Rotor and motor

A rotor and rotor shaft technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as defect, easy relative displacement, rotor drop test, etc., to reduce assembly difficulty, increase difficulty, Avoid or test the effect of undesirable phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

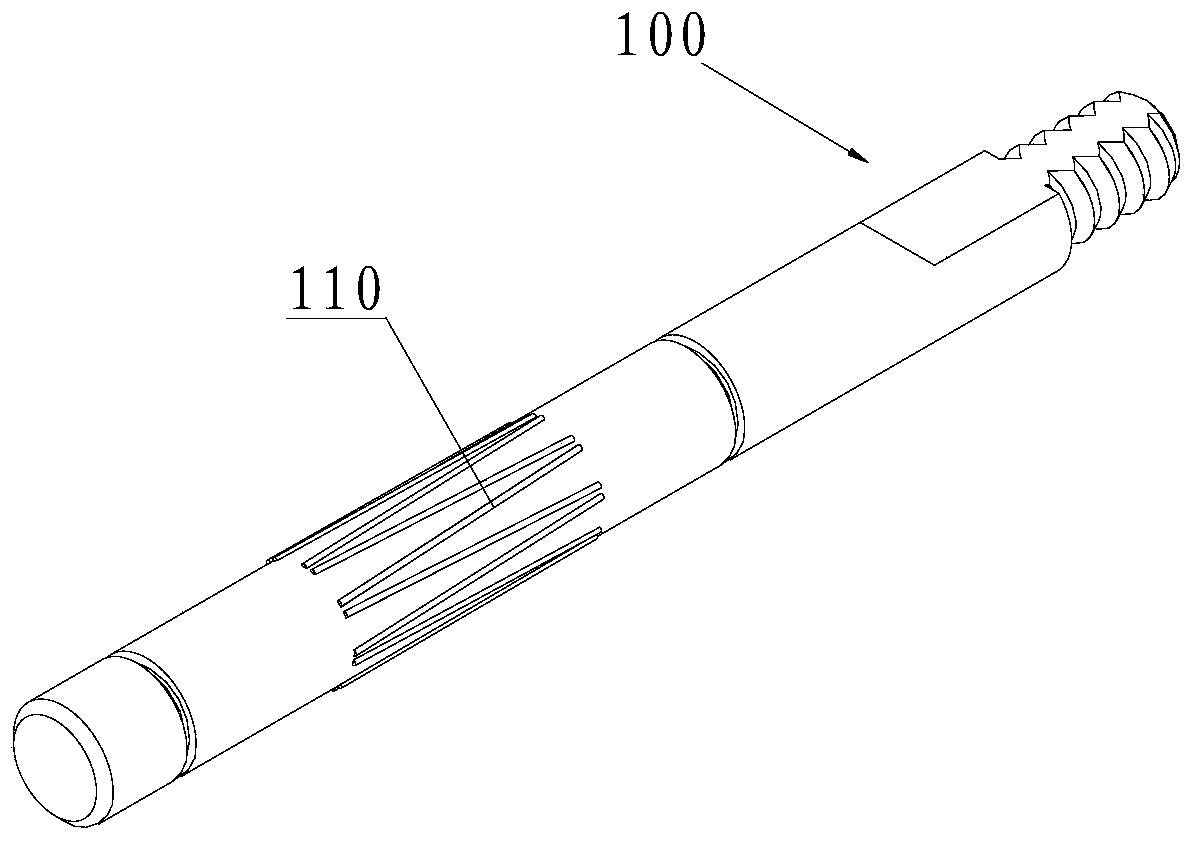

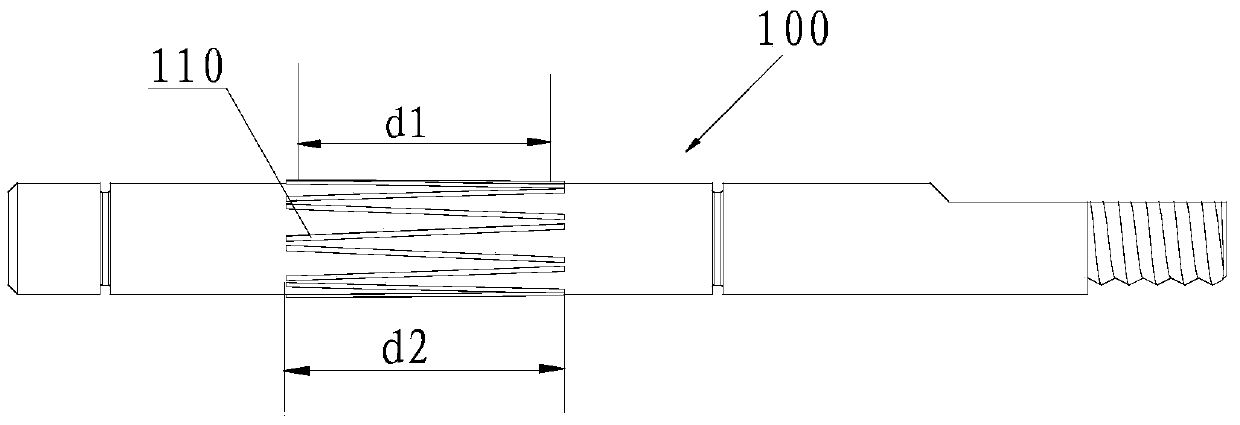

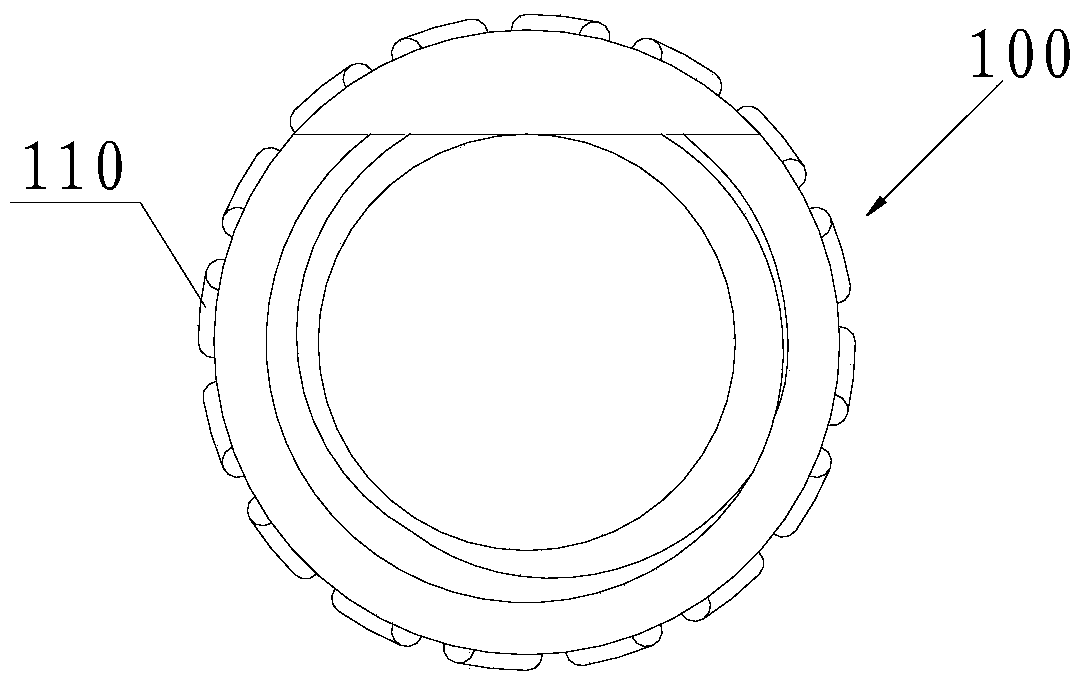

[0022] see Figure 1 to Figure 3 , the present invention provides a rotor, including a rotor core and a rotor shaft 100 sleeved in the rotor core. Wherein, a raised knurling 110 is provided on the area of the rotor shaft 100 mated with the rotor core, and the raised knurling 110 is not parallel to the centerline (axis) of the rotor shaft 100 .

[0023] The rotor of the present invention is mainly improved on the rotor shaft 100. On the basis of the traditional rotor shaft, the rotor shaft 100 of the present invention is provided with raised knurling 110 on the area matching the rotor core, without increasing the rotor Under the premise that it is difficult for the shaft 100 to enter the iron core, the interference and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com