Antistatic material, self-cleaning light diffusion plate prepared therefrom, and preparation method of self-cleaning light diffusion plate

A light diffusion plate, antistatic technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of impact, light energy loss, light energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The antistatic material of the present invention weighs each component according to the components and content ratio shown in Table 1, stirs and mixes them evenly in a reactor at a high speed, and then heats them at 230°C under continuous stirring until fully melted and mixed Uniform, then shape, cool and collect. The resistivity of the obtained antistatic material was tested according to the GB / T1410-2006 standard, and the specific results are shown in Table 1.

[0060] In the preparation of the above-mentioned antistatic material of the present invention, the heating and melting temperature can be set at 100° C. to 300° C., specifically, the standard is to achieve sufficient and uniform melting and mixing.

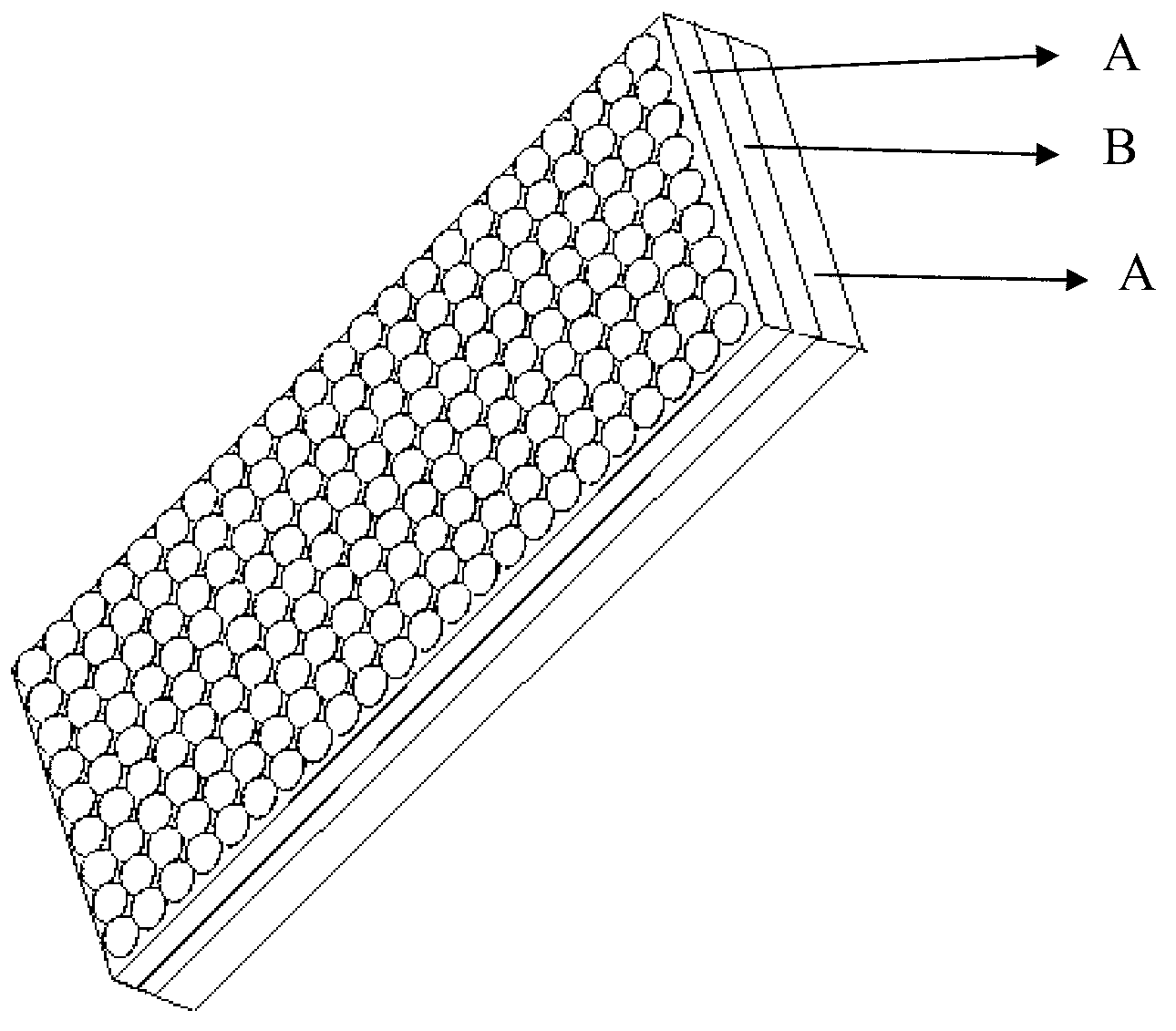

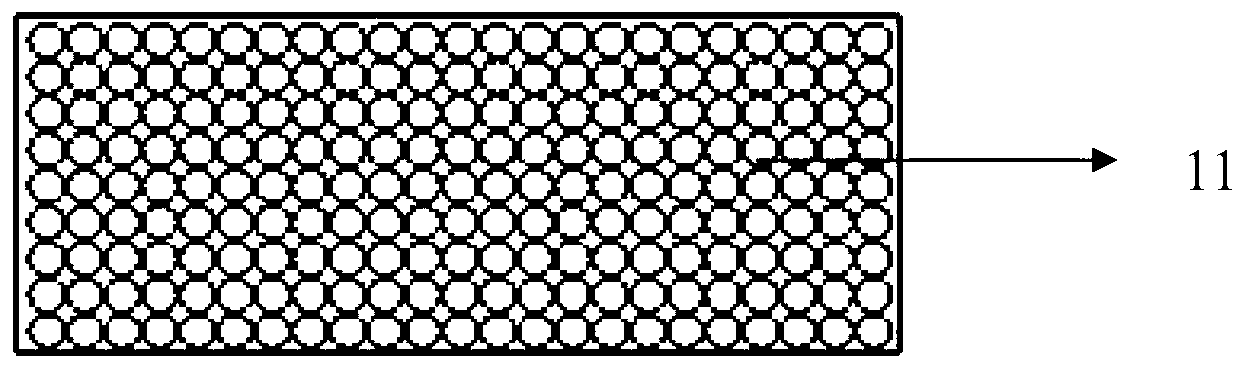

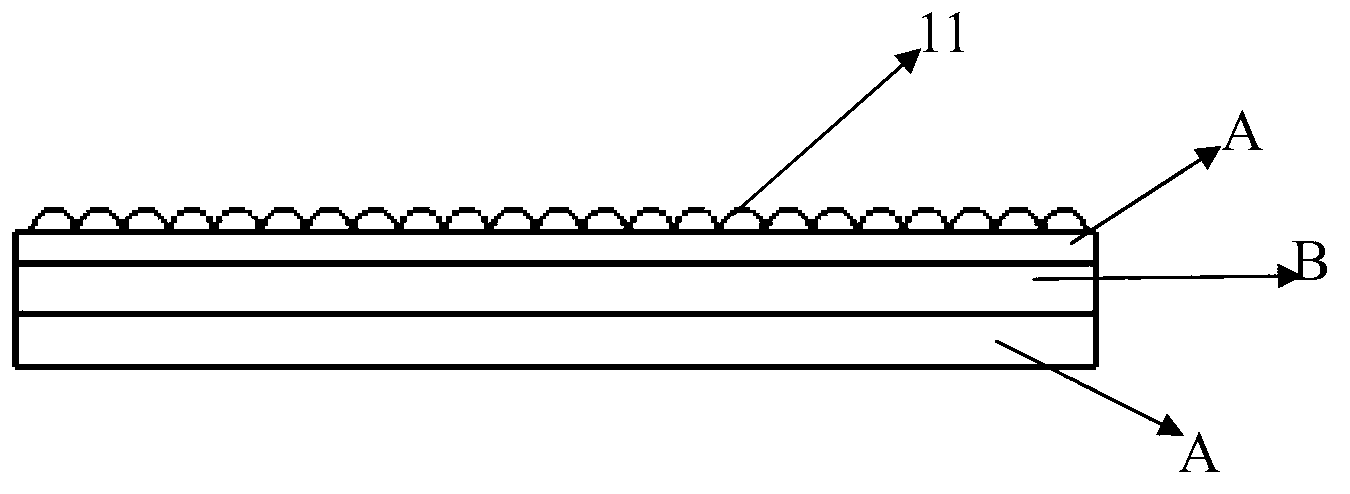

[0061] Such as Figure 1 to Figure 3 As shown, a self-cleaning light diffuser plate made of the above antistatic material is a three-layer composite layer structure composed of two surface layers A and a middle layer B, and multiple layers are evenly distributed on...

Embodiment 2

[0084] An antistatic material, the preparation and detection methods are the same as in Example 1, wherein the heating and melting temperature can be set to 100°C, and the components and their content ratios and detection results are shown in Table 1.

[0085] Such as Figure 1 to Figure 7 As shown, a self-cleaning light diffusion plate made of the above-mentioned antistatic material, its structural composition, its preparation method, and the preparation system used are the same as in Example 1. The components, content ratios, and test results are shown in Table 1. ,in:

[0086] In said step 1.3, the head temperature of each twin-screw extruder is 195°C, the screw speed of each twin-screw extruder is 100r / min, and the temperature settings of each zone of each twin-screw extruder are respectively: one zone The temperature is 165°C, the temperature in the second zone is 170°C, the temperature in the third zone is 175°C, the temperature in the fourth zone is 180°C, the temperat...

Embodiment 3

[0091] An antistatic material, the preparation and detection methods are the same as in Example 1, wherein the heating and melting temperature can be set to 300°C, and the components and their content ratios and detection results are shown in Table 1.

[0092] Such as Figure 1 to Figure 7 As shown, a self-cleaning light diffusion plate made of the above-mentioned antistatic material, its structural composition, its preparation method, and the preparation system used are the same as in Example 1. The components, content ratios, and test results are shown in Table 1. ,in:

[0093] In said step 1.3, the head temperature of each twin-screw extruder is 285°C, the screw speed of each twin-screw extruder is 400r / min, and the temperature settings of each zone of each twin-screw extruder are respectively: one zone The temperature is 200°C, the temperature in the second zone is 220°C, the temperature in the third zone is 230°C, the temperature in the fourth zone is 240°C, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com