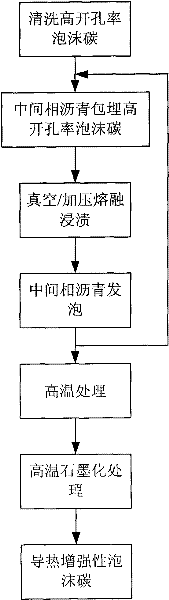

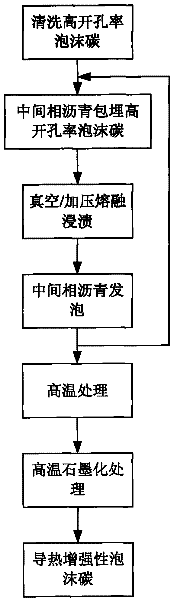

Method for enhancing heat conduction performance of foamy carbon with high aperture ratio

A technology of thermal conductivity and carbon foam, which is applied in the field of inorganic porous materials, can solve the problems of small improvement in material thermal conductivity, decrease in specific thermal conductivity, and long reinforcement period, so as to improve thermal conductivity, mechanical properties, and volume thermal conductivity. The effect of increasing the rate and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Use a bulk density of 0.3g / cm 3, with a porosity of 92%, a thermal conductivity of 42W / (m·K), and a compressive strength of 0.3MPa, the foamed carbon is used as the reinforcement object, and the foamed carbon with a high porosity is cleaned by ultrasonic cleaning to remove the foam Debris in carbon pores.

[0049] 2) Petroleum-based mesophase pitch (SP=280°C) is used as the impregnating agent. The carbon foam was embedded in a stainless steel cylinder with 300 mesh mesophase pitch powder, and the amount of the mesophase pitch powder was 10 times the pore volume of the carbon foam.

[0050] 3) Put the mesophase pitch-embedded carbon foam cylinder into a high-temperature autoclave, evacuate to 100Pa, and then heat to 330°C to melt the mesophase pitch; pressurize it to 0.5MPa with a cylinder of argon, The molten mesophase pitch is impregnated into the pores of the foamed carbon. Stop heating after constant pressure for 1 hour, release the pressure to normal pressure ...

Embodiment 2

[0056] 1) The bulk density is 0.36g / cm 3 The carbon foam with a porosity of 90%, a thermal conductivity of 54W / (m K) and a compressive strength of 0.5MPa is the reinforcement object; the carbon foam with a high porosity is cleaned by ultrasonic cleaning to remove the foam Debris in carbon pores.

[0057] 2) Use naphthalene-based mesophase pitch (SP=270°C) as the impregnating agent. The carbon foam was embedded in a stainless steel cylinder with 250 mesh mesophase pitch powder, and the amount of the mesophase pitch powder was 10 times the pore volume of the carbon foam.

[0058] 3) Put the mesophase pitch-embedded carbon foam cylinder into a high-temperature autoclave, evacuate to 100Pa, and then heat to 320°C to melt the mesophase pitch; pressurize it to 1MPa with a cylinder of argon to melt the The mesophase pitch is impregnated into the foam carbon pores. Stop heating after constant pressure for 1 hour, release the pressure to normal pressure after cooling to normal tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com