Graphene/polypropylene conductive nano composite material and preparation method thereof

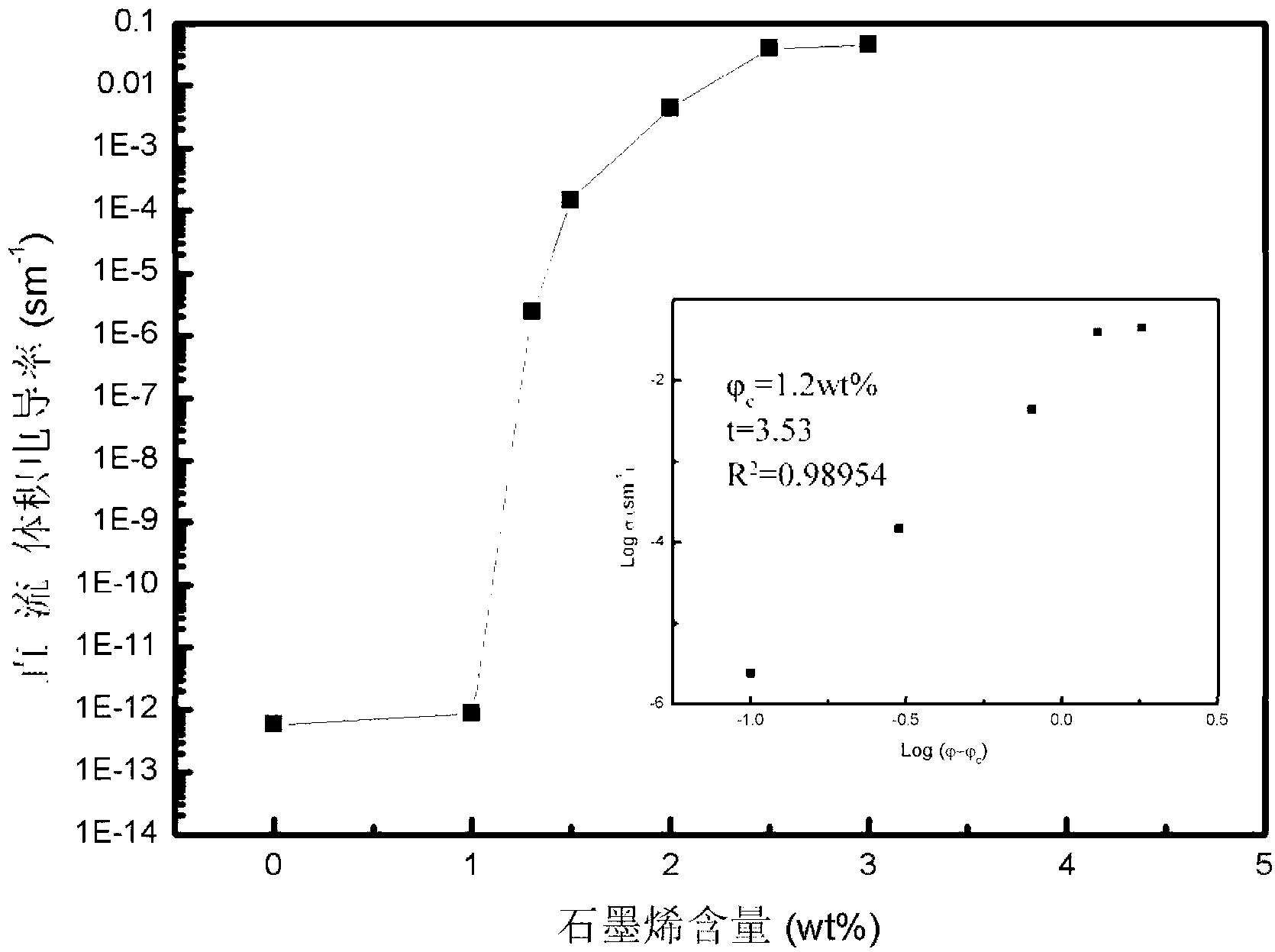

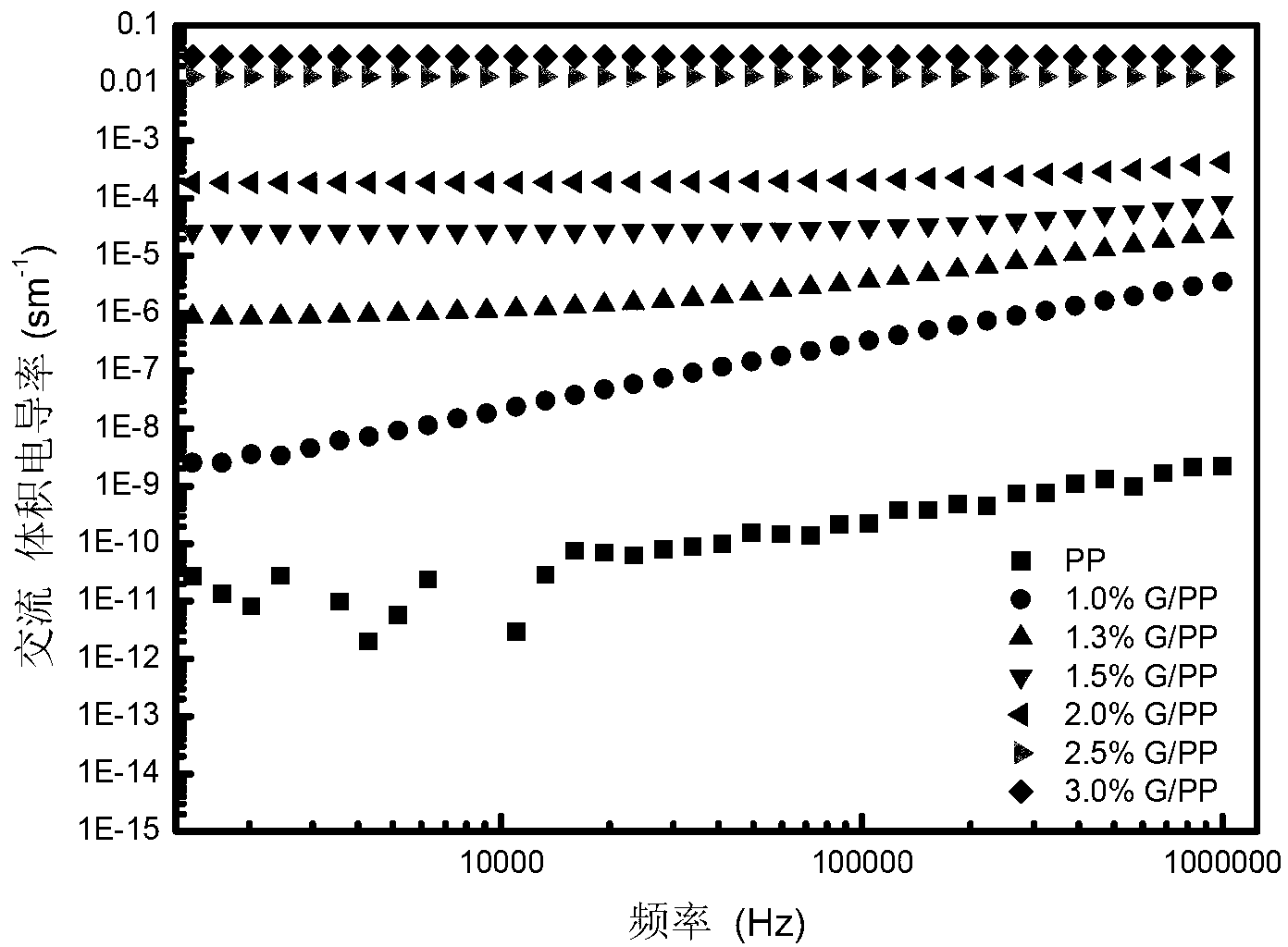

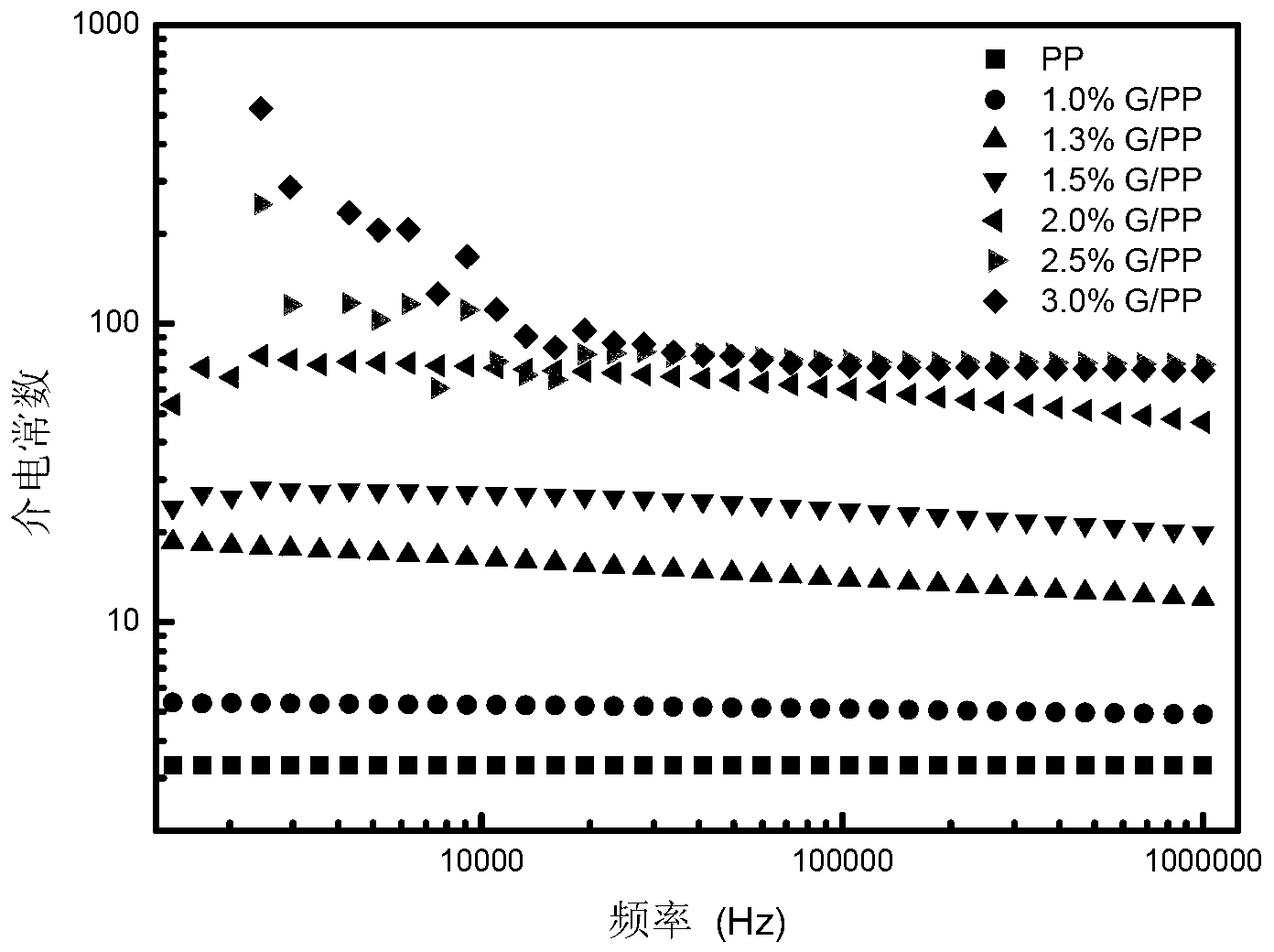

A conductive composite material and conductive nanotechnology, which are applied in the field of graphene/polypropylene conductive nanocomposite materials and their preparation, can solve the problems of complex operation means and high conductive percolation threshold of the composite, and achieve cost reduction, promotion of dispersion, and electrical performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. preparation graphene content is the graphene / polypropylene conductive nanocomposite material of 1.0wt%

[0025] 0.01 g of graphene was dispersed in 1 ml of xylene, and ultrasonically dispersed in an ultrasonic processor at room temperature for 3 hours to obtain a graphene dispersion. 0.975g polypropylene and 0.015g maleic anhydride grafted polypropylene were added in 8ml xylene, mechanically stirred at 110°C, solution blended to form a continuous and uniform polymer solution. Add the above-mentioned graphene dispersion into the above-mentioned polymer solution, add 1ml of xylene, and control the concentration of the entire mixed system to be 1g / 10ml. Continue mechanical stirring for 4 hours under the premise of constant temperature, pour the above-mentioned mixture into 200ml of dehydrated ethanol while it is hot, filter the product and wash it with dehydrated ethanol for 3 times, after suction filtration, put the above-mentioned product in a 50°C oven Af...

Embodiment 2

[0026] Embodiment 2. preparation graphene content is the graphene / polypropylene conductive nanocomposite material of 1.3wt%

[0027] 0.013 g of graphene was dispersed in 1.5 ml of xylene, and ultrasonically dispersed in an ultrasonic processor at room temperature for 3 hours to obtain a graphene dispersion. The polypropylene of 0.9675g and the maleic anhydride grafted polypropylene of 0.0195g were added in 6.5ml xylene, and mechanical stirring and solution blending at 120° C. formed a continuous and uniform polymer solution. The above-mentioned graphene dispersion was added to the above-mentioned polymer solution, and 3ml of xylene was added to control the concentration of the entire mixed system to be about 0.91g / 10ml. Continue mechanical stirring for 4.5h under the premise of constant temperature, pour the above-mentioned mixture into 250ml of absolute ethanol while it is hot, filter the product and wash it with absolute ethanol for 3 times, after suction filtration, put the...

Embodiment 3

[0028] Embodiment 3. preparation graphene content is the graphene / polypropylene conductive nanocomposite material of 1.5wt%

[0029] 0.015 g of graphene was dispersed in 2 ml of xylene, and ultrasonically dispersed in an ultrasonic processor at room temperature for 4 hours to obtain a graphene dispersion. The polypropylene of 0.9625g and the maleic anhydride grafted polypropylene of 0.0225g were added in 6ml xylene, mechanically stirred at 125°C, solution blended to form a continuous and uniform polymer solution. The above-mentioned graphene dispersion was added to the above-mentioned polymer solution, and 4ml of xylene was added to control the concentration of the entire mixed system to be 0.83g / 10ml. Continue mechanical stirring for 5 hours under the premise of constant temperature, pour the above-mentioned mixture into 280ml of absolute ethanol while it is hot, filter the product and wash it with absolute ethanol for 3 times, and put the above-mentioned product in a 55°C ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com