Method for preparing calcium silicate micro power by using high alumina fly ash

A high-aluminum fly ash and calcium silicate technology, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve problems such as unfavorable large-scale industrialization promotion, expensive organic matter, consumption price, etc., and alleviate the supply of aluminum resources. Crisis, no three-waste emissions, and the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

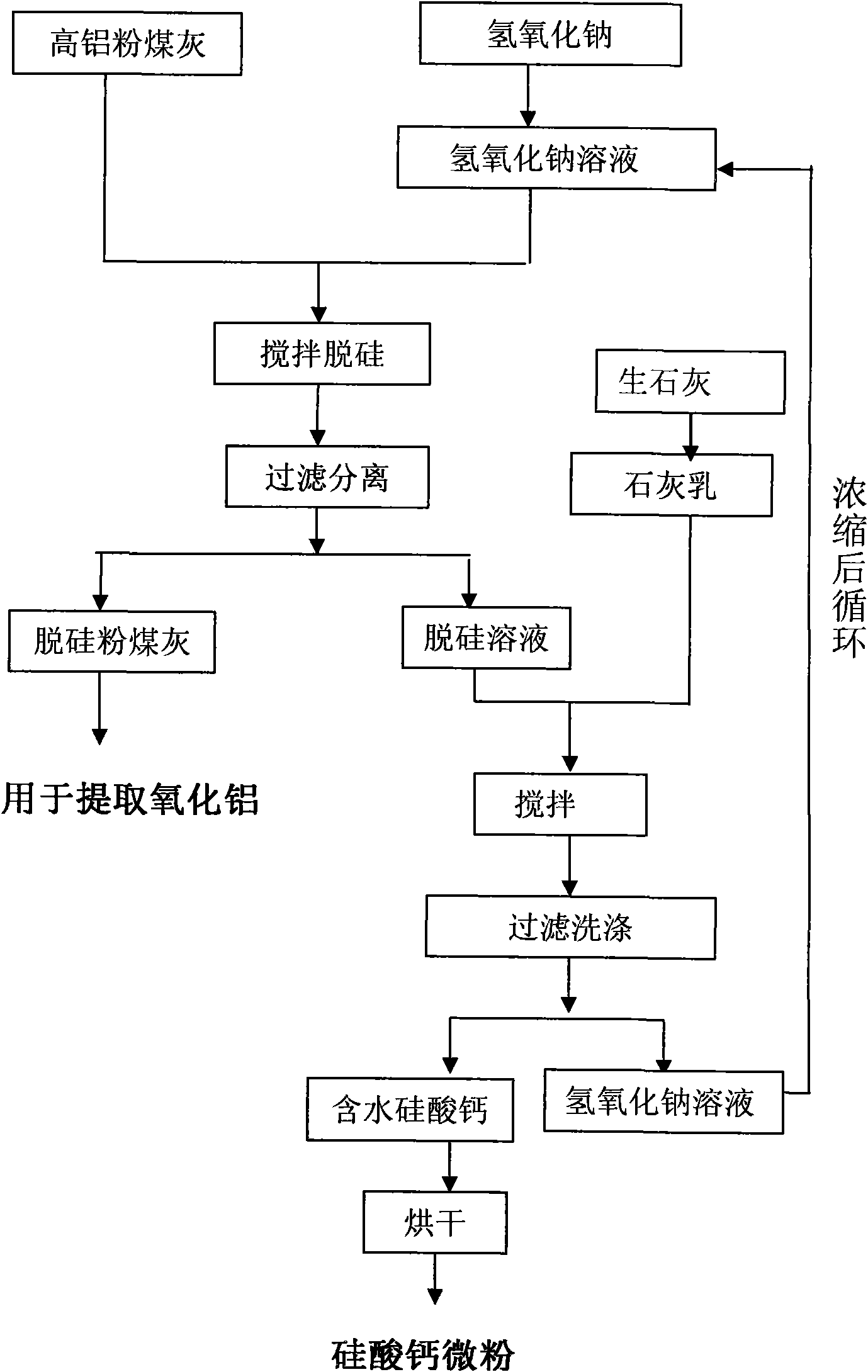

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] Referring to accompanying drawing, production step of the present invention is:

[0026] ①Select Al-containing 2 o 3 42.5%, SiO 2 46.7% high alumina fly ash is used as the main raw material. According to the mass ratio of sodium hydroxide and high aluminum fly ash of 0.5:1, the sodium hydroxide solid was weighed. Dissolve it in water, and keep stirring to prevent the solidification of sodium hydroxide, and prepare a sodium hydroxide solution with a concentration of 15%. Add high aluminum fly ash to the prepared sodium hydroxide solution. The sodium hydroxide solution dissolved with high-aluminum fly ash was subjected to desiliconization reaction at 120°C, and the desiliconization reaction time was 2 hours. Stir continuously during the desiliconization process to prevent the agglomeration of fly ash in local areas.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com