A kind of preparation method of high elasticity warm polyester composite yarn

A polyester composite yarn, high elasticity technology, used in filament/thread forming, complete sets of equipment for the production of artificial threads, fiber processing, etc., can solve the problems of uneven oiling, low bonding tightness, and low oiling efficiency , to ensure the uniformity of distribution, prevent precipitation, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

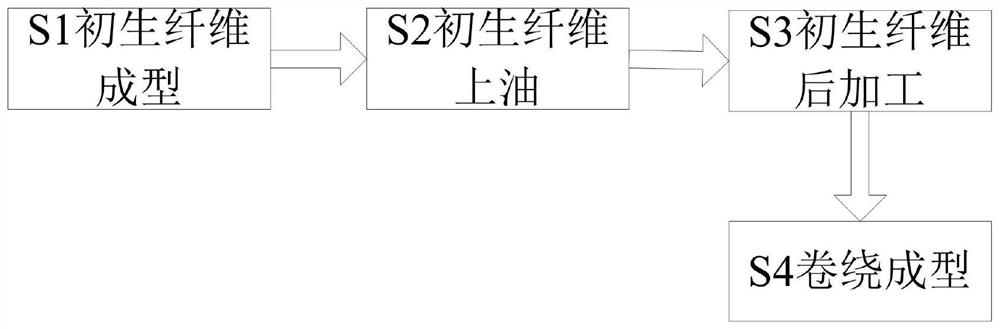

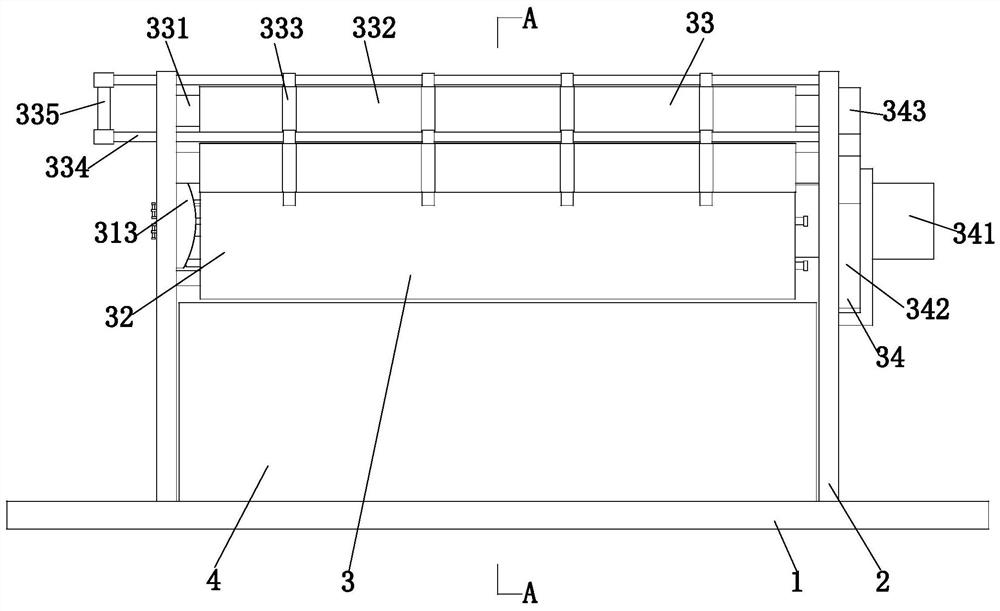

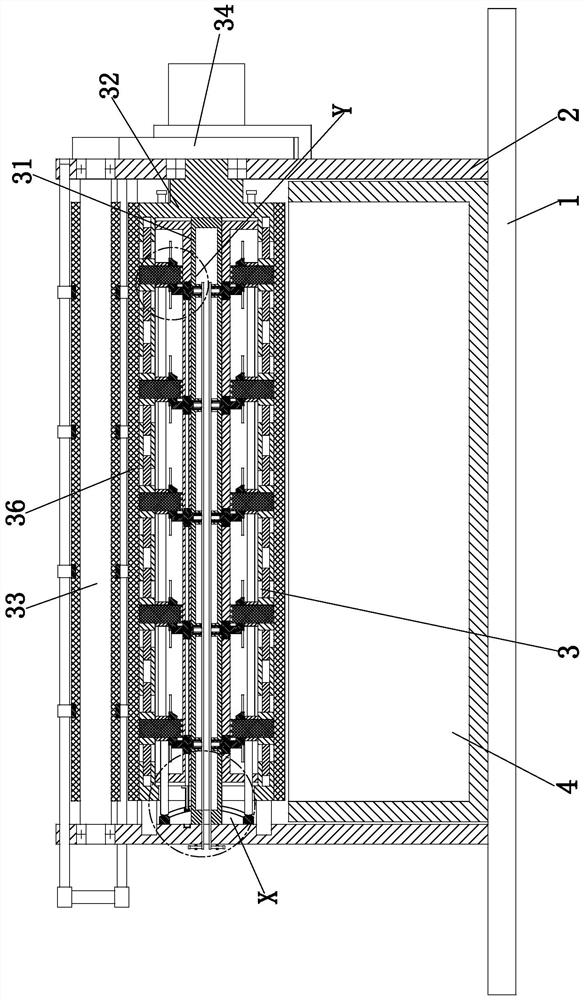

[0036] Such as Figure 1 to Figure 7 As shown, a method for preparing a high-elastic warm polyester composite yarn uses a kind of oiling equipment, the oiling equipment includes a bottom plate 1, a mounting plate 2, an oiling device 3 and a recovery box 4, and is prepared by the above-mentioned oiling equipment The specific method and flow of high elastic thermal insulation polyester composite yarn is as follows:

[0037] S1. Nascent fiber forming: use a melt spinning machine to extrude the raw materials mixed in proportion from the spinneret hole, and the polymer fine stream is solidified and formed in the spinning field to obtain a nascent fiber;

[0038] S2. Oiling of primary fibers: Use oiling equipment to cooperate with traction equipment to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com