Super-hydrophotic magnetic carbon film, its preparing method and use

A magnetic carbon and super-hydrophobic technology, which is applied to the surface coating liquid device, pretreatment surface, special surface, etc., can solve the problem that the conductivity and magnetism are easily damaged by rain, the surface of the material is easily polluted, and it takes a lot of manpower and effort. Material resources and other issues, to achieve the effect of low cost, simple device and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Add polyvinyl alcohol (PVA) into deionized water, fully stir and dissolve to prepare a 10 wt% polyvinyl alcohol solution. Add ferrous acetate (FeAc 2 ), formulated to contain FeAc 2 The weight percentage is 30wt% precursor solution.

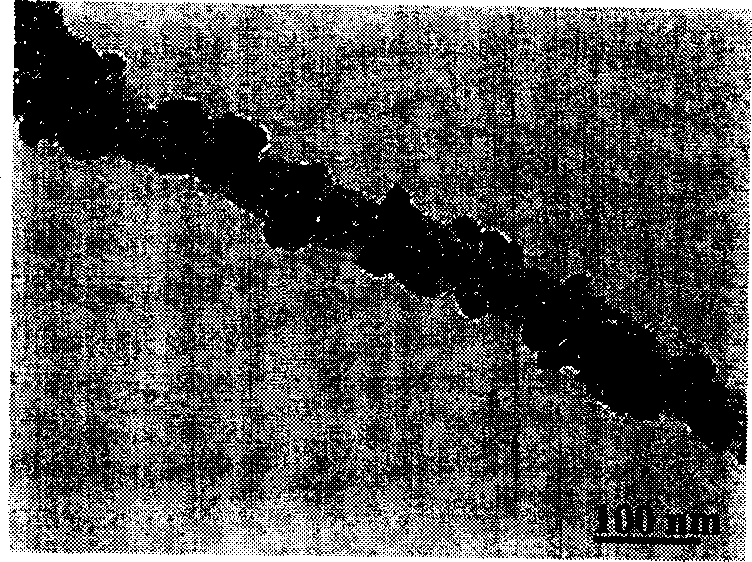

[0040]2. Pack the precursor solution prepared in step 1 into the liquid feeding device of the existing spinning device, insert the positive electrode into the solution, connect the negative electrode to the grounded receiving device, and adjust the spinning working distance (needle tip to The distance between the receiving devices) is 8cm; turn on the high-voltage power supply, adjust the spinning voltage to 10kV, the precursor mixed solution forms a Taylor cone at the spinneret of the jetting device, and divides into jet streams at the spinneret, accompanied by As the solvent volatilizes, solidified precursor composite nanofibers with a diameter of 180 nanometers are obtained on the receiving device, and the ferrous salt is covered b...

Embodiment 2

[0045] 1. Add polyvinyl alcohol (PVA) into deionized water, fully stir and dissolve to prepare a 20 wt% polyvinyl alcohol solution. Add ferrous acetate (FeAc 2 ), formulated to contain FeAc 2 The weight percentage is 50wt% precursor solution.

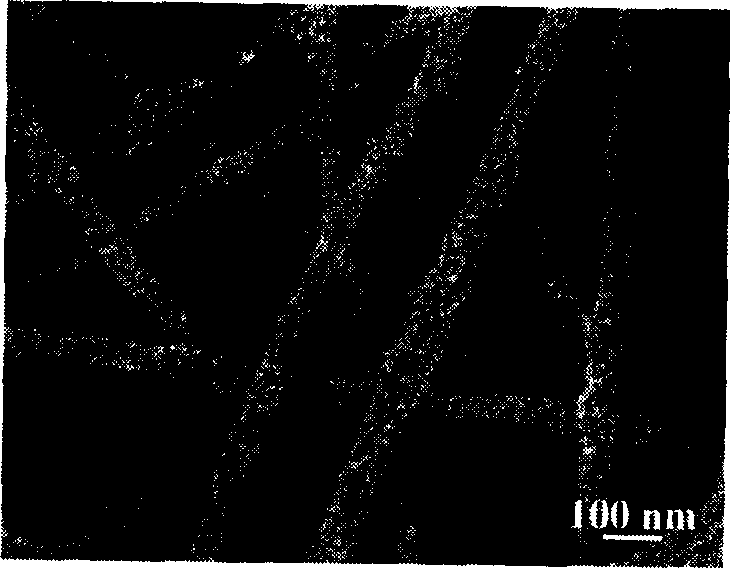

[0046] 2. Pack the precursor solution prepared in step 1 into the liquid feeding device of the existing spinning device, insert the positive electrode into the solution, connect the negative electrode to the grounded receiving device, and adjust the spinning working distance (needle tip to The distance between the receiving devices) is 20cm; turn on the high-voltage power supply, adjust the spinning voltage to 25kV, the precursor mixed solution forms a Taylor cone at the spinneret of the jetting device, and splits into jet streams at the spinneret, accompanied by As the solvent volatilizes, solidified precursor composite nanofibers with a diameter of 200 nanometers are obtained on the receiving device, and the ferrous salt is covered ...

Embodiment 3

[0050] 1. Add polyacrylonitrile (PAN) into N,N-dimethylformamide (DMF), fully stir and dissolve to prepare a 10wt% polyacrylonitrile solution by weight. Then add iron acetylacetonate (Fe(Acc) 3 ), formulated to contain Fe(Acc) 3 The weight percentage is 30wt% precursor solution.

[0051] 2. Pack the precursor solution prepared in step 1 into the liquid feeding device of the existing spinning device, insert the positive electrode into the solution, connect the negative electrode to the grounded receiving device, and adjust the spinning working distance (needle tip to The distance between the receiving devices) is 8cm; turn on the high-voltage power supply, adjust the spinning voltage to 10kV, the precursor mixed solution forms a Taylor cone at the spinneret of the jetting device, and divides into jet streams at the spinneret, accompanied by As the solvent volatilized, solidified precursor composite nanofibers with a diameter of 200 nanometers were obtained on the receiving de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com