Steel-plastic wound multiple pipe and manufacturing device and manufacturing technique of steel-plastic wound multiple pipe

A manufacturing device and manufacturing process technology, which is applied in the field of large-diameter steel-plastic composite pipe, steel-plastic winding composite pipe and its manufacturing equipment, can solve the problem that the pipeline cannot be used for conveying liquid under pressure, etc., and achieves the optimization of the process and the scope of application The effect of increasing the wide and pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

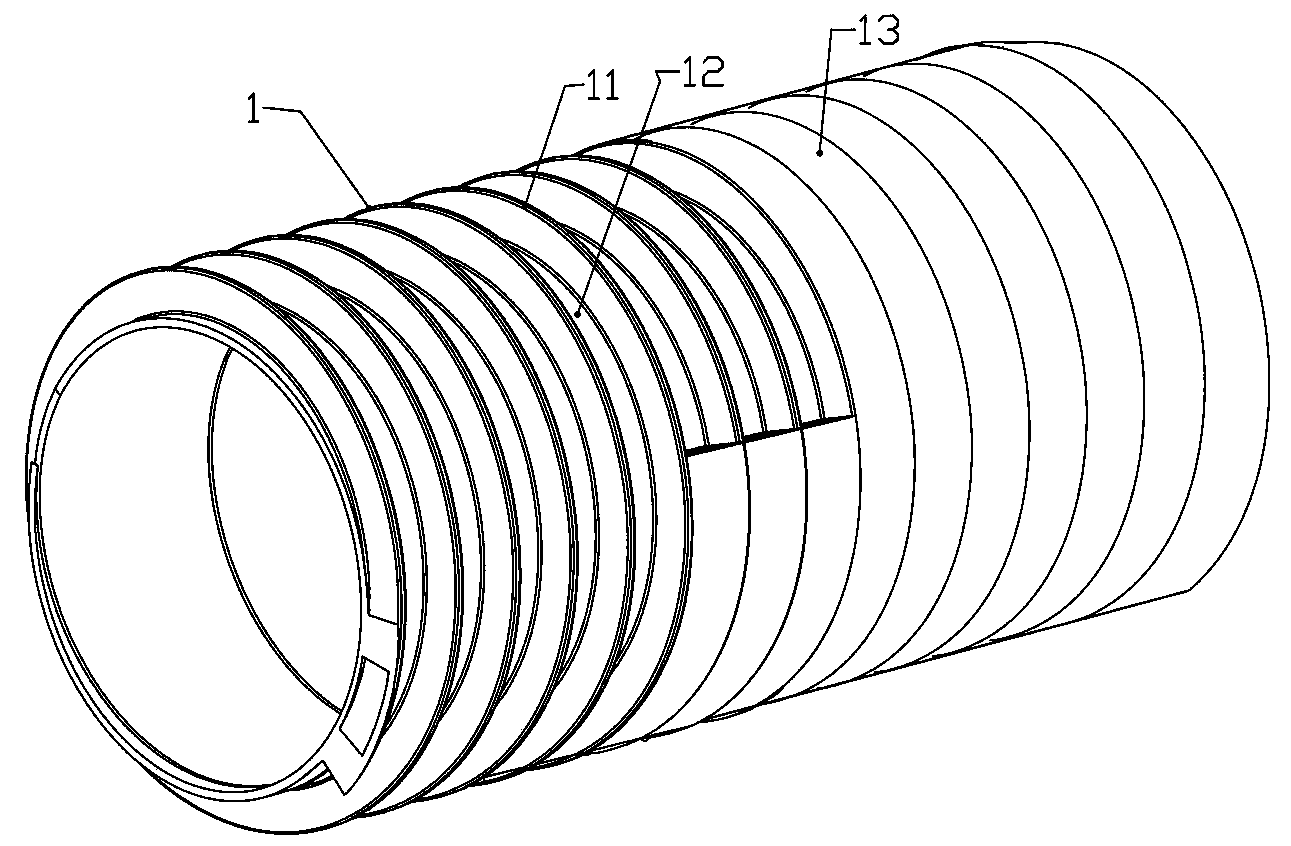

[0042] Such as Figure 1 to Figure 6 as shown,

[0043] A steel-plastic winding composite pipe includes at least the following two basic styles.

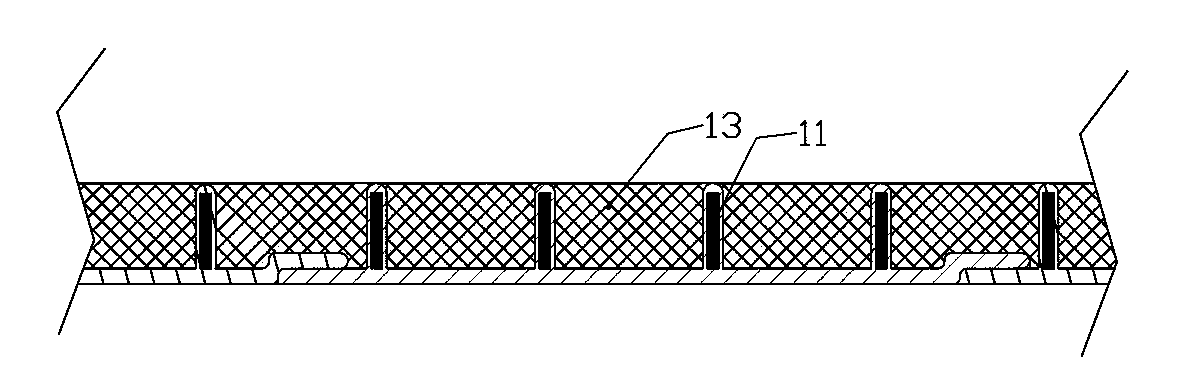

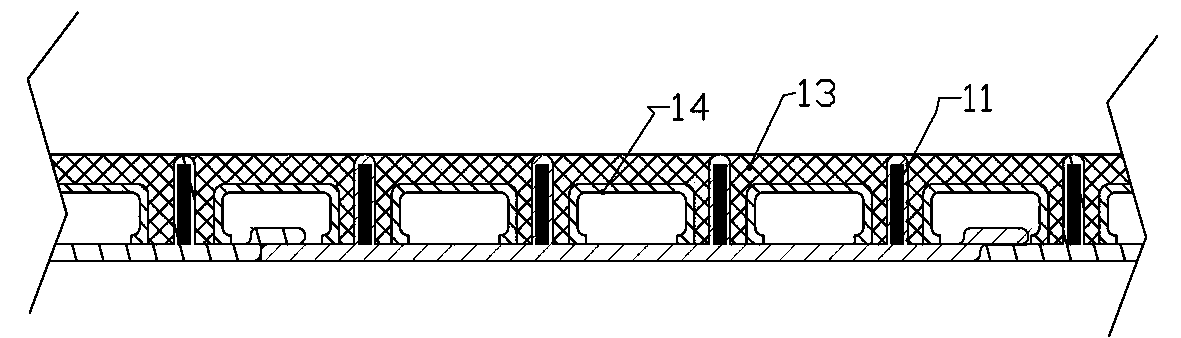

[0044] Style 1, a spiral steel-plastic winding composite pipe formed by winding steel-plastic strips and hot-melt welding. There are vertical reinforcing ribs 11 and grooves 12 on the outer surface of the steel-plastic winding composite pipe 1. In the groove 12 between two reinforcing ribs on the outer surface of the pipe matrix, there is a spiral plastic filler 13 filled with thermoplastic and condensed, such as figure 1 and figure 2 As shown, a flat-walled structure is formed on the outer surface of the steel-plastic wound composite pipe, forming a solid double-flat-walled pipe.

[0045] Wherein the style of the reinforcing rib can be any style in the prior art and the existing market, Figure 4 to Figure 6 Only three common pipe wall styles are listed in , by filling the groove with plastic material and compacting to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com