Laserwelding method for repairing penetrating defect of base metal

A laser welding and penetrating technology, which is applied in the direction of laser welding equipment, welding equipment, workpiece edge, etc., can solve the problems of product scrapping, loss, and affecting the overall performance of the equipment, so as to enhance the tightness of bonding and prevent undercutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

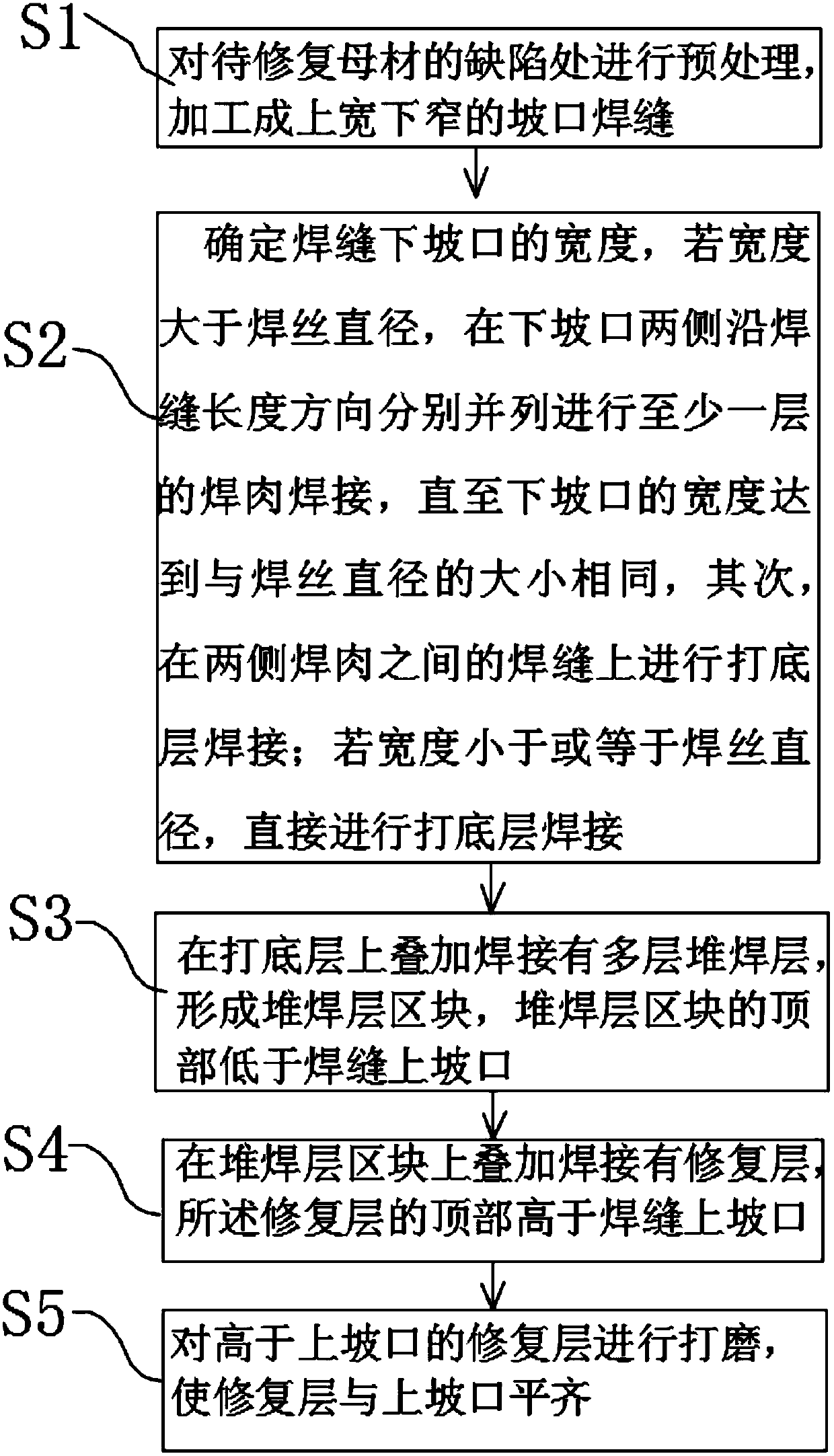

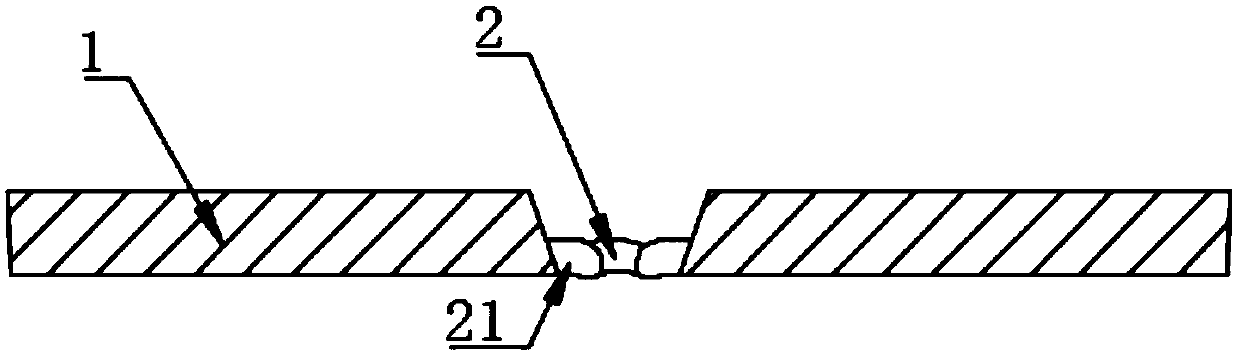

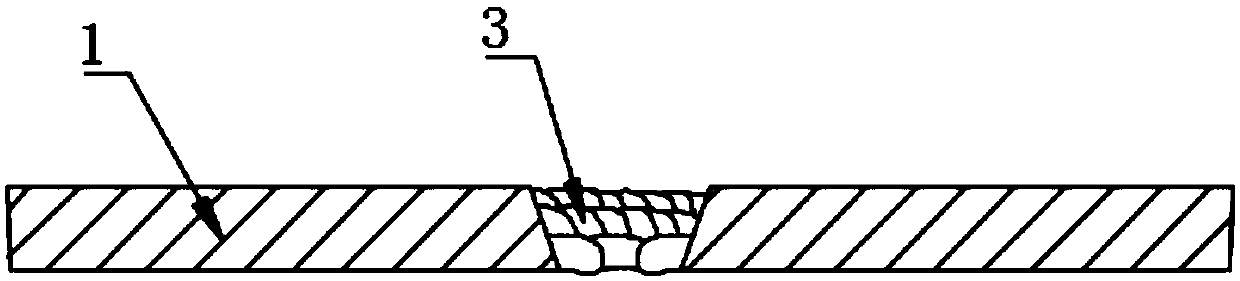

[0039] Such as Figure 1-Figure 9 As shown, the present invention is a laser welding method for repairing penetrating defects of base metal, comprising the following steps:

[0040] S1. Perform pretreatment on the defect of the base metal to be repaired, and process it into a groove weld with a wide top and a narrow bottom.

[0041] Among them, prior to the pretreatment, fluorescent detection and X-ray detection are performed on the base material in sequence to determine the defect type and defect location, that is, to determine the defect type as a penetrating defect.

[0042] Pretreatment is machining by machining center or manual processing by electric drill or grinding head. For the defects on the surface of the base metal, the defects are directly processed into a groove weld with a wide top and a narrow bottom.

[0043] S2. Determine the width of the downward groove of the weld. If the width is greater than the diameter of the welding wire, at least one row of weld meat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com