Reinforced HDPE double-wall corrugated pipe and production method thereof

A double-wall corrugated pipe and reinforced technology, applied in the field of reinforced HDPE double-wall corrugated pipe and its preparation, can solve the problems of high use risk and difficult structure, and achieve the effects of cost saving, good impact performance and tight adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

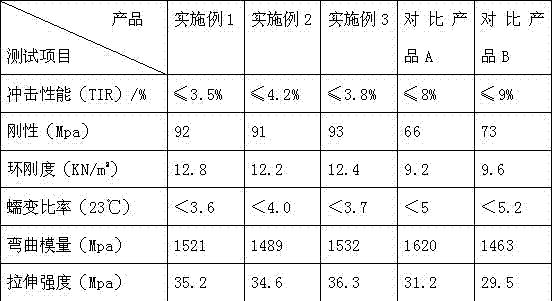

Examples

Embodiment 1

[0019] A formulation of reinforced HDPE double-wall corrugated pipe, which is composed of the following materials in parts by weight: 280 parts of high-density polyethylene, 80 parts of chopped glass fiber, 8 parts of elastomer, 12 parts of phenolic resin, 30 parts of wood powder, 8 parts of joint agent, 10 parts of calcium carbonate, 10 parts of nano-scale silicon oxide, 1 part of antioxidant, 26 parts of methyl silicone oil and 4 parts of lubricant.

[0020] Described coupling agent is stearic acid, and described lubricant is polyethylene wax, and described elastomer is POE, and described antioxidant is antioxidant 1076, and the particle diameter of described calcium carbonate is 60 nanometers, so The mesh number of said wood powder is 80 mesh, and the length of said chopped glass limit is 1mm.

[0021] A preparation method for reinforced HDPE double-wall bellows, comprising the following steps:

[0022] S1. Wood powder treatment: Dry the wood powder at 180°C for 3 hours wi...

Embodiment 2

[0028] A formulation of reinforced HDPE double-wall corrugated pipe, which consists of the following materials in parts by weight: 300 parts of high-density polyethylene, 90 parts of chopped glass fiber, 10 parts of elastomer, 16 parts of phenolic resin, 35 parts of wood powder, 6 parts of joint agent, 12 parts of calcium carbonate, 12 parts of nano-scale silicon oxide, 1.5 parts of antioxidant, 30 parts of methyl silicone oil and 3 parts of lubricant.

[0029] The coupling agent is composed of aluminum ester acid and titanium ester acid in a weight ratio of 1:1, the lubricant is polyethylene wax, the elastomer is EVA, and the antioxidant is antioxidant 1076 , the particle size of the calcium carbonate is 80 nanometers, the mesh number of the wood powder is 100 mesh, and the length of the chopped glass limit is 2mm.

[0030] A preparation method for reinforced HDPE double-wall bellows, comprising the following steps:

[0031] S1. Wood powder treatment: Dry the wood powder at ...

Embodiment 3

[0037] A formulation of reinforced HDPE double-wall corrugated pipe, which is composed of the following materials in parts by weight: 320 parts of high-density polyethylene, 60 parts of chopped glass fiber, 8 parts of elastomer, 15 parts of phenolic resin, 20 parts of wood powder, 8 parts of joint agent, 15 parts of calcium carbonate, 6 parts of nano-scale silicon oxide, 2 parts of antioxidant, 25 parts of methyl silicone oil and 2 parts of lubricant.

[0038] Described coupling agent is aluminum ester acid, and described moistening agent is polyethylene wax, and described elastomer is EVA, and described antioxidant is antioxidant 1076, and the particle diameter of described calcium carbonate is 120 nanometers, so The mesh number of said wood powder is 70 mesh, and the length of said chopped glass limit is 3mm.

[0039] A preparation method for reinforced HDPE double-wall bellows, comprising the following steps:

[0040] S1. Wood powder treatment: Dry the wood powder at 150°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com