Preparation method of high density polyethylene hollow wrapped pipe

A technology of high-density polyethylene and manufacturing methods, which is applied in the field of pipe manufacturing, can solve the problems of high specificity, low ring stiffness and impact resistance of sewage pipes, achieve superior performance, improve impact resistance and ring stiffness, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

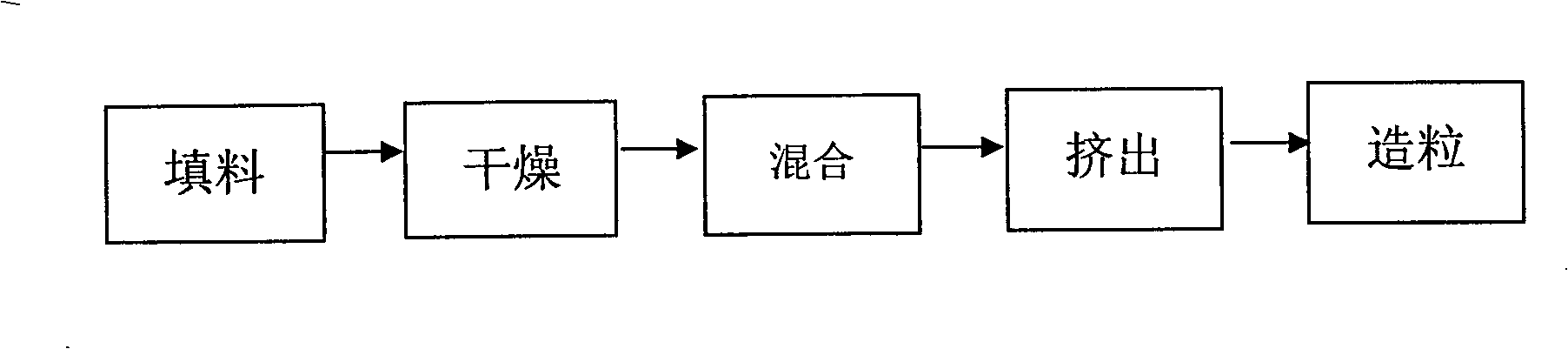

[0010] Modifier production:

[0011] Modifier formula: low-density polyethylene (LDPE) resin 10Kg, high-density polyethylene (HDPE) resin 5Kg, CaCO 3 Powder 85Kg, titanate 0.5Kg, liquid paraffin 4Kg.

[0012] CaCO 3 After the powder and titanate are dried, add liquid paraffin, mix and activate at 110±5°C for 8 minutes, mix with LDPE resin and HDPE resin, melt and extrude in an extruder, and granulate.

[0013] Sewage pipe material formula:

[0014] name

Proportion (parts by weight)

Require

HDPE

100

Density: 0.94-0.96g / m3

Melt index: 0.25g / 10min

modifier

25

5

Colorant carbon black

0.03

[0015] Dry the material before mixing, because if the surface humidity of HDPE is not treated, it will seriously affect the quality of the product, so it must be dehumidified and dried, and the optimum temperature is 120 °C.

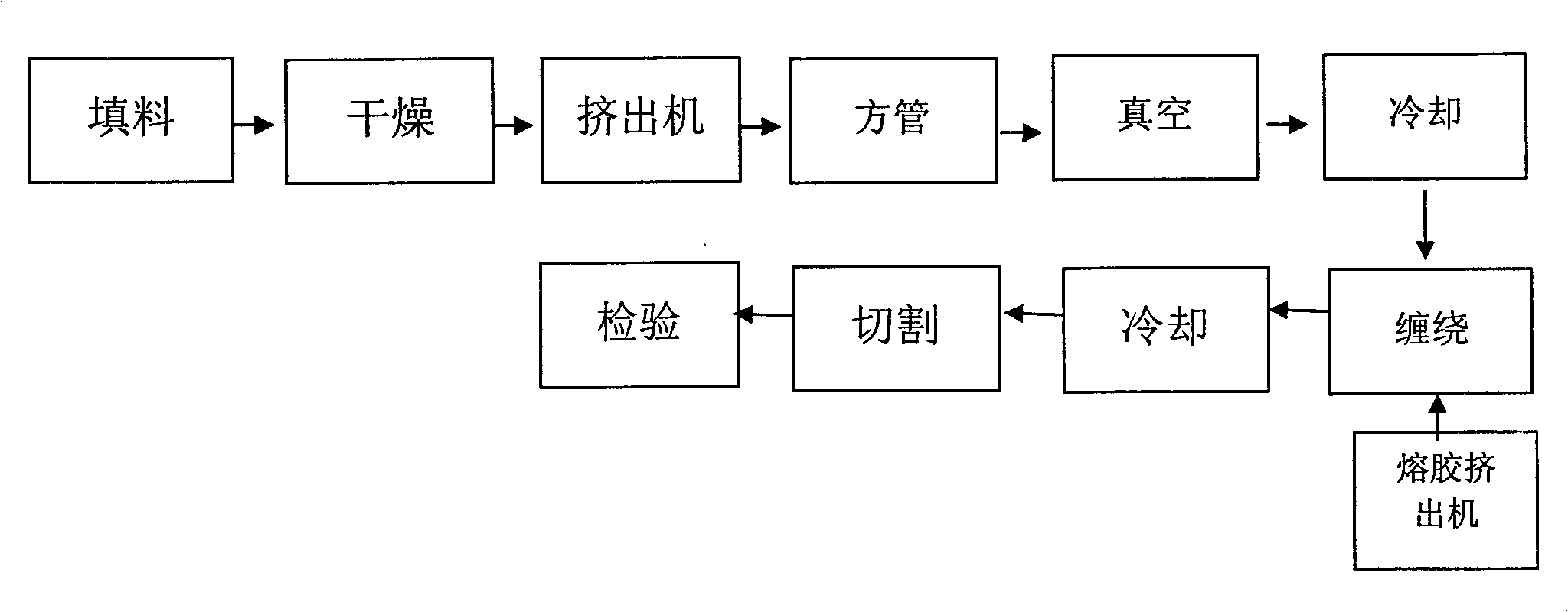

[0016] Then the materials are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com