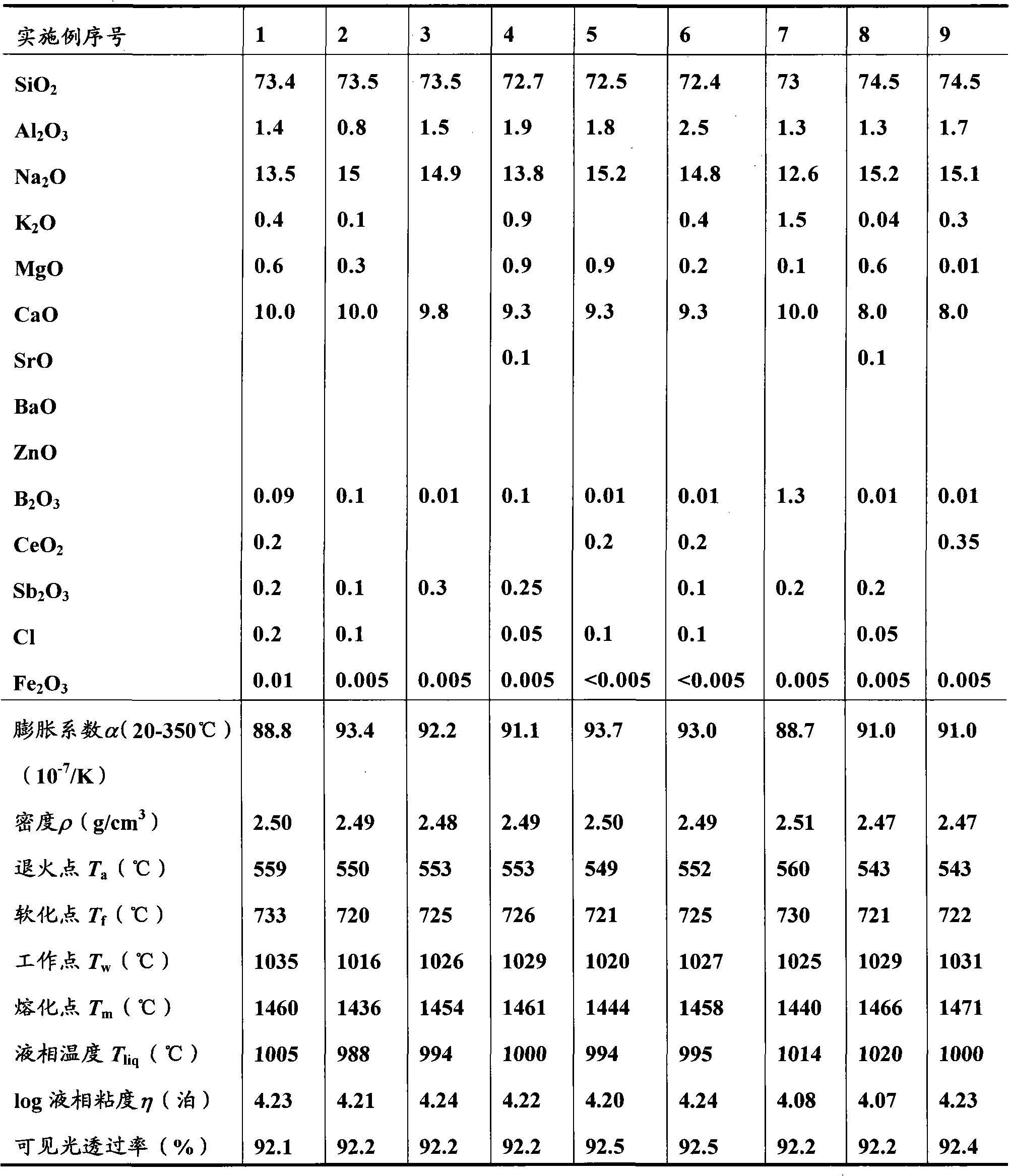

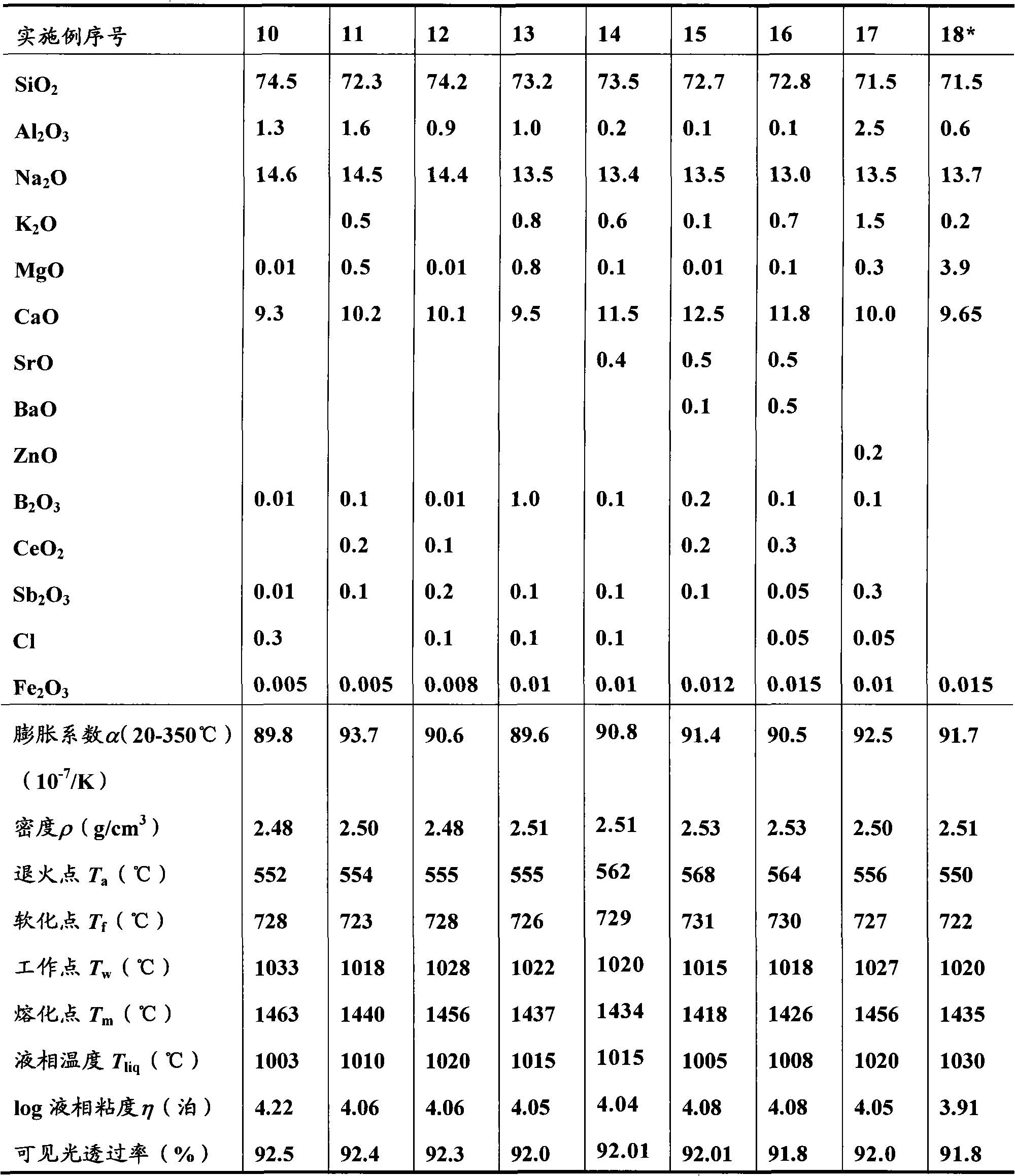

Examples

Embodiment 19-21

[0089] Embodiments 19 and 20 are formulated according to No. 7 and No. 15 of Table 1, and adopt sodium pyroantimonate to introduce Sb 2 o 3 , according to 6 times of Sb 2 o 3 The weight of sodium nitrate (NaNO 3 ), adding a small amount of nickel powder to the batch.

Embodiment 21

[0090] Embodiment 21 according to No. 18 composition batching in table 1, does not quote Sb 2 o 3 , using Glauber's salt (Na 2 SO 4 ) and carbon powder as clarifying agent.

[0091] Examples 19-21 are all prepared according to 500g of glass, and the glass batch is filled in a platinum-rhodium crucible, and melted in a high-temperature silicon-molybdenum rod electric furnace for 4 hours at a melting temperature of 1450°C. The melted glass is cast into blocks and annealed.

[0092] NiS crystals were detected on the obtained glass. As a result, no NiS crystals were found in the glass samples of Examples 19 and 20, but NiS crystals existed in the glass samples of Example 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com