Fibre structure of polyester/carbone nanotube nano composite and its preparation method

A nano-composite material and fiber structure technology, applied in the direction of fiber processing, single-component polyester artificial filament, filament/wire forming, etc., to achieve the effect of improving the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

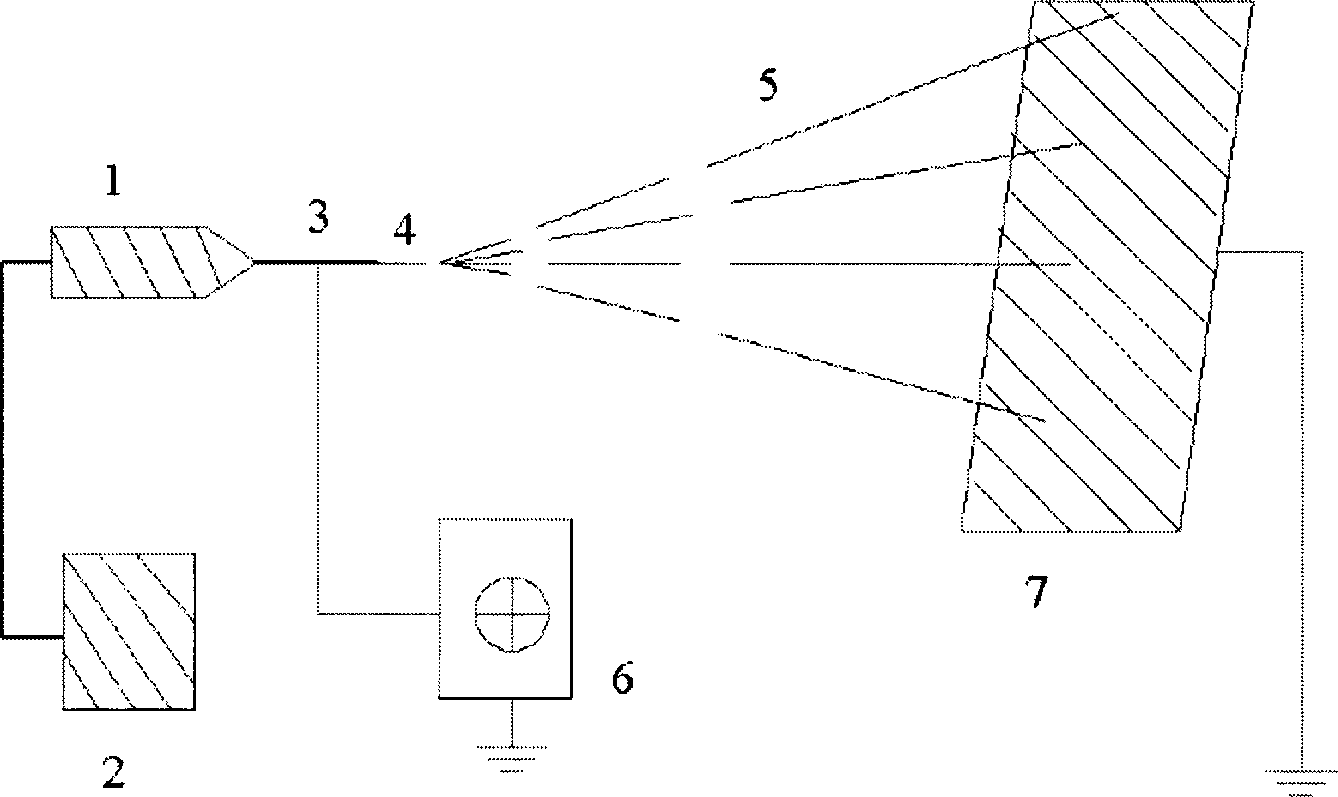

Method used

Image

Examples

Embodiment 1

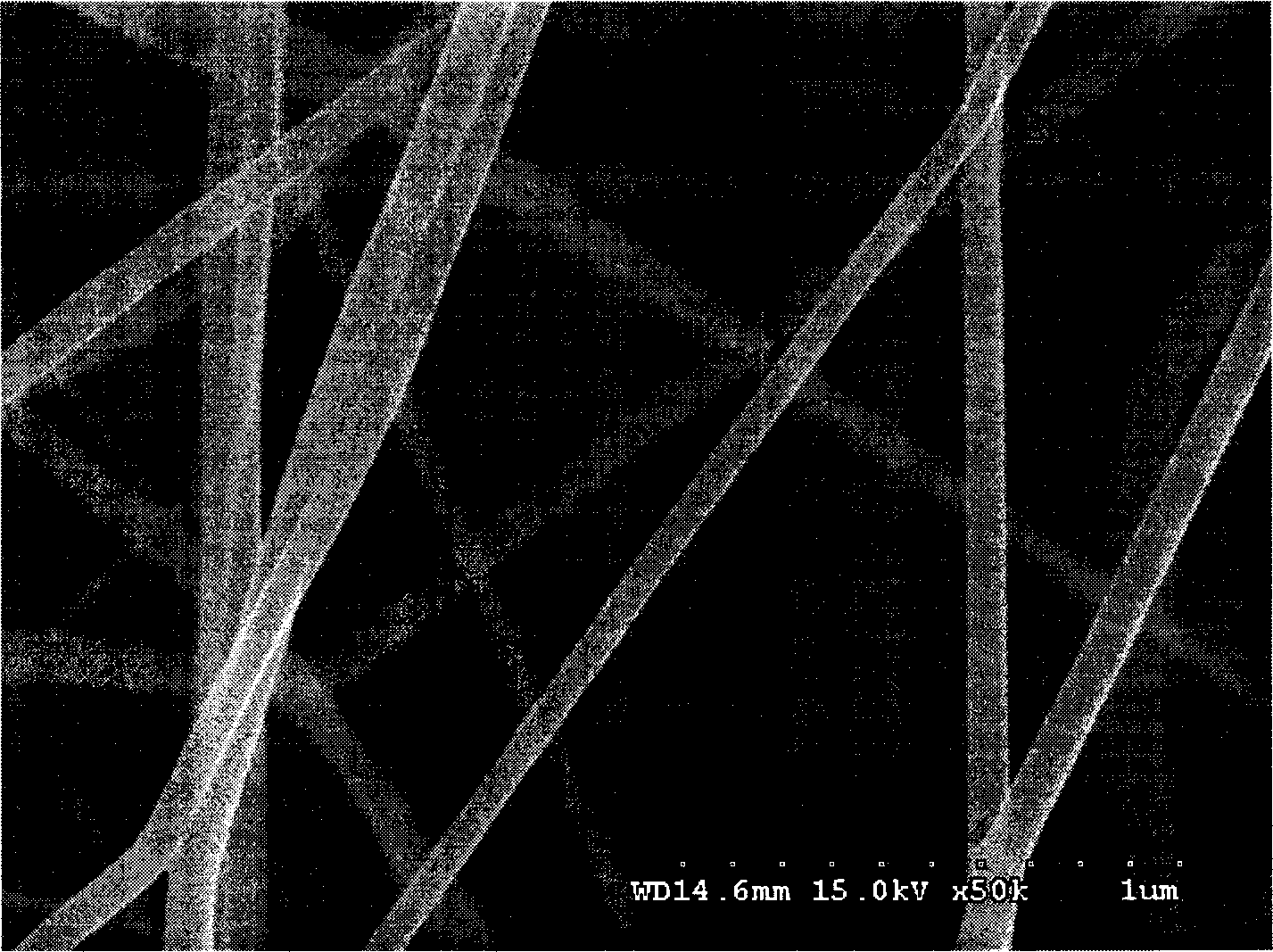

[0037] Add 0.01g of single-walled carbon tubes and 0.99g of polybutylene terephthalate into a 50mL weighing bottle containing 20mL of dichloroacetic acid, perform ultrasonic treatment (200W, 40kHz), and magnetically stir to obtain a uniform solution. Then take 1mL of the solution and put it in the liquid reservoir of the metering pump, and collect the obtained fibers on the grounded aluminum foil at the injection speed of 1mL / h and the working distance of 1kV / cm. The fiber diameter measured by SEM is about 100nm.

Embodiment 2

[0039] Add 0.005g of multi-walled carbon tubes and 0.995g of polyethylene terephthalate to a 25mL weighing bottle filled with 10mL of equal volume ratio of dichloromethane and trifluoroacetic acid mixed solvent, ultrasonic treatment (100W, 40kHz) , magnetically stirred to obtain a homogeneous solution. Then take 1mL of the solution and put it in the liquid reservoir, and under the condition of 1kV / cm working distance, the obtained fibers are collected on the grounded aluminum foil. The fiber diameter measured by SEM is about 500nm. The electrical conductivity of the nonwoven film measured by the two-electrode method was 7.4×10 -16 S / cm. The non-woven membrane is semi-hydrophobic, and the contact angle with water is about 100 degrees. The non-woven membrane can permeate small molecules such as water, acetone, ethanol, etc., but can intercept particles such as montmorillonite dispersed in water. figure 2 It is a real photo of the non-woven membrane after repeated suction fi...

Embodiment 3

[0041] 0.1g of multi-walled carbon tubes and 0.9g of polyethylene naphthalate were added to a 50mL weighing bottle filled with 20mL of hexafluoroisopropanol, ultrasonically treated (100W, 40kHz) for 0.5h, and magnetically stirred to obtain a uniform solution. Then take 1mL of the solution and put it in the reservoir, and at the working distance of 2kV / cm, the obtained fibers are collected on the grounded aluminum foil. The fiber diameter measured by SEM is about 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dimension diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com