Graphene dispersion liquid and preparation method thereof

A graphene dispersion liquid and graphene technology, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. problem, to achieve the effect of improving dispersion, easy purchase, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of graphene:

[0042](1) Preparation of graphite oxide: raw material is 1500 mesh natural graphite powder (Shanghai Yifan Graphite Co., Ltd.), 220ml of 98% concentrated sulfuric acid, 3.5g sodium nitrate, 21g potassium permanganate; above-mentioned substances are added to 10g natural stone In the ink powder, the mixture was stirred in an ice bath for 1 hour, and the temperature of the mixture was controlled at 20°C or below. The above mixed solution was taken out, and reacted for 4 hours while stirring in a 35° C. water bath; after adding 500 ml of deionized water, the resulting suspension was reacted at 90° C. for 15 minutes. Finally, 600ml of deionized water and 50ml of hydrogen peroxide were added and reacted for 5 minutes to obtain a graphene oxide dispersion. Filtrate the obtained dispersion while hot, wash out the metal ions with dilute hydrochloric acid solution, wash with deionized water to remove the acid, repeat the washing until the pH...

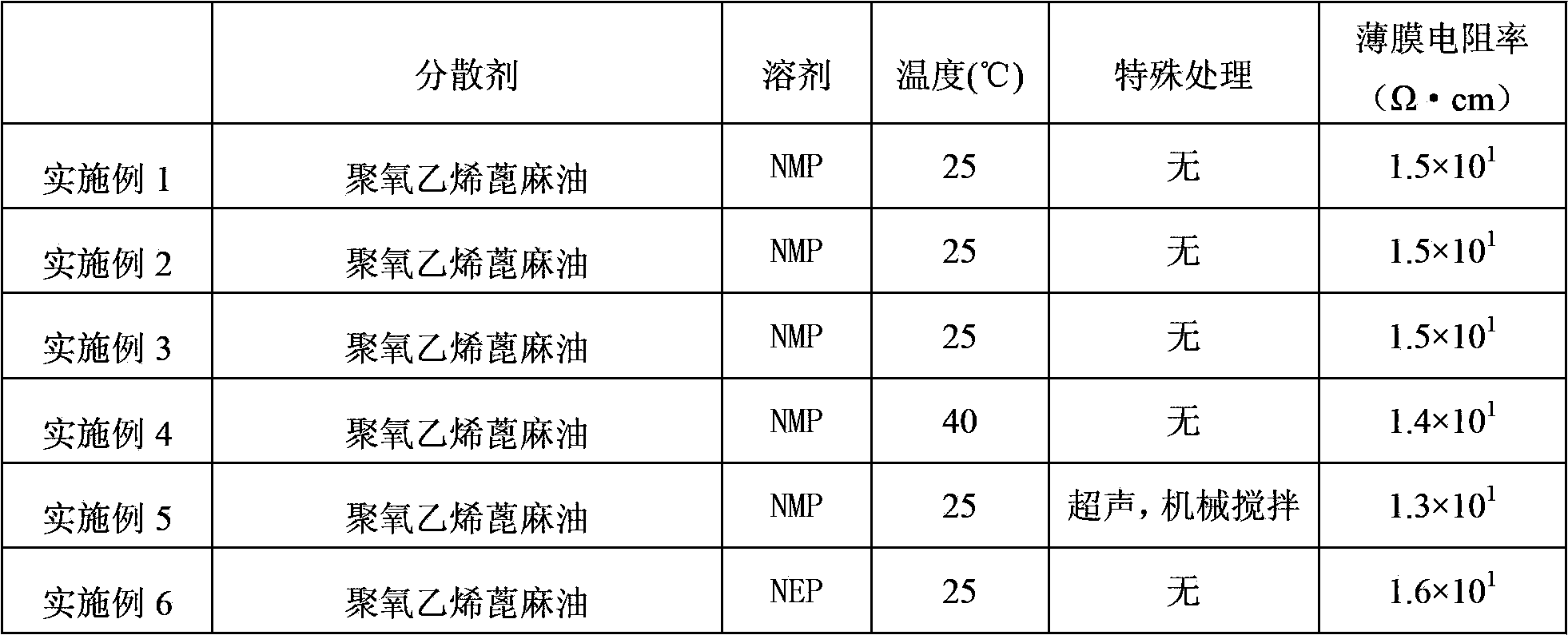

Embodiment 1

[0044] Under the condition of 25° C., 40 mg of graphene powder and 40 g of N-methylpyrrolidone (NMP) were fully mixed, and then 10 mg of polyoxyethylene castor oil was added and mixed evenly.

[0045] The dispersion liquid can be dispersed stably for more than a week. The sheet resistivity is shown in Table 1.

Embodiment 2

[0047] Under the condition of 25° C., 4 mg of graphene powder and 400 g of N-methylpyrrolidone (NMP) were fully mixed, and then 1 mg of polyoxyethylene castor oil was added, and mixed evenly.

[0048] The dispersion liquid can be dispersed stably for more than a week. The sheet resistivity is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com