CPVC used for high Vicat power cable sleeve and its preparation method

A technology of power cable and CPVC resin, which is applied in the field of CPVC for high-dimensional power cable casing and its preparation, can solve the problems of low heat resistance, insufficient temperature resistance, easy to break, etc., and achieves high mechanical strength, convenient Popularity and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

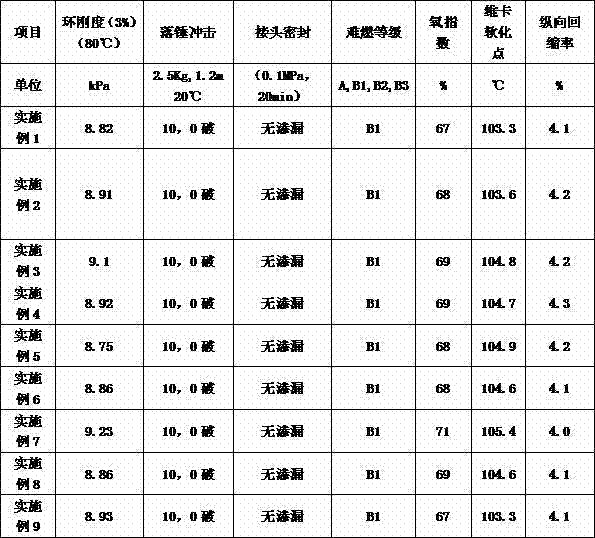

Examples

Embodiment 1

[0027] Embodiment 1: A kind of CPVC for high-dimensional card power cable casing, comprising:

[0028] 80 parts of CPVC resin, special resin for pipe prepared by aqueous phase suspension method, chlorine content 76%, polymerization degree 700;

[0029] 10 parts of PVC resin, resin for pipes;

[0030] 5 parts of stabilizer are composite lead salt stabilizers;

[0031] 1.2 parts of internal lubricant is stearic acid;

[0032] 2 parts external lubricant, which is paraffin;

[0033] 5 parts of impact modifier, which is CPE resin;

[0034] 2 parts processing aid, ACR201;

[0035] 20 parts of filler, which is light calcium carbonate;

[0036] 0.05 part of pigment is molybdenum chrome red pigment.

[0037] Add the above raw material components into the high mixer in proportion, put them into the cold mixing pot when they are hot mixed to 110°C, and discharge them when they are cold mixed to 45°C to obtain CPVC for high-vicat power cable casing.

Embodiment 2

[0038] Embodiment 2: A kind of CPVC for high-dimensional card power cable casing, comprising:

[0039] 80 parts of CPVC resin, special resin for pipe prepared by aqueous phase suspension method, chlorine content 76%, polymerization degree 800;

[0040] 10 parts of PVC resin, resin for pipes;

[0041] 5 parts of stabilizer are composite lead salt stabilizers;

[0042] 1.2 parts of internal lubricant is stearic acid;

[0043] 2 parts of external lubricant, PE wax;

[0044] 5 parts of impact modifier, which is CPE resin;

[0045] 2 parts processing aid, ACR201;

[0046] 20 parts of filler, which is light calcium carbonate;

[0047] 0.05 part of pigment is iron red pigment.

[0048] Add the above raw material components into the high mixer in proportion, put them into the cold mixing pot when they are hot mixed to 110°C, and discharge them when they are cold mixed to 45°C to obtain CPVC for high-vicat power cable casing.

Embodiment 3

[0049] Embodiment 3: A kind of CPVC for high-dimensional card power cable casing, comprising:

[0050] 80 parts of CPVC resin, special resin for pipe prepared by aqueous phase suspension method, chlorine content 76%, polymerization degree 1000;

[0051] 10 parts of PVC resin, resin for pipes;

[0052] 5 parts of stabilizer are composite lead salt stabilizers;

[0053] 1.2 parts internal lubricant, which is oxidized polyethylene wax;

[0054] 2 parts of external lubricant, PE wax;

[0055] 5 parts of impact modifier, which is CPE resin;

[0056] 2 parts processing aid, ACR201;

[0057] 20 parts of filler, which is light calcium carbonate;

[0058] 0.05 part of pigment is positive red pigment.

[0059] Add the above raw material components into the high mixer in proportion, put them into the cold mixing pot when they are hot mixed to 110°C, and discharge them when they are cold mixed to 45°C to obtain CPVC for high-vicat power cable casing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com