Polyethylene and polyvinyl chloride modified environment-friendly plastic check well and preparation method thereof

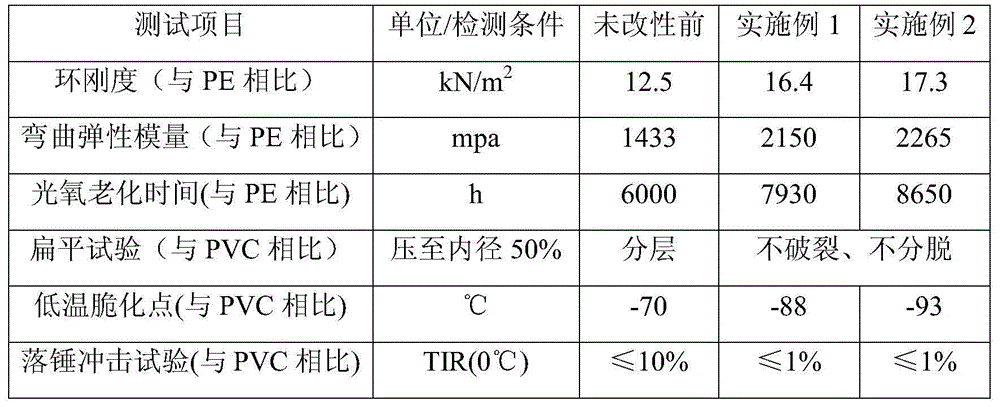

A polyvinyl chloride, environmentally friendly plastic technology, applied in the field of plastic inspection wells and its preparation, can solve the problems of temperature sensitivity, poor ring stiffness, and poor impact strength, and achieve low temperature resistance, good ring stiffness, and impact strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

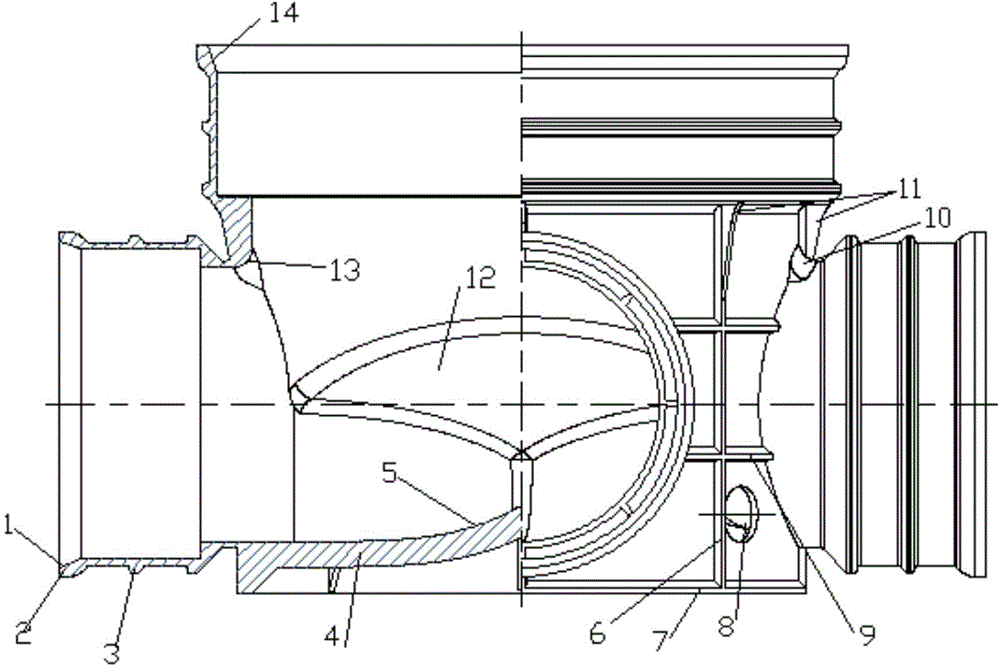

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned polyethylene and polyvinyl chloride modified environmental protection plastic inspection well comprises the following steps:

[0029] a. Weigh polyethylene resin, 50% coupling agent in total, compatibilizer and reinforcing agent in parts by weight, stir at 60-100°C for 5-20 minutes, and then cool to 30~38°C, after granulation, get spare material I;

[0030] b. After weighing polyvinyl chloride resin, stabilizer, pigment, processing modifier, remaining coupling agent, antioxidant, light stabilizer, remaining compatibilizer and impact modifier according to parts by weight, Stirring at 110-135°C for 7-30 minutes, then cooling to 30-43°C to obtain spare material II;

[0031] c. Mix spare material Ⅰ and spare material Ⅱ for 5-15 minutes. After the temperature reaches 60-80°C, cool to 32-38°C. After cooling and molding, polyethylene and PVC modified environmentally friendly plastic inspection well.

[0032]In the preparation me...

Embodiment 1

[0035] Polyethylene and polyvinyl chloride modified environmentally friendly plastic inspection wells, composed of the following components by weight:

[0036] 150 parts of polyvinyl chloride resin, 75 parts of polyethylene resin, 25 parts of activated nano barium sulfate, 1 part of carbon black, 6 parts of calcium zinc stabilizer, 10 parts of processing aid DOP (dioctyl phthalate), polyethylene 1 part of wax, 1 part of paraffin, 1680.5 parts of phosphorous acid antioxidant, 0.5 part of light stabilizer benzophenone, 5 parts of compatibilizer GMA (glycidyl methacrylate), impact modifier CPE (chlorinated polyvinyl chloride) 10 parts, glass fiber 5 parts and titanate coupling agent NDZ-4011 parts. And adopt following preparation method:

[0037] a. Add high-density polyethylene resin, titanate coupling agent NDZ-401 (50% of the total number of parts), compatibilizer GMA (50% of the total number of parts), and reinforcing agent into the high-speed mixer by weight Stir in medium...

Embodiment 2

[0043] Polyethylene and polyvinyl chloride modified environmentally friendly plastic inspection wells, composed of the following components by weight:

[0044] 150 parts of polyvinyl chloride resin, 75 parts of polyethylene resin, 25 parts of active nano-talc powder, 1 part of titanium dioxide, 3 parts of organotin stabilizer, 10 parts of processing aid DOP, 1 part of polyethylene wax, 1 part of paraffin wax, phosphorous acid Antioxidant 1680.5 parts, light stabilizer benzotriazole 0.5 parts, compatibilizer GMA 5 parts, impact modifier CPE 10 parts, glass fiber 5 parts and titanate coupling agent NDZ-4011 parts.

[0045] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com