Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

A polyethylene composite pipe, flame retardant and antistatic technology, applied in the direction of pipes, applications, rigid pipes, etc., can solve the problems of poor weldability and insufficient axial tensile resistance, and achieve long service life and good resistance to rapid cracking , the effect of high rigidity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

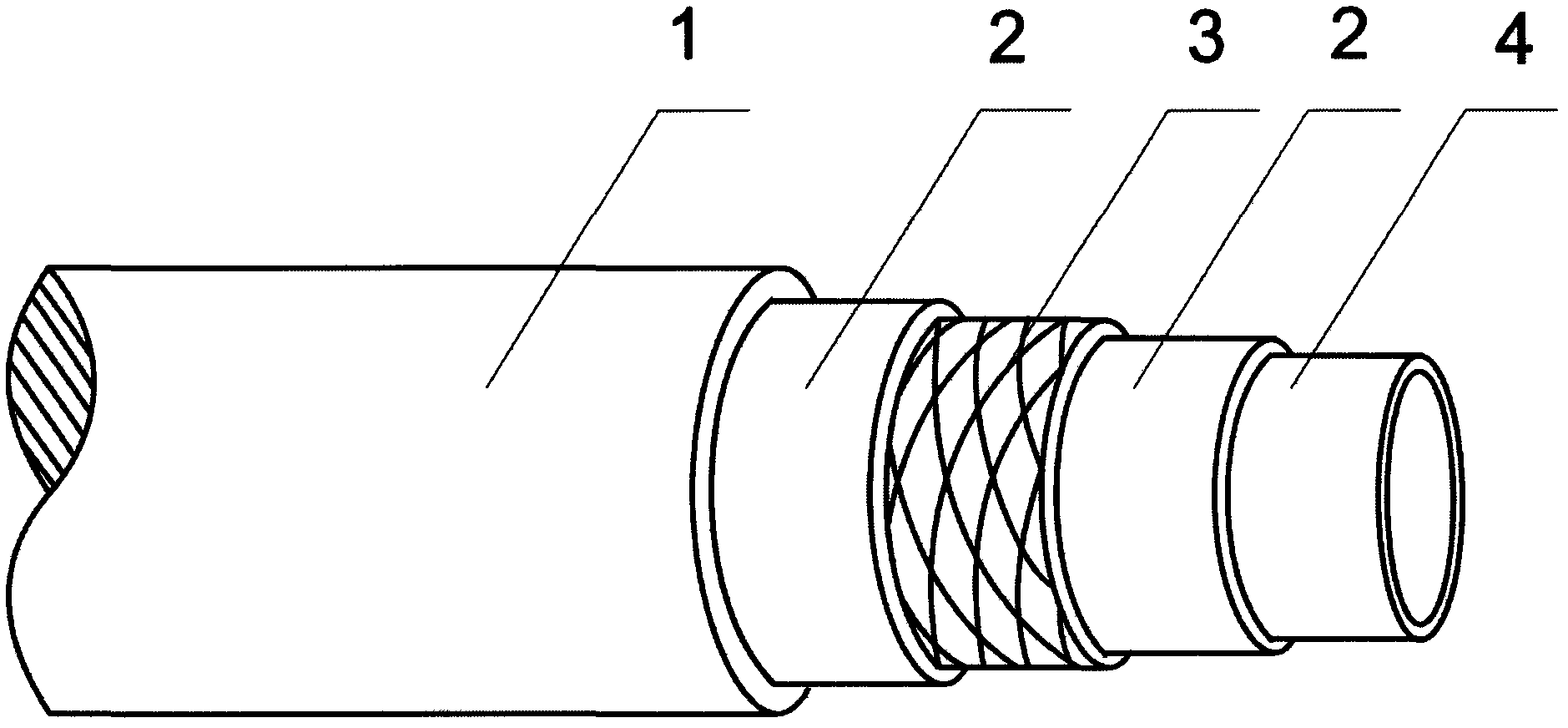

[0029] See figure 1 , The composite pipe is mainly divided into three layers, the outer layer of plastic 1, the steel mesh skeleton 3 and the hot melt adhesive 2 composed of reinforced skeleton bonding layer, and the inner layer of plastic 4. The reinforced skeleton bonding layer is located between the outer plastic 1 and the inner plastic 4, that is, between the outer surface of the core tube and the inner surface of the outer tube. Under certain temperature conditions, the high-performance hot melt adhesive 2 At the joint interface, the steel mesh skeleton 3 and the modified polyethylene in the outer plastic 1 and the inner plastic 4 are firmly combined. Because the steel mesh skeleton 3 is wrapped in continuous thermoplastic to form a reinforced skeleton, and through a composite process, the steel mesh skeleton 3 is combined with the outer layer plastic 1 and the inner layer plastic 4 into a whole, which significantly improves the comprehensive performance of the composite pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com