Patents

Literature

32results about How to "Improve fit compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

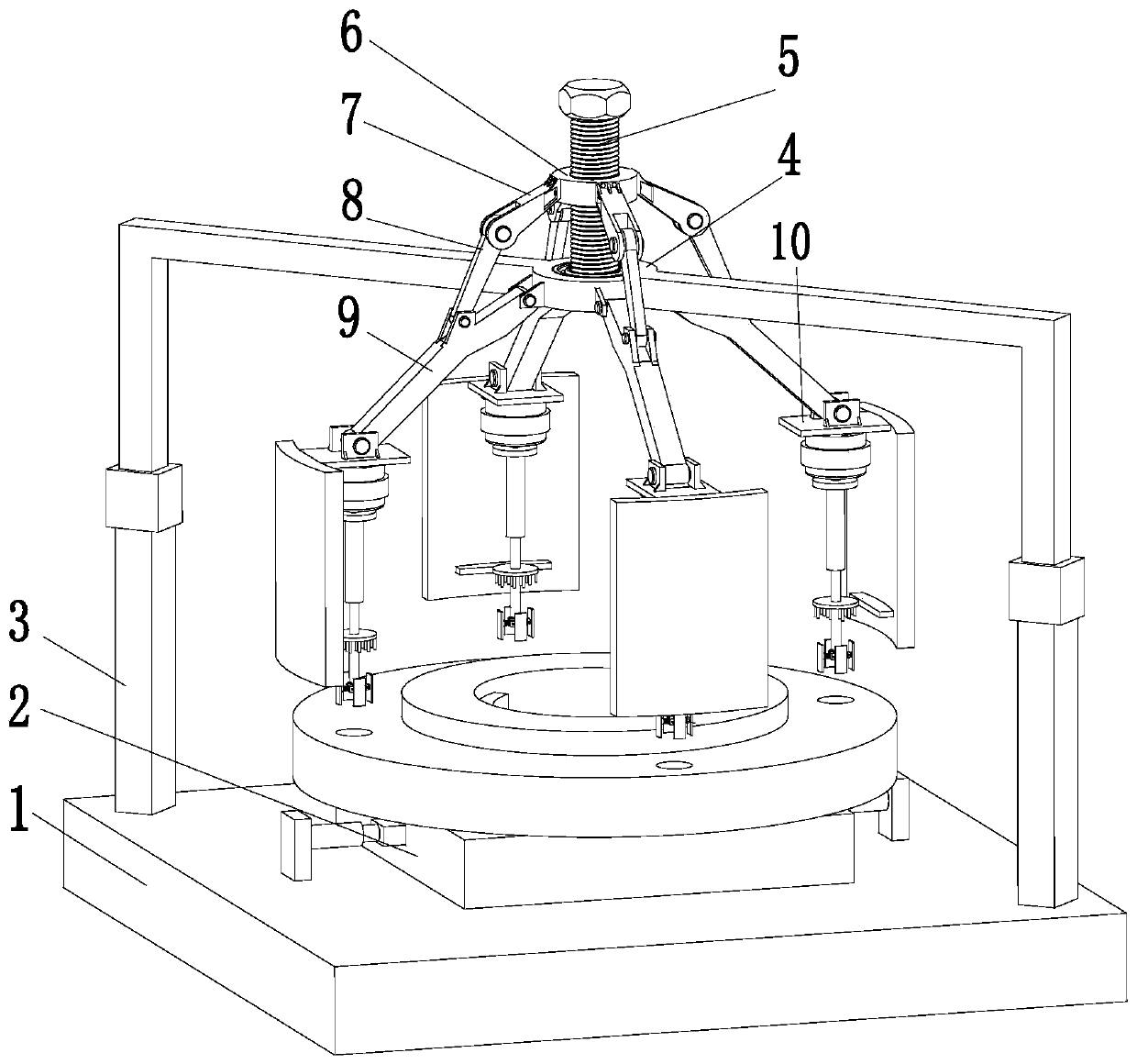

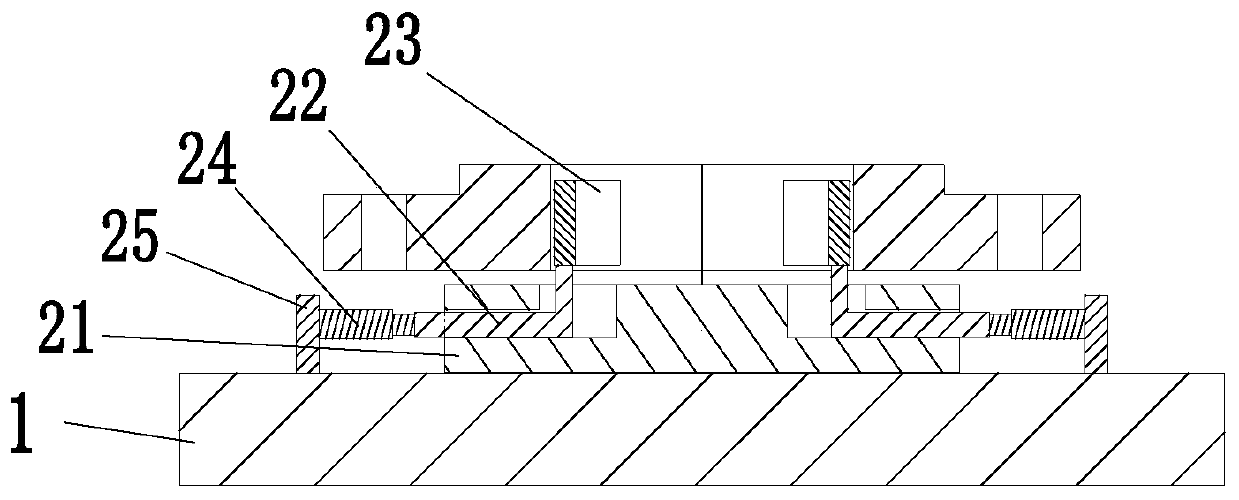

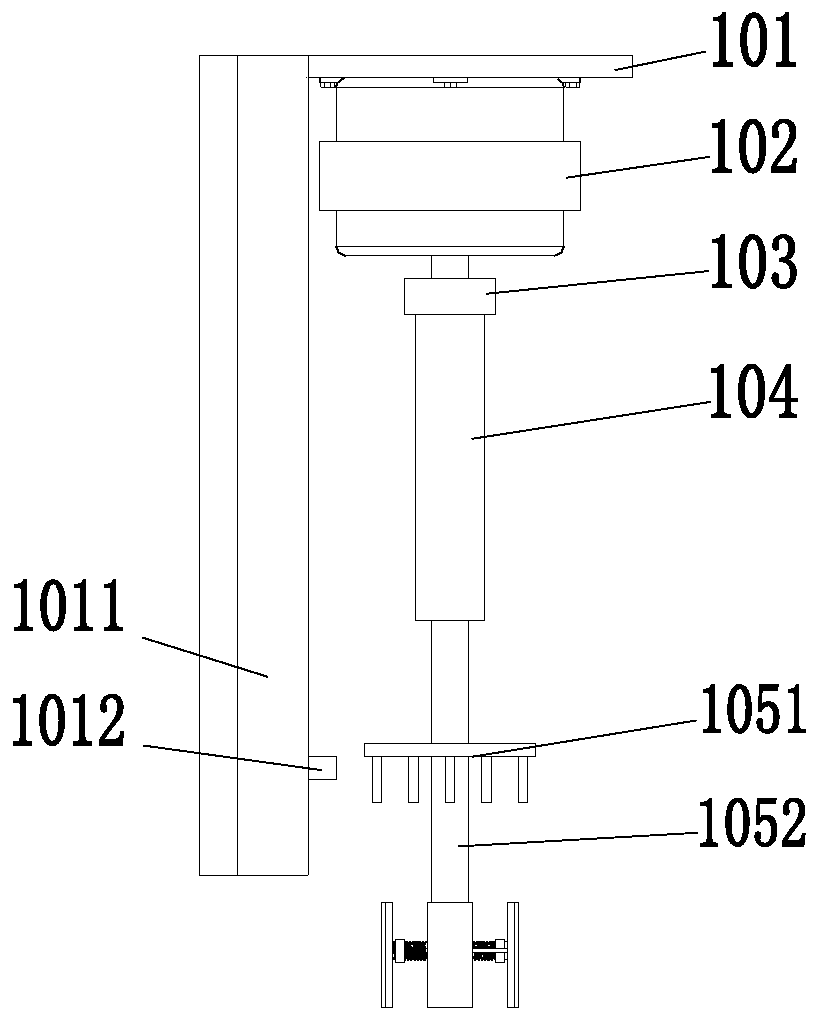

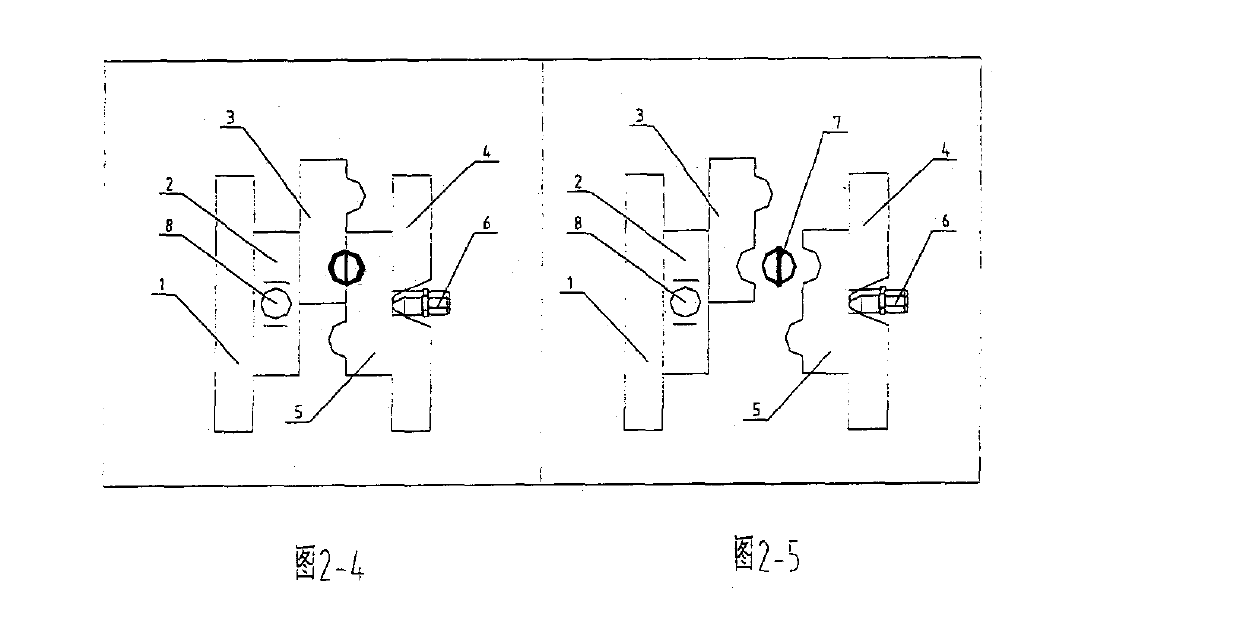

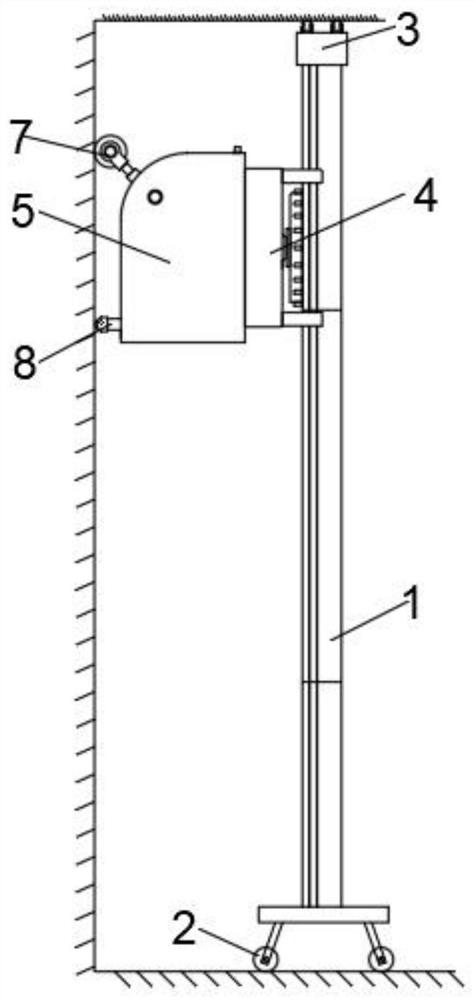

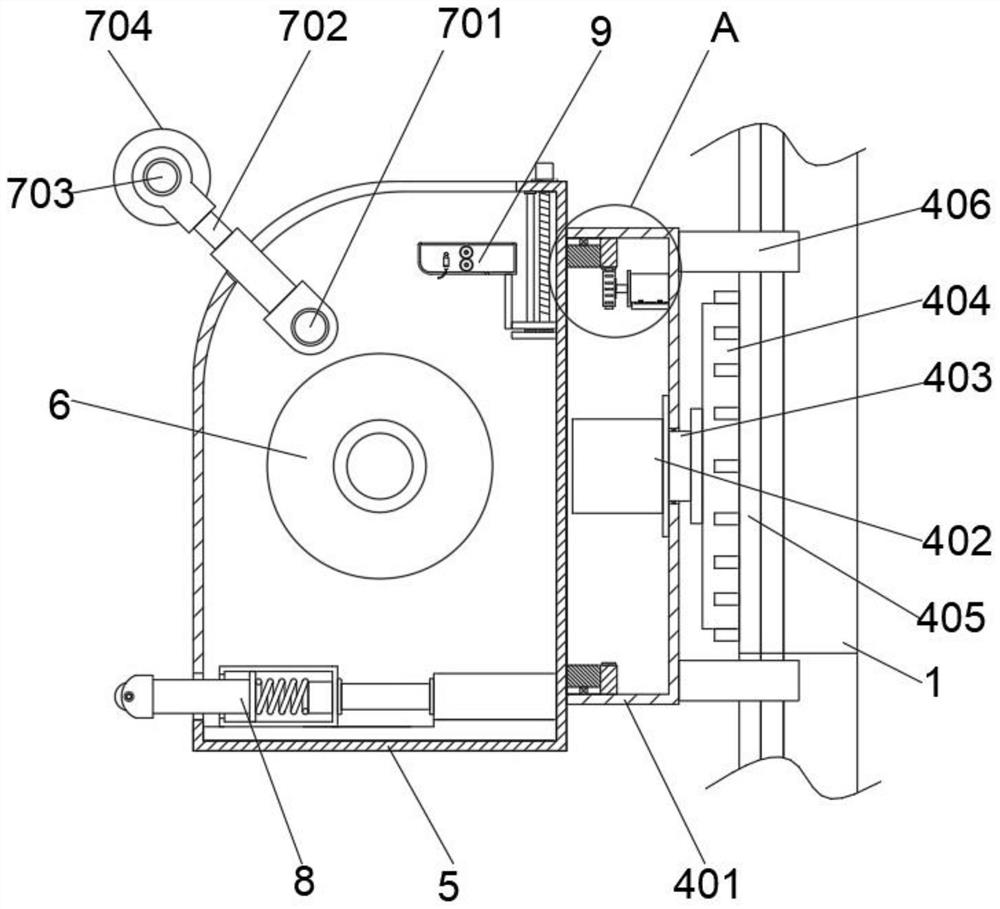

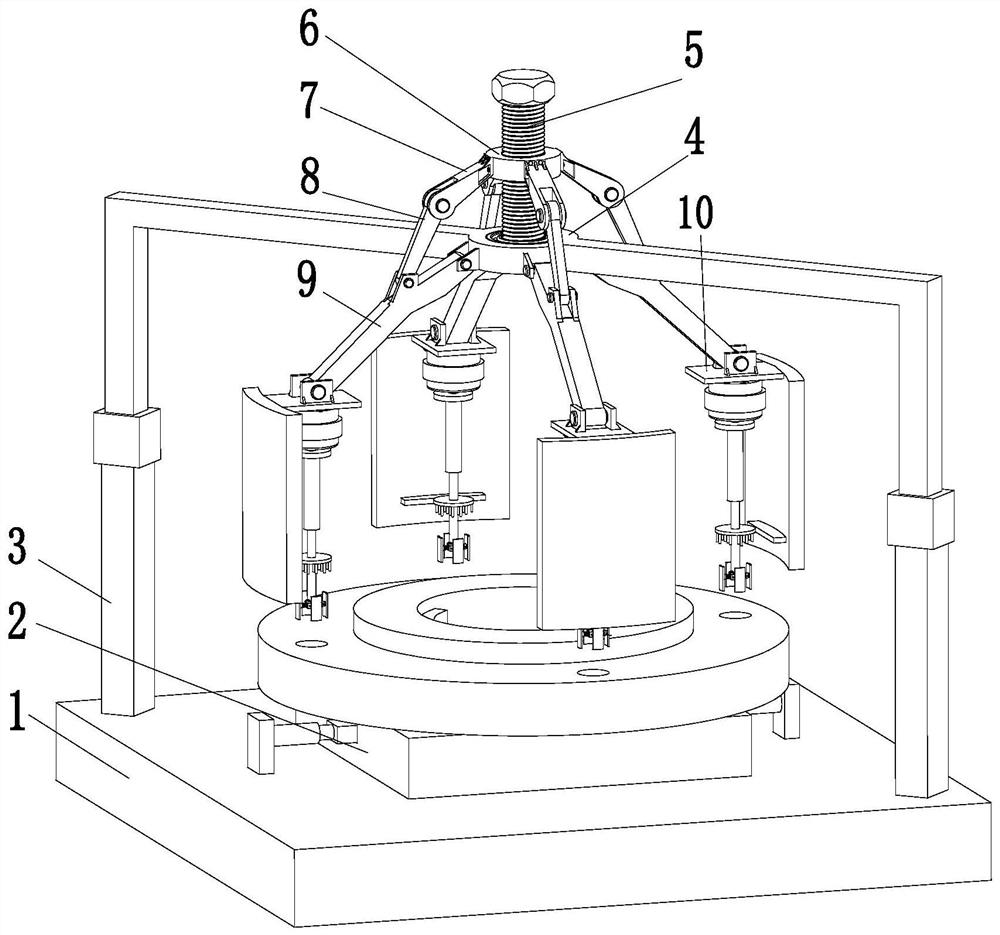

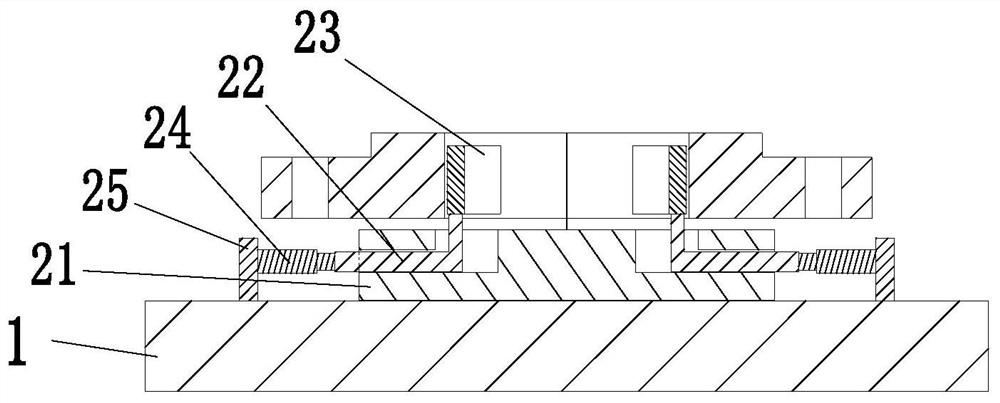

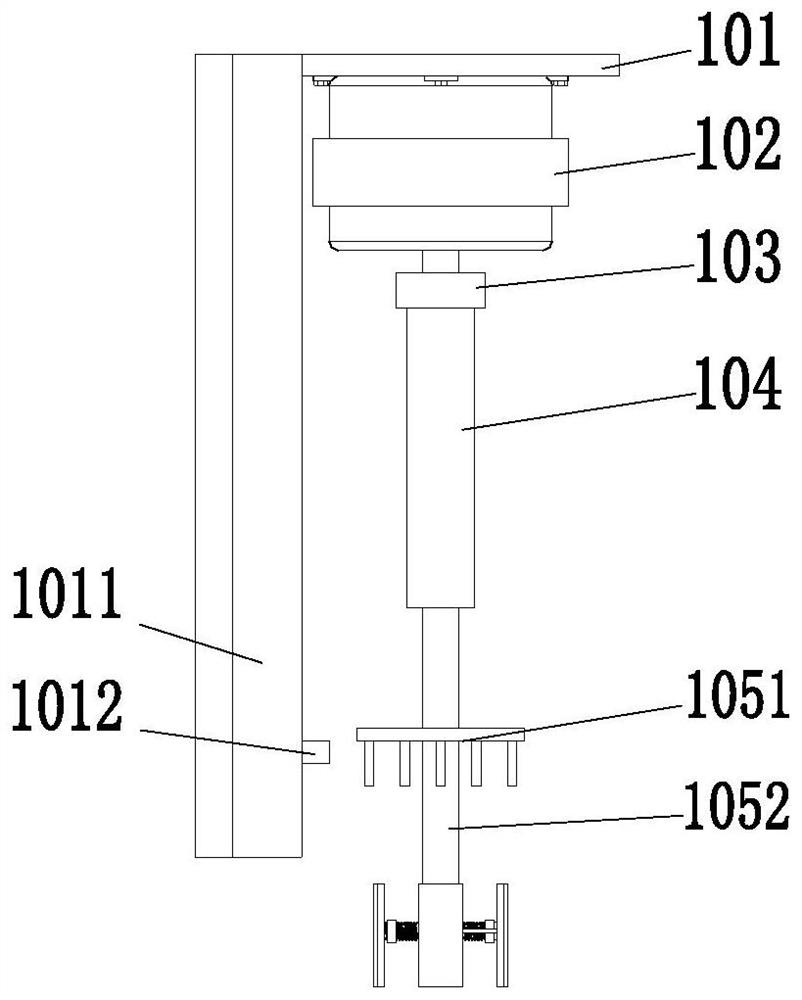

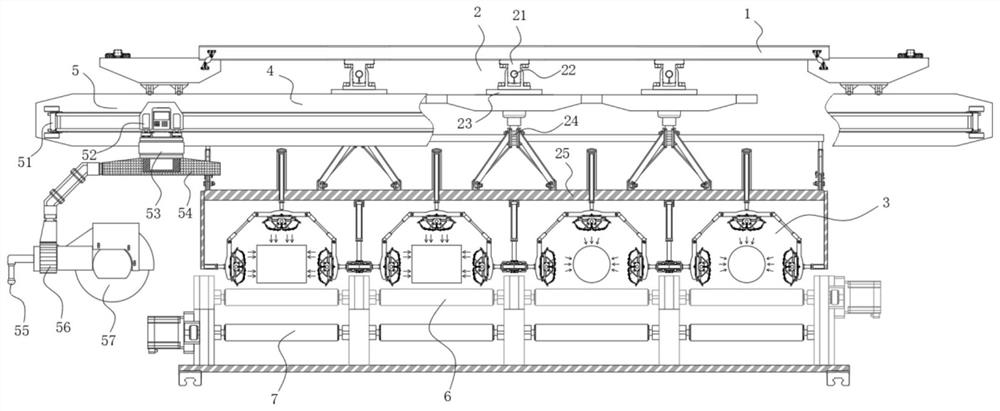

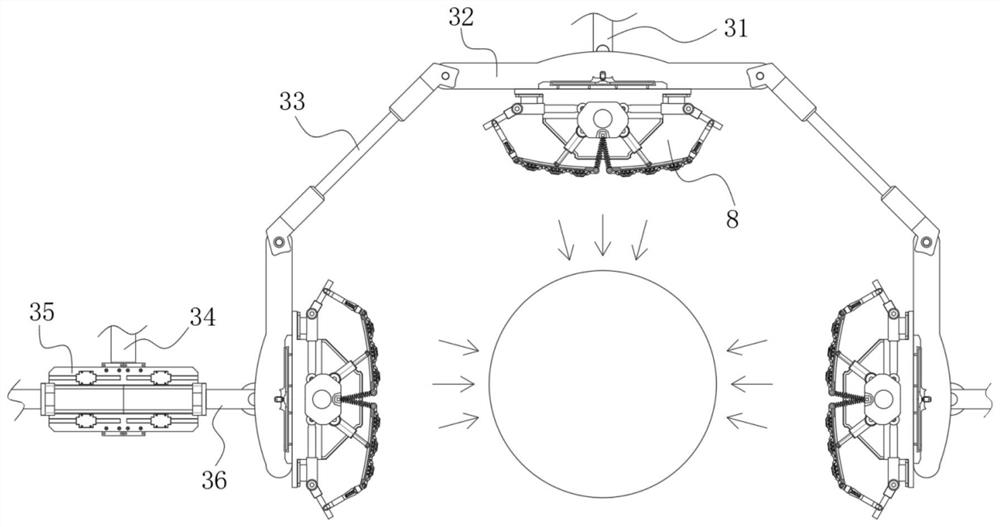

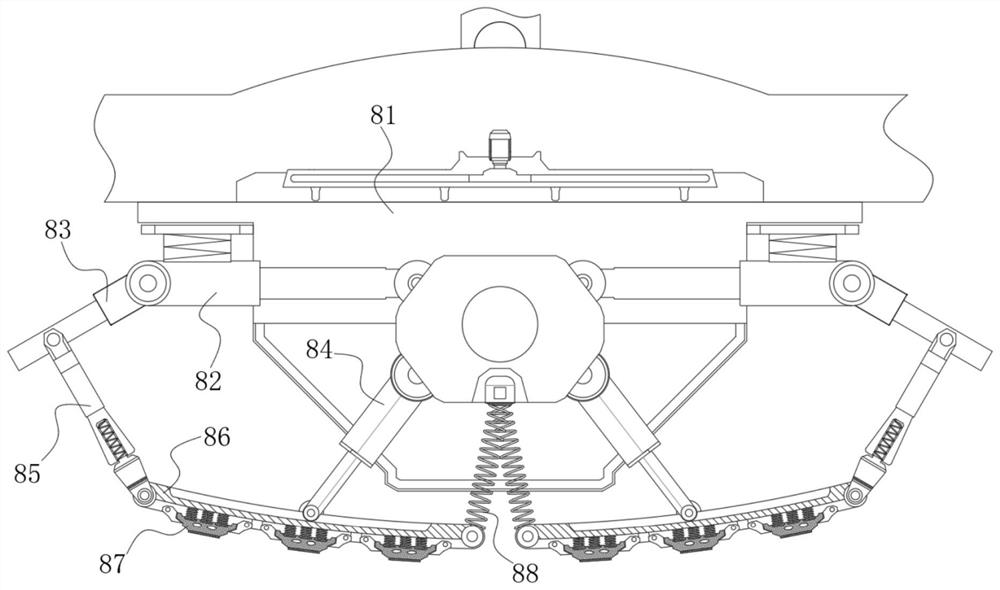

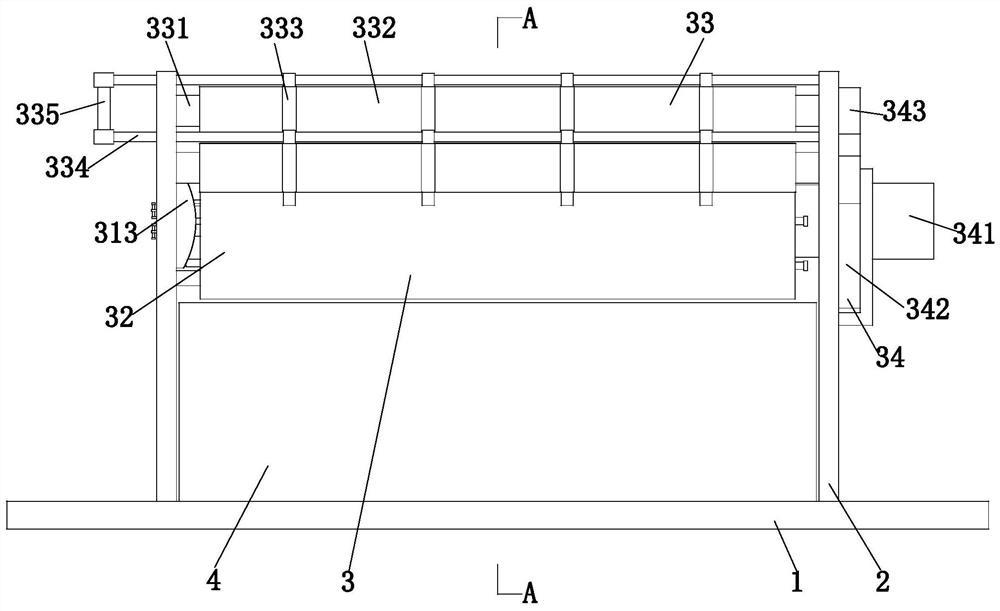

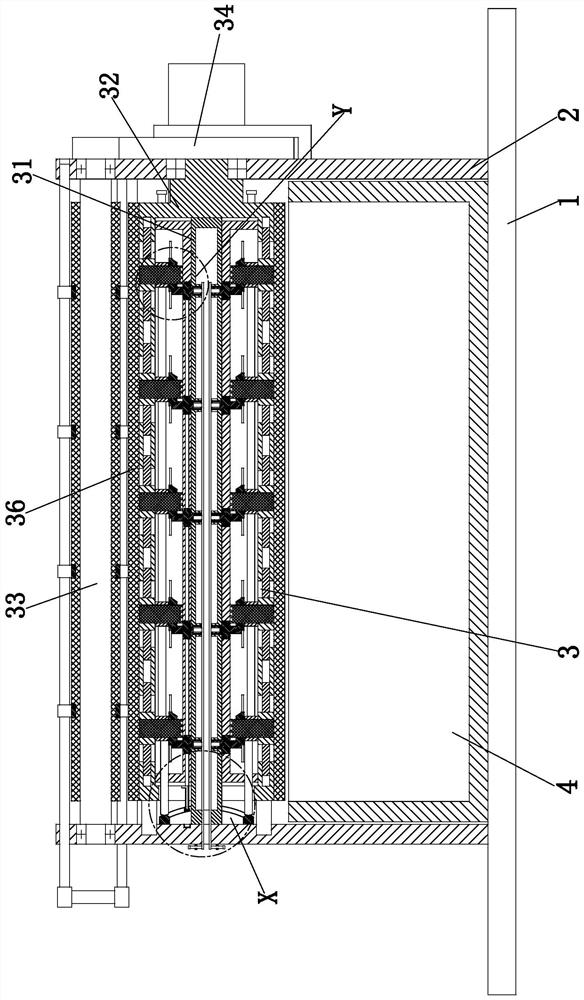

Manufacture machine for stainless steel alloy flange

ActiveCN111469013AFast and stable lockPlay a locking roleGrinding drivesGrinding machinesStructural engineeringAlloy

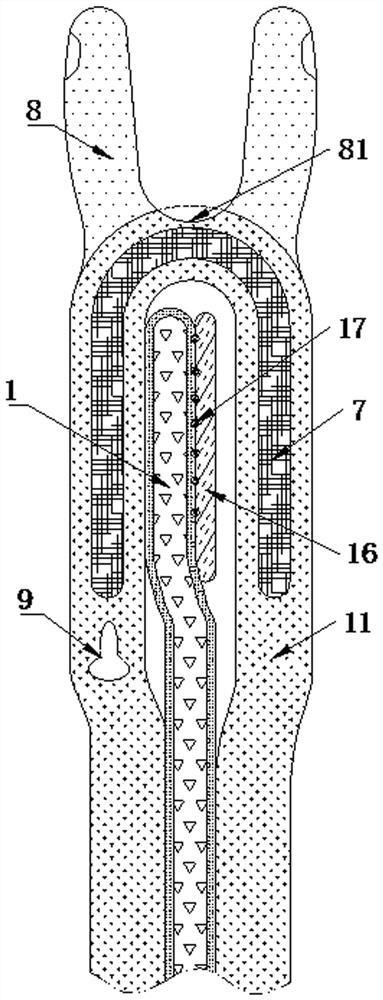

The invention relates to a manufacture machine for a stainless steel alloy flange. The manufacture machine comprises a base, a limit mechanism, L-shaped rods, a circular base, a bolt, an annular block, adjustment arms, connection arms, driven arms and polishing mechanisms. The upper end surface of the base is provided with the limit mechanism, the front right and rear left portions of the upper end surface of the base are provided with the L-shaped rods, the circular base is installed between the inner sides of the upper ends of the L-shaped rods, and the circular base is connected with the lower end of the bolt through a bearing. The annular block is connected to the middle of the bolt in a thread cooperation mode, four adjustment arms are symmetrically installed on the outer side surfaceof the annular block, the lower end of each adjustment arm is connected with the middle of the upper surface of the corresponding driven arm through the corresponding connection arm, and the lower end of each driven arm is provided with the polishing mechanism through a hinge. The manufacture machine can solve the problems that when burrs of a bolt hole in a flange are removed in the prior art, the effect of locking the flange by a clamp of processing equipment is poor, the processing equipment can only process one bolt hole, and burrs of the upper surface of the bolt hole need to be subjected to secondary processing through other equipment.

Owner:盐城斯天康精密制造有限公司

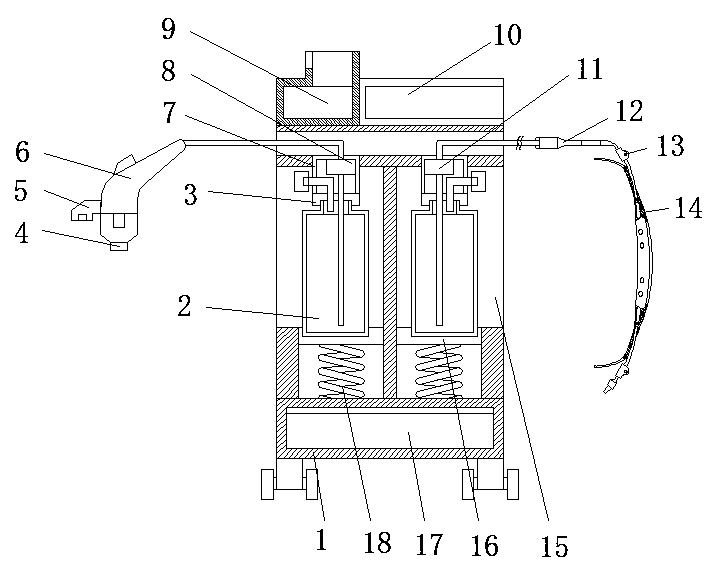

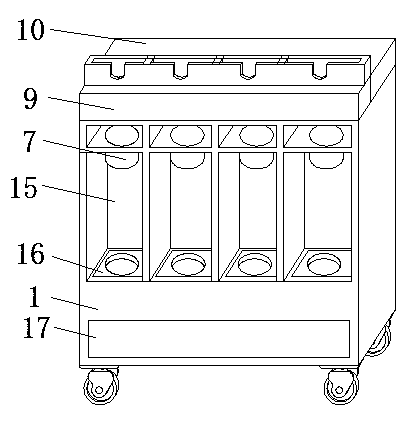

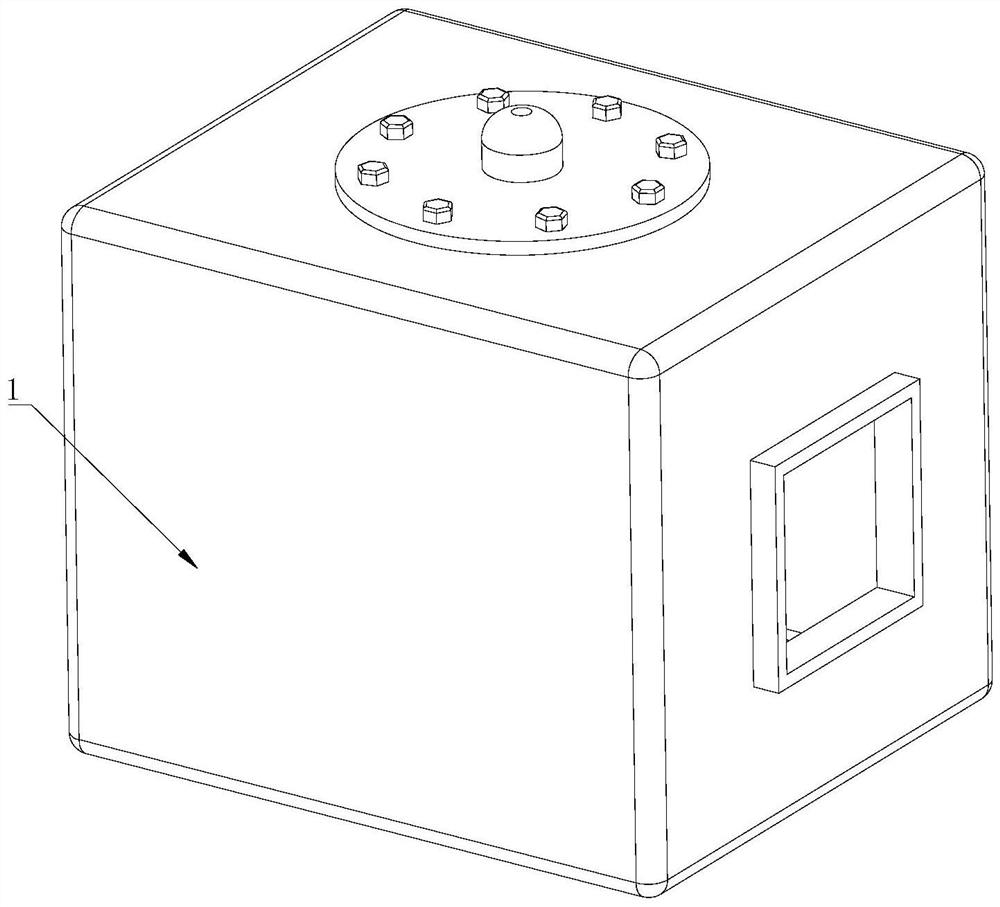

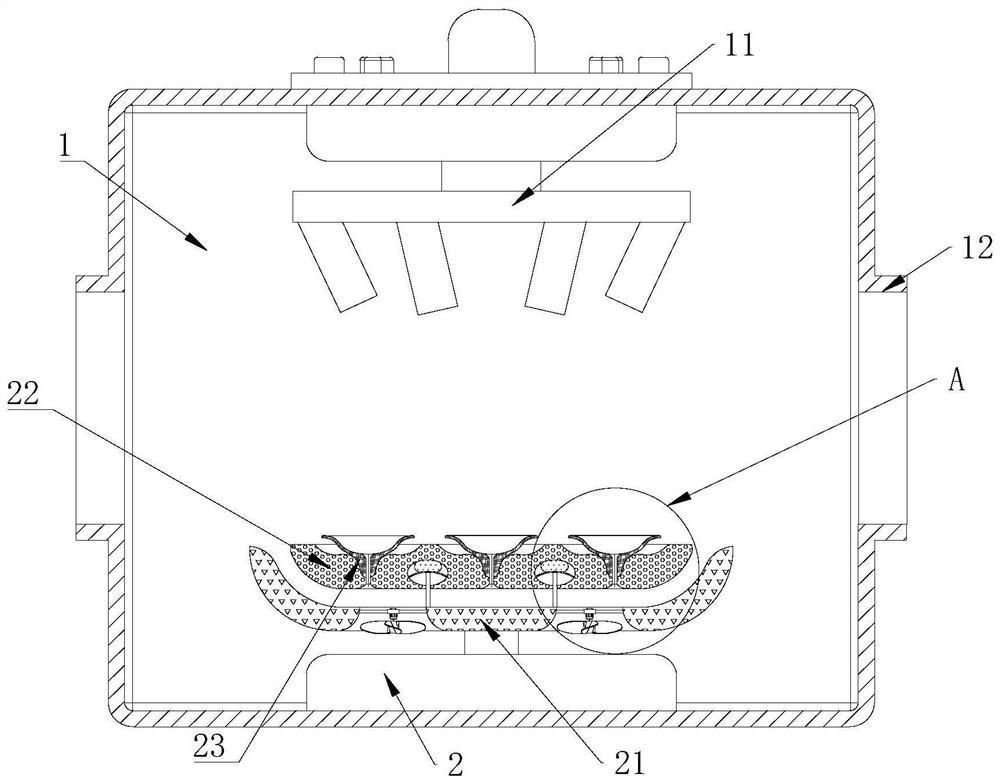

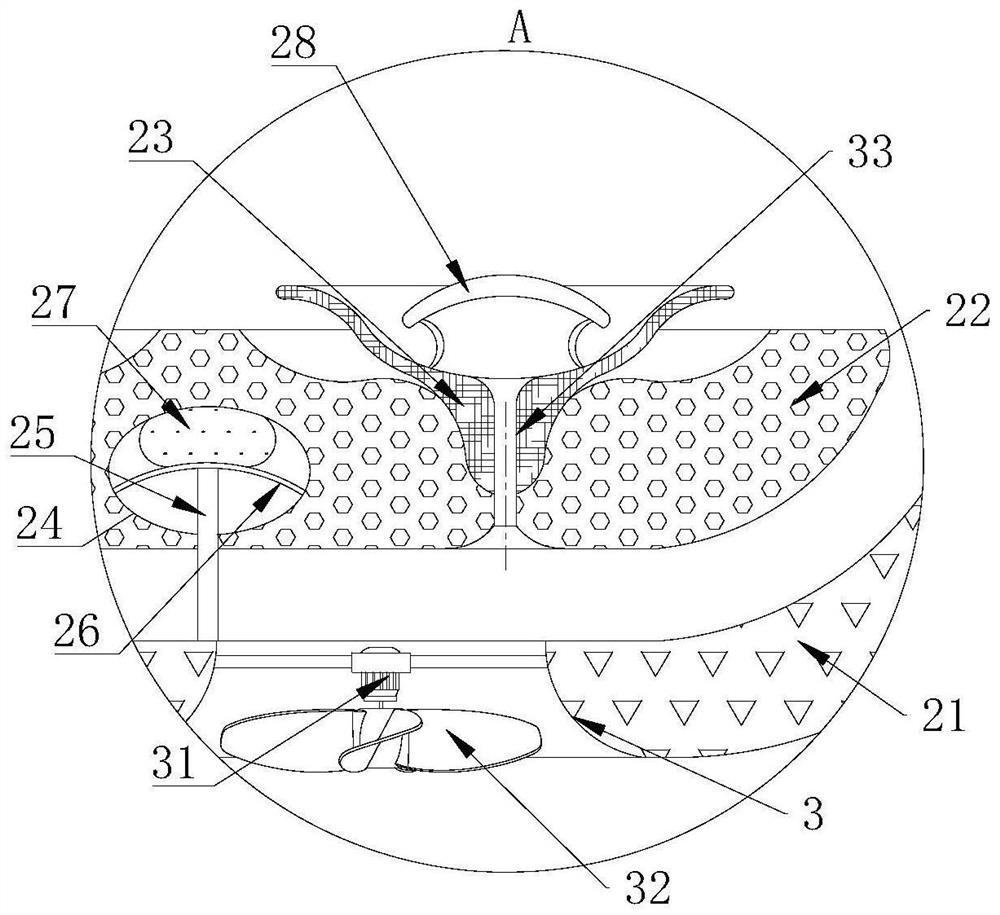

Debridement device for dermatological department

PendingCN111281574AAvoid pollutionAvoid the risk of fungal spreadDiagnosticsSurgeryDermatology departmentApparatus instruments

The invention discloses a debridement device for the dermatological department, belongs to the technical field of medical instruments, and aims to solve the problems that a disinfectant diffuses at awound part, clothes or a bed surface and the like are easy to pollute, and the risk of fungus diffusion is easy to occur. The debridement device specifically comprises a box body, a plurality of mounting grooves are formed in the two sides of the box body, universal wheels with foot brakes are connected to the four corners of the bottom of the box body through bolts, shells are mounted at the topends of the interiors of the mounting grooves, and a micro conveying pump and a micro liquid suction pump are mounted in the positions, located on the two sides of the box body, of the shells correspondingly. According to the debridement device, clothes or a bed surface and the like can be prevented from being polluted when a wound is disinfected and cleaned, an infection area is isolated, the risk of fungus diffusion is avoided, the safety performance is high, the attaching tightness between a protective cover and the skin of a patient is improved, cleaning liquid is prevented from flowing out of the bottom of the protective cover, and infection caused by overflowing of the cleaning liquid is avoided.

Owner:武蕴萍

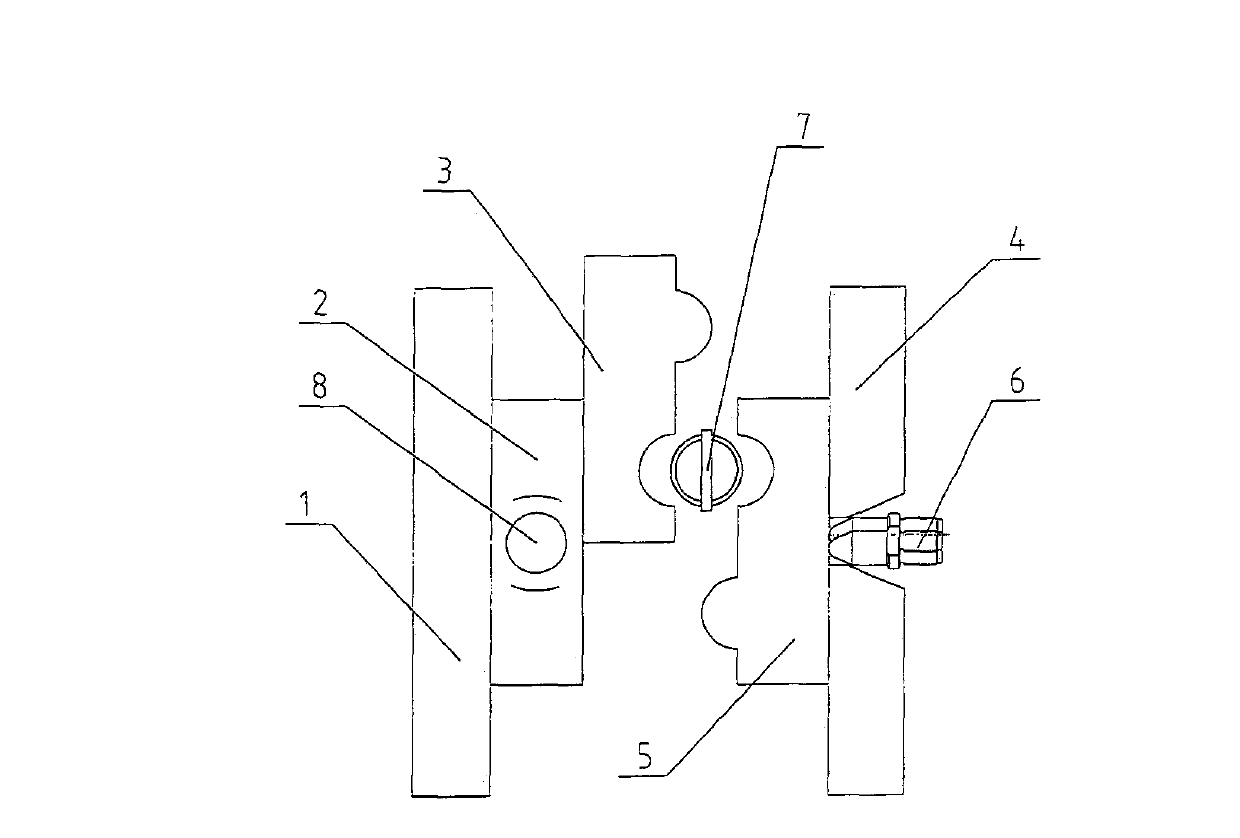

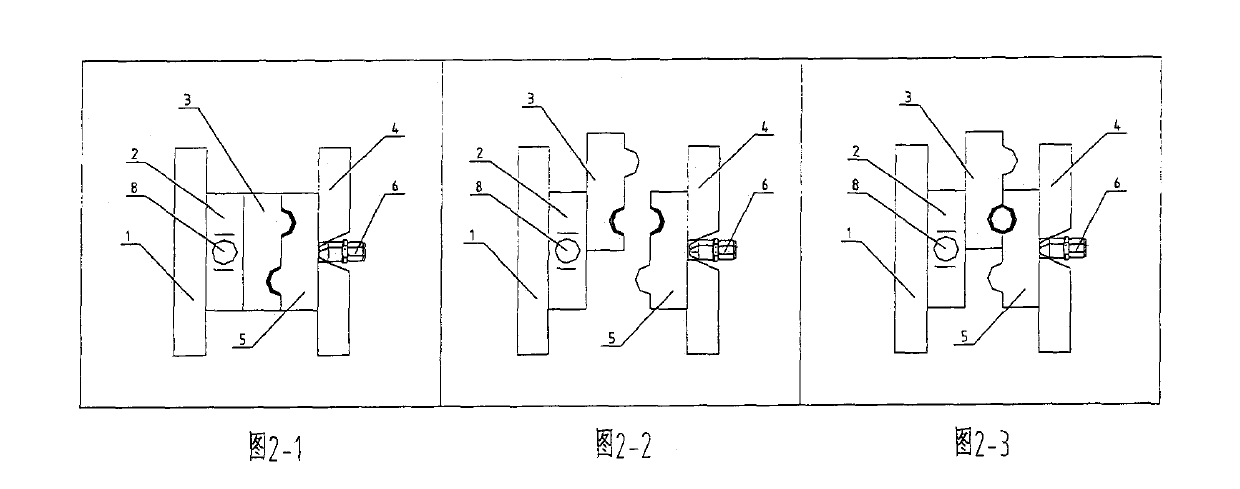

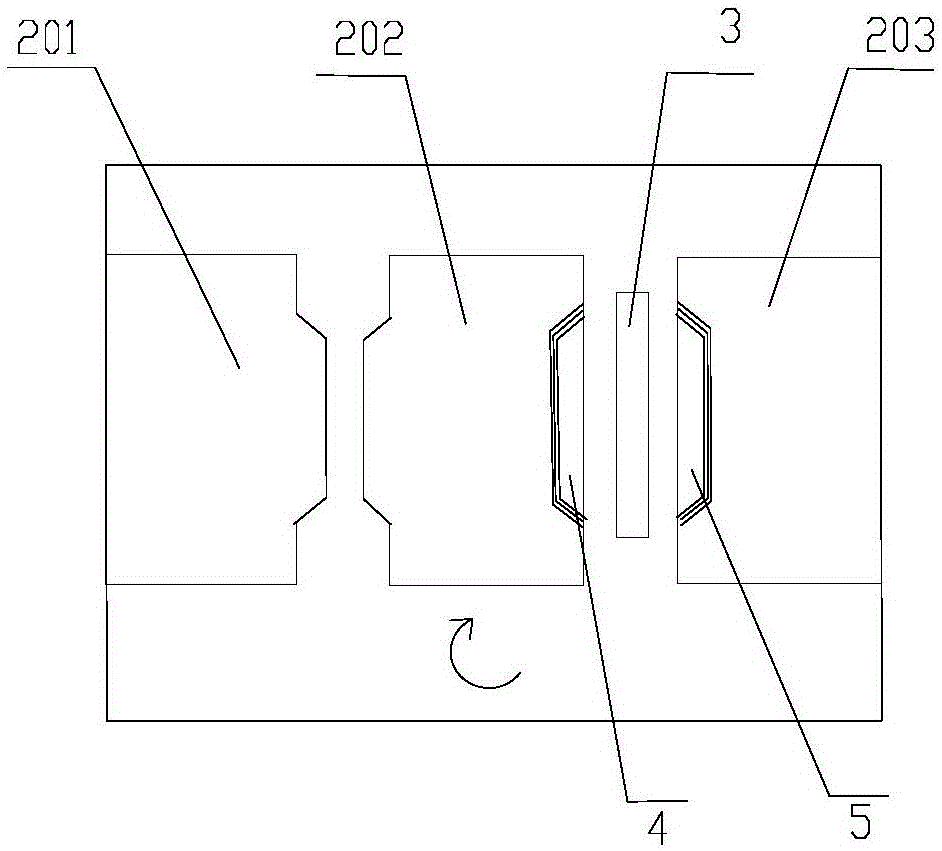

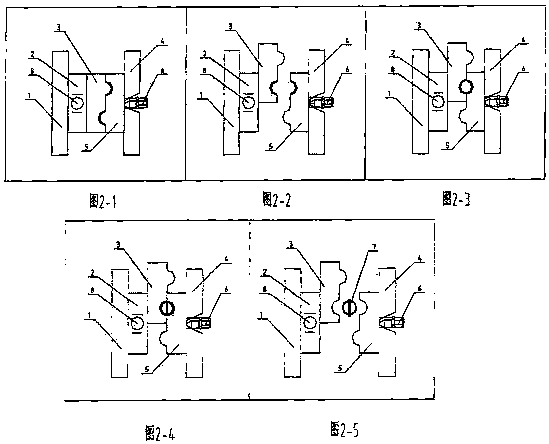

Hollow injection molding method

InactiveCN103317660AImprove stabilityImprove fit compactnessHollow articlesMaterial resourcesInjection moulding

The invention relates to a hollow injection molding method including a movable plate, a movable mold, a sub mold driving device, a sub mold, a fixed plate, a fixed mold and an injection molding mechanism. The method is characterized in that: after the movable mold, the sub mold, the fixed mold complete mold clamping to obtain a mold, an injection molding machine performs an injection action, after finishing the injection, the mold is opened to a required distance, the movable mold drives the sub mold to match a next station by the sub mold driving device, then the mold clamping is carried out again, original separated different part products are spliced together, then a secondary injection is carried out, the separated different products perform injection molding together by plastics, and hollow injection molding products are obtained. Thought the hollow injection molding method, some procedures that need a second processing especially withrealing hollow products which need welding, are designed to be carried out in the mold, withrealing hollow plastic parts are final products when leaving a mold cavity, the quality stability and the combining tightness of a product assembly are improved, and manpower, material resources and workshop space are saved.

Owner:BORCH MACHINERY

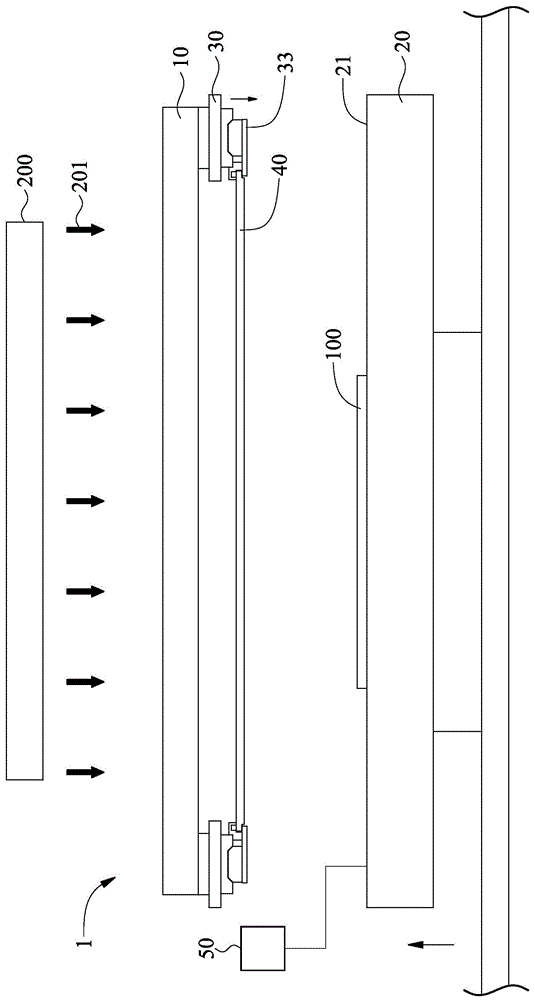

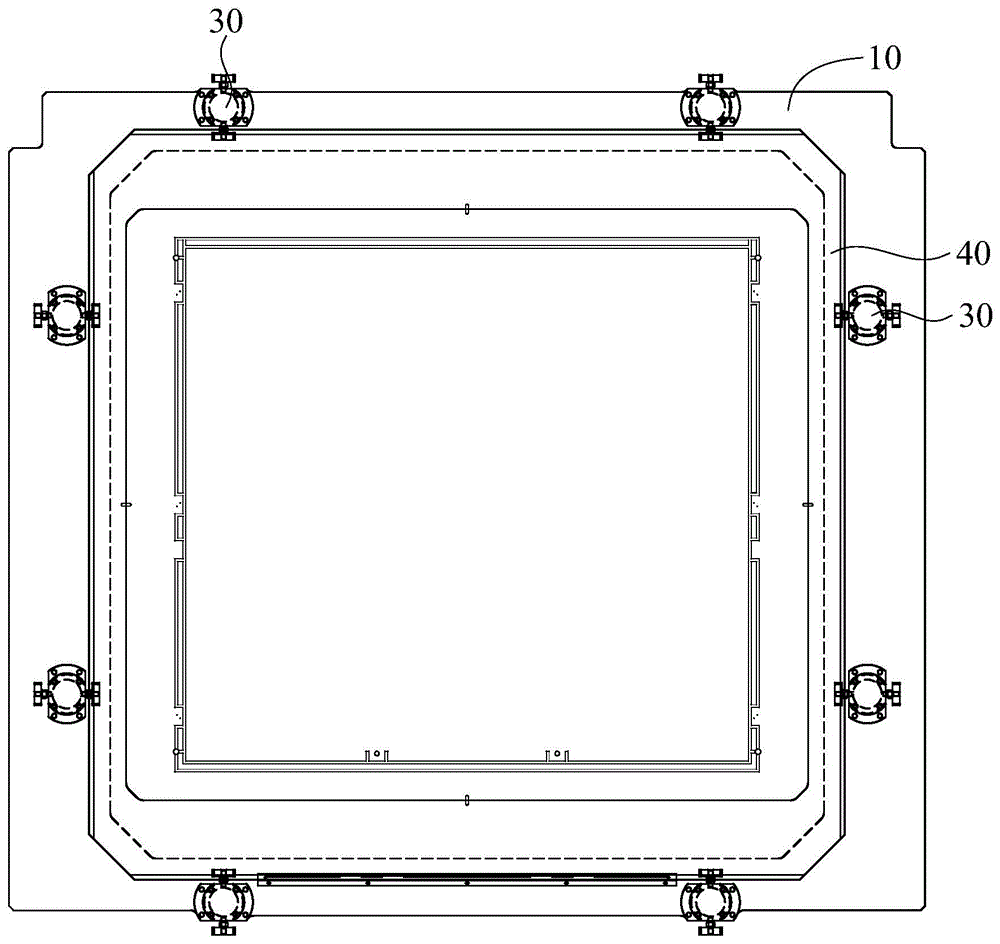

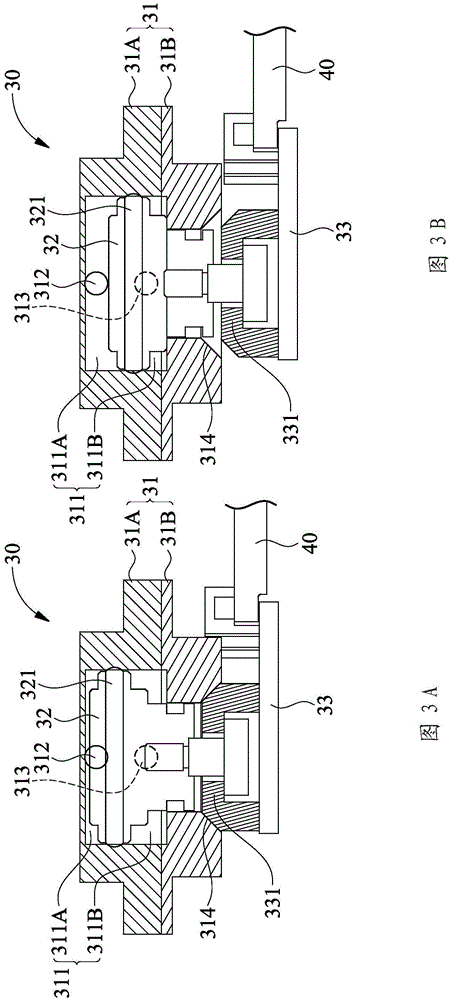

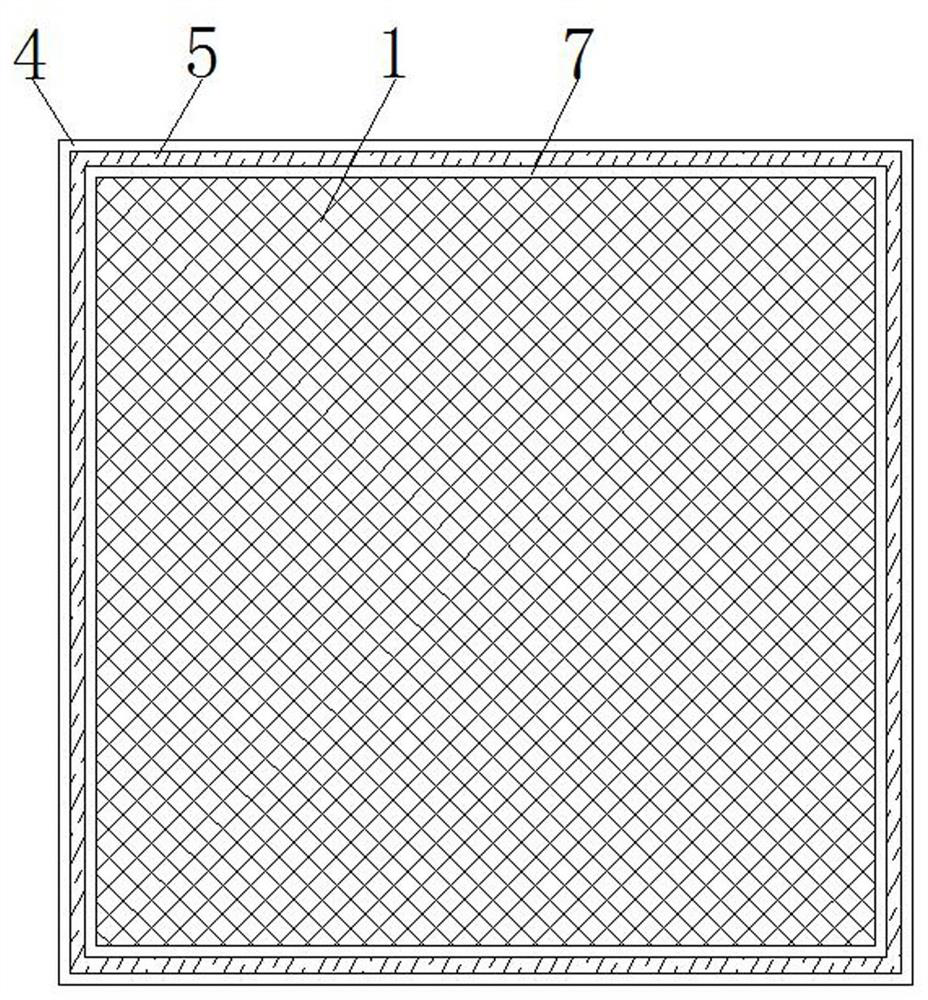

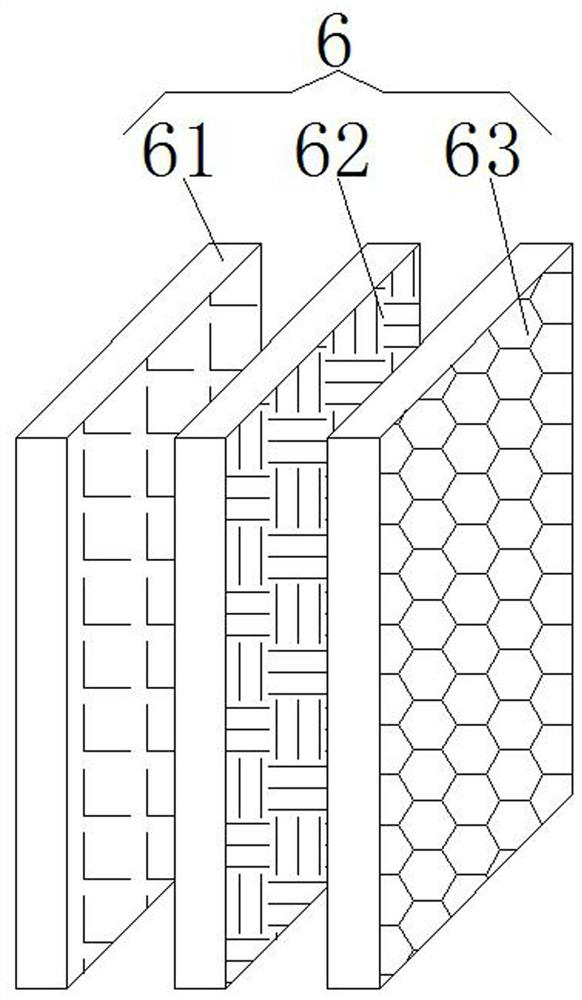

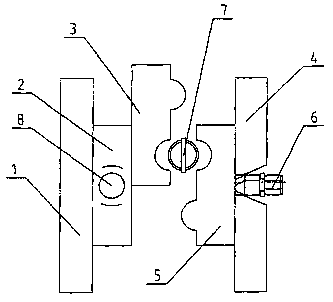

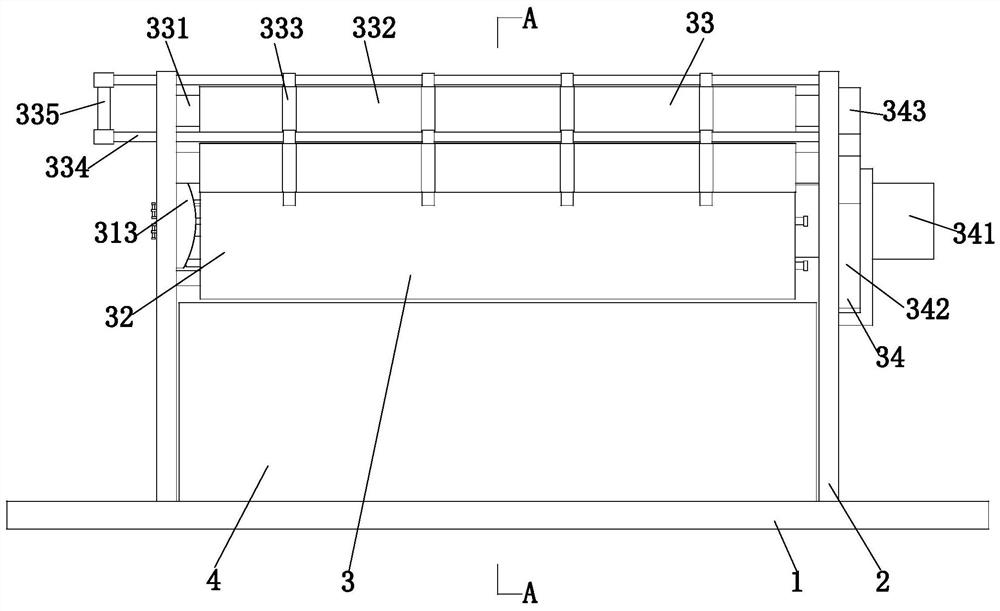

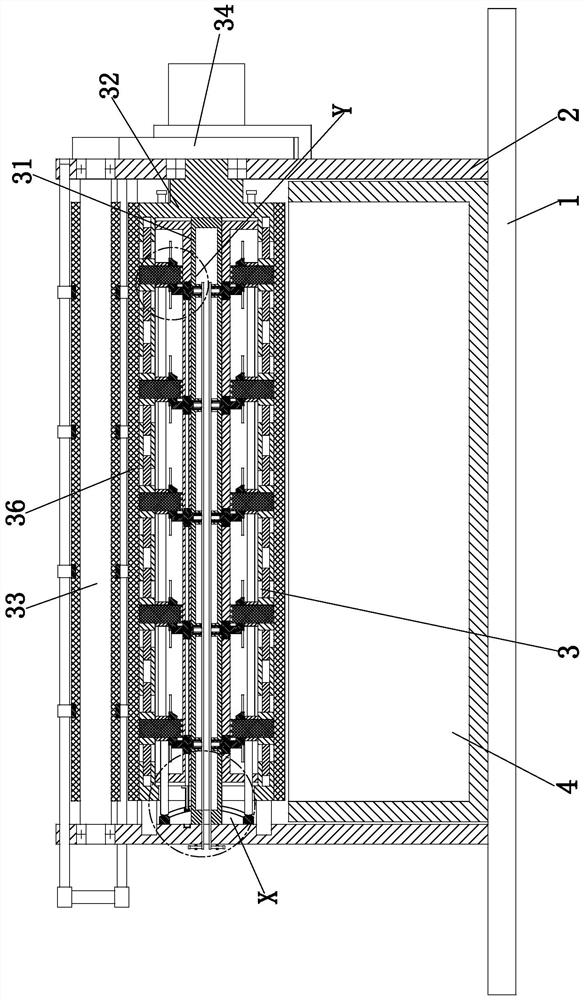

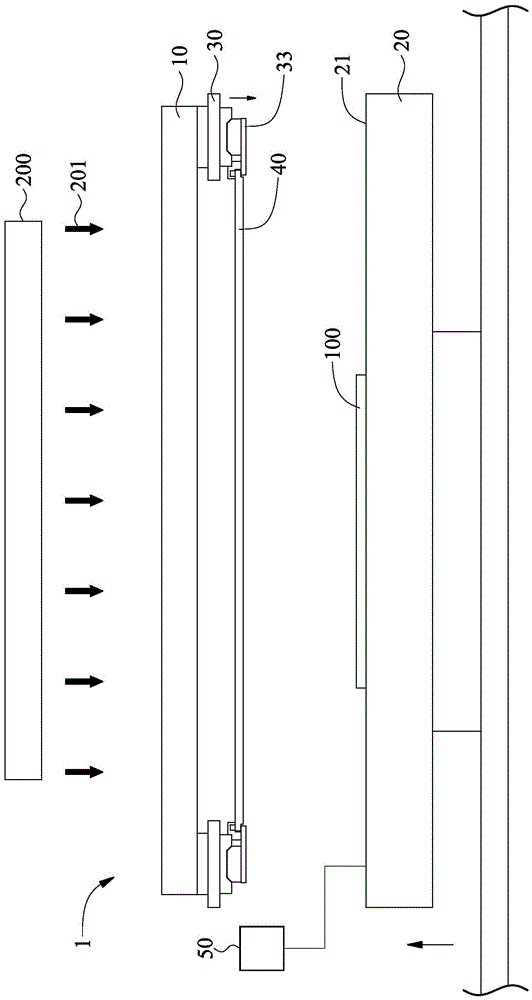

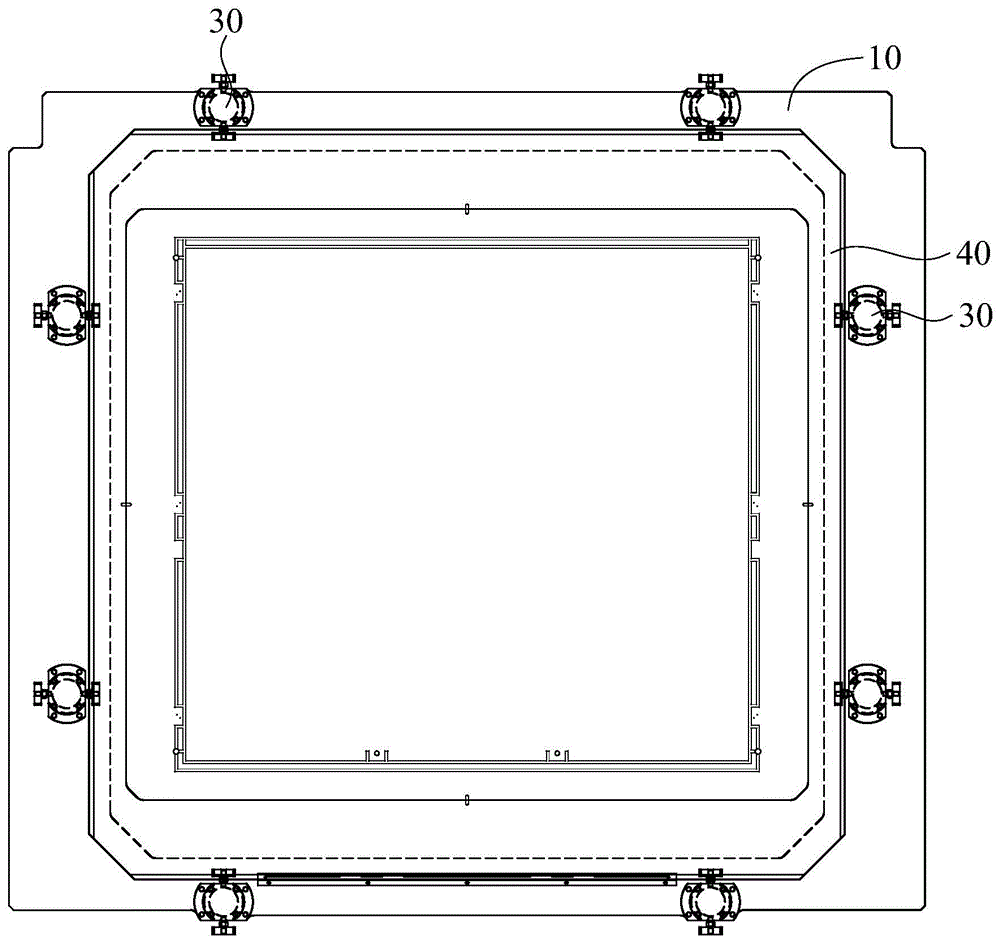

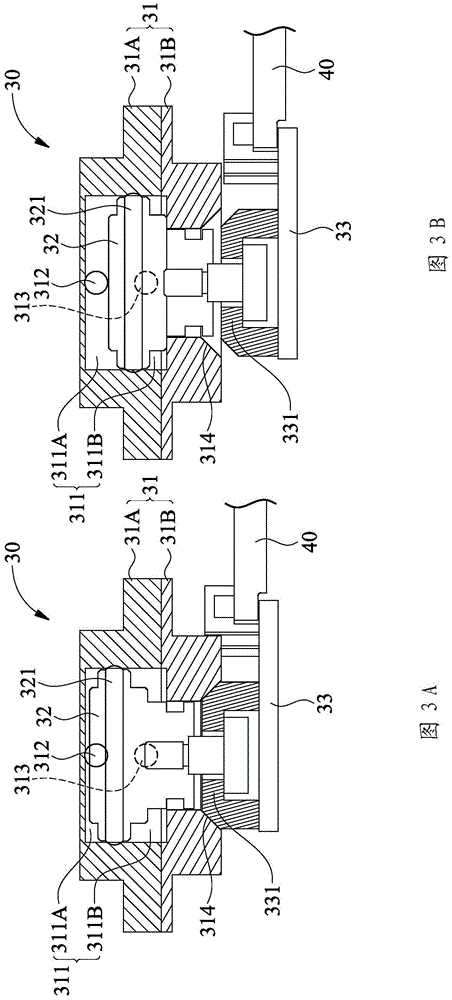

Exposure platform of exposure machine

InactiveCN105093839AImprove the disadvantage of not being able to deform with the flatness of the substrateImprove fit compactnessPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsUnit/actuation

The invention discloses an exposure platform of an exposure machine. The exposure platform comprises an exposure frame, an objective table, a plurality of elevating units and a light-transmitting plate, wherein the objective table can approach to or keep away from the exposure frame; an accommodating region is formed in the upper surface of the objective table, and is used for putting a substrate and projecting incident light of an exposure light source to the substrate; the elevating units are arranged on the exposure frame; and the light-transmitting plate is combined with a clamp of each elevating unit, and is driven by the elevating units to move towards or away from the accommodating region of the objective table. The light-transmitting plate of the exposure platform disclosed by the invention is fixed to the bottom surface of the exposure frame through the clamps and the elevating units; and when vacuum pumping is carried out in the exposure step of a circuit board manufacture procedure, the light-transmitting plate can be driven by the elevating units, can be fitted to the substrate, and can deform along with the flatness of the substrate, so that the fitting tightness of the light-transmitting plate and the substrate is increased to improve the exposure resolution ratio.

Owner:CHIME BALL TECH

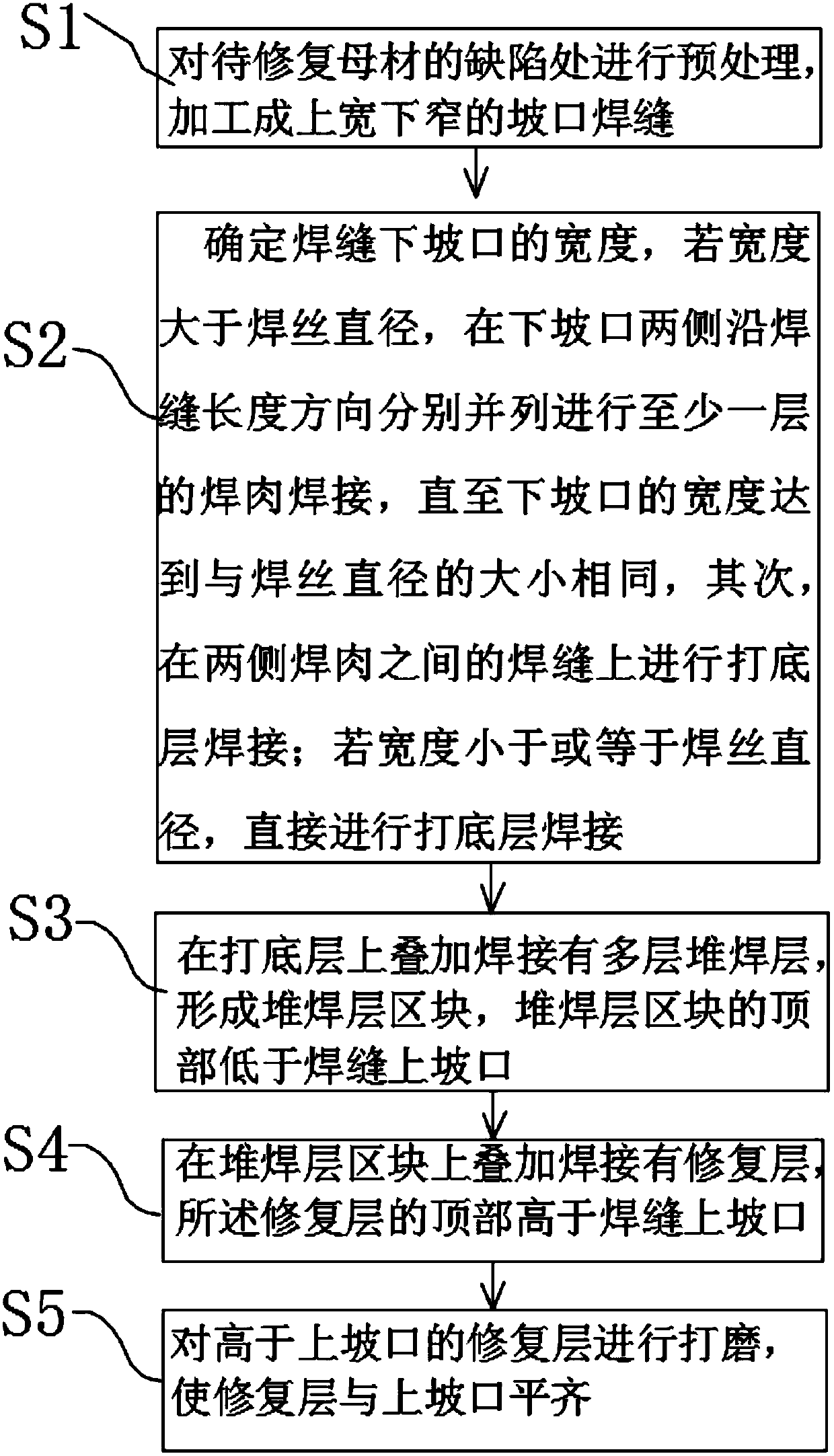

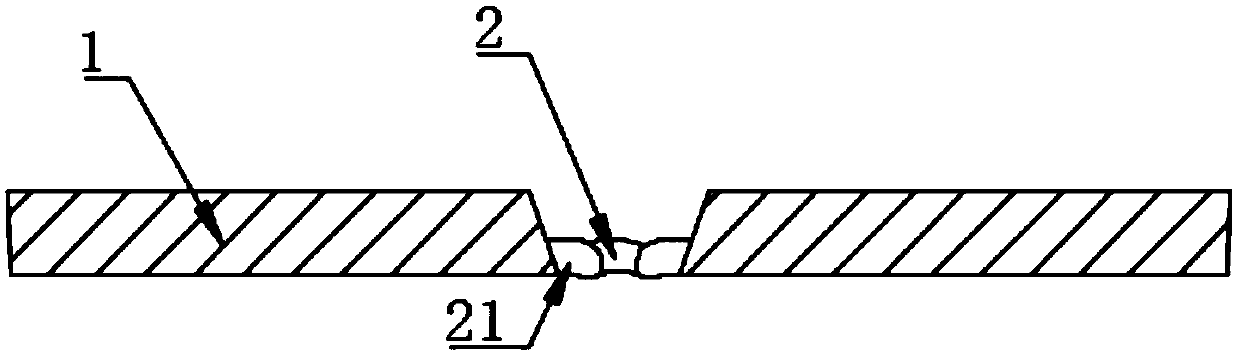

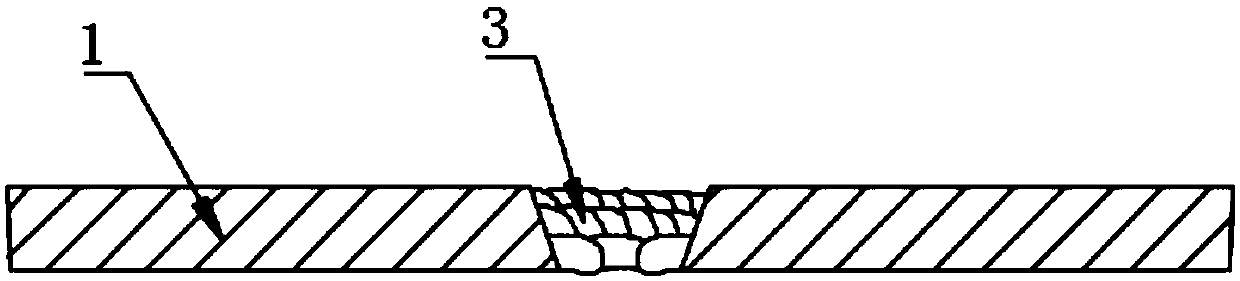

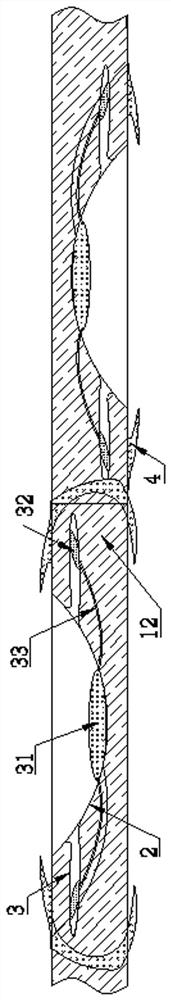

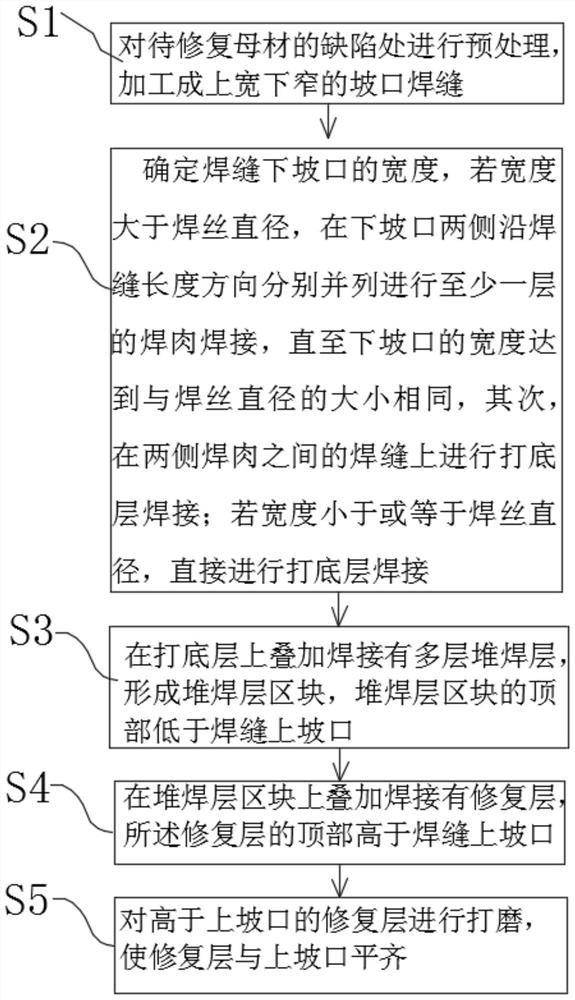

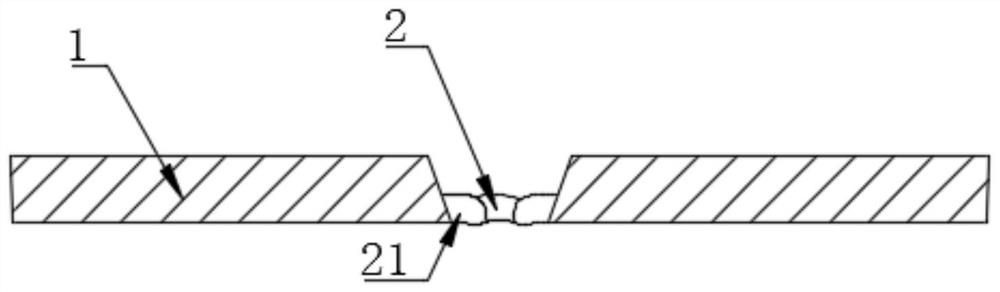

Laserwelding method for repairing penetrating defect of base metal

ActiveCN109664023AEnsure normal exposureAvoid crack defectsLaser beam welding apparatusWorkpiece edge portionsArchitectural engineeringLaser

The invention relates to a laser welding method for a repairing penetrating defect of base metal. The method comprises the following steps that S1, the to-be-repaired defect of the base material is pretreated and machined into a groove weld joint with a wide upper portion and a thin lower portion; S2, the width of a weld joint lower groove is determined, if the width of the lower groove is greaterthan the diameter of a welding wire, at least one layer of convex weld welding are conducted on the two sides of the lower groove side by side in the length direction of the weld joint until the width of the lower groove is the same as the diameter of the welding wire, then priming layer welding is conducted on the weld joint between convex welds on the two sides, and if the width is smaller thanor equal to the diameter of the welding wire, the priming layer is directly welded; S3, multiple welding layers are superimposed and welded on the priming layer, a welding layer zone is formed, and the top of a welding layer block is lower than a weld joint upper groove; S4, a repair layer is superimposed and welded on the welding layer block, and the top of the repair layer is higher than the weld joint upper groove; and S5, the repair layer higher than the upper groove is ground, and thus the repair layer is flush with the upper groove.

Owner:丁二纲

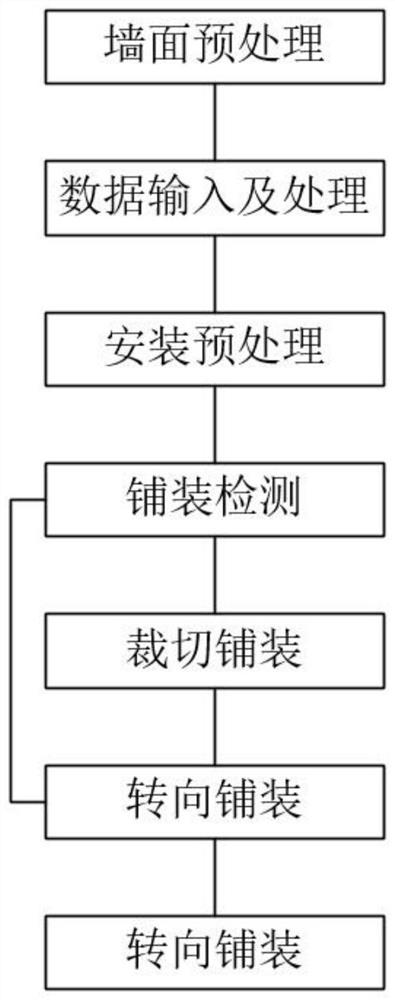

Quality-guaranteeing and efficient laying method of composite geomembrane applied to municipal engineering

PendingCN113882690AImprove fit tightnessImprove fit compactnessSubsonic/sonic/ultrasonic wave measurementApparatus for force/torque/work measurementEnvironmental resource managementGeomembrane

The invention discloses a quality-guaranteeing and efficient laying method of a composite geomembrane applied to municipal engineering, and relates to the technical field of composite geomembrane laying. The laying device a splicing type supporting frame, bottom electric universal wheels, top electric universal wheels, a multifunctional driving structure, a laying box, a material winding drum, a laying assembly, a detection assembly and a cutting and pasting assembly. On the basis of realizing automatic comprehensive laying of the equipment, the fitting compactness of the composite geomembrane and the detection of the wall laying effect are further realized, so that the laying is more efficient and intelligent, data help is provided for later laying of other walls, the laying effect is better and better, and the problems that the traditional manual laying is relatively low in intelligence, and the laying effect is poor and cannot be detected are solved.

Owner:合肥海博工程设计集团有限公司

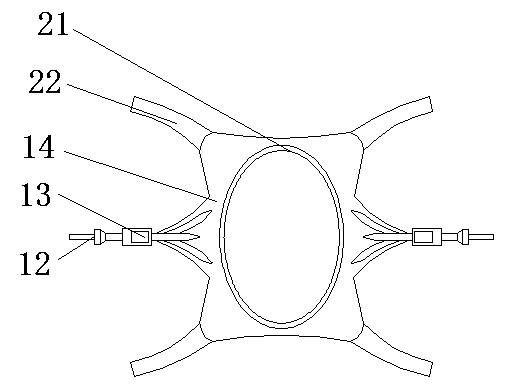

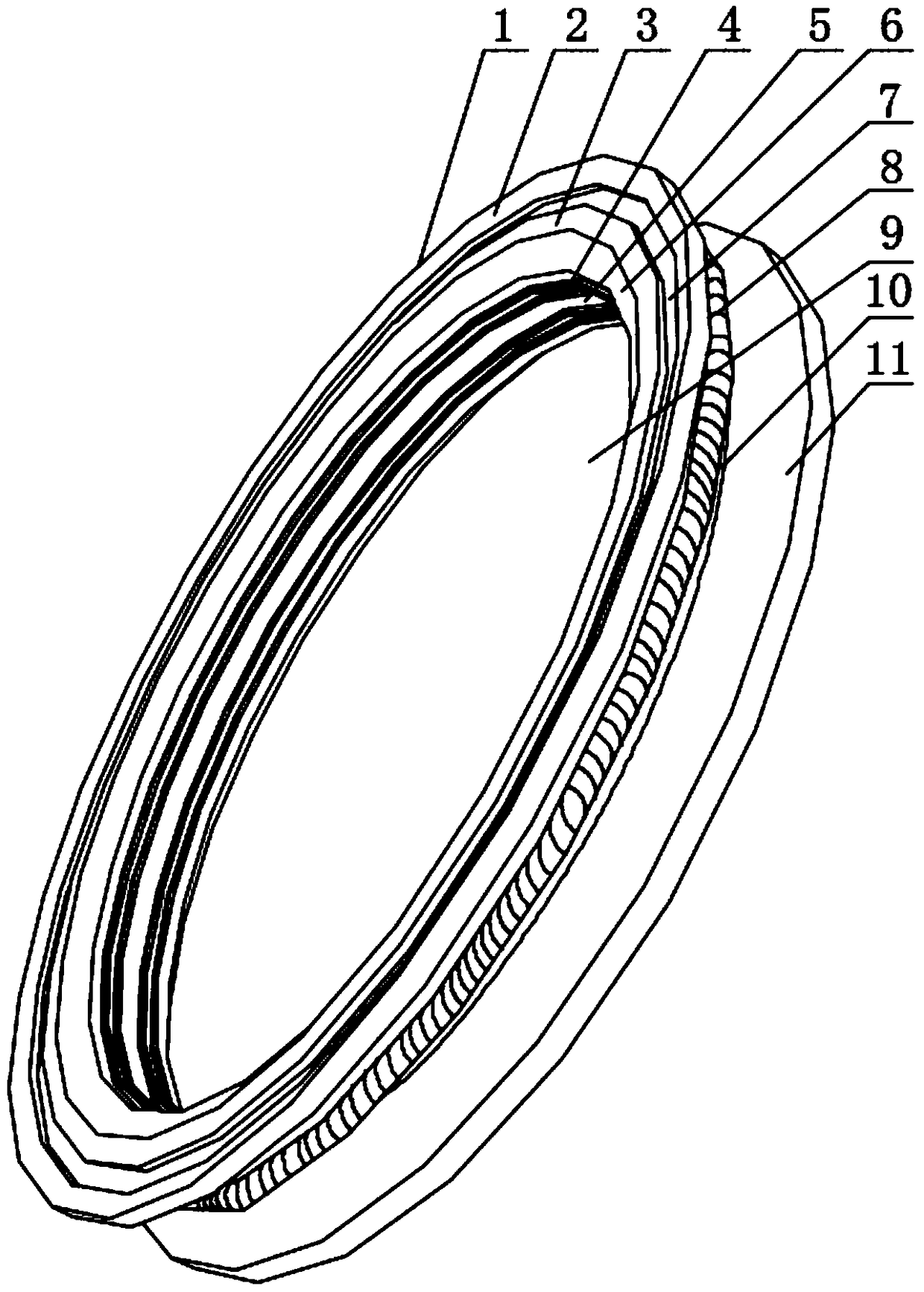

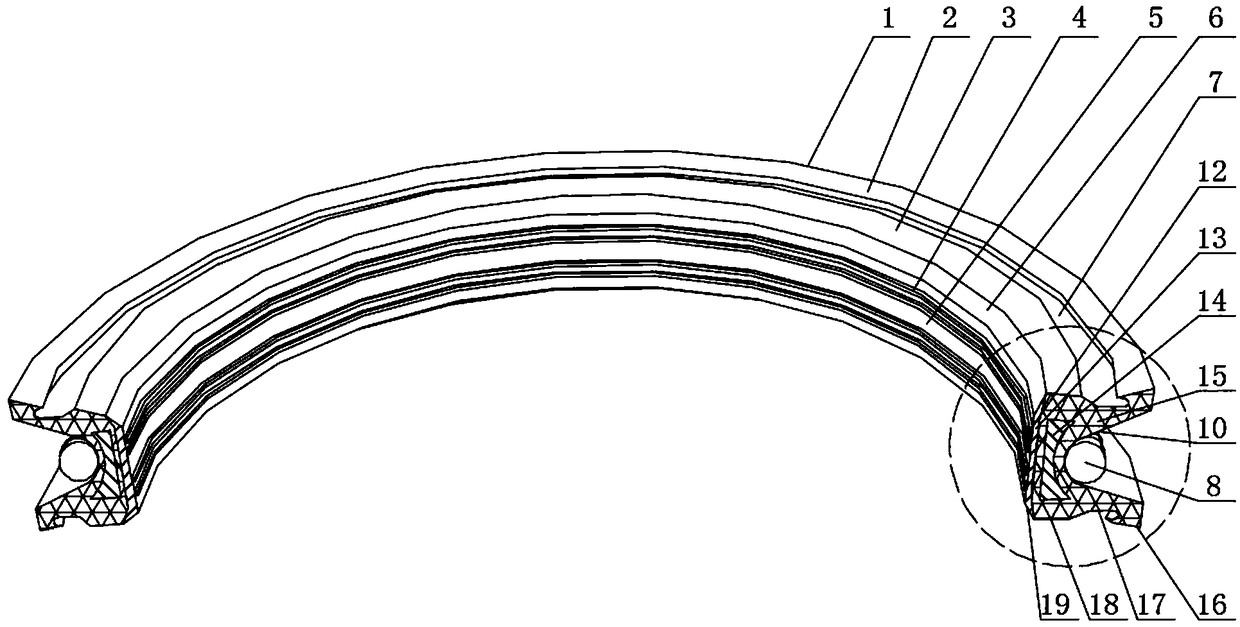

Marine rudderstock double-sided lip seal ring

PendingCN109027239AImprove sealingAutomatically compensates for wearEngine sealsLip sealPolytetrafluoroethylene

The invention relates to a marine rudderstock double-sided lip seal ring which comprises a seal ring body. An upper inner side lip and an upper outer side lip as well as a lower inner side lip and a lower outer side lip are integrally arranged at the upper end and the lower end of the seal ring body in a coaxial opposite-symmetrical outwards-inclined extending way; a sealing surface on which the lip sealing end between the upper inner side lip and the upper outer side lip is located is perpendicular to a seal ring inner hole, and a sealing surface on which the lip sealing end between the lowerinner side lip and the lower outer side lip is located is perpendicular to the seal ring inner hole, so that a double-sided end surface sealing structure is formed; sloping bench ring surfaces are integrally arranged on one sides, close to the seal ring inner hole, of the top parts and the bottom parts of the upper and lower inner side lips; a stainless steel strengthened ring is arranged in themiddle of the peripheral rubber of the seal ring body; and polytetrafluoroethylene seal rings are arranged in the sloping bench ring surfaces. The marine rudderstock double-sided lip seal ring provided by the invention adopts a double-sided lip sealing structure so as to be good in rudderstock sealing effect, less in vibration sensitivity, and less in rudderstock surface wear.

Owner:TIANJIN BAOBOTE SEALING TECH

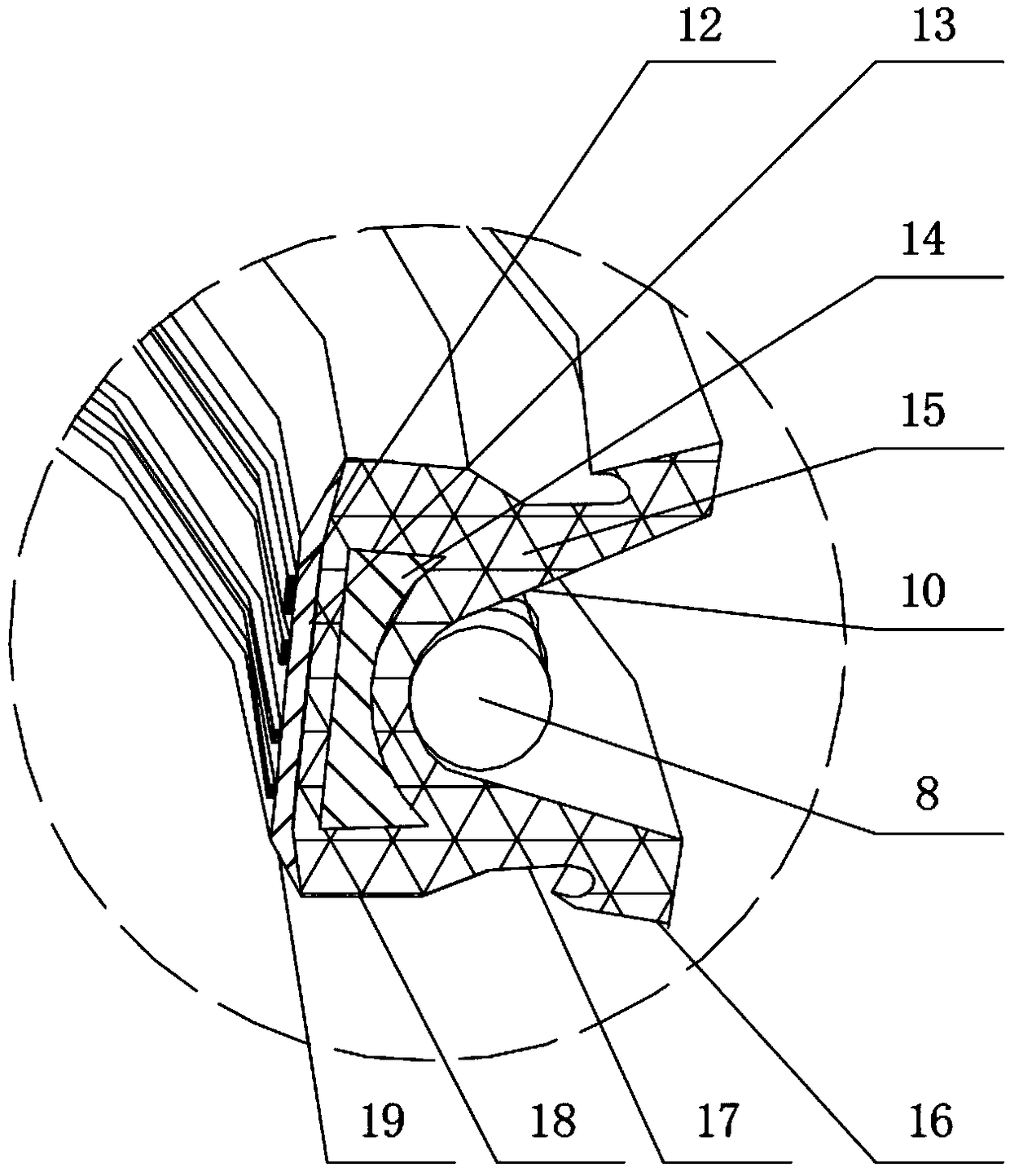

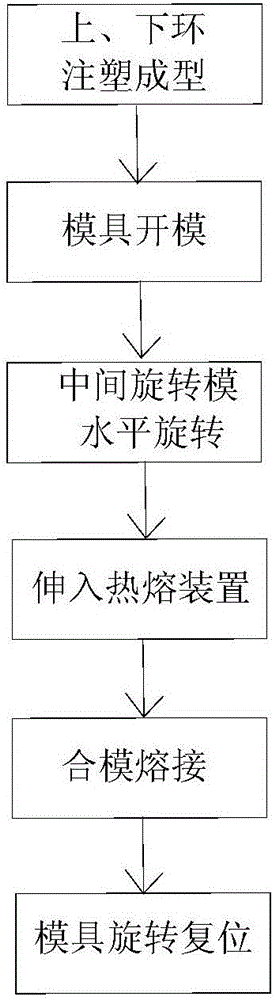

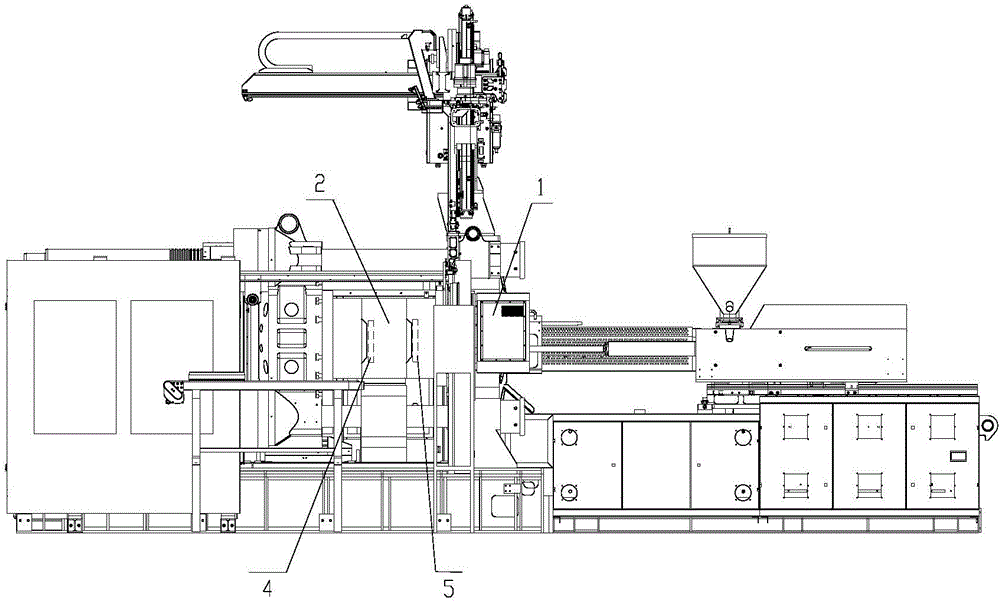

Manufacturing method for balancing ring of washing machine

The invention discloses a manufacturing method for a balancing ring of a washing machine, and the balancing ring is automatically produced by intelligent production equipment for the balancing ring of the washing machine. The manufacturing method specifically comprises the following steps of: (1) injection-molding in a mould region of an injection molding machine to form an upper ring and a lower ring of the balancing ring of the washing machine, and cooling and molding; (2) opening the injection molding machine to rotate a middle rotary mould of the mould by 180 degrees, and enabling a mould side with an upper ring to be opposite to a mould side with a lower ring; (3) introducing a hot melting device into the mould region of the injection molding machine, heating the upper ring and the lower ring to a needed hot melting temperature, and dropping the hot melting device out of the mould region; (4) closing the mould again for effectively melting the upper ring and the lower ring together, thereby forming the balancing ring of the washing machine; and (5) opening the mould to take out the balancing ring of the washing machine. According to the manufacturing method disclosed by the invention, injection-molding and melting of the upper ring and the lower ring of the balancing ring are carried out in the mould, and the balancing ring finished product has been the finished product while leaving a mould cavity, so that assembly quality stability and fit tightness of the balancing ring of the washing machine are improved, and therefore, manpower and material resources are saved, and production cost is reduced.

Owner:BORCH MACHINERY

Building steel formwork structure

ActiveCN112942804AReduce the difficulty of transportationImprove fit tightnessForming/stuttering elementsForm treatmentCamStructural engineering

The invention relates to a building steel formwork structure. The building steel formwork structure comprises a bottom plate, a formwork main body and a demolding device, wherein the demolding device comprises a mounting frame, a connecting plate, a lifting frame, a vibration cam, a transmission mechanism, a vibration plate and a vibration rod, and the formwork main body comprises a plurality of side plates, sealing pieces, rubber gaskets and connecting rods which are arranged from top to bottom. According to the building steel formwork structure, both the formwork main body and the bottom plate are of a detachable structure, the formwork main body can be separately conveyed in a transferring process, compared with an overall conveying mode, the transportation difficulty is obviously reduced, after concrete is formed, the side wall of the formwork main body is evenly knocked through the demolding device, and the knocking force tends to be large from small, so that the formwork main body or concrete is prevented from being damaged by sudden increase of the knocking force, and additionally, the condition that the separation speed of the formwork main body and the concrete cannot be increased due to small knocking force is avoided.

Owner:浙江隆曦建筑工程有限公司

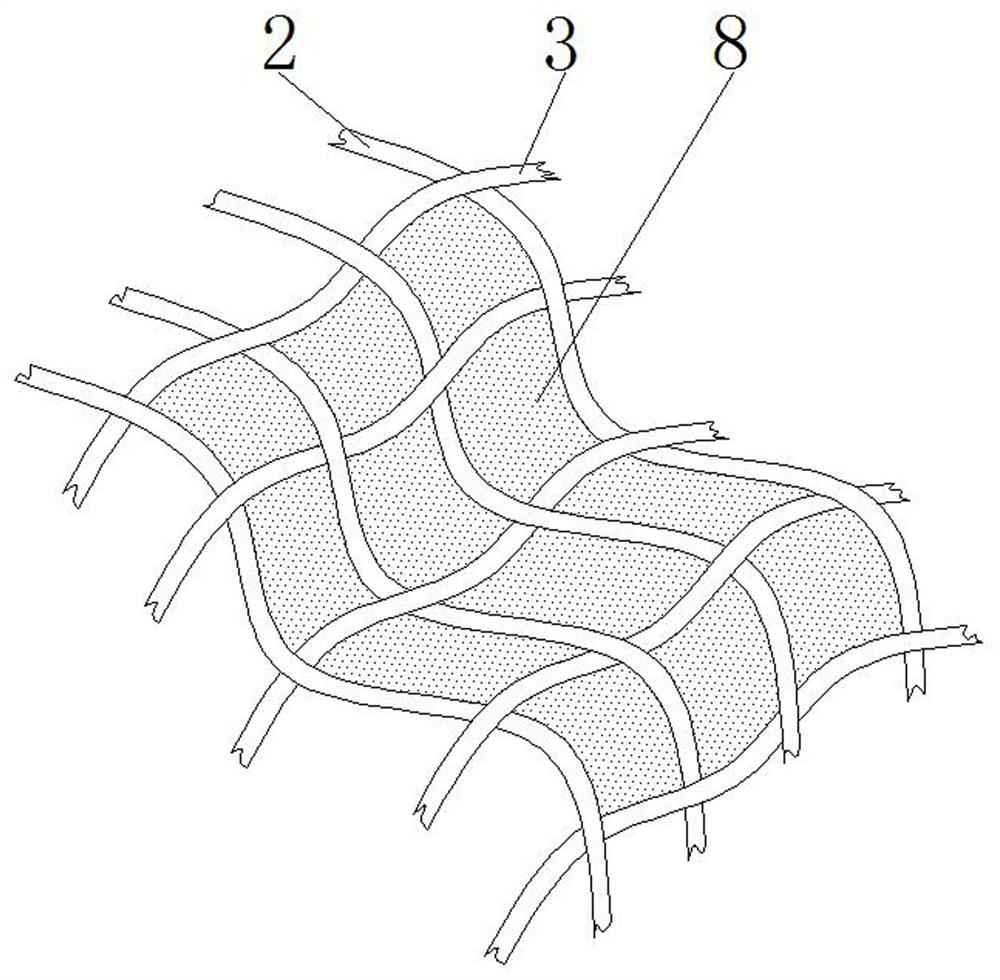

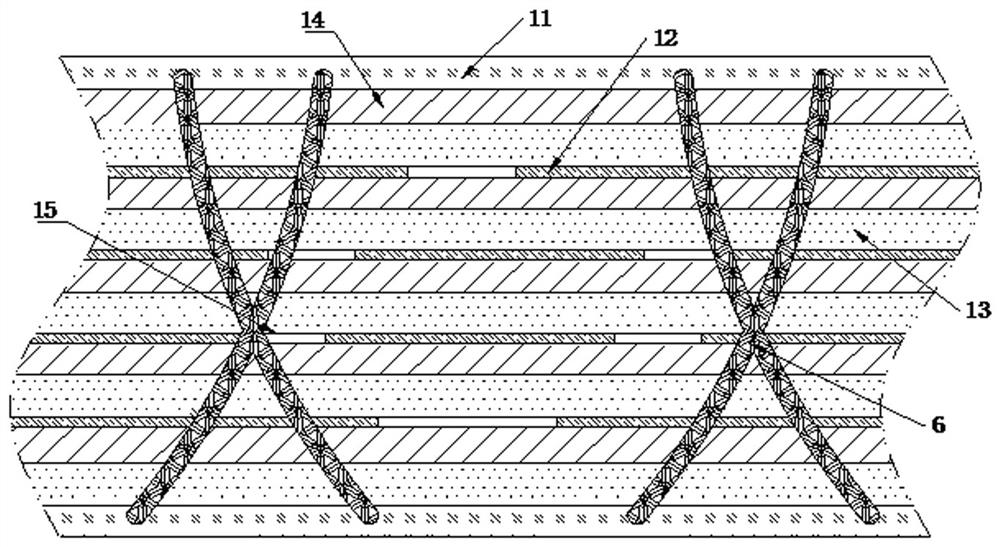

Multi-layer non-woven geotextile and preparation method thereof

InactiveCN111823661AImprove acceleration performanceHigh material strengthSynthetic resin layered productsWoven fabricsPolyesterPolymer science

The invention provides a multi-layer non-woven geotextile and a preparation method thereof. The multi-layer non-woven geotextile comprises a base cloth layer, the base cloth layer is formed by weavingwarp and weft yarns in a crossed mode, an edge covering layer is sewn on the outer side of the base cloth layer through nylon threads, a reinforcing layer is sewn at the bottom of the base cloth layer, and the reinforcing layer comprises a cotton-linen textile layer, a woven silk screen layer, a wear-resistant coating layer, polyester yarns, high-strength fiber yarns and aramid fiber yarns. According to the invention, the cotton-linen textile layer, the woven silk screen layer and the wear-resistant coating layer are matched, the overall reinforcing effect of the base cloth layer is enhanced,the extrusion pressure at the bottom of the base cloth layer can be effectively released, the base cloth layer is prevented from being torn and damaged by sharp stones and convex blocks, and the overall material strength of the warp yarns and the weft yarns is enhanced through cooperation of the polyester yarns, the high-strength fiber yarns and the aramid yarns, so that the overall tearing strength of the base cloth layer is directly enhanced, the stress buffer effect of the base cloth layer is further enhanced, and the overall service life of the base cloth layer is prolonged.

Owner:YIXING JIEGAO NON WOVEN FABRIC

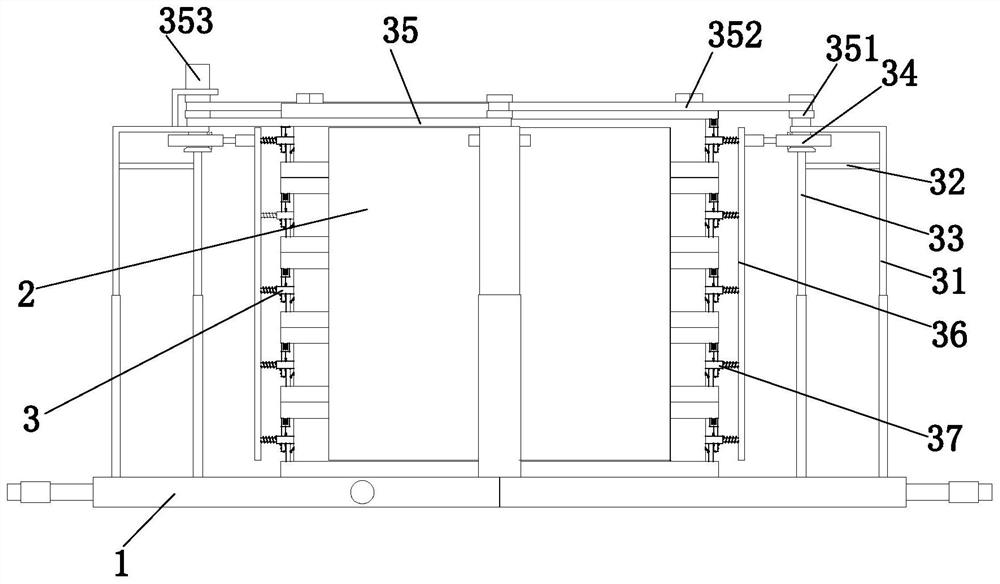

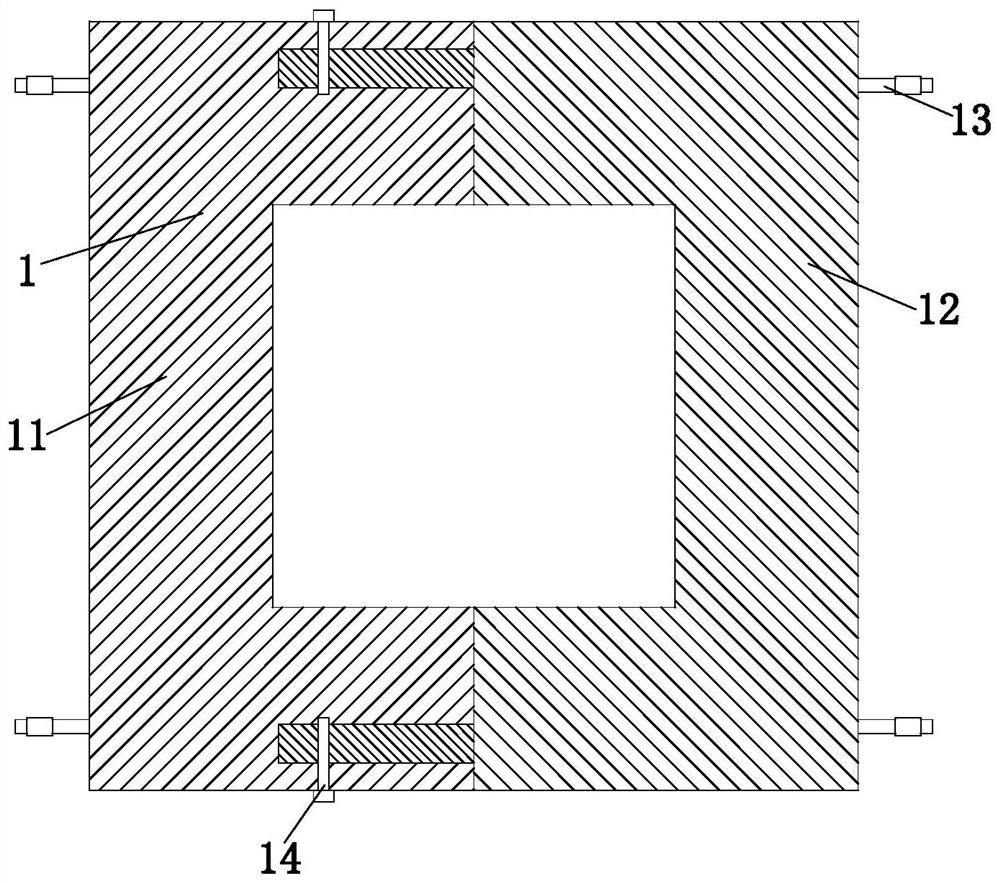

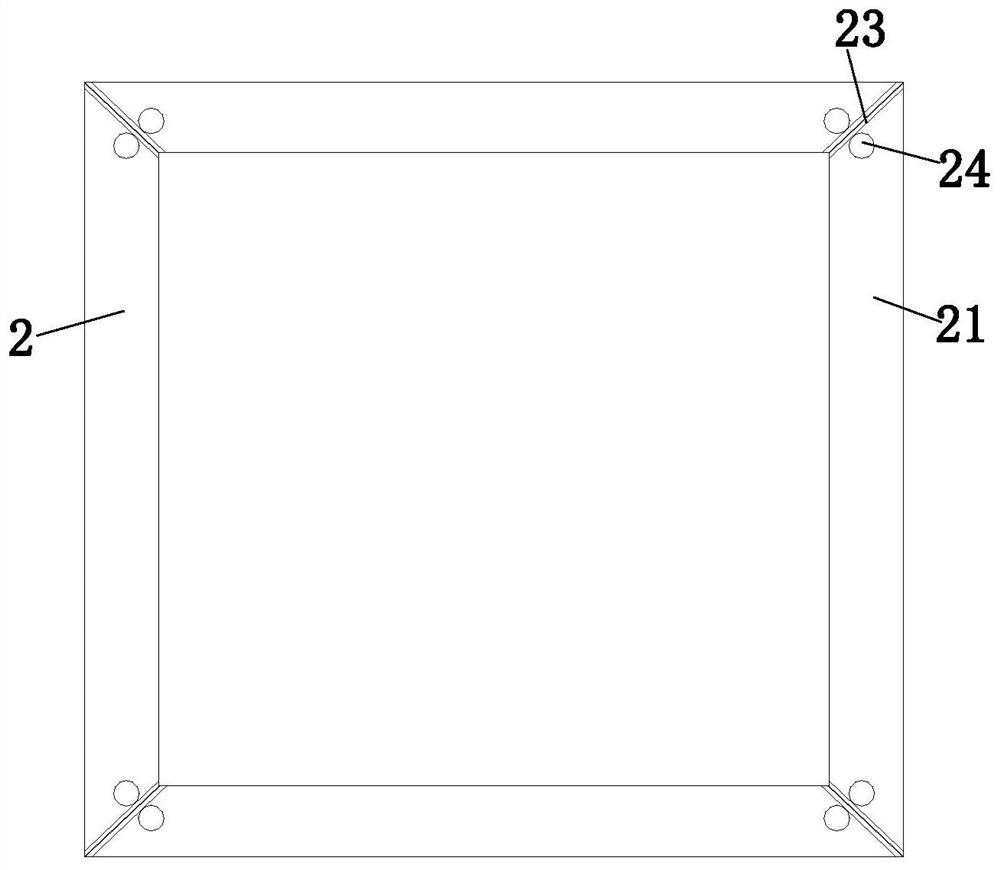

A stainless steel alloy flange manufacturing and processing machine

ActiveCN111469013BFast and stable lockPlay a locking roleGrinding drivesGrinding machinesStructural engineeringSS - Stainless steel

The invention relates to a stainless steel alloy flange manufacturing and processing machine, comprising a base, a limit mechanism, an L-shaped rod, a circular seat, a bolt, an annular block, an adjusting arm, a connecting arm, a driven arm and a grinding mechanism, and the upper end surface of the base The limit mechanism is installed on the top, and L-shaped rods are installed on the right front and left rear of the upper end surface of the base. A circular seat is installed between the inner side of the upper end of the L-shaped rod. The circular seat is connected with the lower end of the bolt through a bearing, and the middle of the bolt is threaded. A ring block is connected in a matching manner. Four adjusting arms are symmetrically installed on the outer surface of the ring block. The lower end of each adjusting arm is connected to the upper middle part of the slave arm through the connecting arm, and the lower end of the slave arm is installed through a hinge. There is a grinding mechanism. The present invention can solve the existing problem of deburring the bolt holes on the flange: the fixture of the processing equipment has poor locking effect on the flange; the processing equipment can only process one bolt hole at a time, and the burr on the upper end surface of the bolt hole needs other Equipment secondary processing.

Owner:盐城斯天康精密制造有限公司

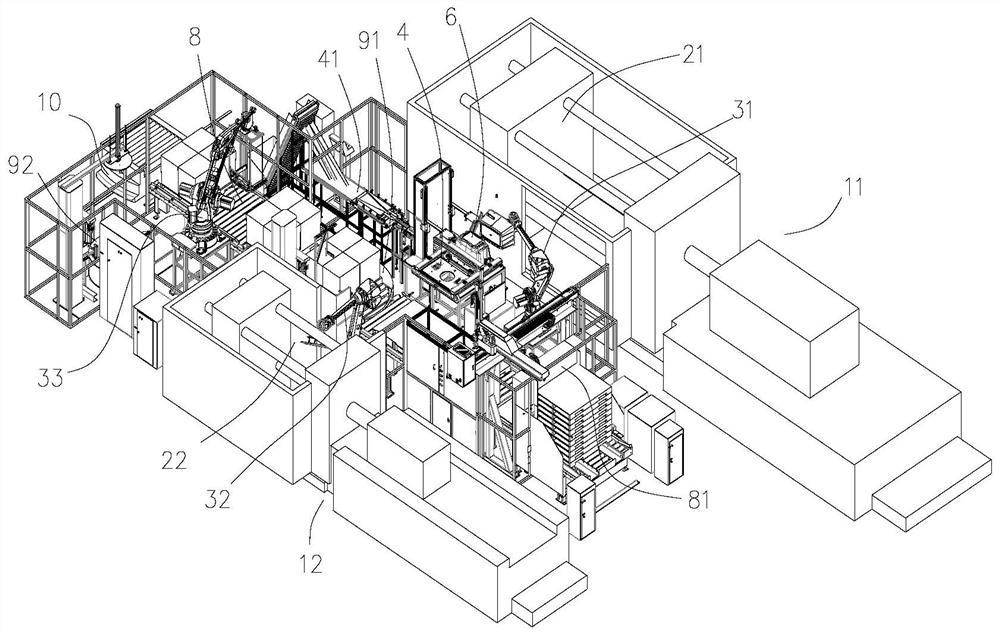

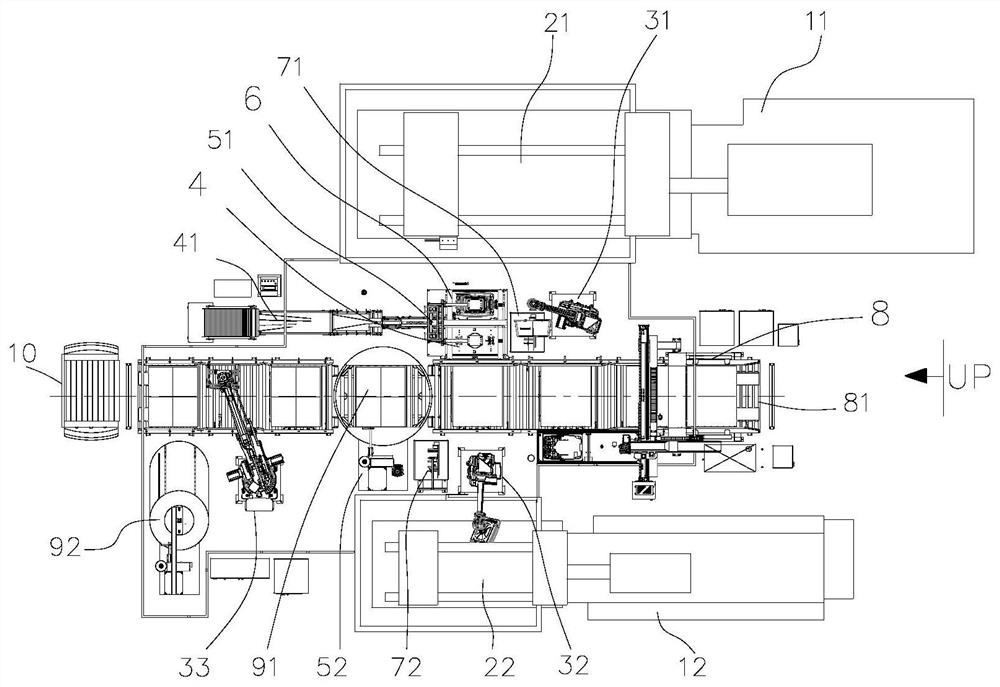

An intelligent production equipment for household storage boxes

ActiveCN109205293BSave spaceImprove stabilityControl devices for conveyorsMechanical conveyorsProduction lineMaterial resources

The invention discloses an intelligent production equipment for household storage boxes, including a conveying line, a box body production line, a box cover production line and an AGV intelligent transport vehicle. The box body production line and the box cover production line are arranged on the conveyor both sides of the line. Compared with the conveyor line, the mold area of the box production line is set upstream of the mold area of the box cover production line. The production equipment of this invention forms a fully automatic high-speed unmanned intelligent production line for plastic products, including robot picking, rapid prototyping, online detection, intelligent control, remote diagnosis and other functions, which improves the stability of product assembly quality and tightness of cooperation , while saving manpower, material resources and plant space, reducing production costs.

Owner:BORCH MACHINERY

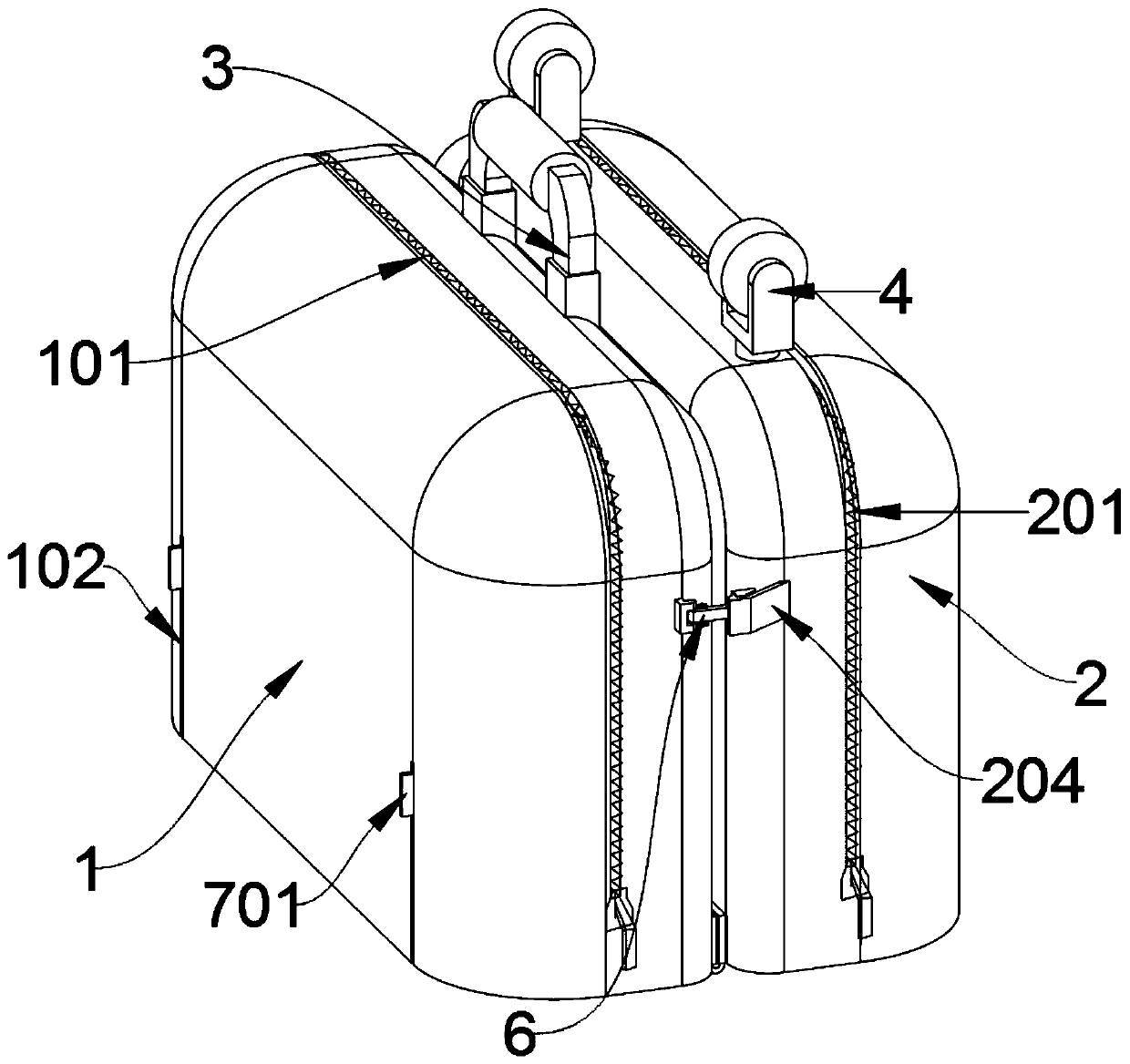

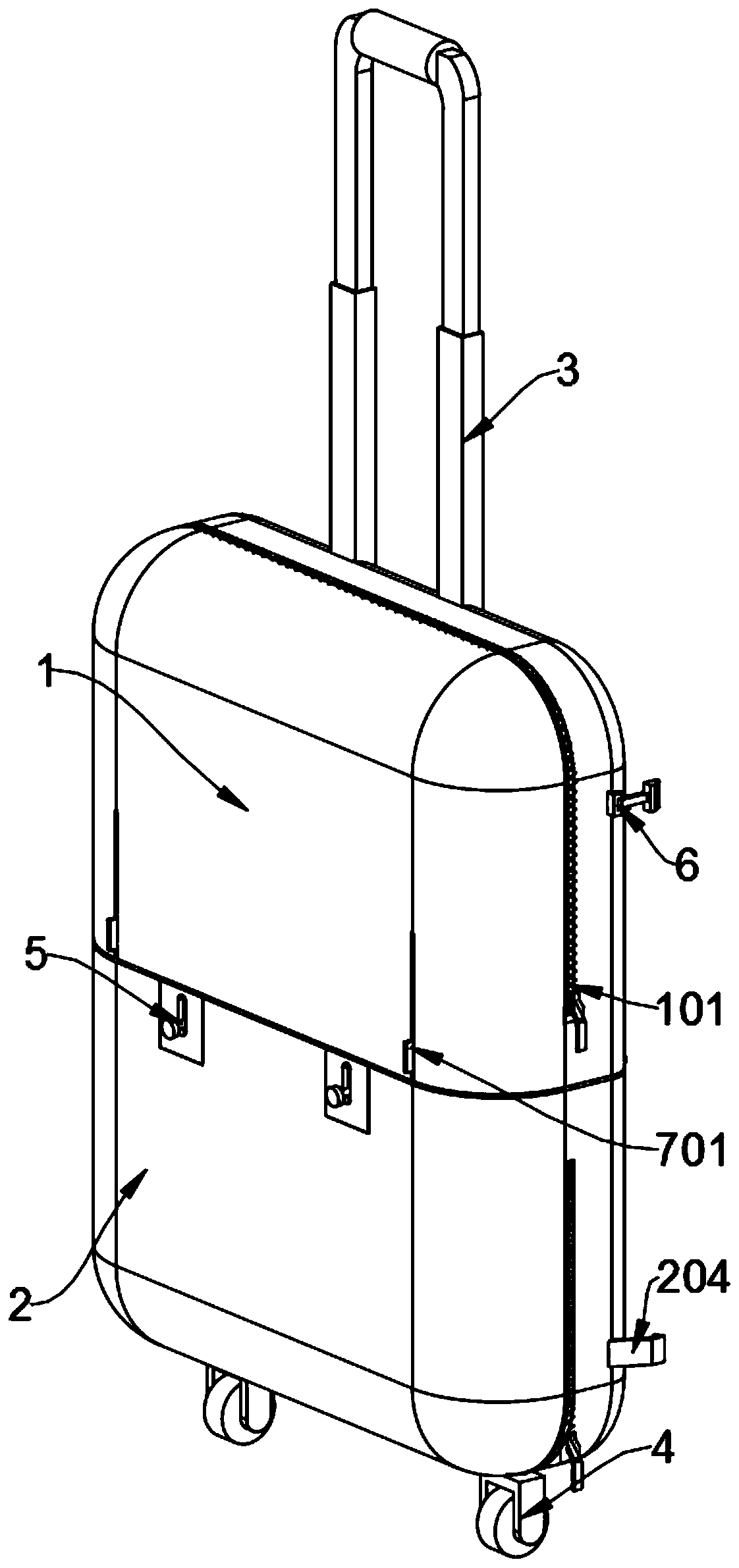

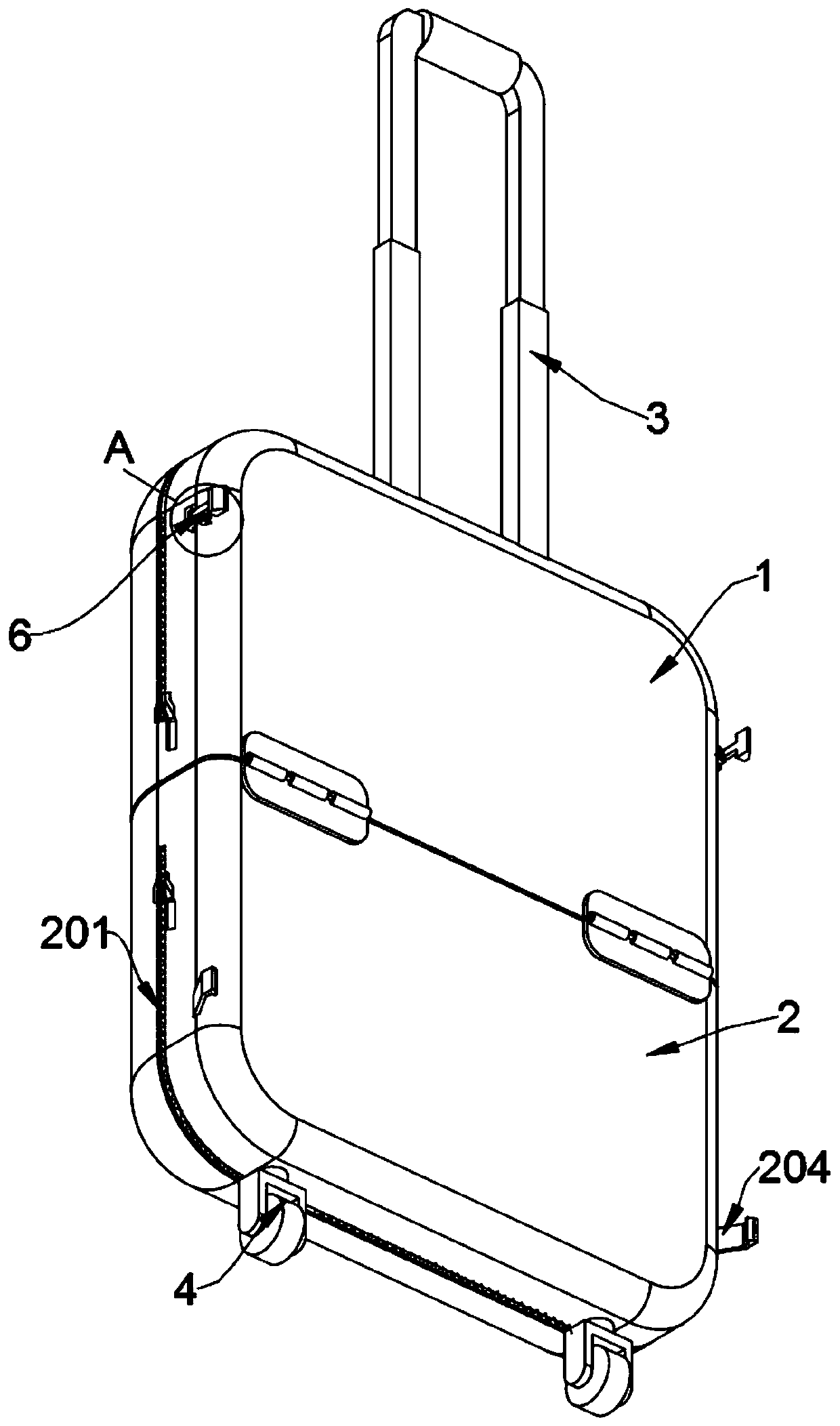

Non-shoulder-carrying device for school supplies

InactiveCN111387686AImprove fit compactnessImprove folding resistanceTravelling sacksLuggageStructural engineeringSchool supplies

The invention provides a non-shoulder-carrying device for school supplies. The non-shoulder-carrying device comprises an upper folding bag, universal wheels, inner buckles, side buckles, reinforcing rods, an upper clamping plate and a lower clamping plate. A lower folding bag is hinged to the lower part of the upper folding bag; an upper chain seam is vertically formed in the middle of the upper folding bag; the upper sliding groove is divided into a left position and a right position and is formed in the two sides of the front lower portion of the upper folding bag, a lower chain seam is vertically formed in the middle of the lower folding bag, the two sides of the front portion of the upper surface of the lower folding bag are provided with locking block grooves respectively, a lower sliding groove is formed in the upper portion of the lower folding bag, and lower locking handles are fixedly connected to the two sides of the lower folding bag. The upper folding bag and the lower folding bag can be unfolded and thus the upper folding bag and the lower folding bag form a high double-layer bag body. The lower end of the lower folding bag is provided with the universal wheels; aftera telescopic rod is unfolded, a student can pull the telescopic rod to walk, so that situations that the spine protrudes backwards, protrudes laterally, inclines forwards or twists because the knapsack is too heavy, muscles are possibly fatigued due to extreme tension, and the neck, shoulders and the back are easily injured are avoided.

Owner:SUZHOU WEITENG ENTERPRISE MANAGEMENT CONSULTING SERVICE CO LTD

High-efficiency wood cutting machine and cutting method for construction engineering

ActiveCN113319943BIncreased diameter limitsIncrease limit rangeProfiling/shaping machinesStructural engineeringHoist device

Owner:GUANGZHOU CITY CONSTR COLLEGE

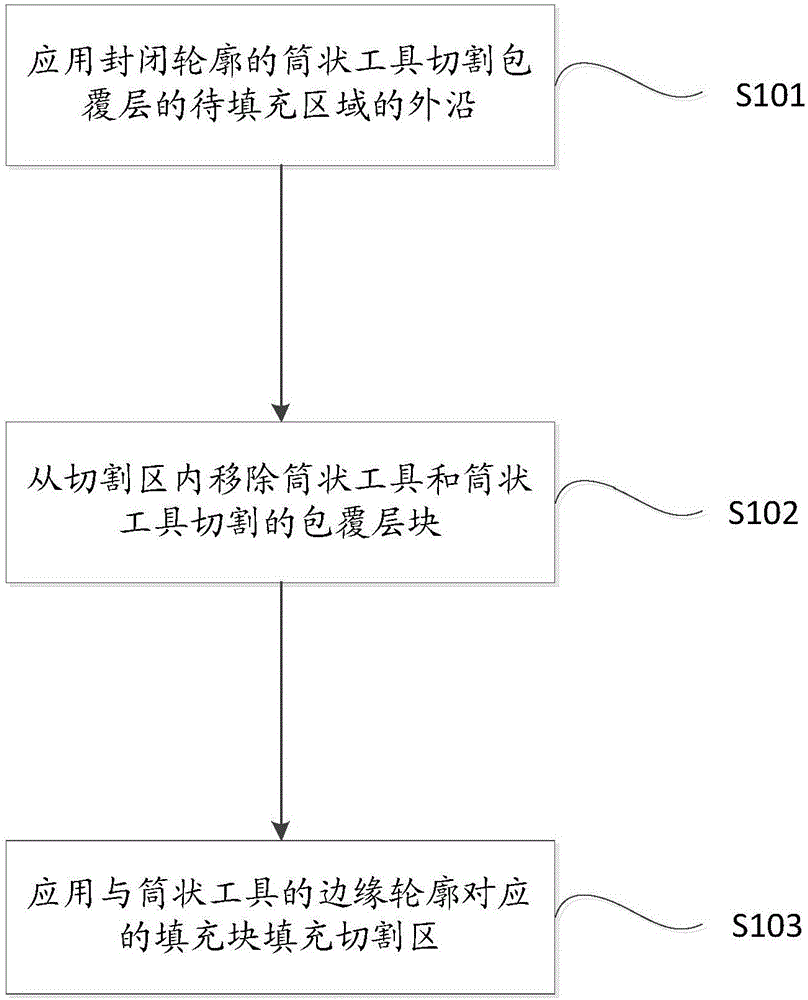

Filling method for external coating layer of building

The invention relates to the technical field of buildings, and discloses a filling method for an external coating layer of a building. The filling method for the external coating layer of the building comprises the steps that a cylindrical tool with a closed contour is used for cutting the outer edge of a to-be-filled area of the coating layer; the cylindrical tool and coating layer blocks cut by the cylindrical tool are removed from the cutting area; the filling blocks corresponding to the edge contour of the cylindrical tool are used for filling in the cutting area. By means of the filling method for the external coating layer of the building, the work convenience and construction effect for conducting filling and repairing on the external coating layer of the building are significantly improved, and meanwhile the construction cost is reduced.

Owner:JILIN KELONG BUILDING ENERGY SAVING TECH

Multi-material in-mold assembling method

InactiveCN109747098AImprove stabilityImprove fit compactnessCoatingsMulti materialMaterial resources

The invention relates to a multi-material in-mold assembling method. The method comprises a movable mold, a sub-mold, a fixed mold and injection devices; a sub-mold positioning device, a sub-mold driving device and an ejection device are arranged on the movable mold; and a product assembling mechanism and an air blowing device are arranged on the fixed mold. Thedevice is characterized in that after the movable mold, the sub-mold and the fixed mold are assembled,the injection devices perform injection to the fixed mold, the molds are opened after the injection is completed, the movable mold drives the sub-mold to adapt to multi-station production requirements through the sub-mold driving device, then the sub-mold positioning is conducted through the sub-mold positioning device, then the molds are assembled, and products of different working procedures are assembled through the product assembling mechanism. The method and the device have the advantages that certain procedures needing secondary processing, especially movable parts are carried out in the mold, the plastic part is a final finished product when the plastic part leaves a mold cavity, the quality stability and the matchingtightness of the product assembly are improved, and manpower and material resources and workshop space are saved.

Owner:十堰昶耀科技服务有限公司

Absorbent article with improved waist cut piece and side seam

ActiveCN113599086AImprove wearing experienceReduce strangulationAbsorbent padsBandagesNursing careMechanical engineering

The invention belongs to the technical field of medical care, and particularly relates to an absorbent article with improved waist cut piece and side seam, which comprises a waist cut piece structure; water absorption cloth is arranged on the side wall of the waist cut piece structure; the end part of the water absorption cloth is longer than the end part of the waist cut piece structure; the end part of the water absorption cloth bypasses the end part of the waist cut piece structure and wraps two sides of the end part of the waist cut piece structure; and the waist cut piece structure is fixedly connected with the side wall of the water absorption cloth bypassing the end part of the waist cut piece structure. Since isolation cloth isolates the waist cut piece structure from the water absorption cloth on one side, the water absorption cloth on one side cannot be directly pulled by a structural rubber band, the water absorption cloth on one side is in a freely folded state, and compared with the water absorption cloth directly pressed with the structural rubber band, the water absorption cloth in the freely folded state is more fluffy and softer and does not have harder creases, so that a user of the paper diaper can make contact with the water absorption cloth in the freely folded state in a wearing process, so that the wearing experience is improved, and tightening marks are reduced.

Owner:山东茁彼母婴用品有限公司

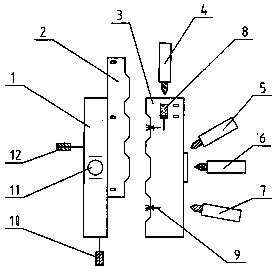

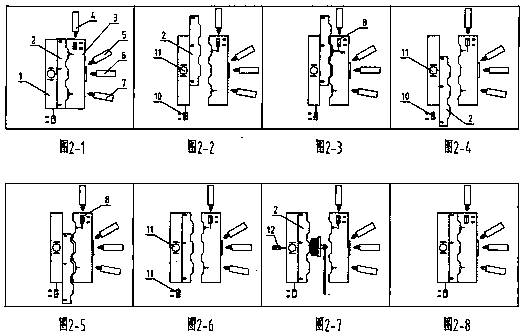

Hollow injection molding method

InactiveCN109747102AImprove stabilityImprove fit compactnessCoatingsMaterial resourcesInjection moulding

The invention relates to a hollow injection molding method. A movable plate, a movable mold, a sub-mold driving device, a sub-mold, a fixed plate, a fixed mold and an injection mechanism are involvedin the method. The method is characterized in that the movable mold, the sub-mold, and the fixed mold are closed, then an injection molding machine performs injection operation, after the injection iscompleted, mold opening is carried out until a required distance is achieved, the movable mold drives the sub-mold to be matched with the next station through the sub-mold driving device, then the mold closing action is carried out again, original separated part products are spliced together, then secondary injection is carried out, and the separated different products are injected together through plastics to complete hollow injection molding products. According to the method, certain procedures needing secondary processing, especially the hollow products which are provided with seals and need to be welded, are designed to be carried out in the molds, and the hollow plastic parts with the seal are the final finished products when leaving mold cavities, so that the product assembly quality stability and the fit tightness are improved, and the manpower and material resources and the workshop space are saved.

Owner:十堰昶耀科技服务有限公司

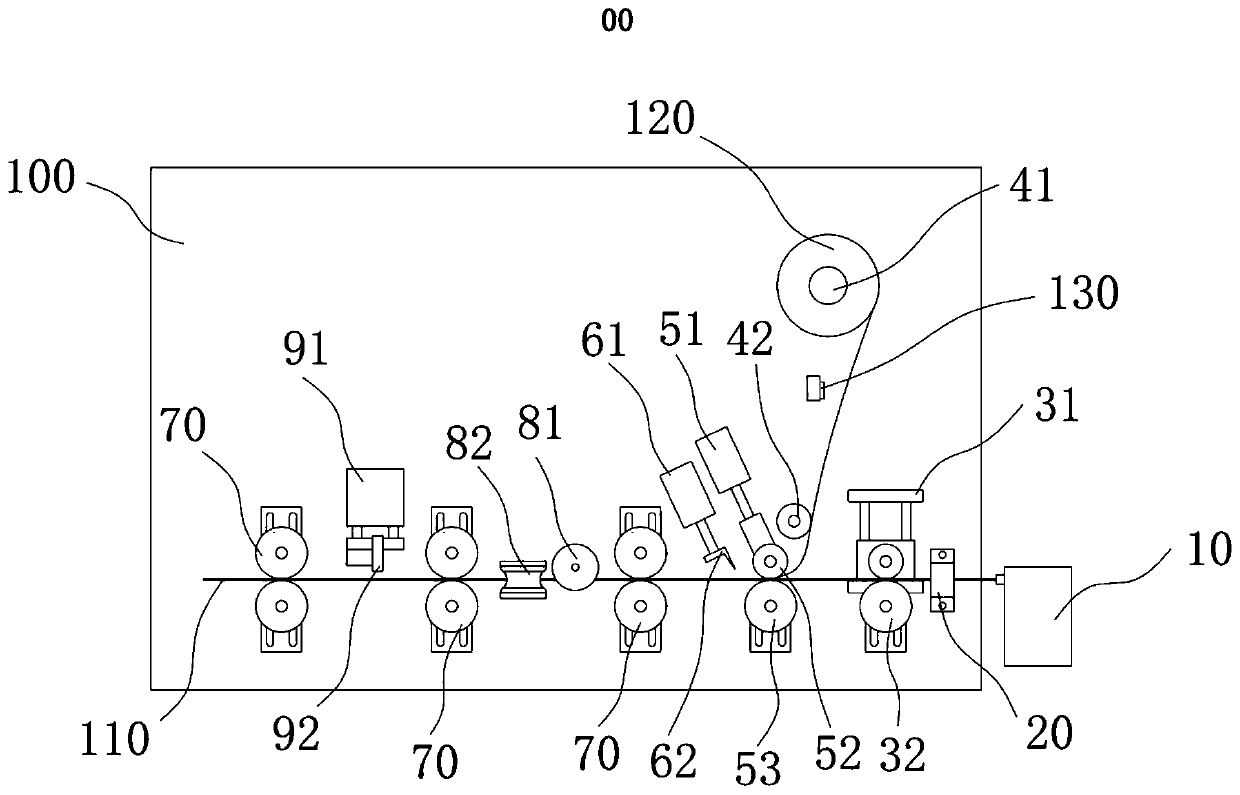

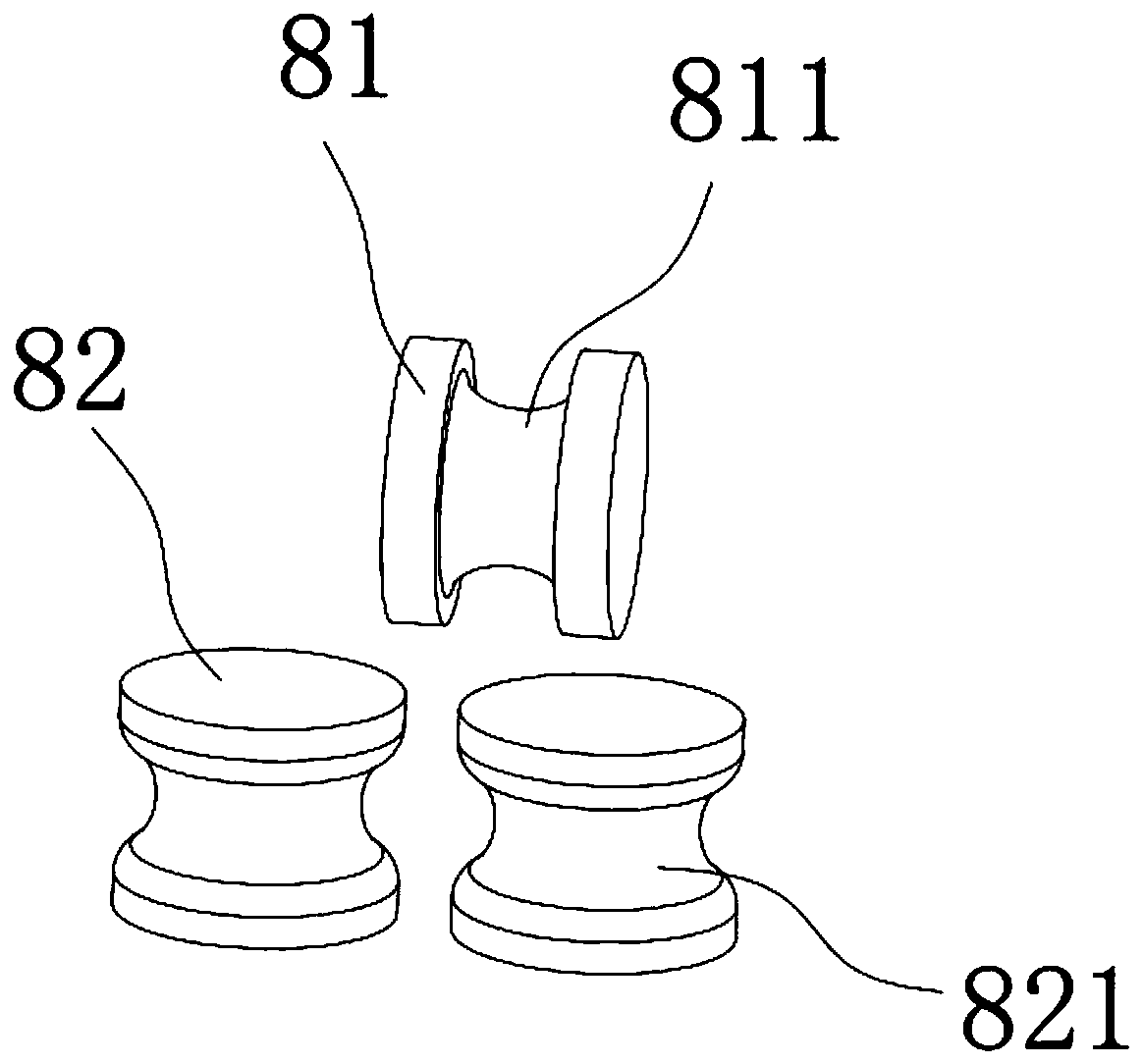

Automatic laminating device for copper-aluminum isolation aluminum foil

InactiveCN111469526AImprove heat exchange capacityImprove fit compactnessLamination plant layoutLamination ancillary operationsMetallurgyEngineering

The invention discloses an automatic laminating device for a copper-aluminum isolation aluminum foil. The device comprises a machine table, a counting mechanism, an aluminum foil pressing mechanism, an aluminum foil assembly, a cutter mechanism and a laminating mechanism; a counting station, a pressing station, a cutting-off station and a laminating station are sequentially arranged on the machinetable; an aluminum foil discharging station is arranged at the upper part of the pressing station; the counting mechanism is arranged at the counting station; the counting mechanism comprises a metercounter and a first supporting wheel; the aluminum foil pressing mechanism is arranged at the pressing station; the aluminum foil pressing machine comprises a first air cylinder, an aluminum foil pressing wheel and a second supporting wheel; an aluminum foil assembly is arranged at the aluminum foil discharging station and comprises an aluminum foil winding drum and an aluminum foil guide wheel,the cutter mechanism is provided with a cutting-off station, the cutter mechanism comprises a second air cylinder and a cutter, the laminating mechanism is arranged at the laminating station, and thelaminating mechanism comprises a vertical laminating wheel and a lateral laminating wheel.

Owner:滁州仕达家电配件有限公司

Laser Welding Method for Repairing Penetrating Defects of Base Metal

ActiveCN109664023BEnsure normal exposureAvoid crack defectsLaser beam welding apparatusWorkpiece edge portionsStructural engineeringLaser soldering

The invention relates to a laser welding method for a repairing penetrating defect of base metal. The method comprises the following steps that S1, the to-be-repaired defect of the base material is pretreated and machined into a groove weld joint with a wide upper portion and a thin lower portion; S2, the width of a weld joint lower groove is determined, if the width of the lower groove is greaterthan the diameter of a welding wire, at least one layer of convex weld welding are conducted on the two sides of the lower groove side by side in the length direction of the weld joint until the width of the lower groove is the same as the diameter of the welding wire, then priming layer welding is conducted on the weld joint between convex welds on the two sides, and if the width is smaller thanor equal to the diameter of the welding wire, the priming layer is directly welded; S3, multiple welding layers are superimposed and welded on the priming layer, a welding layer zone is formed, and the top of a welding layer block is lower than a weld joint upper groove; S4, a repair layer is superimposed and welded on the welding layer block, and the top of the repair layer is higher than the weld joint upper groove; and S5, the repair layer higher than the upper groove is ground, and thus the repair layer is flush with the upper groove.

Owner:丁二纲

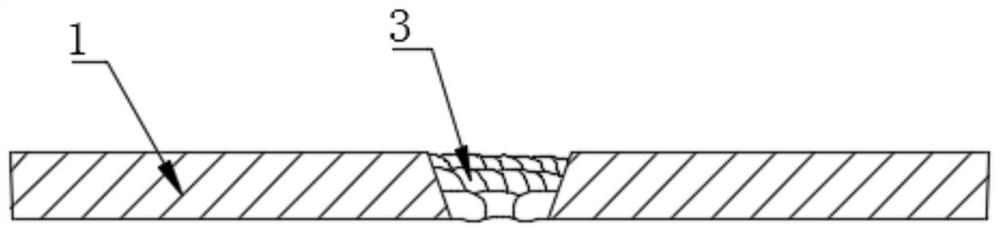

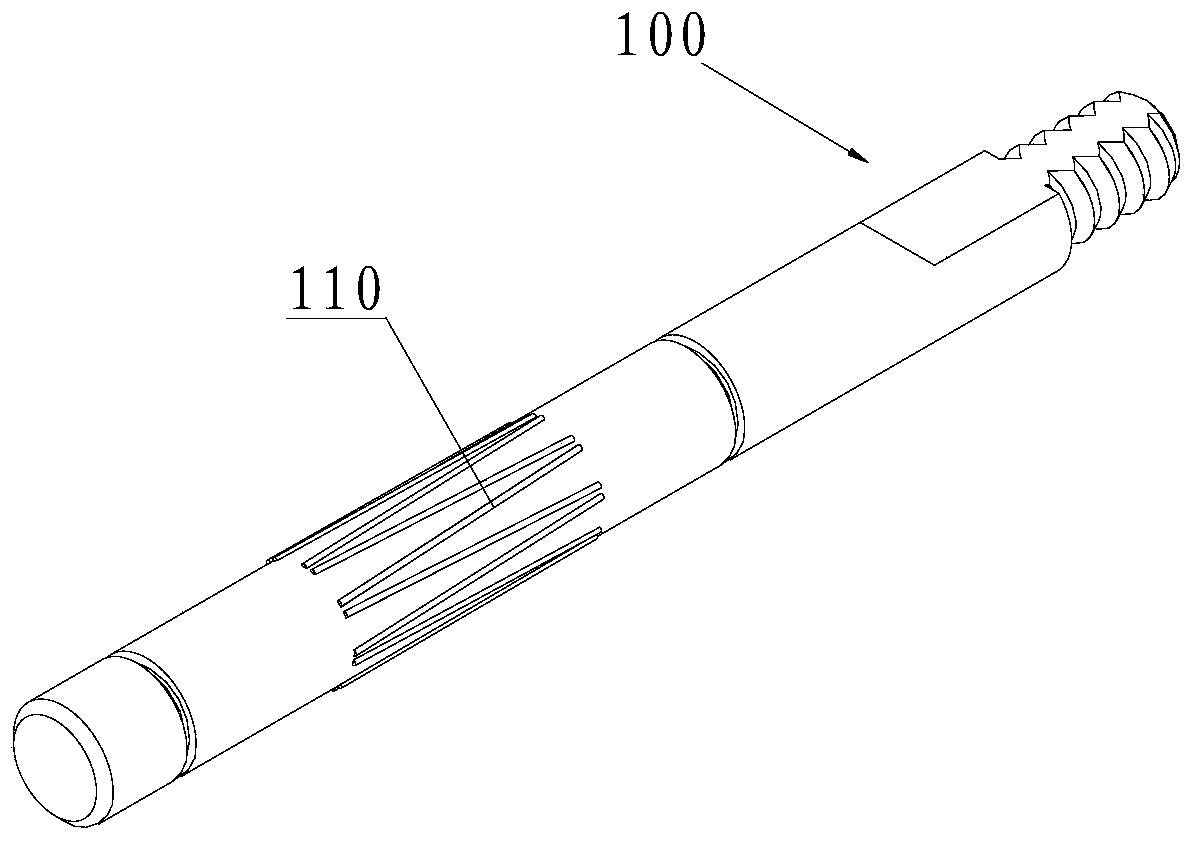

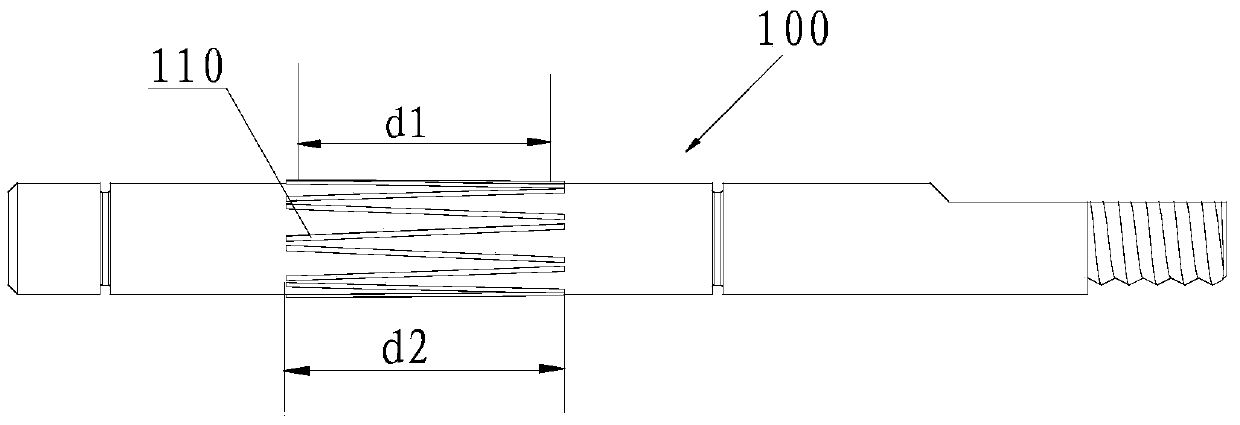

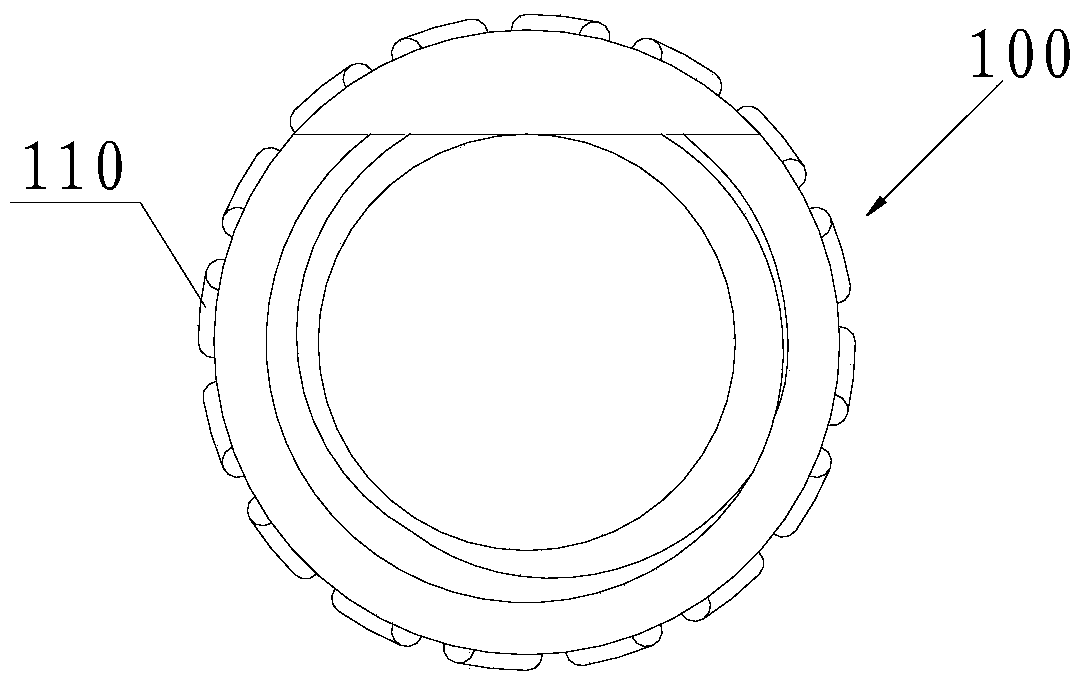

Rotor and motor

ActiveCN105529846BPrevent fallingReduce the difficulty of assemblyMagnetic circuit rotating partsRelative displacementEngineering

The invention discloses a rotor and a motor. The rotor comprises a rotor core and a rotor shaft (100), wherein the rotor shaft (100) is sleeved with the rotor core; a convex knurling (110) is arranged in a region, matched with the rotor core, of the rotor shaft (100); and the convex knurling (110) is not parallel to a center line of the rotor shaft (100). The convex knurling (110) is arranged on the rotor shaft (100); and the rotor shaft (100) is matched with the rotor core through the convex knurling (110), so that the defect caused by too high or too low magnitude of interference in the circumference fit process is avoided; the magnitude of interference between the rotor shaft (100) and the rotor core is increased under the premise of not increasing the difficulty that the rotor shaft (100) enters the rotor core; the difficulty of axial relative displacement of the rotor core and the rotor shaft (100) is increased; and falling of the rotor or the phenomenon of a poor test is effectively prevented.

Owner:GREE ELECTRIC APPLIANCES INC +1

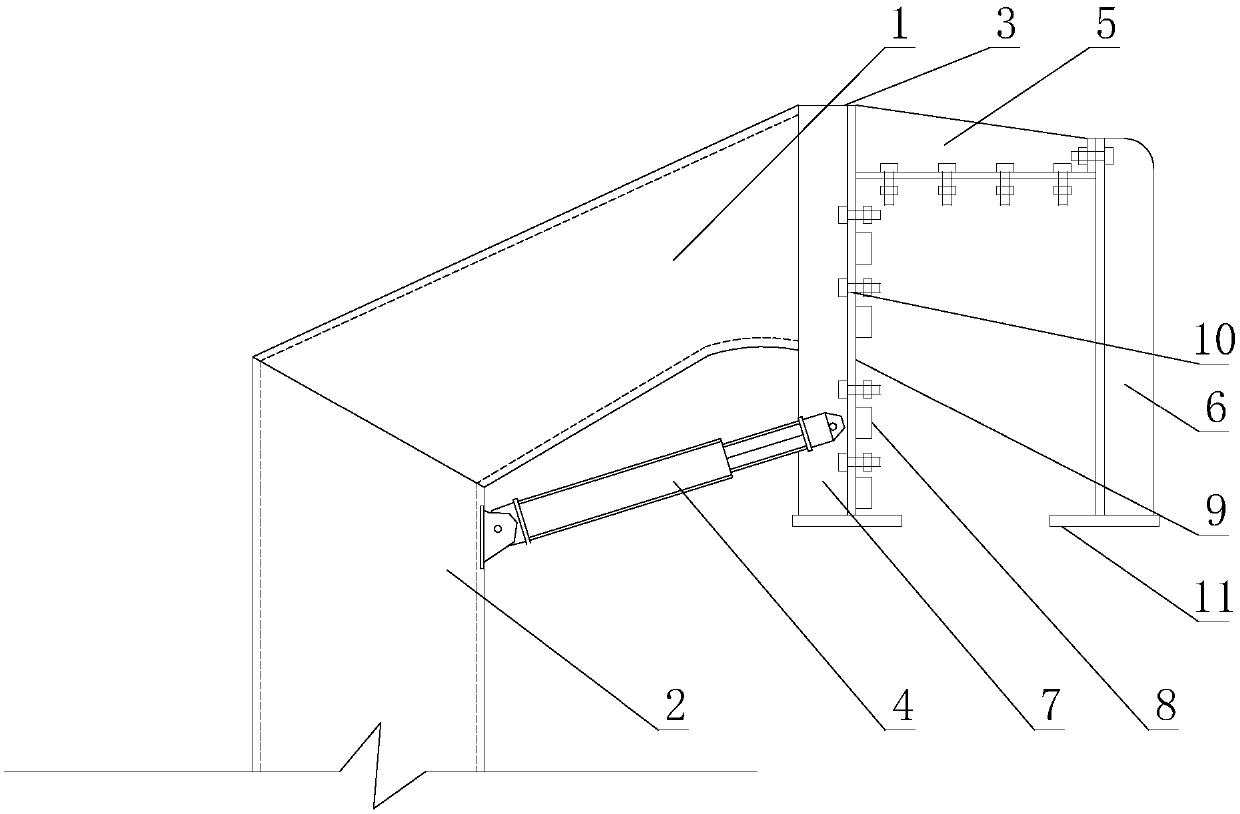

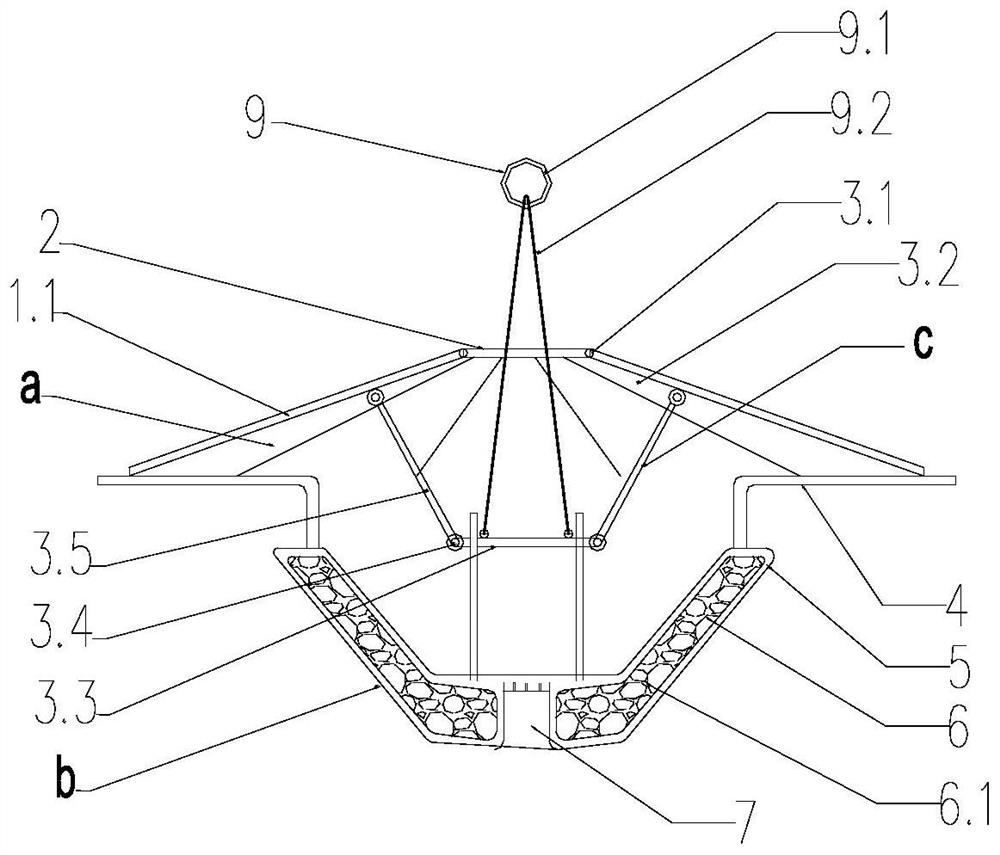

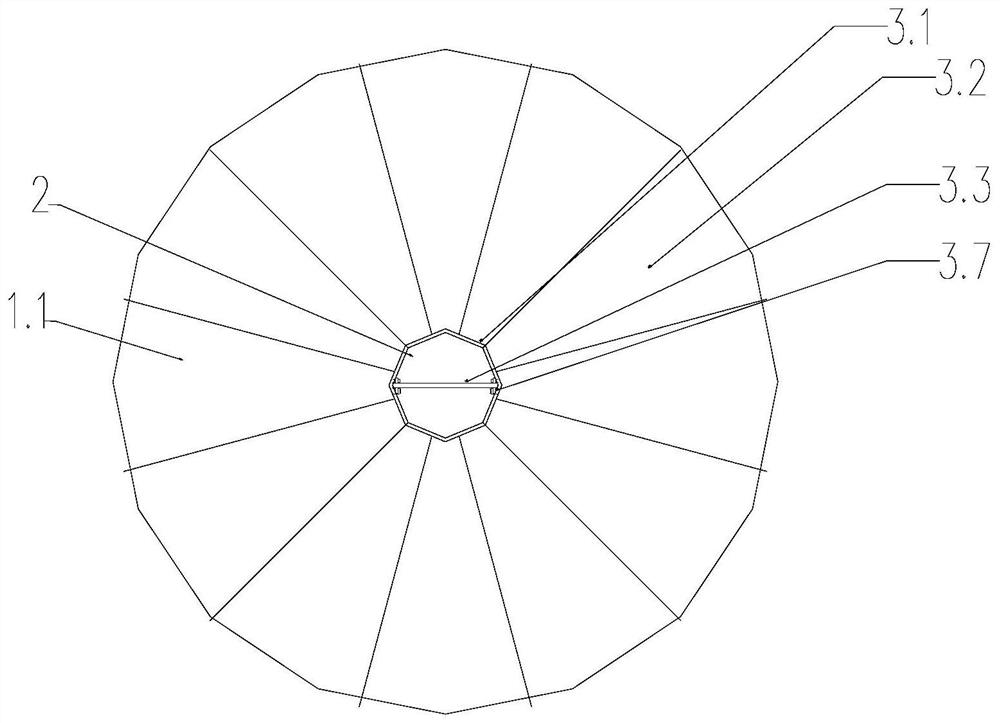

Sky railway beam column facilitating assembly of rail beam

ActiveCN108049262ANo effect on mechanical propertiesEasy to holdRailway tracksRailway transportArchitectural engineeringBeam column

The invention discloses a sky railway beam column facilitating assembly of a rail beam. The sky railway beam column comprises a stand column and a mounting section connected to the upper end of the stand column. The mounting section is used for being connected with the rail beam and comprises a mounting plate, a first connecting plate and a second connecting plate. One end of the first connectingplate is connected with the upper end of the mounting plate, and the other end of the first connecting plate is connected with the upper end of the second connecting plate. A door frame shape is defined by the first connecting plate, the second connecting plate and the mounting plate, a door type space for mounting the rail beam is defined by door-frame-shaped structures, and the first connectingplate serves as a cross beam of the door-frame-shaped structure. The mounting section is further provided with bolt holes used for connecting the rail beam and the mounting section through bolts. Themounting plate is fixedly connected with the stand column, and the second connecting plate and the first connecting plate are connected through bolts. The beam column is used for mounting the rail beam and has the characteristic that the rail beam is convenient to mount.

Owner:黑冻科技有限公司

Self-consumable simple thermal insulation cover of molten iron transport tank and its application method

ActiveCN109807314BAchieve full coverageImprove insulation effectMelt-holding vesselsInsulation layerSlag

Owner:武汉钢铁有限公司

Equipment for full-automatic detection of mobile phone line and use method thereof

ActiveCN113189469AEasy to fixAvoid problems that affect test resultsCleaning using toolsPrinted circuit testingComputer hardwareEmbedded system

The invention belongs to the technical field of mobile phone detection, and particularly relates to equipment for full-automatic detection of a mobile phone line and a use method of the equipment. The equipment includes a shell, a detection equipment assembly is mounted in the shell; the detection equipment assembly is installed on the inner side wall of the top of the shell. A rotating device is arranged on the inner side wall of the bottom of the shell; the rotating device is fixedly connected to the interior of the shell. A supporting table is arranged at the top end of the rotating device; the supporting table is fixedly connected to the rotating device. The top of the supporting table is fixedly connected with a sliding rod. A detection table is arranged at the top of the supporting table; a buffer cavity is formed in a position, corresponding to the sliding rod, of the bottom of the detection table. The top end of the sliding rod is fixedly connected with a first elastic film; the suction cups are mounted on the placement table of the detection equipment, so that the mobile phone circuit board can be stably fixed on the detection table after being placed in the detection device, and the problem that the detection result is affected due to displacement of the mobile phone circuit board on the detection table when the mobile phone circuit board is detected can be avoided.

Owner:深圳市磐锋精密技术有限公司

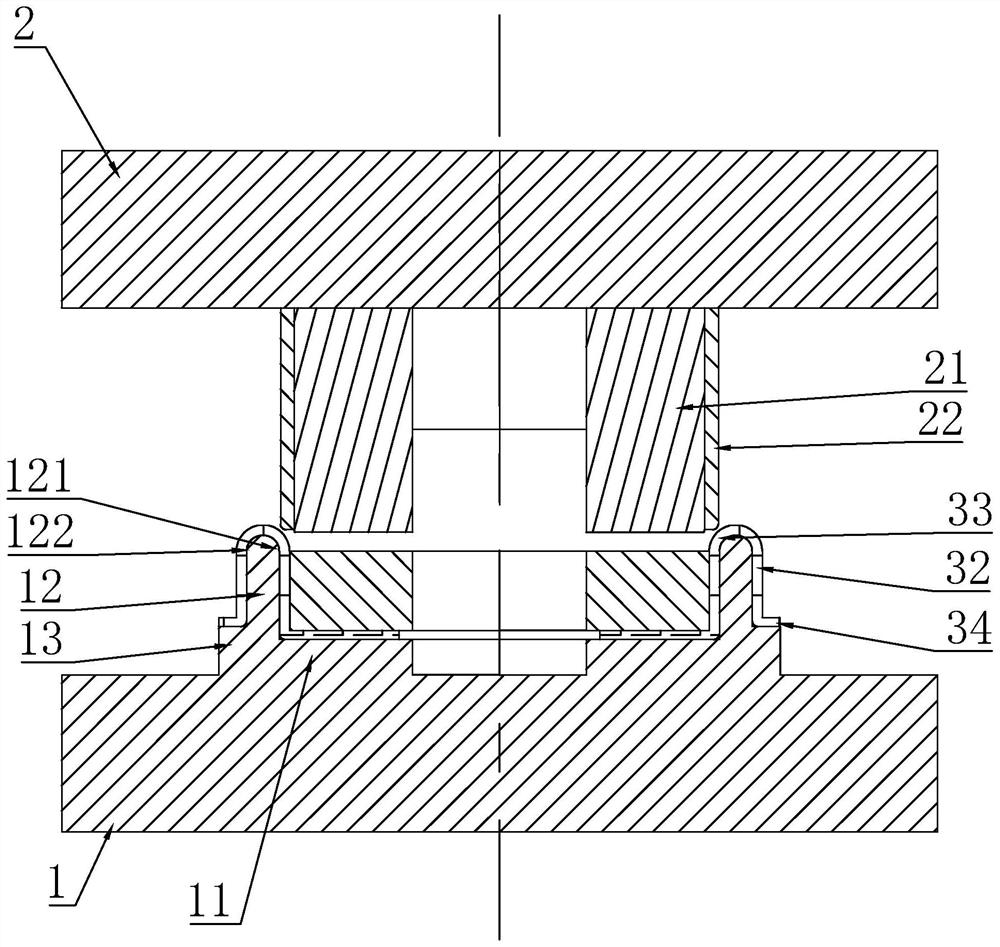

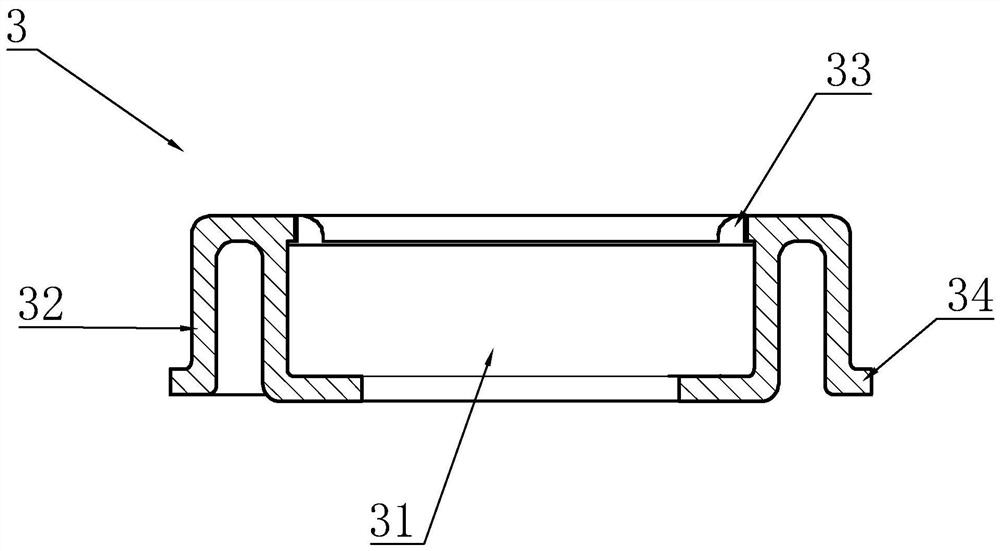

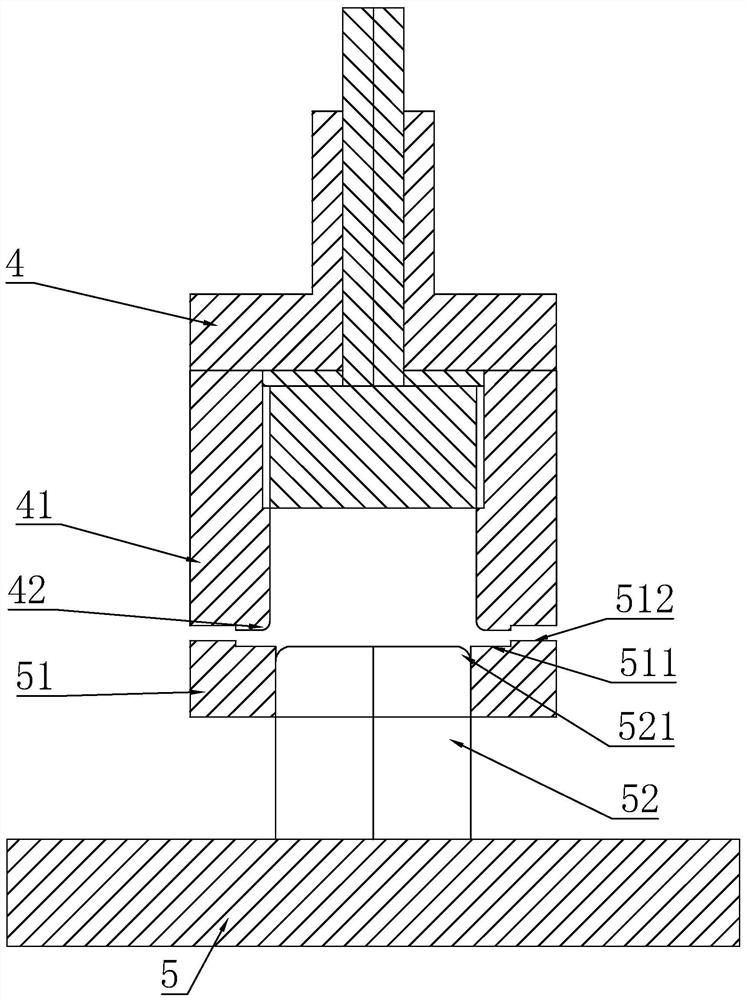

Machining device for stamping bearing with counterbore

The invention discloses a machining device for a stamping bearing with a counterbore. The machining device comprises the bearing, a stamping base arranged outside the bearing in a sleeving mode and a machining device body used for forming the stamping base and installing the stamping base into the bearing, a cavity allowing the bearing to be placed in is formed in the stamping base, a forming base is formed on the periphery of the stamping base through stamping, the forming base is arranged in a U shape with a downward opening, the bottom of the forming base is higher than the bottom of the stamping base, the machining device body comprises a riveting die, axial movement of the outer ring of the bearing is limited, and the assembling stability of the stamping base and the bearing is improved.

Owner:宁波三耐机械有限公司

A kind of preparation method of high elasticity warm polyester composite yarn

ActiveCN112921421BImprove uniformityGuaranteed uniformity of distributionArtificial thread manufacturing machinesFilament/thread formingYarnPolymer science

Owner:杭州一方化纤有限公司

Exposure platform of exposure machine

InactiveCN105093839BImprove the disadvantage of not being able to deform with the flatness of the substrateImprove fit compactnessPhotomechanical exposure apparatusMicrolithography exposure apparatusVacuum pumpingPhysics

The invention discloses an exposure platform of an exposure machine. The exposure platform comprises an exposure frame, an objective table, a plurality of elevating units and a light-transmitting plate, wherein the objective table can approach to or keep away from the exposure frame; an accommodating region is formed in the upper surface of the objective table, and is used for putting a substrate and projecting incident light of an exposure light source to the substrate; the elevating units are arranged on the exposure frame; and the light-transmitting plate is combined with a clamp of each elevating unit, and is driven by the elevating units to move towards or away from the accommodating region of the objective table. The light-transmitting plate of the exposure platform disclosed by the invention is fixed to the bottom surface of the exposure frame through the clamps and the elevating units; and when vacuum pumping is carried out in the exposure step of a circuit board manufacture procedure, the light-transmitting plate can be driven by the elevating units, can be fitted to the substrate, and can deform along with the flatness of the substrate, so that the fitting tightness of the light-transmitting plate and the substrate is increased to improve the exposure resolution ratio.

Owner:CHIME BALL TECH

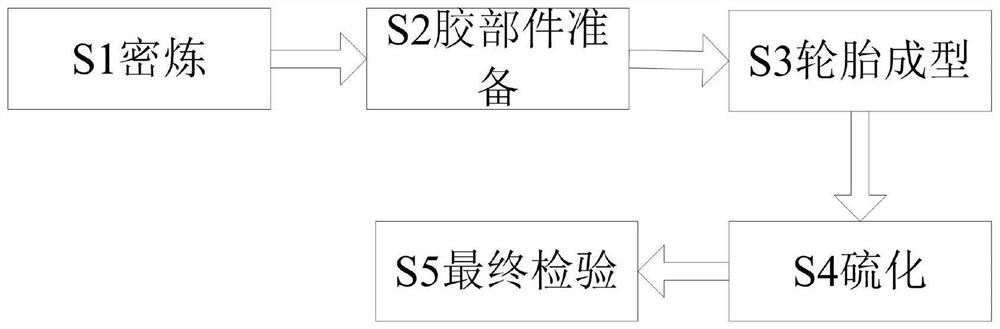

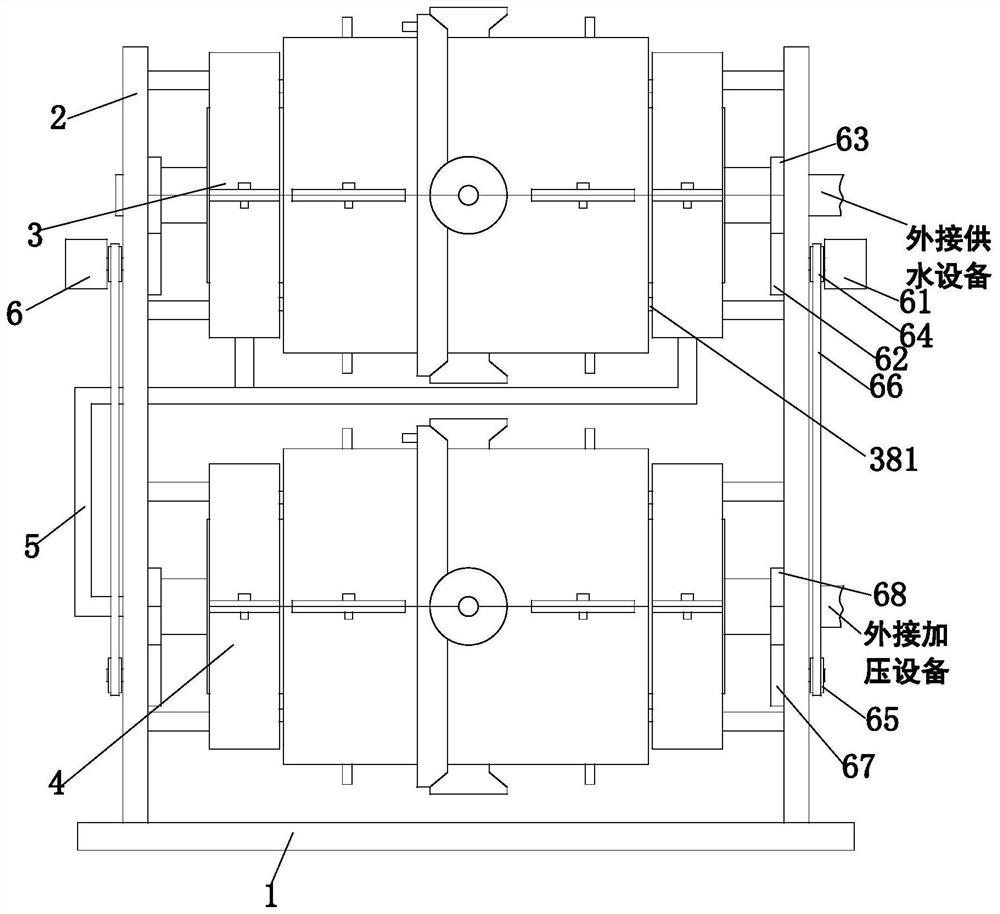

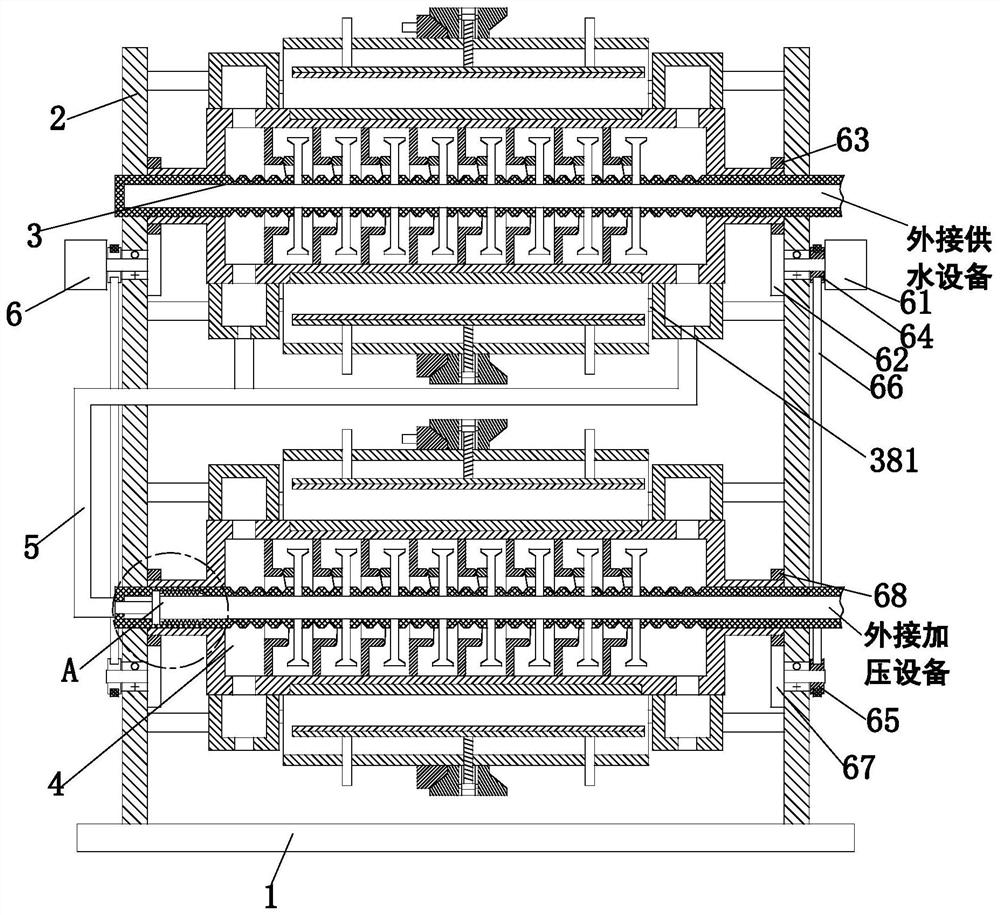

Rubber tire manufacturing process

InactiveCN112476892AAvoid situations of poor elasticityFast exchangeTyresVulcanizationCooling effect

The invention relates to a rubber tire manufacturing process. The process uses cord fabric cooling equipment, and the cord fabric cooling equipment comprises a bottom plate, a mounting plate, a firstcooling device, a second cooling device, a connecting pipe and a driving device. The specific process for preparing a rubber tire by adopting the cord fabric cooling equipment comprises the followingsteps of banburying, preparing a rubber part, forming the tire, performing vulcanizing and performing final inspecting. The first cooling device and the second cooling device which are different in temperature are arranged to conduct graded cooling treatment on cord fabric, the cooling efficiency can be improved, and meanwhile the situation that the elasticity of the cord fabric becomes poor due to the fact that the temperature of the cord fabric drops too fast is avoided; and after the temperature of cooling water of the first cooling device rises to a certain degree, the cooling water can beused for the second cooling device to cool the cord fabric, the overall water consumption is reduced, the contact area and the attachment tightness of the cord fabric and the surface of a cooling roller are increased through an auxiliary mechanism in the cooling process, the heat exchange speed is increased, and the cooling effect is guaranteed.

Owner:李岑丽

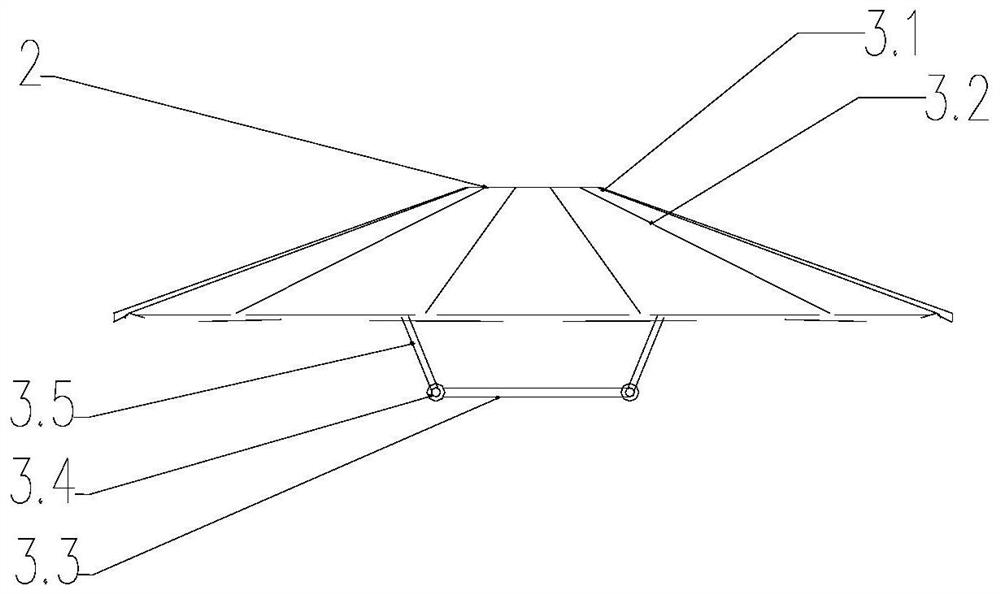

Sunshade production clamping device based on looseness prevention

InactiveCN114589630AGuaranteed bonding efficiencyAvoid the problem of offset in processing and grindingGrinding work supportsGrinding/polishing safety devicesStructural engineeringMachining

The sunshade production clamping device based on looseness prevention comprises a clamping block and an umbrella rod, one side of the clamping block is fixedly connected with a hydraulic push rod, a clamping and stabilizing mechanism is arranged in the clamping block, and the sunshade production clamping device has the advantage of being high in practicability. By arranging a clamping and stabilizing mechanism, a push block is pushed into a sliding groove, an elastic plate deforms, after the push block is pushed into the sliding groove, a clamping block is pushed continuously, the surface of the clamping block is tightly attached to the outer wall of an umbrella rod, and therefore the umbrella rod is clamped, and the machining efficiency is greatly improved during long-time machining. When the problem that the attaching degree of one side of a clamping block and the outer wall of the umbrella rod is reduced due to slight deviation of the clamping block and a hydraulic push rod occurs, a push block in the clamping block is tightly attached to the outer wall of the umbrella rod again through the rebound force of an elastic plate, and therefore the attaching efficiency of the outer portion of the umbrella rod is automatically guaranteed; and the problem that after long-time clamping and machining, deviation occurs in machining and polishing due to looseness is avoided.

Owner:NANTONG ZHAOWEN LEISURE PROD CO LTD

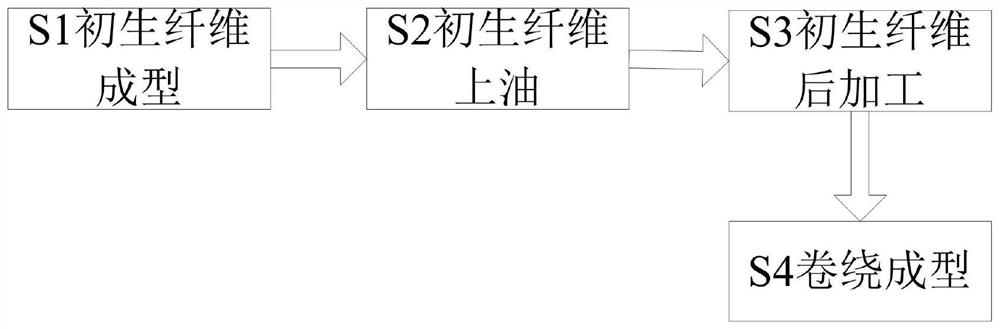

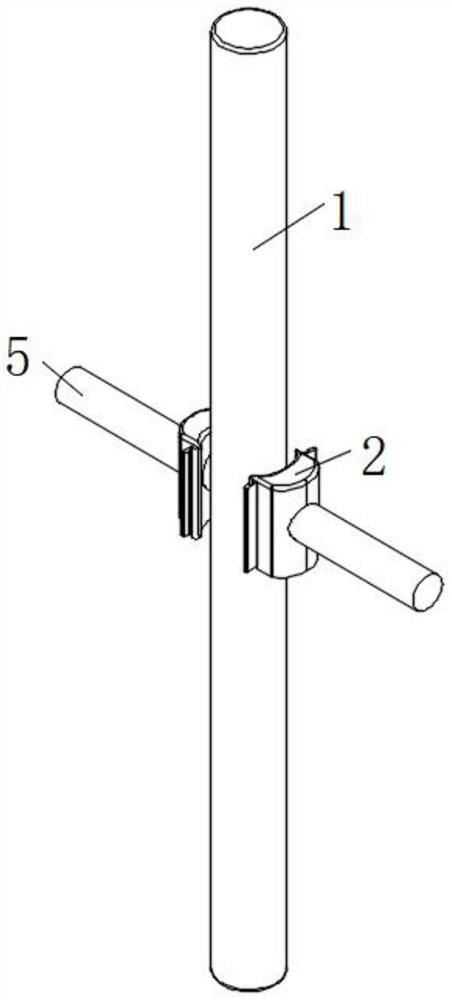

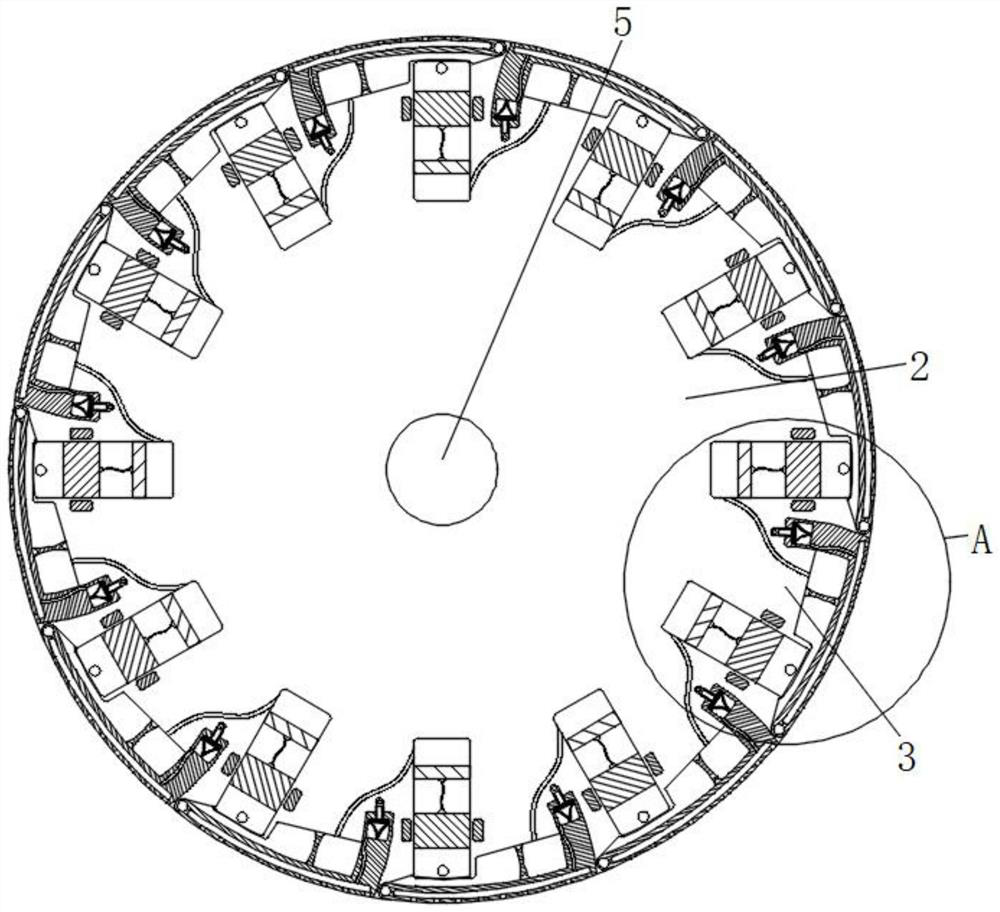

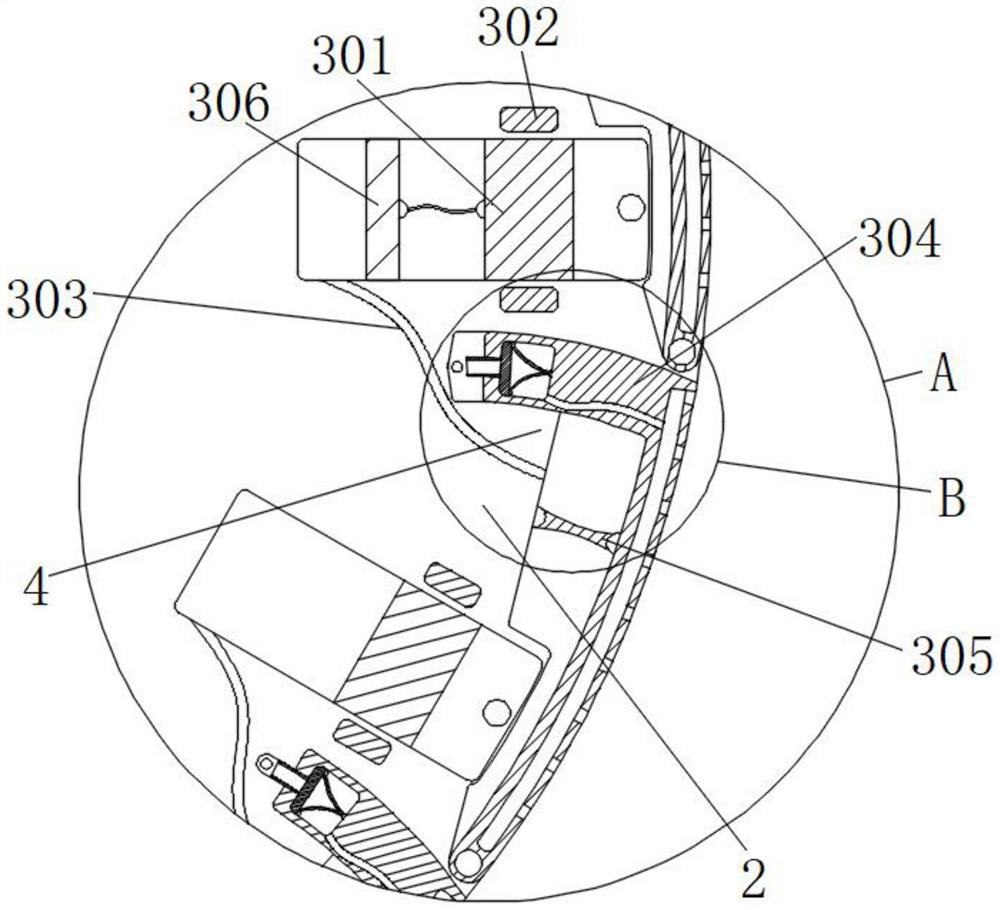

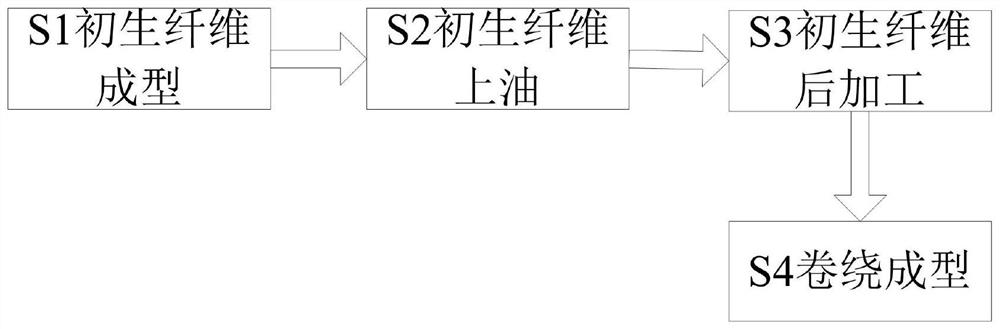

Preparation method of high-elasticity warm-keeping polyester composite filament

ActiveCN112921421AImprove uniformityGuaranteed uniformity of distributionArtificial thread manufacturing machinesFilament/thread formingYarnPolymer science

The invention relates to a preparation method of a high-elasticity warm-keeping polyester composite filament. Oiling equipment is used comprises a bottom plate, a mounting plate, an oiling device and a recovery box. The specific method for preparing the high-elasticity warm-keeping polyester composite yarn by adopting the oiling equipment comprises the following steps of forming nascent fibers, oiling the nascent fibers, post-processing the nascent fibers, and winding and forming. An oiling device comprises a fixing rod, a rotating cylinder, an auxiliary mechanism, a driving mechanism, an oil storage cylinder, an oiling sponge sleeve, an oil absorption column, a sliding block, an oil baffle plate, a limiting cylinder, a connecting rod, a moving rod and a fixing ring. The oiling device is matched with existing traction equipment to complete oiling work of the nascent fibers, and the oil absorption column and the limiting cylinder are driven to stir lubricating oil through relative movement between the moving rod and the fixing ring in the oiling process; and meanwhile, the attaching tightness between the nascent fibers and the oiling sponge sleeve is increased through the auxiliary mechanism, and the oiling uniformity is improved.

Owner:杭州一方化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com