A pre-twisted damping anti-vibration hammer

A technology of anti-vibration hammer and damping, which is applied in the direction of mechanical vibration attenuation devices, etc., and can solve problems such as inaccurate positioning of anti-vibration hammer, loose clamping, and damage to cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

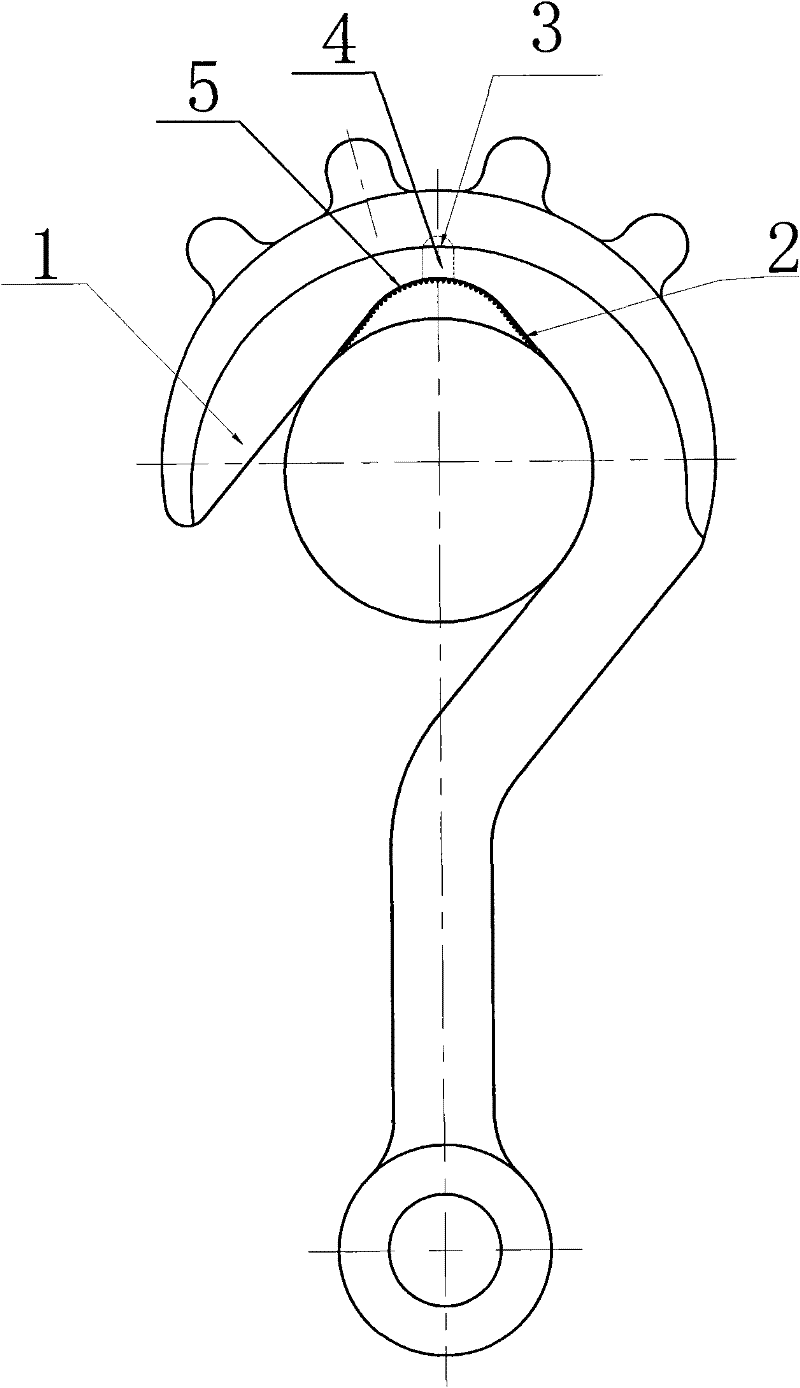

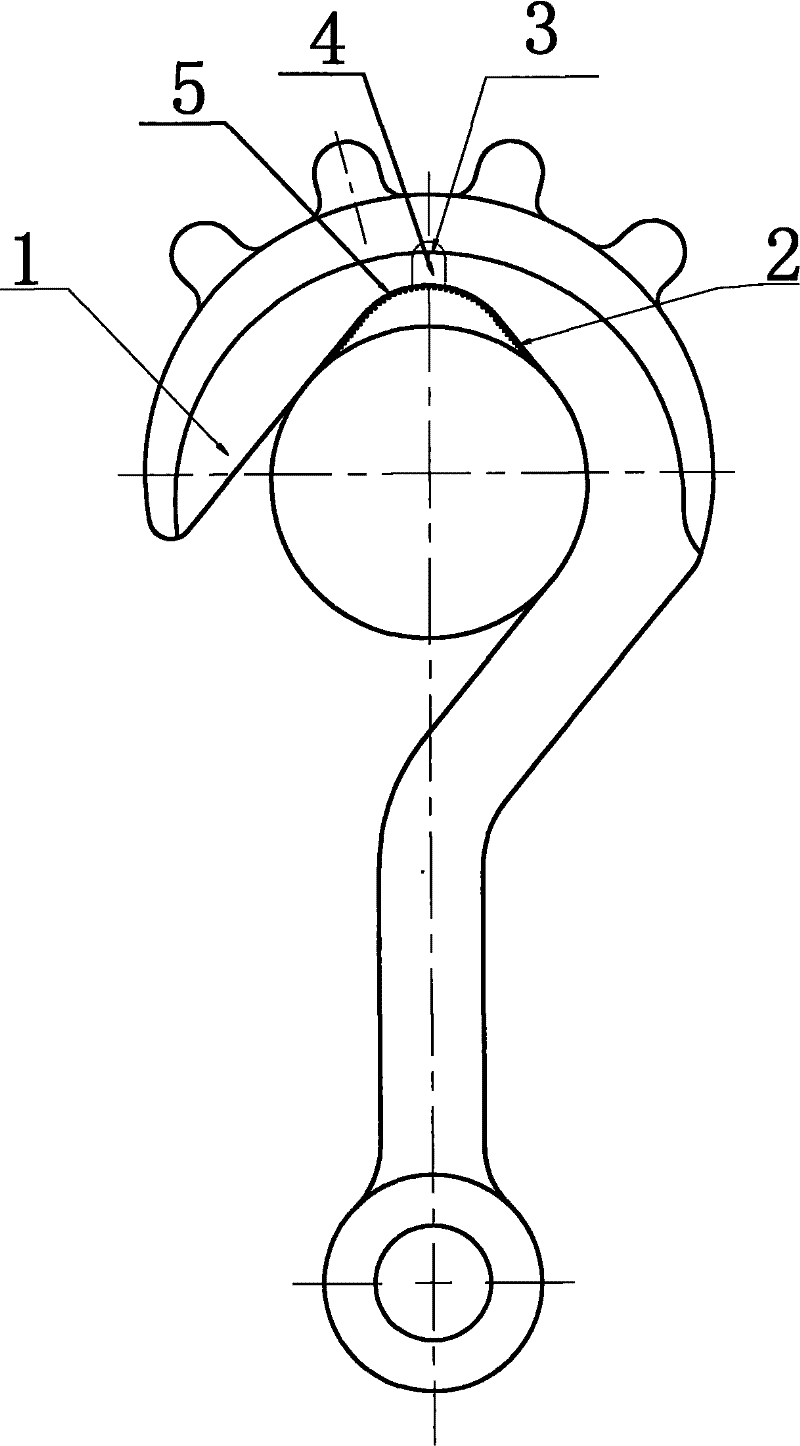

[0012] The pre-twisted anti-vibration hammer wire clip of the present invention includes a wire clip, the upper part of the wire clip is hook-shaped, and the hook-shaped hook surface is a wire clamping surface 1, and a damping anti-slip pad 2 is provided on the wire clamping surface 1 .

[0013] A mounting hole 3 is provided on the wire clamping surface 1; a protrusion 4 matching the mounting hole 3 is provided in the middle of the damping anti-slip pad 2, and the protrusion 4 is embedded in the mounting hole 3, so that the The damping anti-skid pad 2 is connected to the wire clamping surface 1.

[0014] The radian of the upper arc 5 of the wire clamping surface 1 is smaller than that of the wire clamping surface 1 .

[0015] When installing the anti-vibration hammer, the bump 4 of the damping anti-slip pad 2 is installed in the installation hole 3 of the wire clamping surface, and the damping anti-slip pad 2 in the wire clamping surface 1 of the anti-vibration hammer wire cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com