Patents

Literature

58results about How to "Automatically compensates for wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

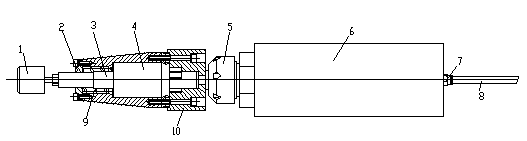

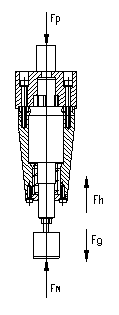

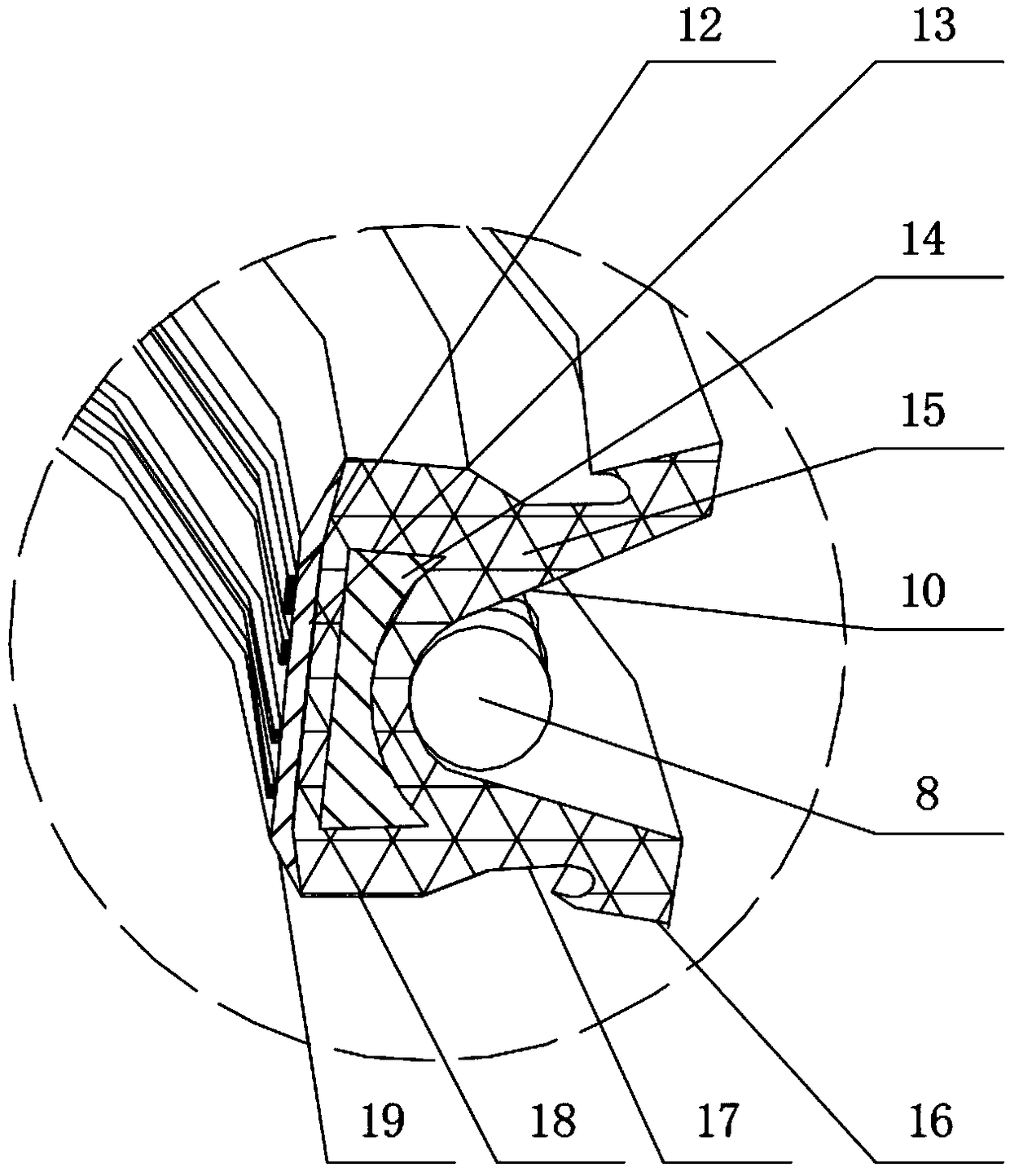

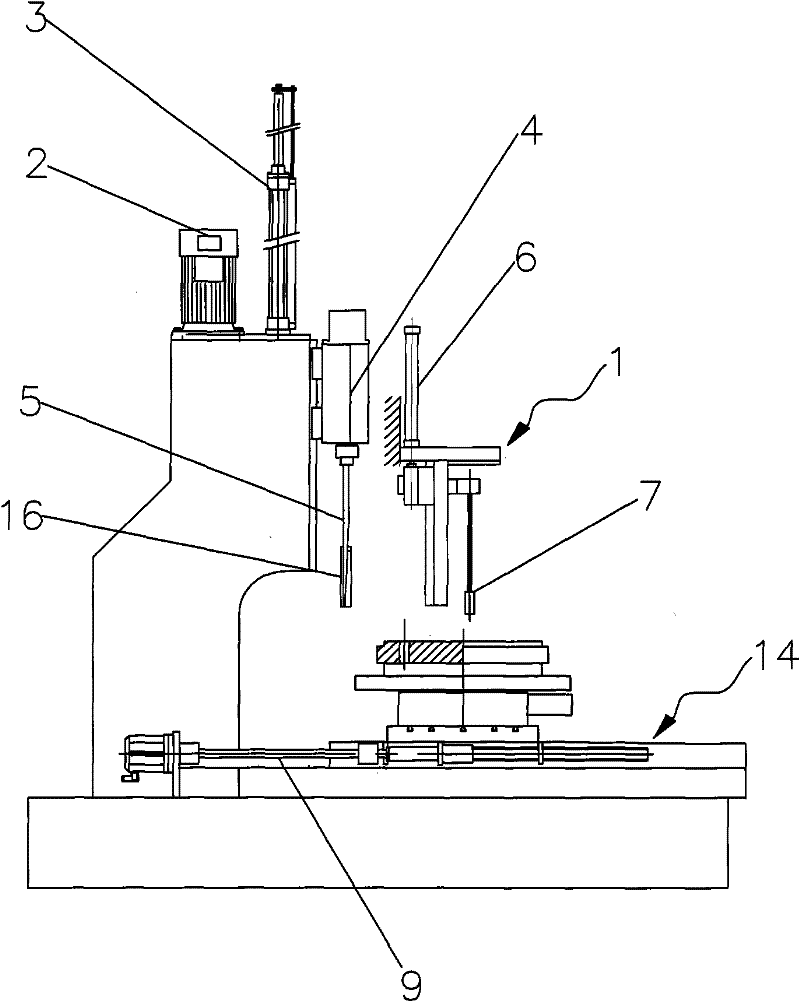

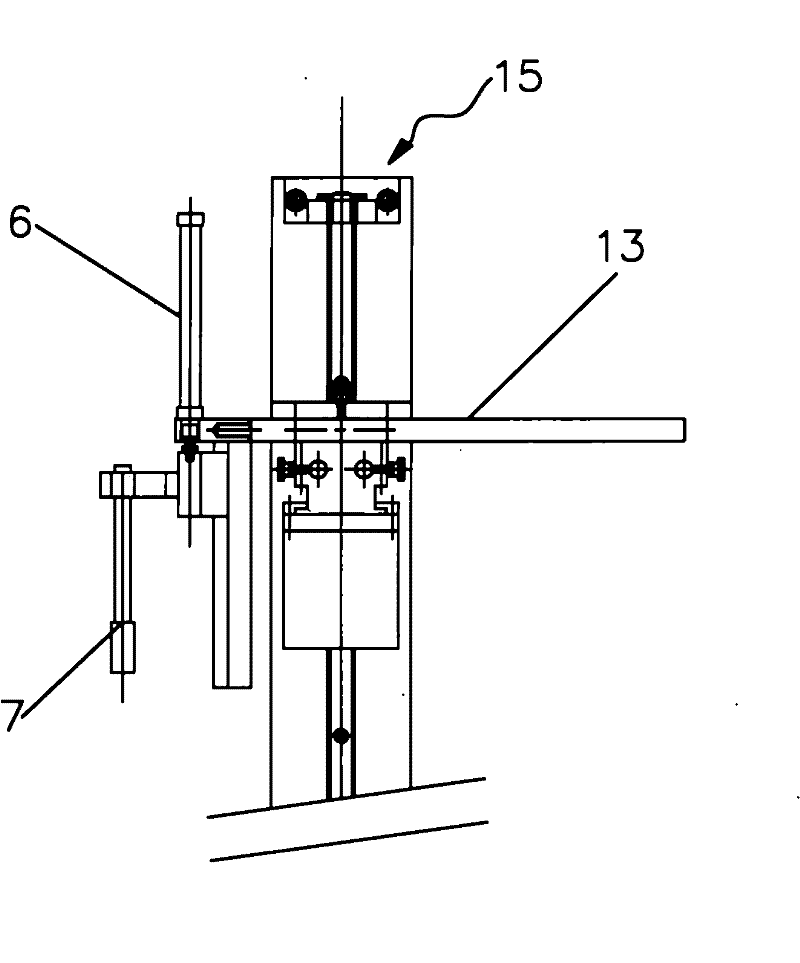

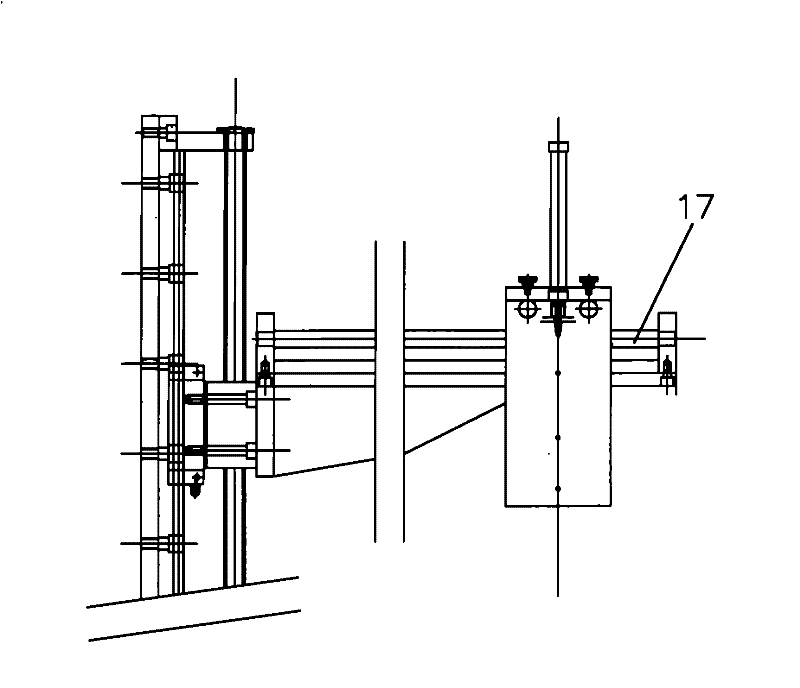

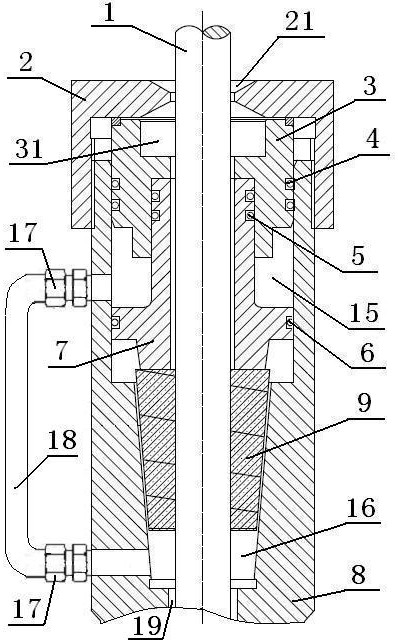

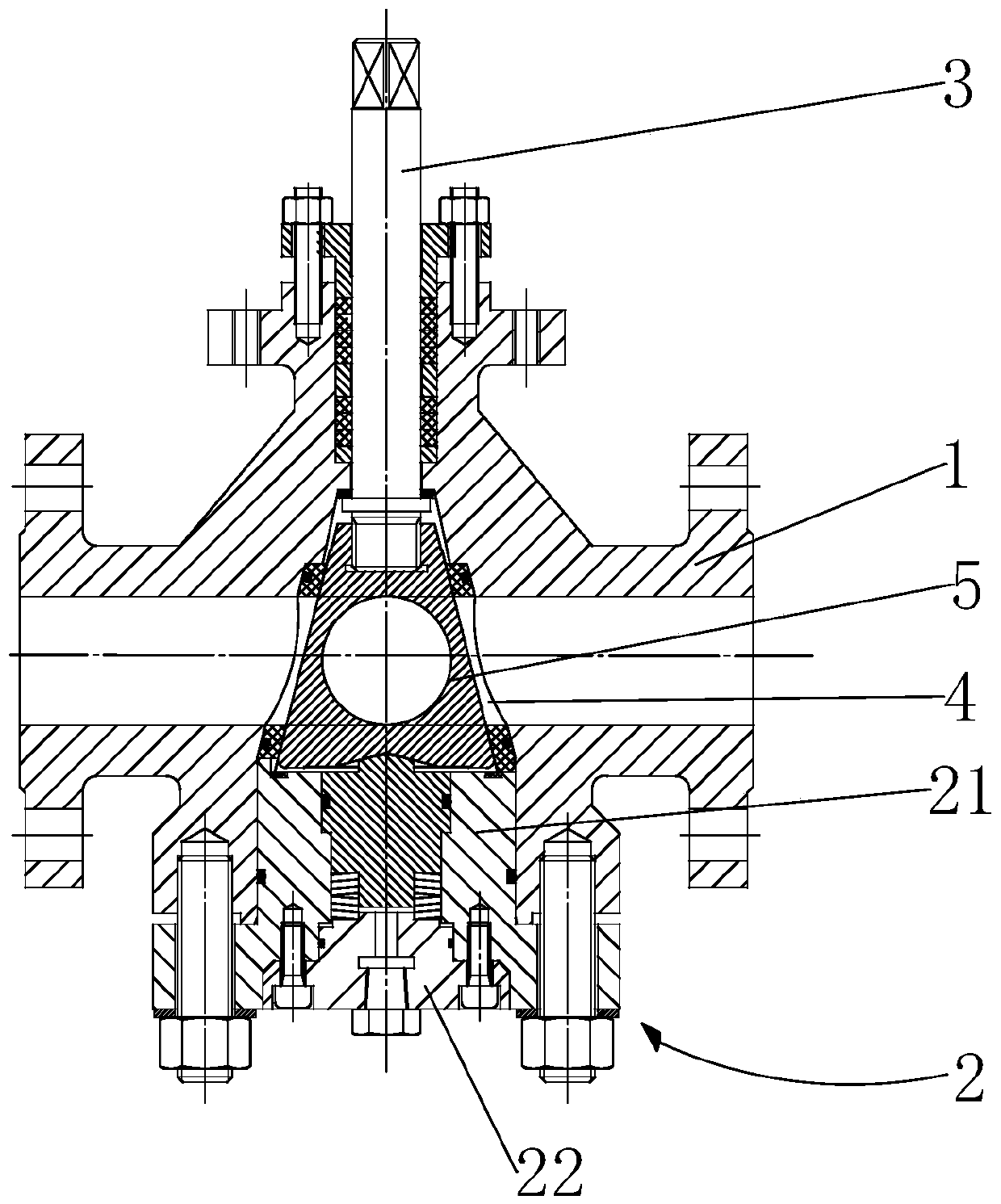

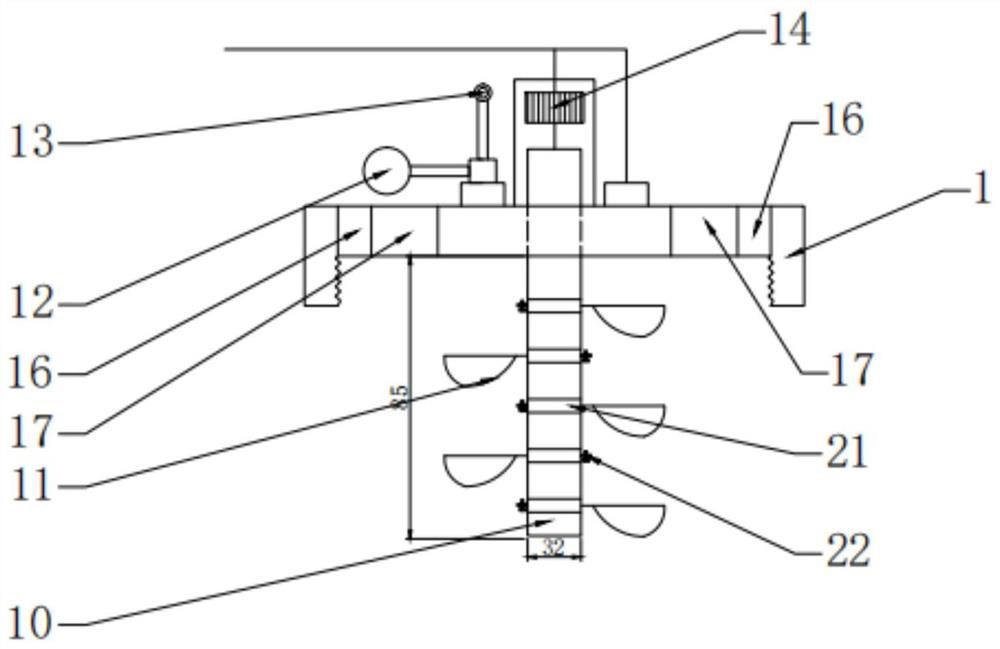

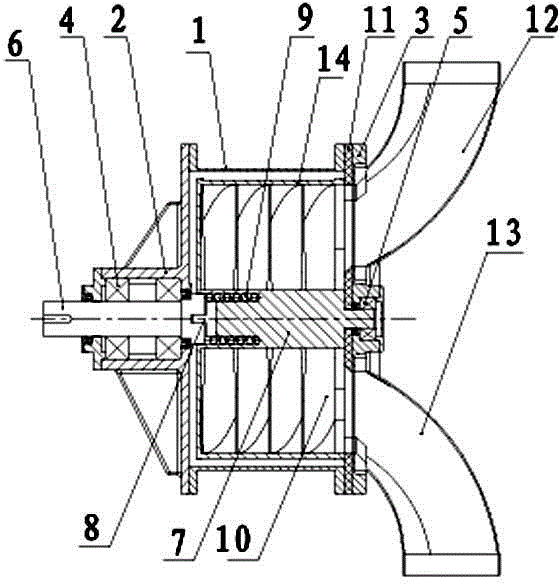

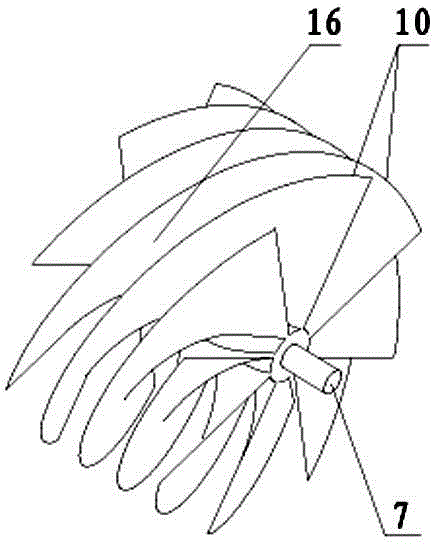

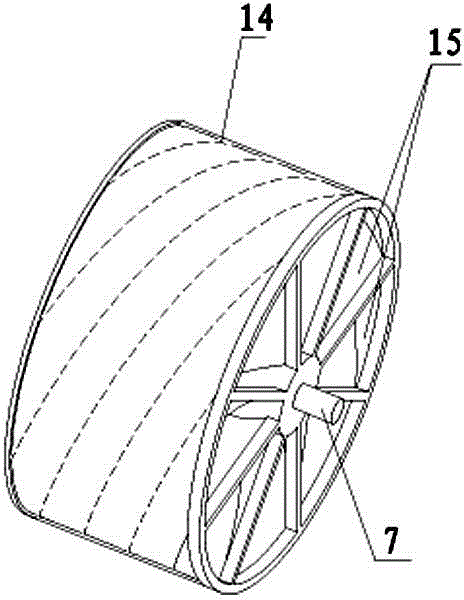

Floating finishing-machining grinding head with controllable grinding force

ActiveCN103522176AAutomatically compensates for wearRealize automatic finishingGrinding headsNumerical controlSystem pressure

The invention relates to a floating finishing-machining grinding head with controllable grinding force. The floating finishing-machining grinding head with the controllable grinding force comprises a grinding head body, a grinding tool head connected with the front end of the grinding head body in a floating mode, a driving mechanism arranged at the rear end of the grinding head body and a grinding pressure control element, wherein a pressure cavity communicated with compressed air is formed inside the grinding head body to meet balancing conditions, and the inside of the pressure cavity is system pressure (the system pressure is provided by the compressed air, and the intensity of the system pressure is controlled by the grinding pressure control element), grinding force, gravity, compensation spring force and frictional force of all movement parts. The floating finishing-machining grinding head with the controllable grinding force can finish different finishing-machining processes such as precision grinding, grinding and polishing through the grinding head composed of the compressed air, a compensation spring and a pressure control and adjustment element, and can automatically compensate tool abrasion in the finishing-machining process. Movement trajectory planning of a finishing-machining tool is carried out by means of CAD / CAM software, and a matched industrial robot or a digital-control machine tool can finish automatic finishing machining of a complex profile surface.

Owner:江苏省(扬州)数控机床研究院 +1

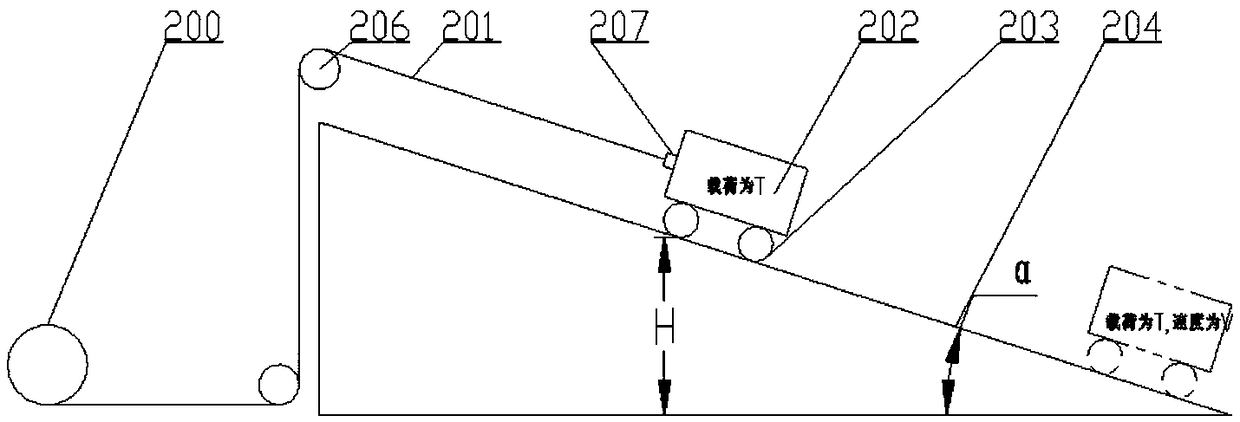

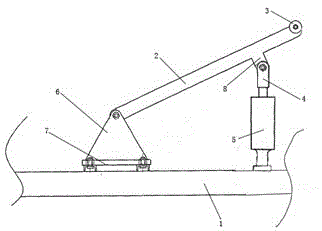

Method for lifting and releasing descending mechanism through intelligent winch device

ActiveCN108946547AIncrease decelerationImprove braking effectWinding mechanismsFluid-pressure actuator componentsBrake torqueControl system

The invention discloses a method for lifting and releasing a descending mechanism through an intelligent winch device. The method comprises the following steps that an information acquisition elementis arranged on an output shaft of a winding drum, the movement speed and position information of a load vehicle which is lifted through the winding drum are acquired; a caliper disc brake is arrangedon the output shaft of the winding drum; a plurality of hydraulic oil ports of the caliper disc brake are connected with a hydraulic system provided with an electromagnetic overflow valve, a proportional pressure reducing valve and an electromagnetic reversing valve correspondingly; the hydraulic system, the information acquisition element and the control system are connected correspondingly, thecontrol system is enabled to control one or more of the electromagnetic overflow valve, the proportional pressure reducing valve and the electromagnetic reversing valve to act according to the movement speed and the position of the load vehicle, the oil supply pressure of the hydraulic system to the caliper disc brake is adjusted so as to adjust the brake torque of the caliper disc brake to the load vehicle. According to the method, the caliper disc brake directly brakes the output shaft of the winding drum, the brake torque is large and adjustable, so that the caliper disc brake is suitable for braking the large load, and the speed reducing and braking effects on the load vehicle are improved.

Owner:63921部队

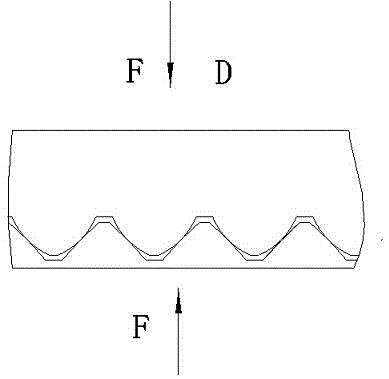

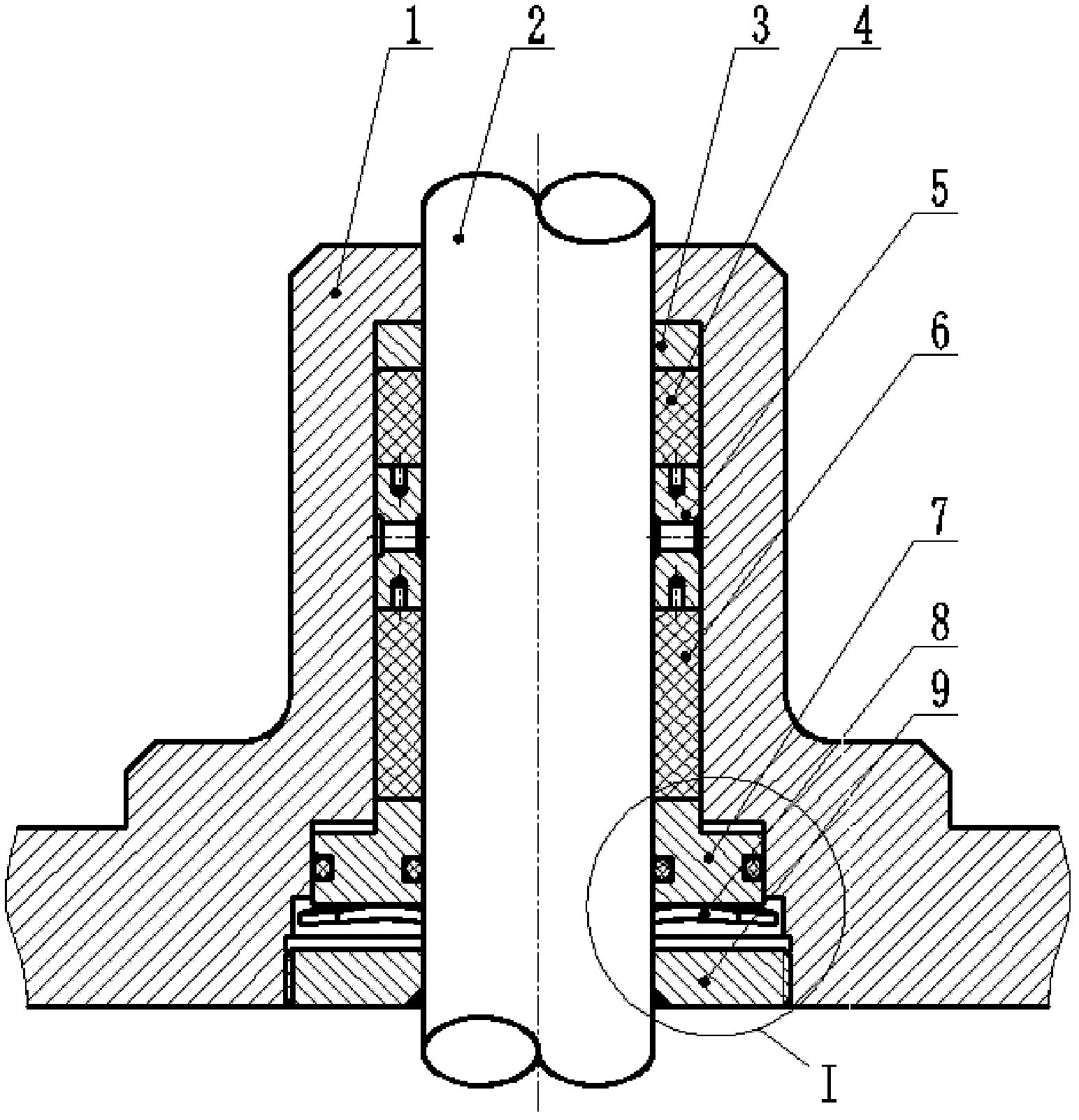

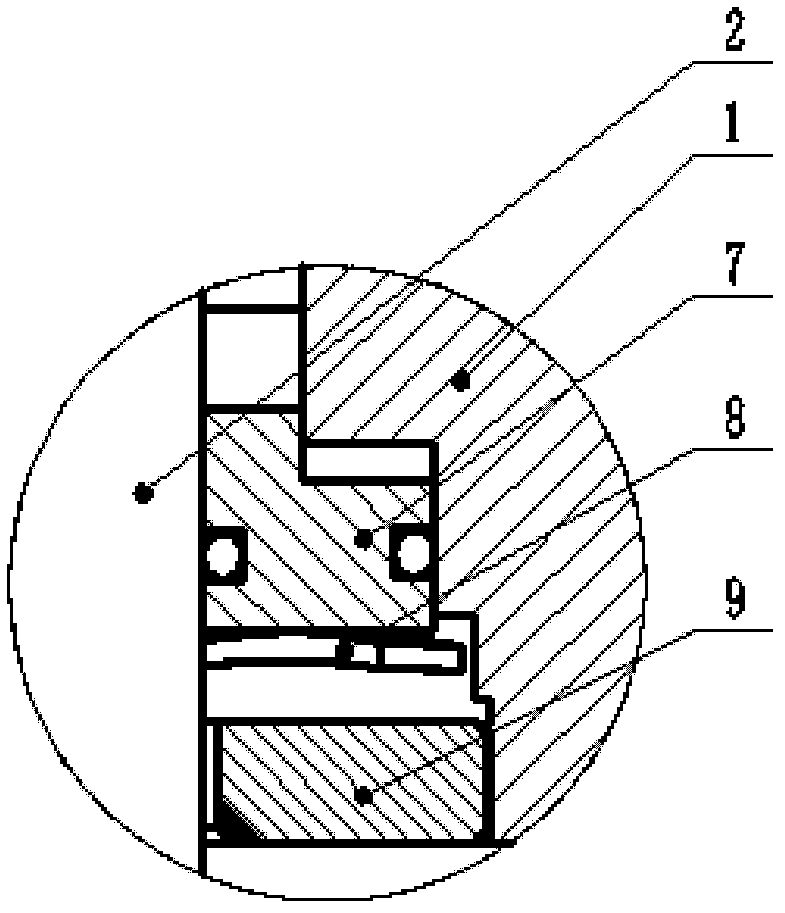

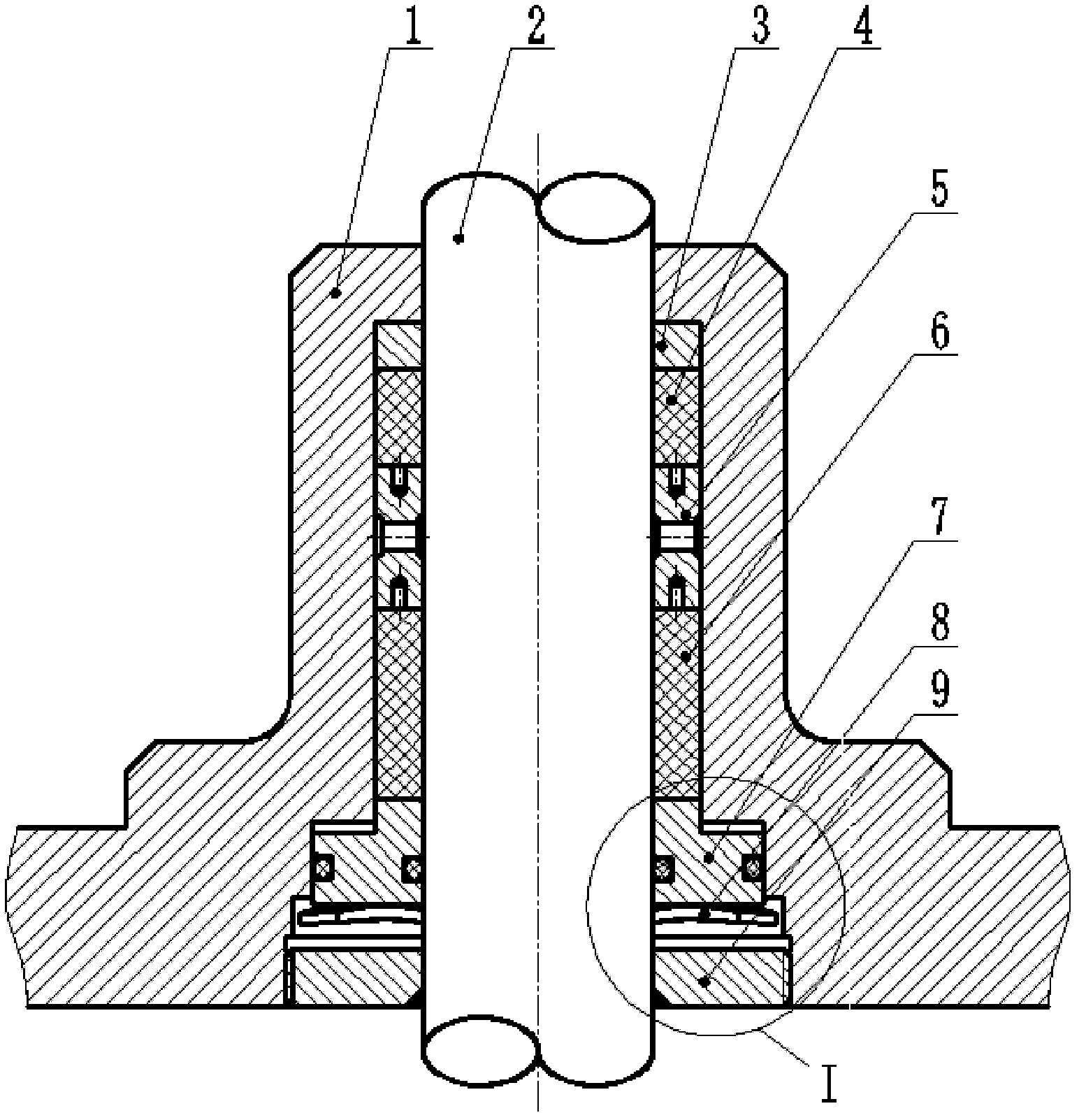

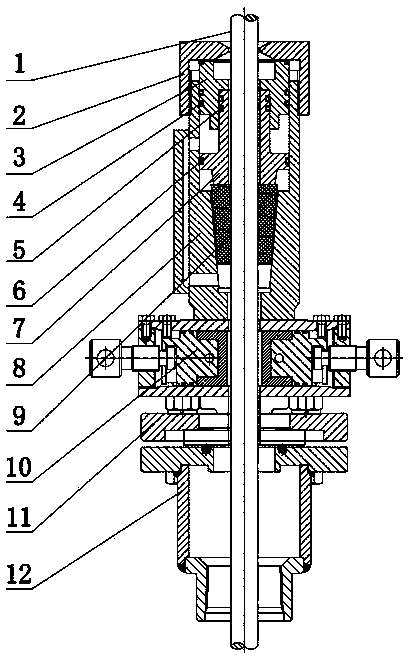

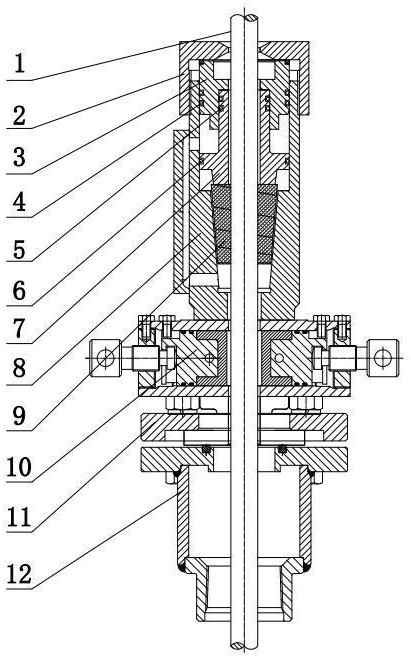

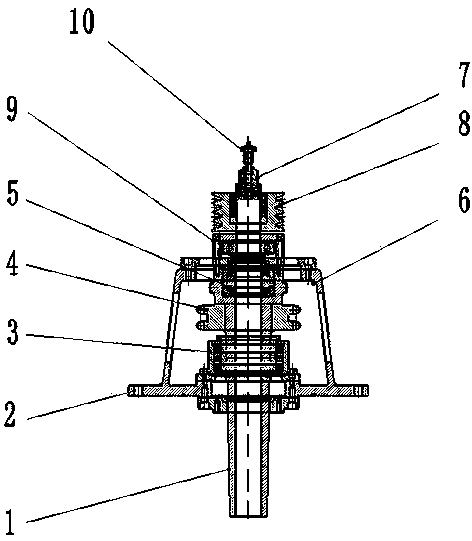

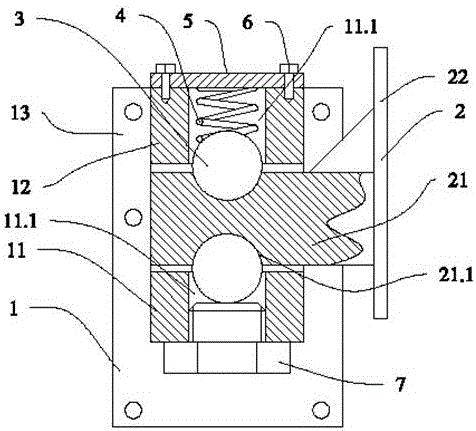

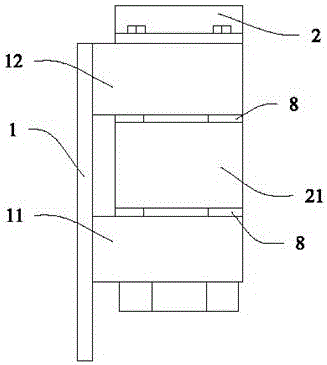

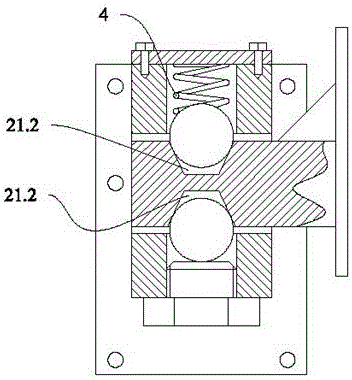

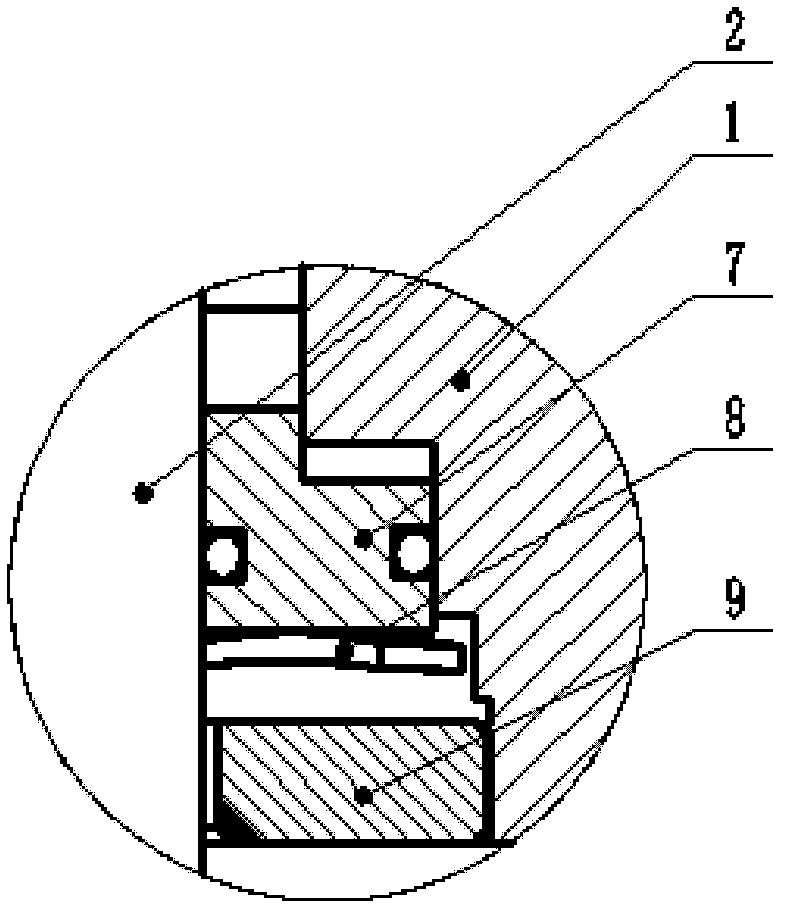

Planetary roller screw with clearance eliminating nut

The invention discloses a planetary roller screw with a clearance eliminating nut. The planetary roller screw with the clearance eliminating nut is used for eliminating the axial clearance between a roller and a nut and the axial clearance between a roller and a screw at the same time. According to the technical scheme, on the basis that elastic elements (7 and 9) are added to half nuts (6 and 10) respectively for pretightening, the clearance eliminating nut (8) is used in cooperation, pretightening force is generated through the combined action of elastic deformation of the elastic elements (7 and 9) and elastic deformation of an elastic thin-wall radial plate A in the clearance eliminating nut (8), and therefore the effect of eliminating the axial clearance between the roller and the nut and the axial clearance between the roller and the screw is achieved. The planetary roller screw with the clearance eliminating nut is simple in structure, convenient to manufacture and high in practicability.

Owner:姚琴

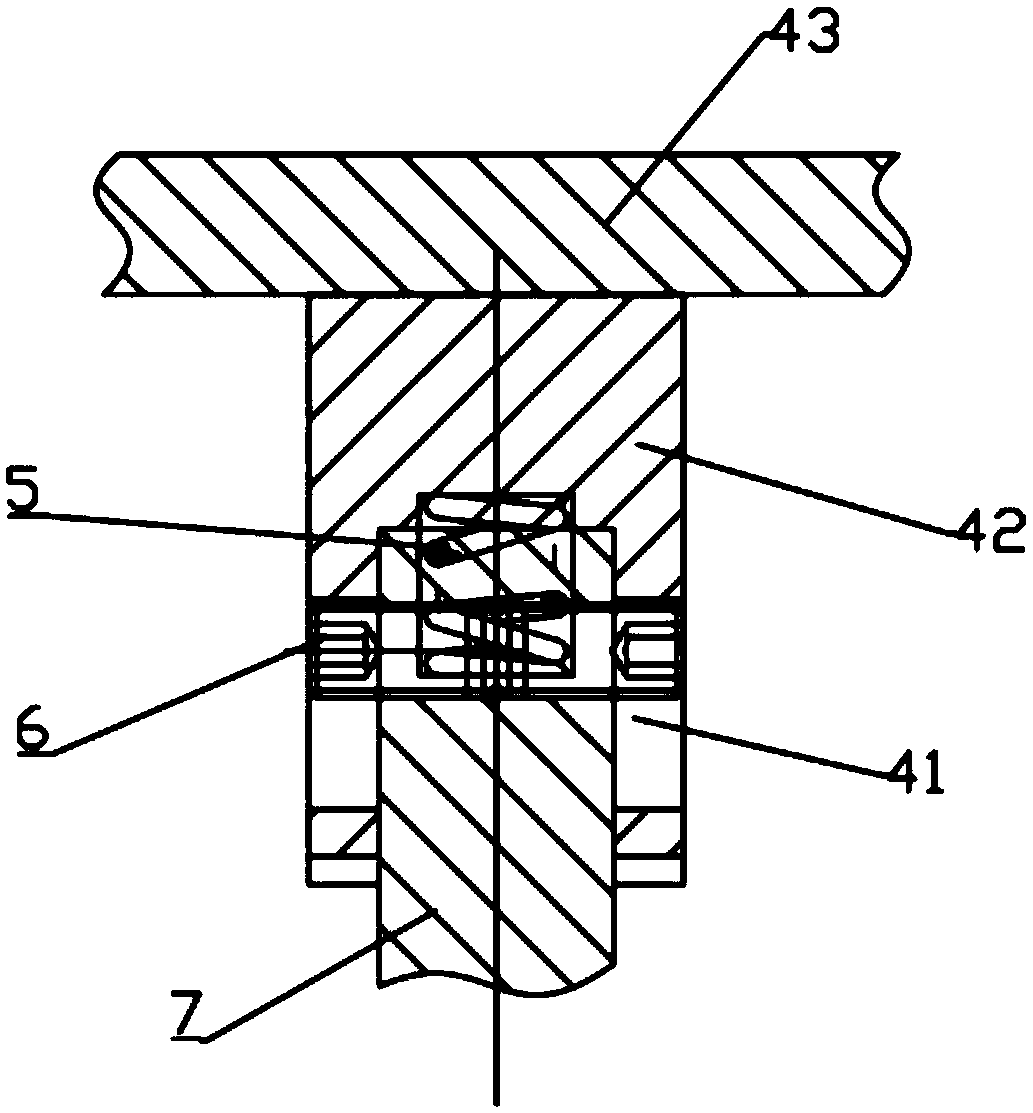

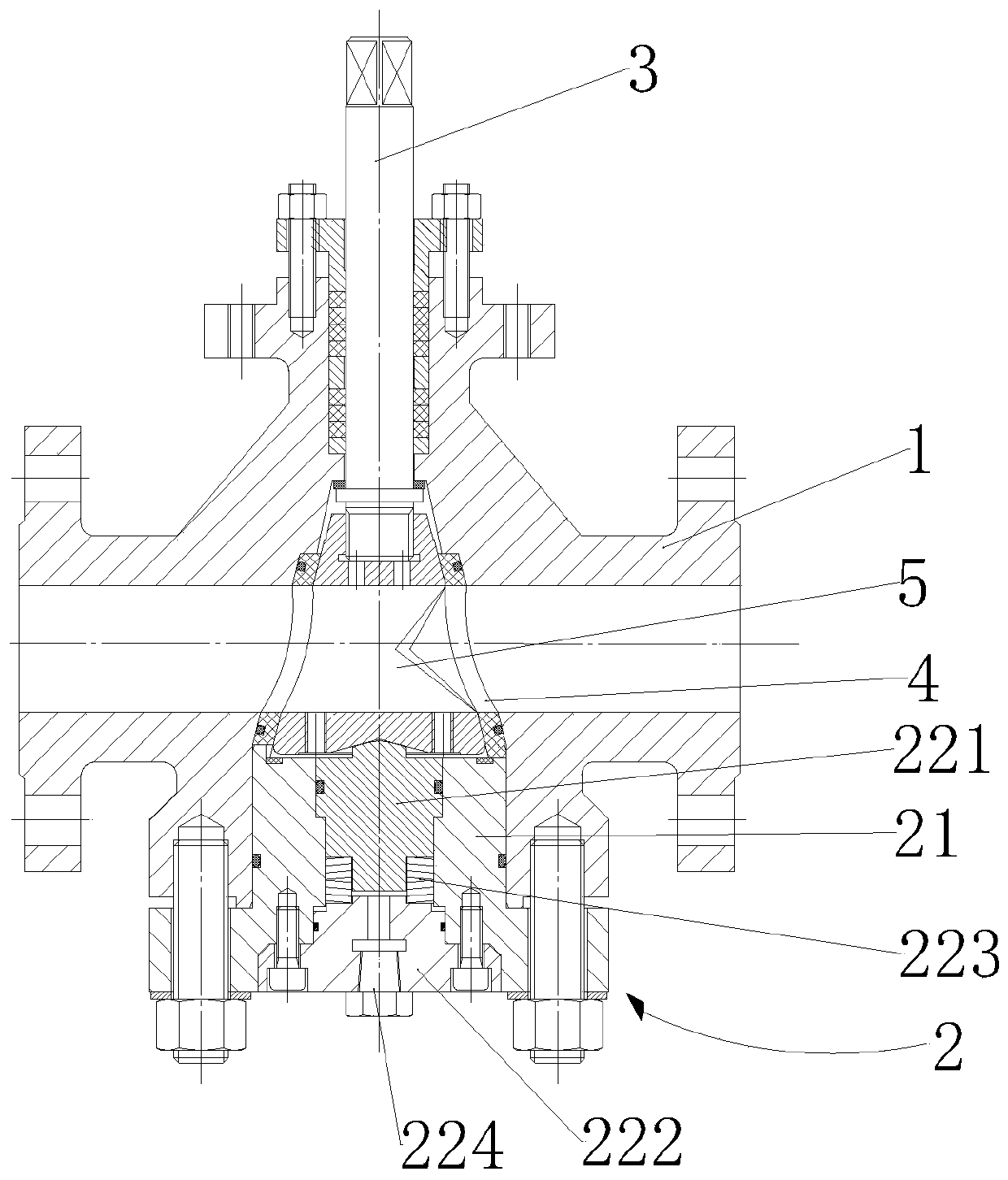

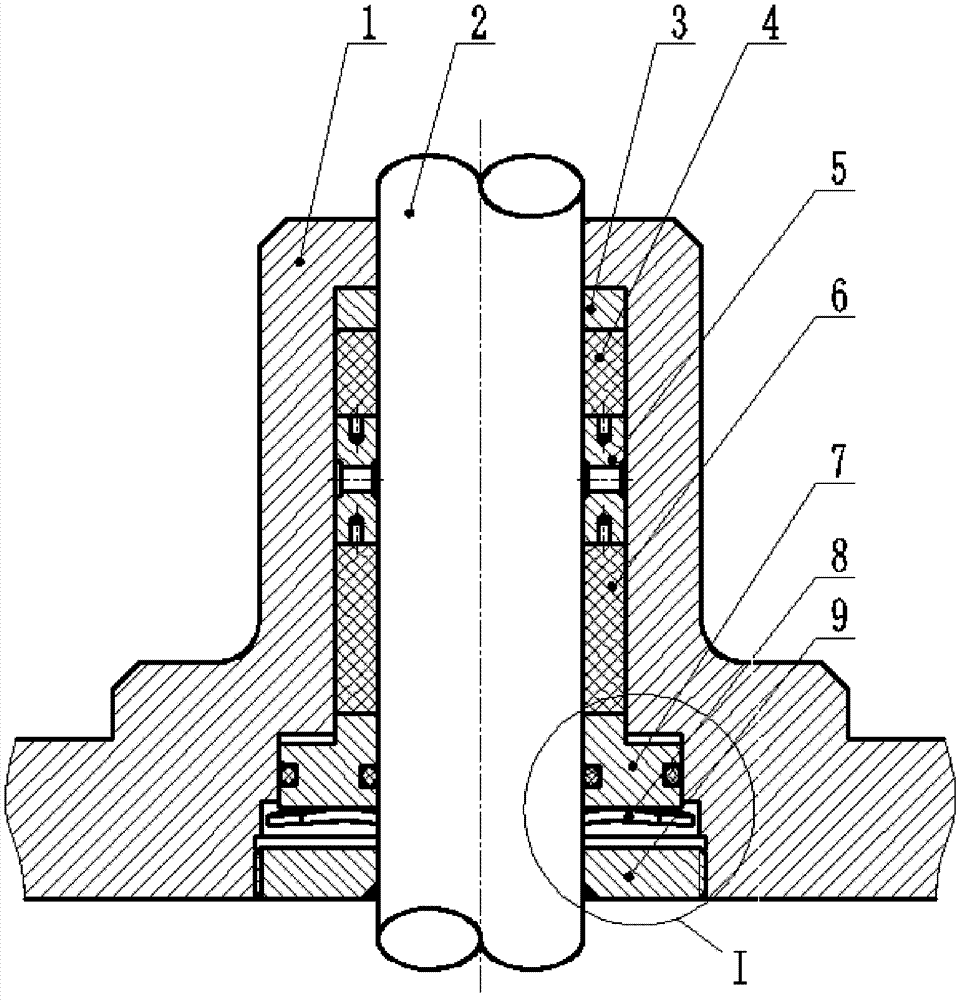

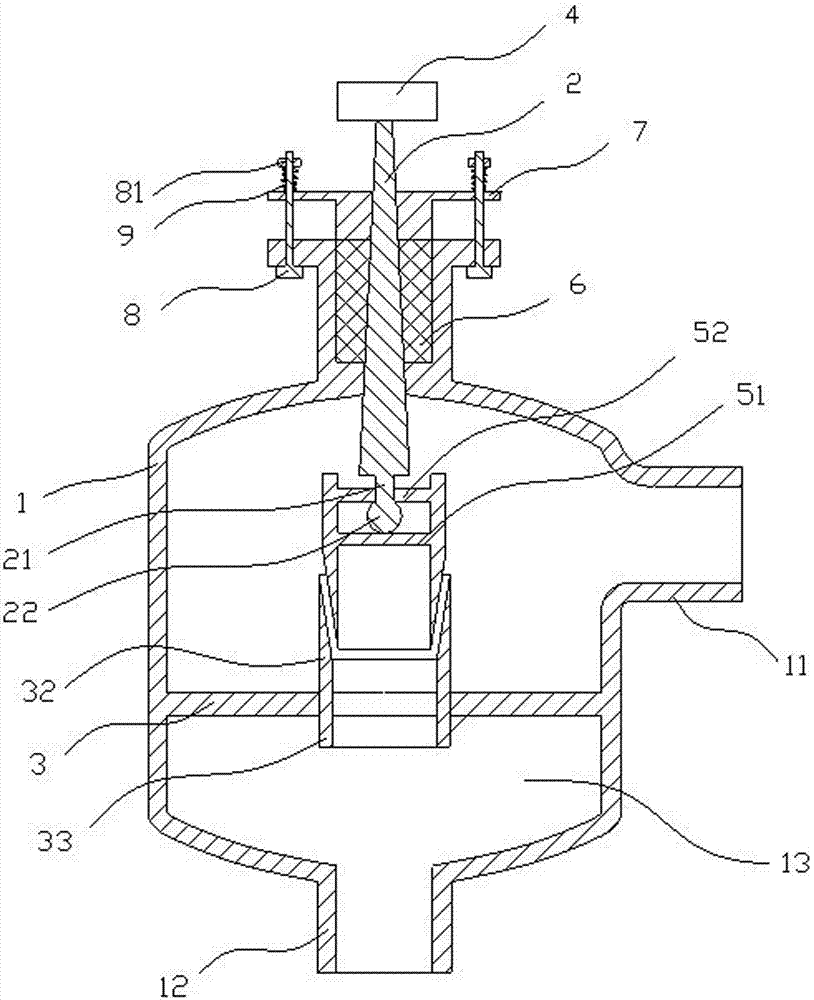

Automatic filling sealing structure for high-pressure valve

The invention relates to an automatic filling sealing structure for a high-pressure valve, which comprises a valve rod filling box body, a valve rod, a filling assembly and a support plate, wherein a difference pressure ring block in a step shaft sleeve structure is coaxially arranged on the valve rod arranged between the support plate and the filling assembly in the filling box body, a gap is formed between the upper plane of the step of the difference pressure ring block and the radial matched surface made in the filling box body, a waveform elastic element is coaxially pressed on the valverod arranged between the difference pressure ring block and the support plate, the filling assembly is coaxially arranged on the valve rod arranged in the filling box body at the inner side of the difference pressure ring block and sequentially comprises a filling pad, woven forming fillings, a filling separation sleeve and forming press ring fillings from top to bottom, the woven forming fillings, the filling separation sleeve and the forming press ring fillings are fixedly assembled. The sealing can be automatically formed under the medium pressure effect, the structure is simple, the effect is obvious, the sealing reliability of the movable sealing position of the valve rod is greatly improved, the filling abrasion can be automatically compensated through the structure, and the sealingpressure of the fillings in the use process is maintained.

Owner:TIANJIN BAILIZHANFA GRP

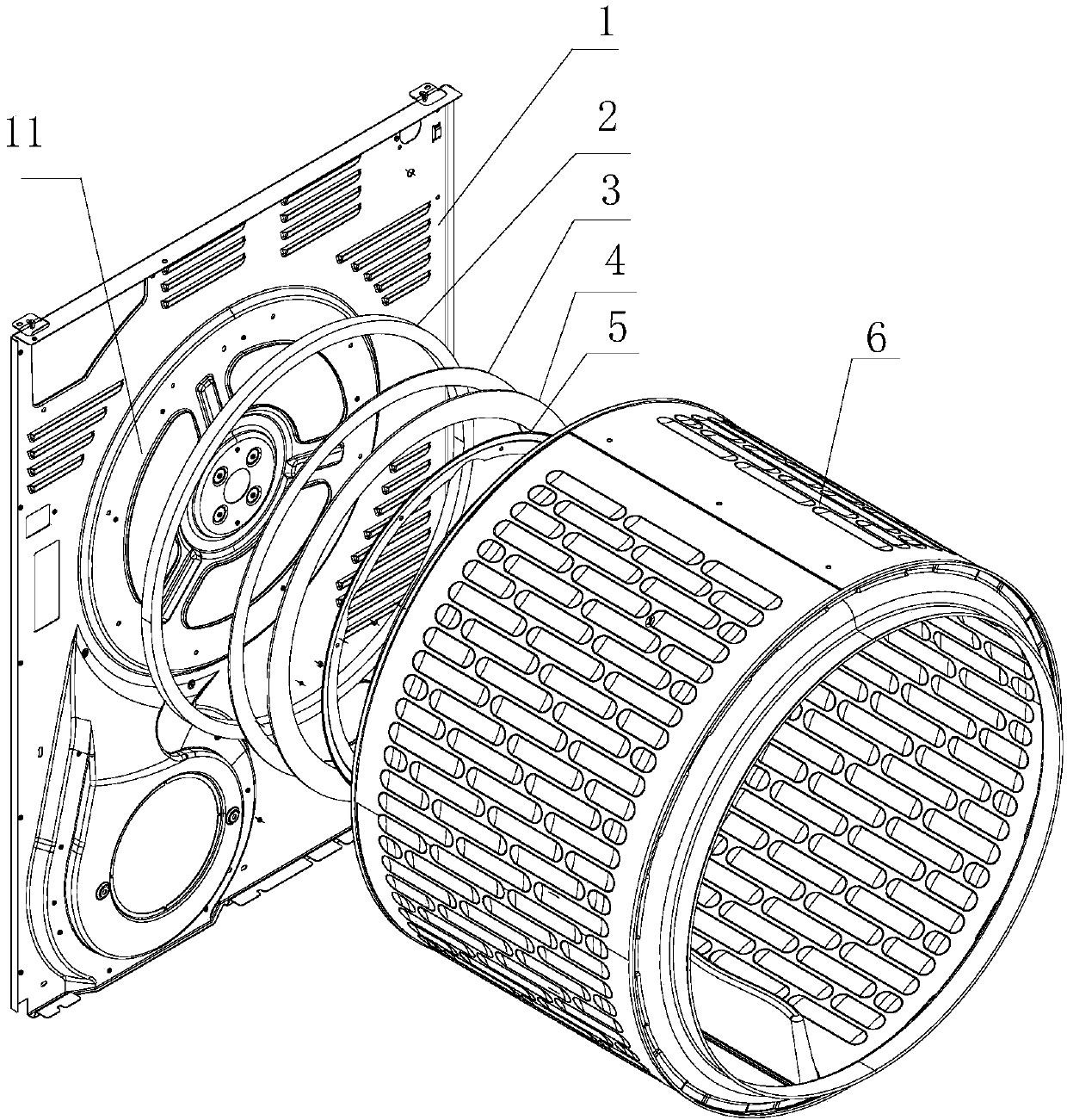

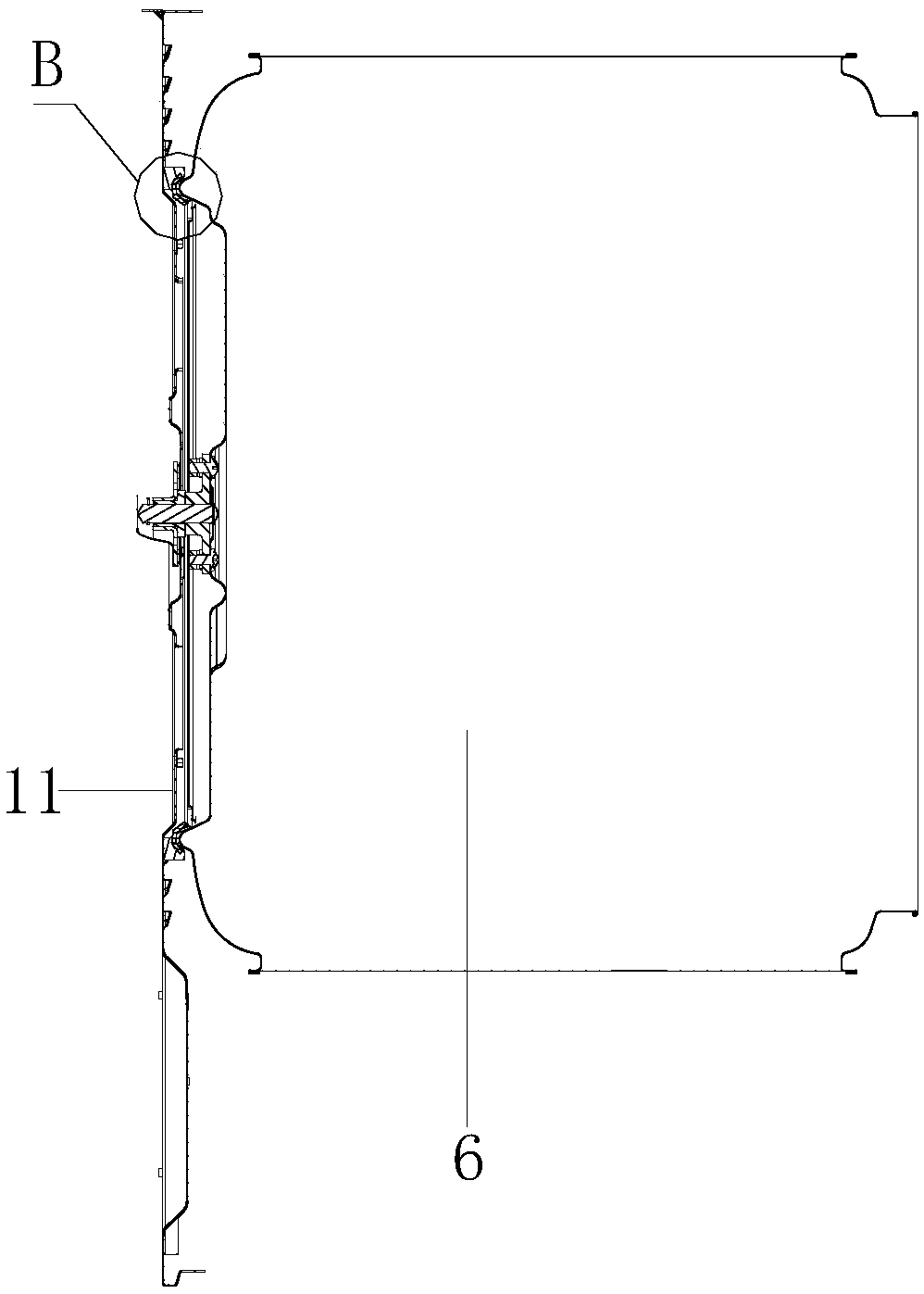

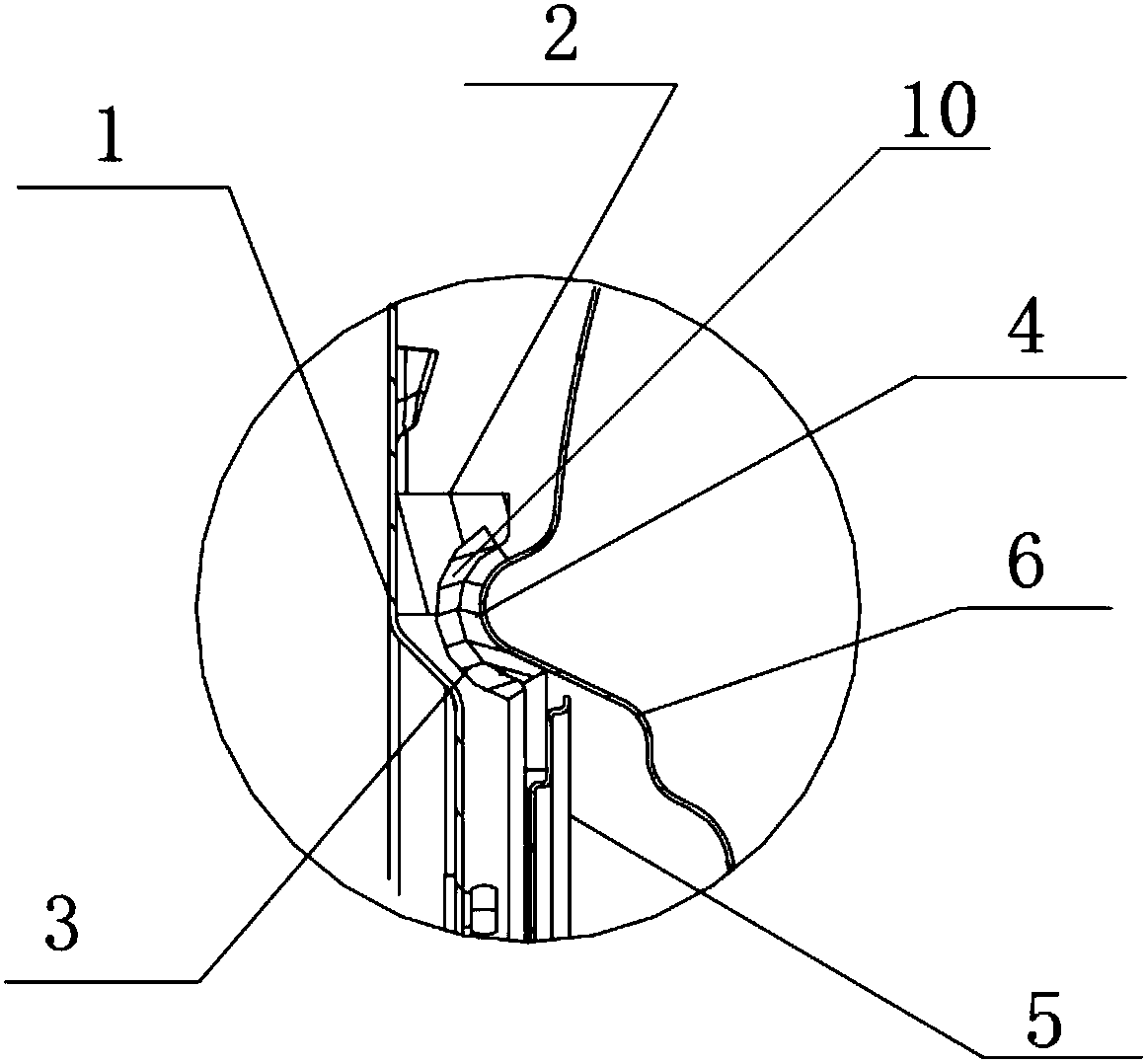

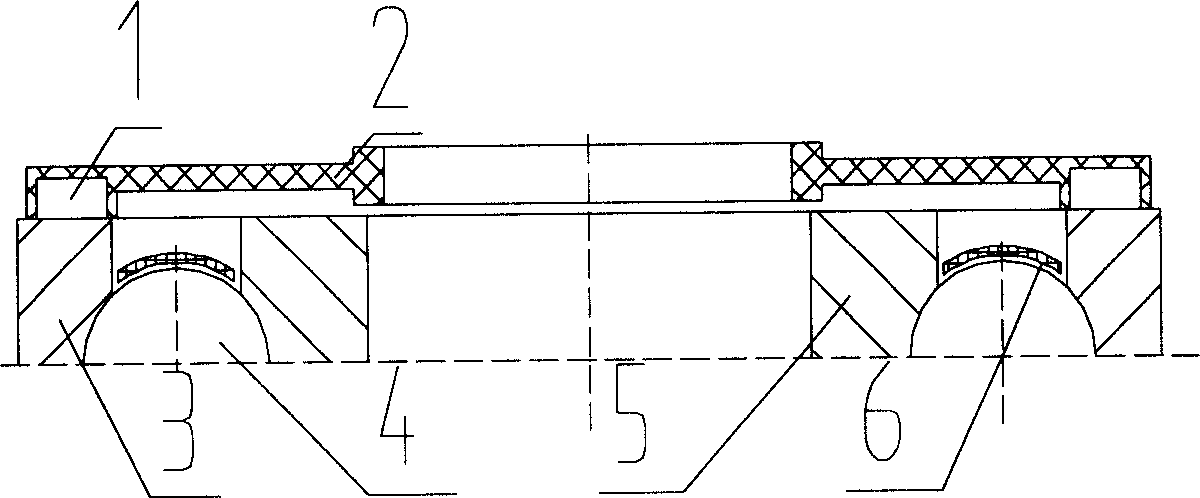

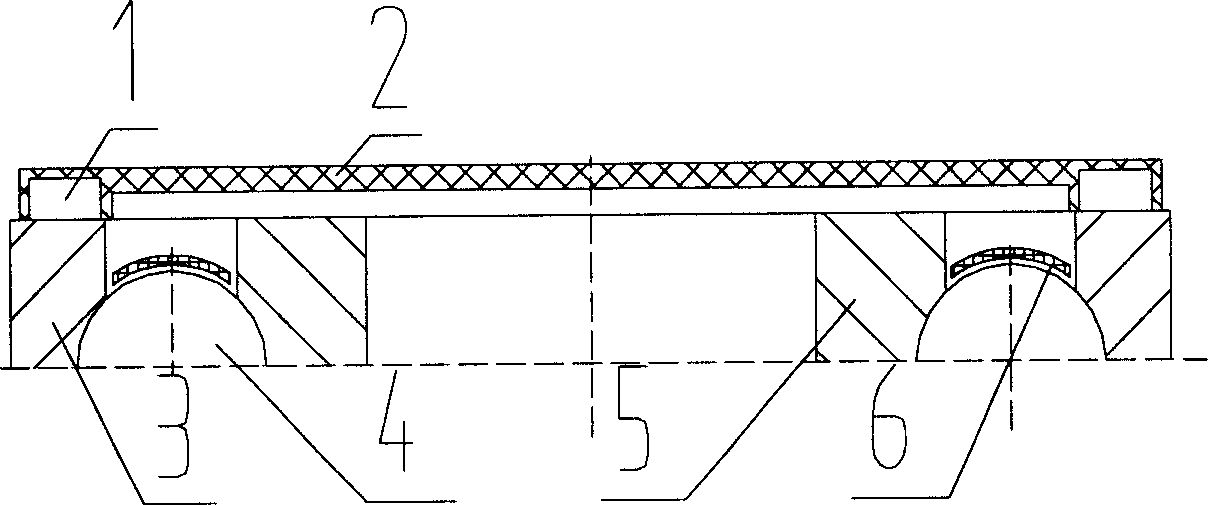

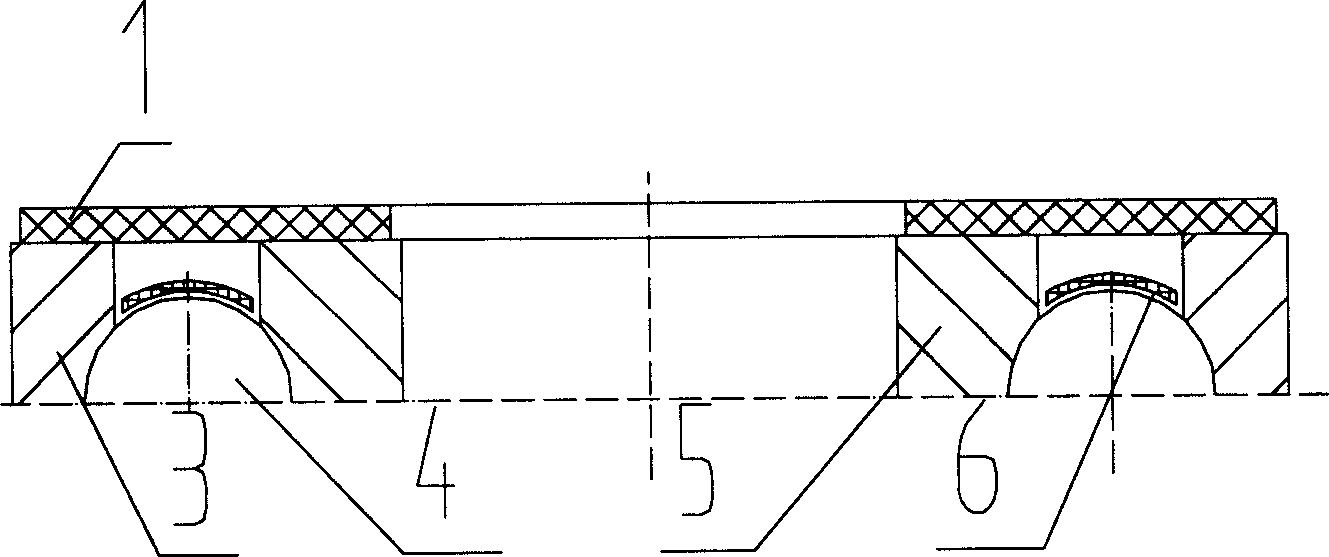

Clothes dryer drum sealing device and clothes dryer

ActiveCN103882661BReduce impactImprove sealingRotating vibration suppressionEngine sealsEngineeringHeat losses

The invention discloses a clothes dryer drum seal and a clothes dryer. The clothes dryer drum seal comprises a circular seal felt and a circular rubber pad. The circular seal felt is arranged between the circular rubber pad and the rear end of a drum, matches with the circular shape of the rear end of the drum and contacts with the rear end of the drum. The circular seal felt is connected with the circular rubber pad. The circular rubber pad is fixed to the inner wall of a drum support plate of a clothes dryer rear shell. The clothes dryer drum seal further comprises an elastic buffer part; the elastic buffer part disposed between the inner wall of the drum support plate of the clothes dryer rear shell and the circular rubber pad is connected with the inner wall of the drum support plate of the clothes dryer rear shell. The clothes dryer drum seal and the clothes dryer have the advantages that sealing performance can be improved, energy resources can be saved, heat loss can be reduced and drying efficiency of the clothes dryer can be improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

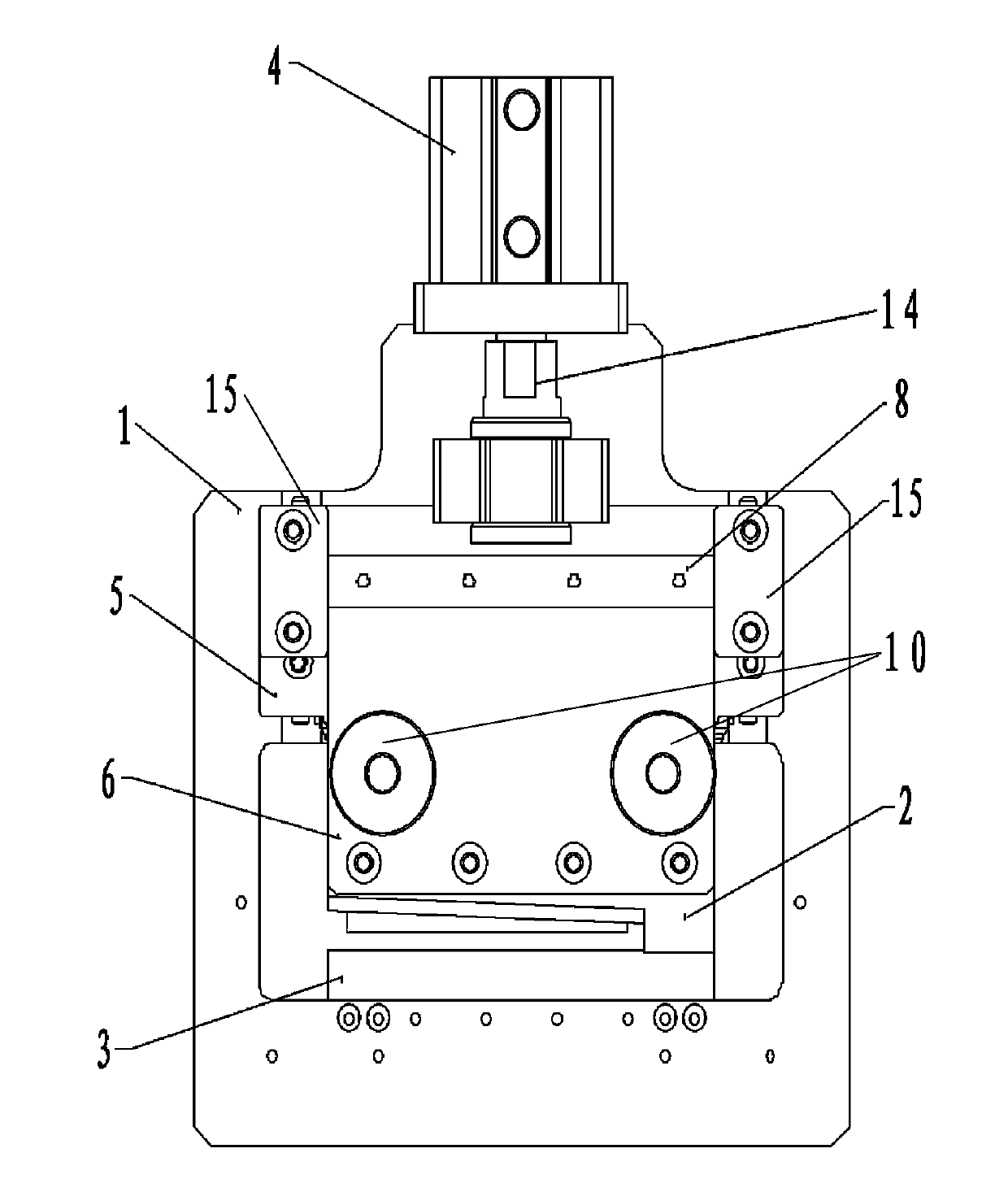

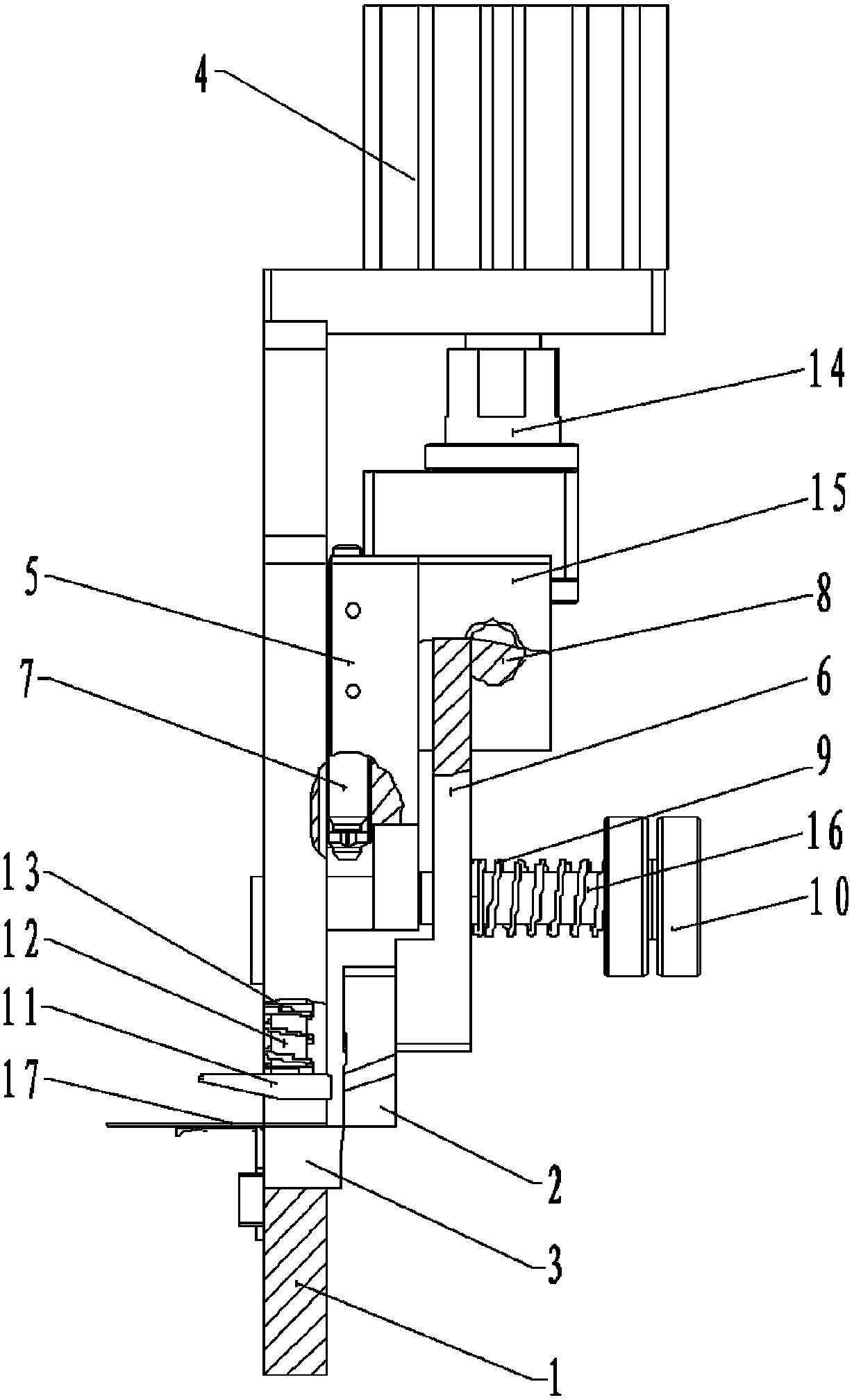

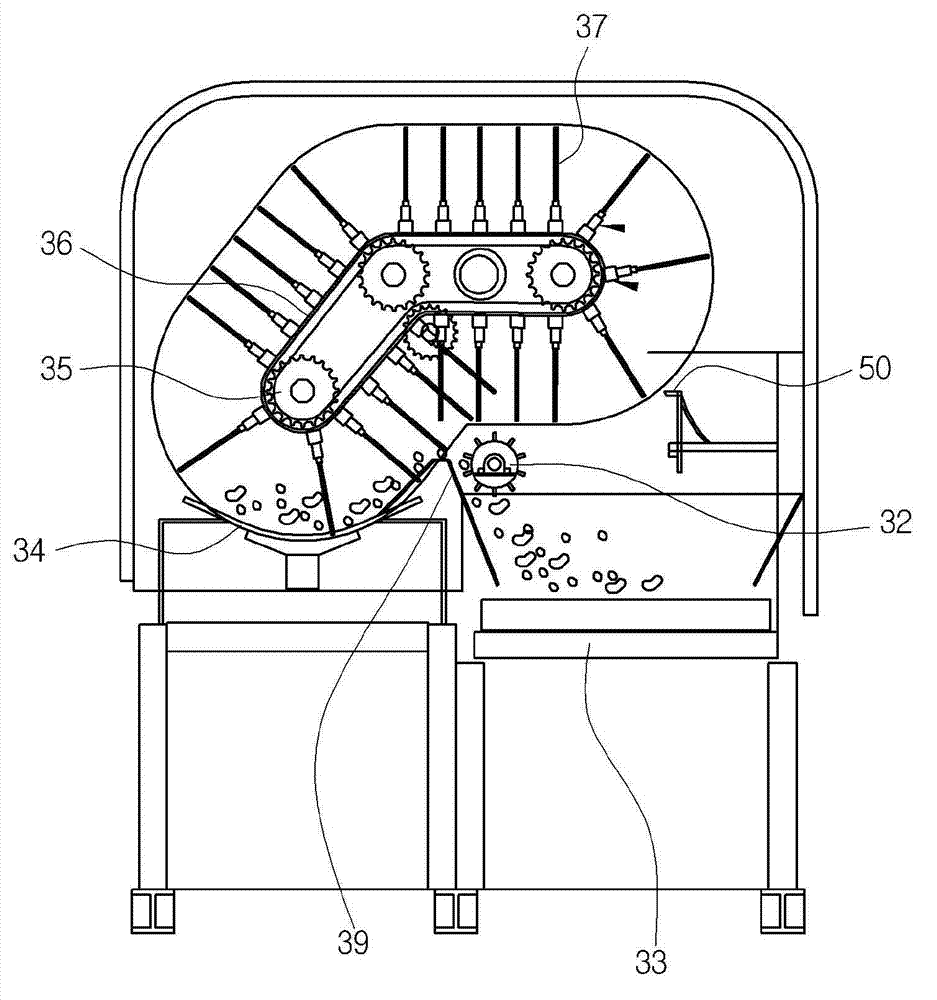

Cutting mechanism of battery pole piece

InactiveCN102306743BReduce wearAutomatically compensates for wearElectrode manufacturing processesMetal working apparatusEngineeringPole piece

The invention discloses a cutting mechanism of a battery pole piece. The cutting mechanism comprises a mounting plate, a cross roller guide, a guide sliding plate, a rotating shaft, a cutter mounting plate, an upper cutter, a lower cutter, a regulating lever and the like. The cutting mechanism of the battery pole piece provided by the invention can be used for maximally minimizing the wears of the upper cutter and the lower cutter by using the high-rigid precision guide of the cross roller guide; meanwhile, the regulating lever and a spring on the regulating lever are utilized to ensure the upper cutter to be flexibly adhered to the lower cutter and automatically compensate the wears, thus effectively controlling the size of burrs in the process of cutting the battery pole piece.

Owner:SUZHOU JIYANG AUTOMATION TECH

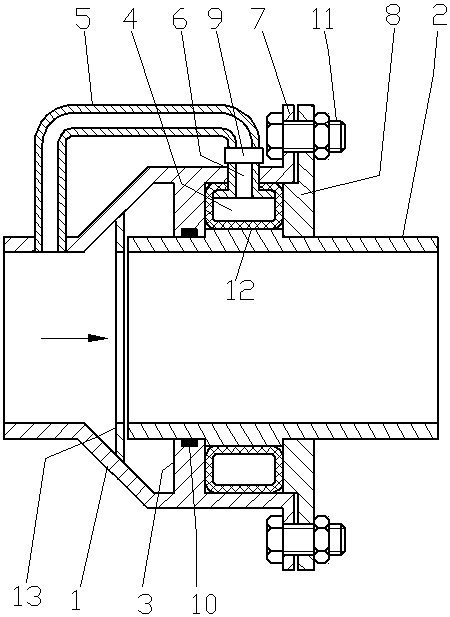

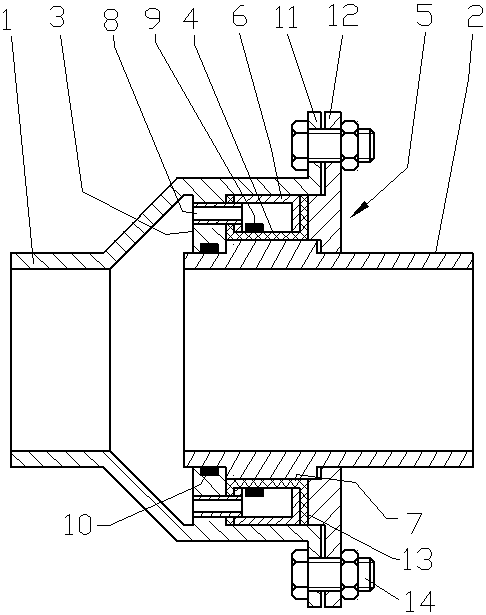

Rotary compensator

InactiveCN108413166AGuaranteed tightnessReduce frictionFluid pressure sealed jointsPipeline expansion-compensationEngineeringNozzle

The invention relates to a rotary compensator. The rotary compensator comprises an outer barrel (1) and an inner barrel (2); the outer barrel is of a diameter-changing structure; the left section of the inner barrel is located in a large-diameter section of the outer barrel; an annular rubber pipe (4) is arranged between the outer barrel and the inner barrel; a baffle ring (3) is arranged on the left side of the annular rubber pipe; a gland (8) is arranged on the right side of the annular rubber pipe; the part, which is located between the baffle ring and the gland, of the inner barrel is a convex part (12); an air nozzle (6) of the annular rubber pipe penetrates through the outer barrel hermetically and is connected with the right end of a guide pipe (5) in a sealed manner; and the left end of the guide pipe extends into a small-diameter section of the outer barrel hermetically. The annular rubber pipe expands due to pressure of liquid, so that sealing between the inner barrel and theouter barrel is realized; the larger the pressure of the liquid is, the closer the contact between the annular rubber pipe and the inner and outer barrels is; when the inner barrel moves in the outerbarrel, the annular rubber pipe is abraded; and as long as the annular rubber pipe is not abraded, the sealing property is not lowered.

Owner:高玉琴

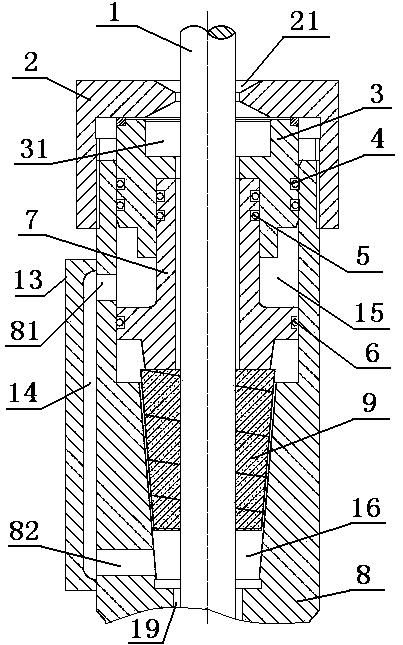

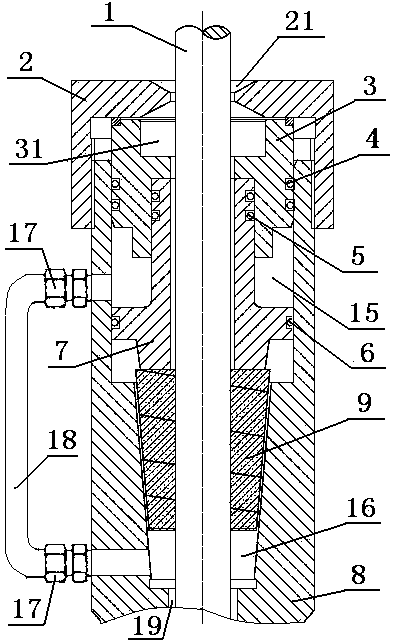

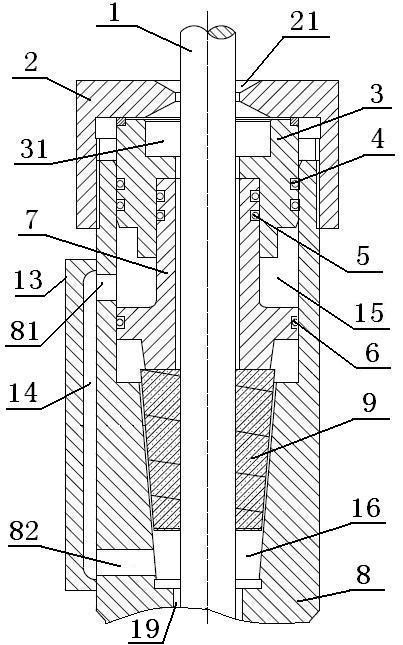

Automatic packing tightening polish rod sealer

ActiveCN111305786AAvoid excessive wearImplementation importSealing/packingOil fieldStructural engineering

The embodiment of the invention discloses an automatic packing tightening polish rod sealer and belongs to the technical field of oil extraction equipment of oil fields. The automatic packing tightening polish rod sealer comprises a packing pressing cap and a packing box connected to the packing pressing cap, wherein a packing, a hydraulic piston and a piston gland are arranged in the packing box;the piston gland, the hydraulic piston and the packing box jointly encircle an upper sealing oil cavity, a lower sealing oil cavity is formed in the packing box below the packing, and pressure oil inan oil well flows into the lower sealing oil cavity and the upper sealing oil cavity successively through a gap. According to the automatic packing tightening polish rod sealer, it is convenient to introduce the pressure oil in the lower sealing oil cavity to the upper sealing oil cavity, the pressure oil is directly acted to the upper surface of the hydraulic piston, and the hydraulic piston under the action of the pressure oil pressurizes and seals the packing automatically to prevent excessive wear of the packing caused by a way of manually increasing a pretightening force generally, so that the service life of the packing is prolonged. The automatic packing tightening polish rod sealer is simple in structure, low in processing and manufacturing cost and safe and reliable.

Owner:江天科技有限公司

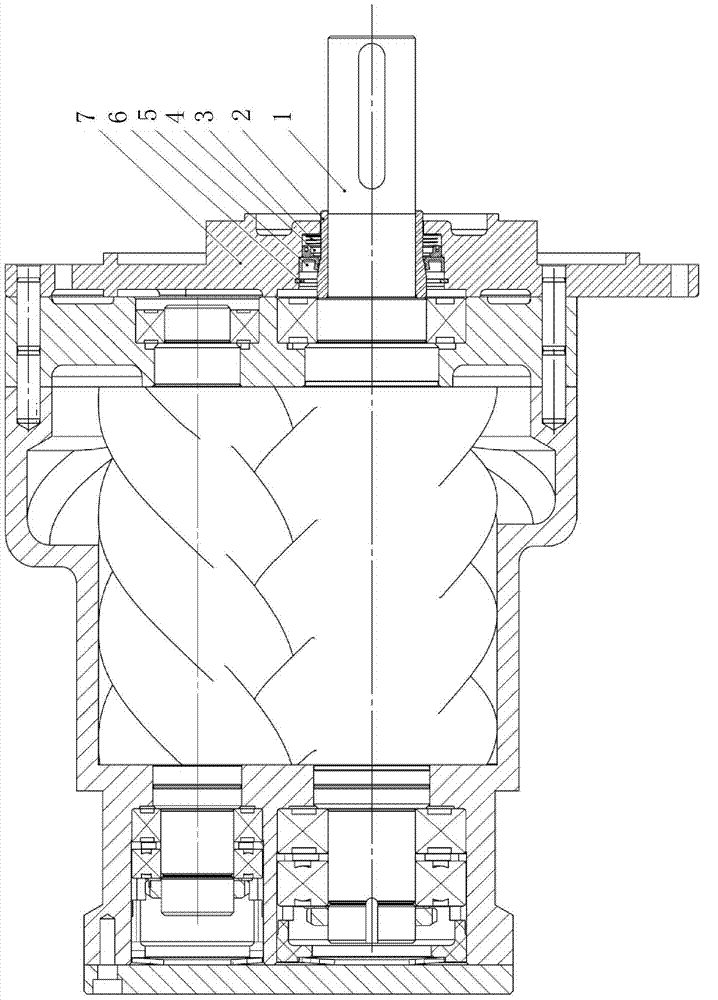

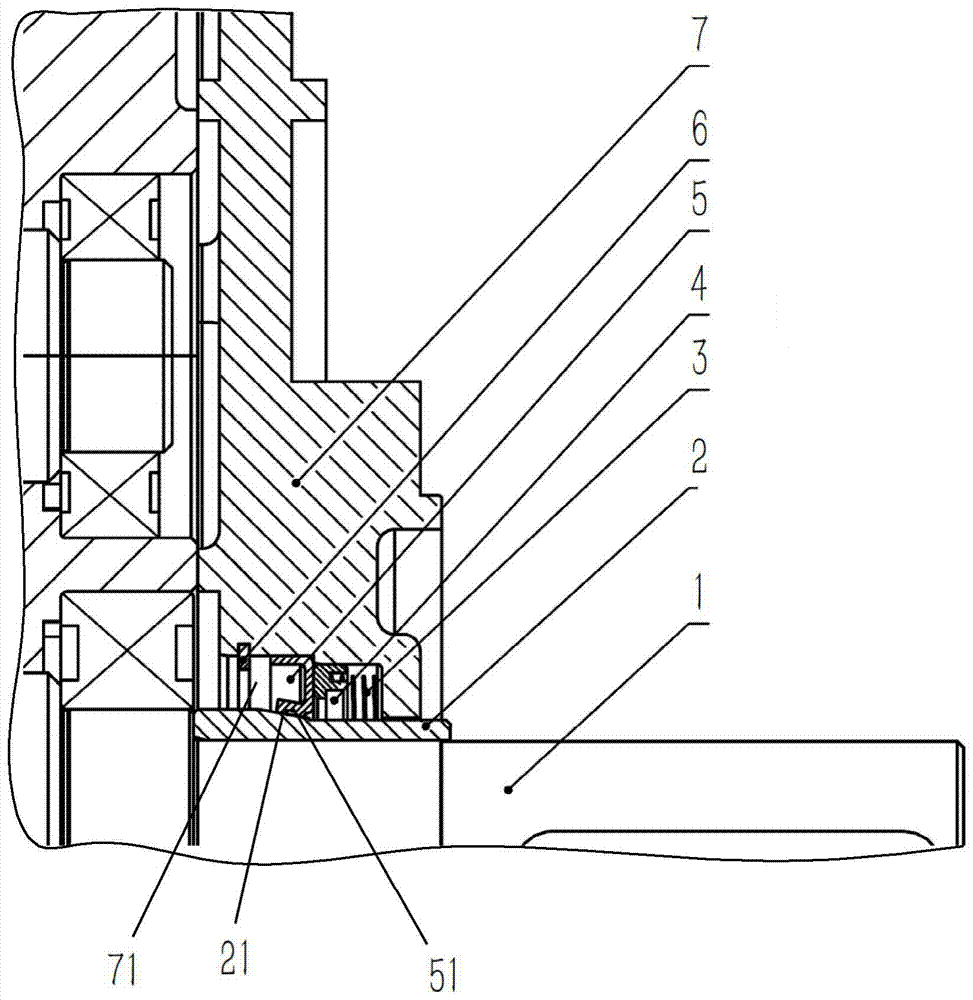

Screw compressor shaft seal with automatic compensation function

InactiveCN104747447AExtended service lifeAutomatic adjustment of contact forceSealing arrangement for pumpsMachines/enginesGas compressorEngineering

The invention discloses a screw compressor shaft seal with an automatic compensation function, and belongs to the technical field of accessories of screw compressors. A screw compressor comprises a projecting shaft and an end cover arranged on the end part of the compressor; the shaft seal comprises a shaft sleeve sleeving the projecting shaft and a lip seal embedded in a center hole in the axial middle of the end cover, and a sealing lip of the lip seal is matched with the outer wall of the shaft sleeve; The screw compressor shaft seal is characterized in that a conic surface is formed in the outer wall of the shaft sleeve, the lip seal is conical, and the conical sealing lip is adhered to the conical surface of the shaft sleeve. The screw compressor shaft seal is capable of prolonging the service life of the lip packing, improving the sealing effect of the lip seal, and lowering the use cost and maintenance cost of the screw compressor.

Owner:SUZHOU TORIN DRIVE EQUIP

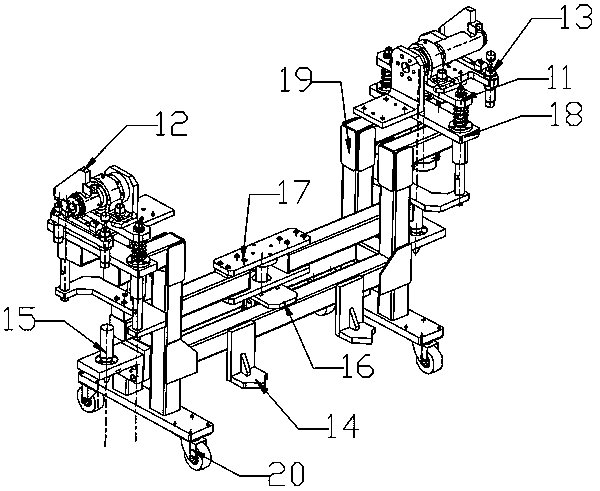

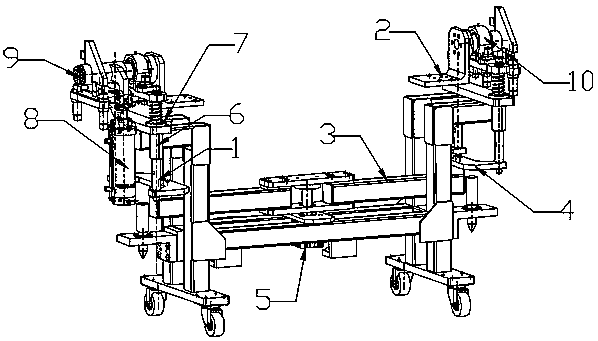

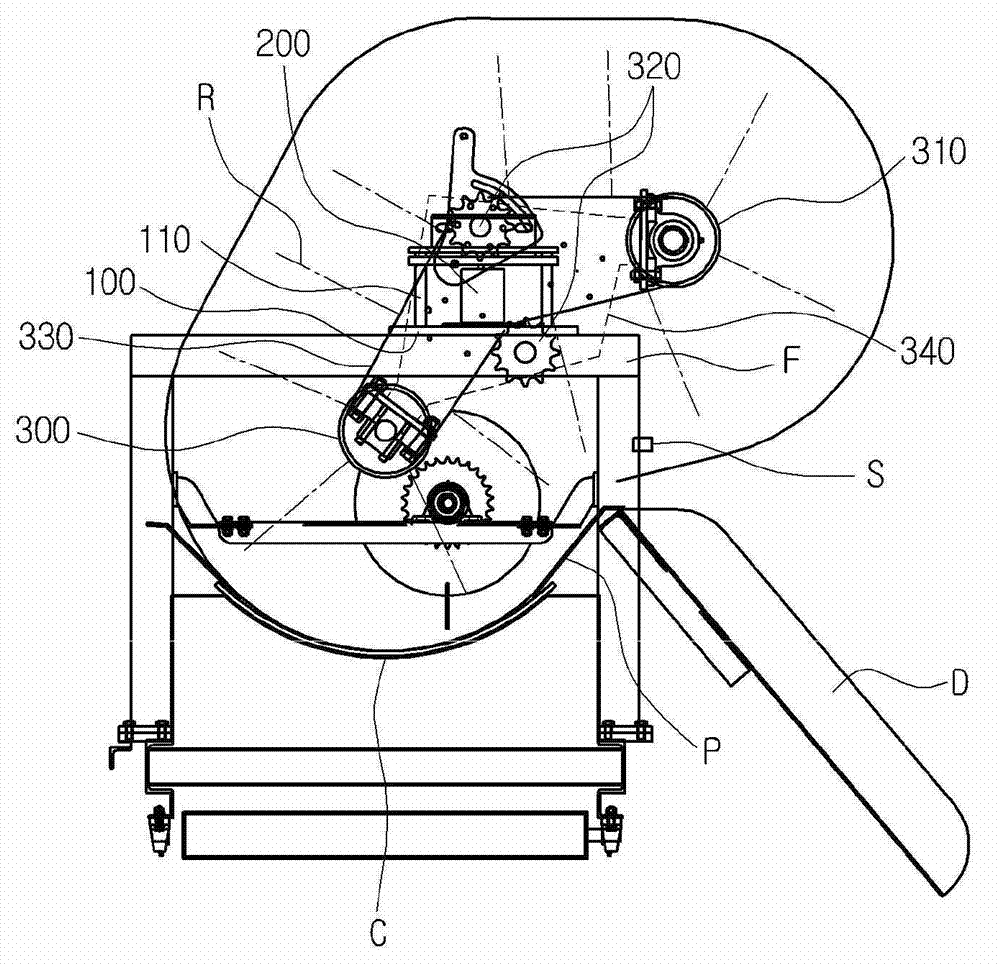

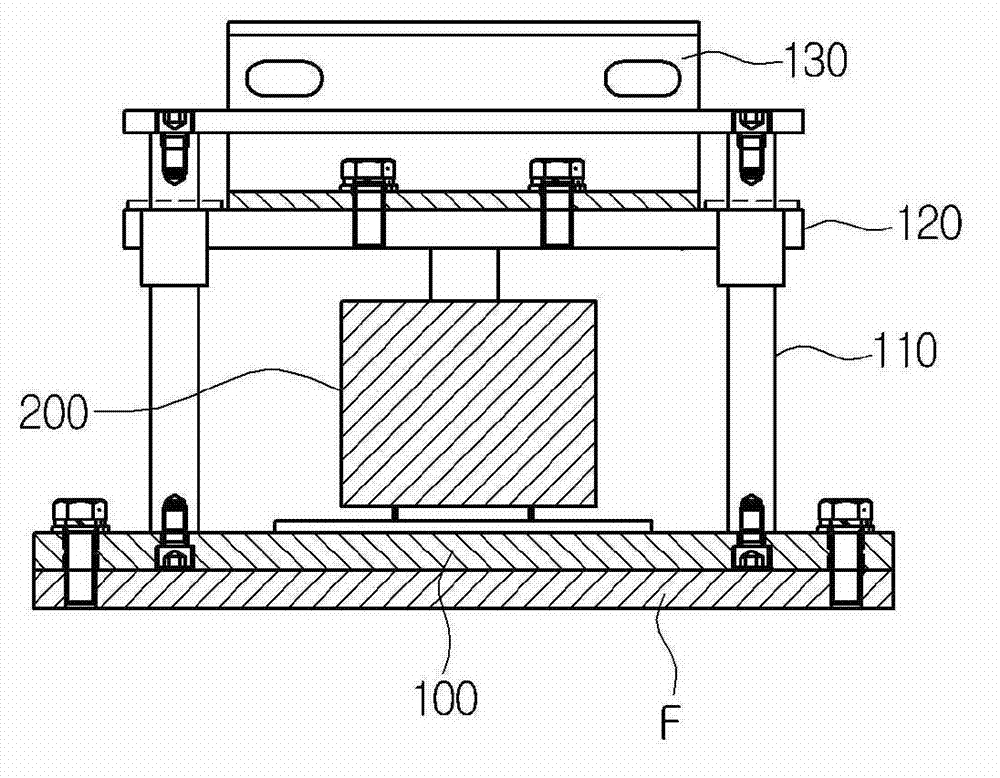

Flexible fixture base capable of achieving quick changing of fixture

PendingCN111482749AAutomatically compensates for wearRapid positioningWelding/cutting auxillary devicesAuxillary welding devicesMachine buildingEngineering

A flexible fixture base capable of achieving the quick changing of a fixture is used in the field of welding for mechanical manufacturing. A cylinder body of a jacking air cylinder of a floating mechanism is fixed on a fixture base; at the time of working, the jacking air cylinder below the floating mechanism pushes the floating mechanism up to an upper limit; at the time of welding, the jacking air cylinder releases air, and a fixture body presses down compression springs by gravity to contact a lower electrode of a welding gun; after the fixture body is stabilized, welding is started; a turnover mechanism is connected with the floating mechanism through bearing seats and floats up or down along with the floating mechanism; turnover air cylinders of the turnover mechanism are connected with turnover shafts on the left sides of the turnover air cylinders; the turnover air cylinders act to drive fixture mounting plates on the turnover shafts to turn over; a quick positioning device performs quick positioning through two V-shaped blocks; and positioning holes in two sides perform precise positioning through positioning pins. The flexible fixture base can achieve the up and down floating, turnover angles and quick positioning of the fixture body as well as the automatic compensation of the abrasion loss of an electrode through the floating mechanism, the turnover mechanism and thequick positioning device; moreover, the flexible fixture base can cooperate with a three-axis straight-line automatic welding machine to achieve flexible welding; and therefore, the production inputcost is reduced and the universality of the device is enhanced.

Owner:XIANGYANG SUNRISE MACHINERY

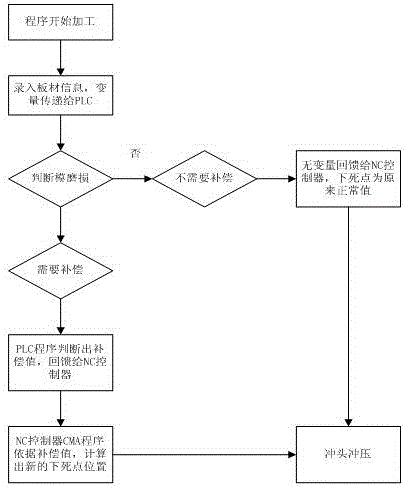

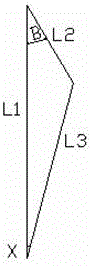

Automatic compensation method of bottom dead center of turret punch press

ActiveCN106111792AAutomatically compensates for wearEnough mold depthShaping toolsPressesEngineeringCompensation methods

The invention relates to an automatic compensation method of a bottom dead center of a turret punch press. The automatic compensation method comprises the following steps that different plate information is inputted by a CMA program, a variable I is transmitted to a PLC, the PLC selects corresponding abrasion loss II according to the variable I, and judges whether the position of the bottom dead center needs to be automatically compensated or not, and when compensation is needed, the abrasion loss II is used as a variable II to be fed back to an NC controller, and a new angle position of the bottom dead center is calculated by the CMA program. The using times of a die core is judged by the PLC to obtain corresponding abrasion loss of the die core, the new angle position of the bottom dead center is calculated by the CMA program for feeding the variable back to the NC controller, the problem that the in-die depth of the die core is not enough since the die core is worn is solved, the abrasion loss can be automatically compensated, and the enough in-die depth of the die core is ensured.

Owner:JIANGSU YAWEI MACHINE TOOL

Novel welding device

ActiveCN104002032ARealize automatic fine-tuningImprove passabilityElectrode supporting devicesElectrode accessoriesForeign matterArchitectural engineering

The invention relates to a novel welding device. The novel welding device comprises a conducting rod, a connecting rod, a conducting plate, a first welding head and a second welding head; the conducting plate is fixed to the conducting rod; two ends of the connecting rods are respectively connected with the conducting rod and the conducting plate; the first welding head is fixed to the conducting plate, and while the second welding head is fixed to the connecting rod; a gap through which a welding wire passes is formed between the first welding head and the second welding head; the connecting rod and the conducting rod are connected through an adjusting bolt; one end of the adjusting bolt, provided with threads, is sleeved with the connecting rod; one end of a straight pin is fixed to the conducting rod through an insulating sleeve. Compared with the prior art, the novel welding device has the beneficial effects that 1) the connecting rod arranged enables separated arrangement of the welding heads, thus the gap at the part in which the welding wire is clamped at the head part of a welding gun can be automatically fine adjusted, the welding wire can pass through smoothly, and a continuous clamping force is provided for the welding wire; 2) the wear can be automatically compensated, foreign matters on the welding wire can be removed, and thereby high conductivity is ensured; 3) the structure is simple, the use effect is great, the welding quality can be effectively improved, and the consumption of welding wire can be reduced.

Owner:中冶辽宁德龙钢管有限公司

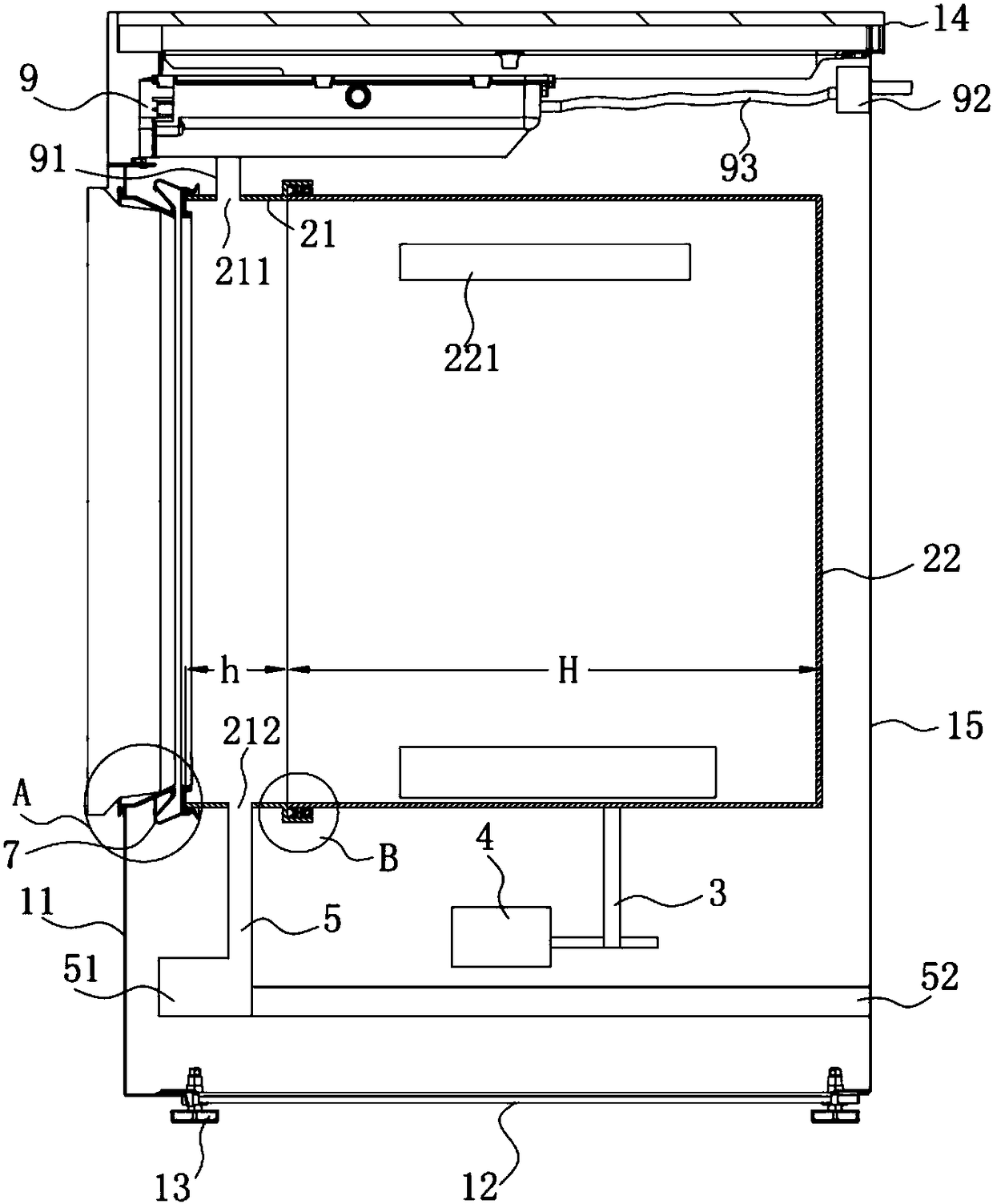

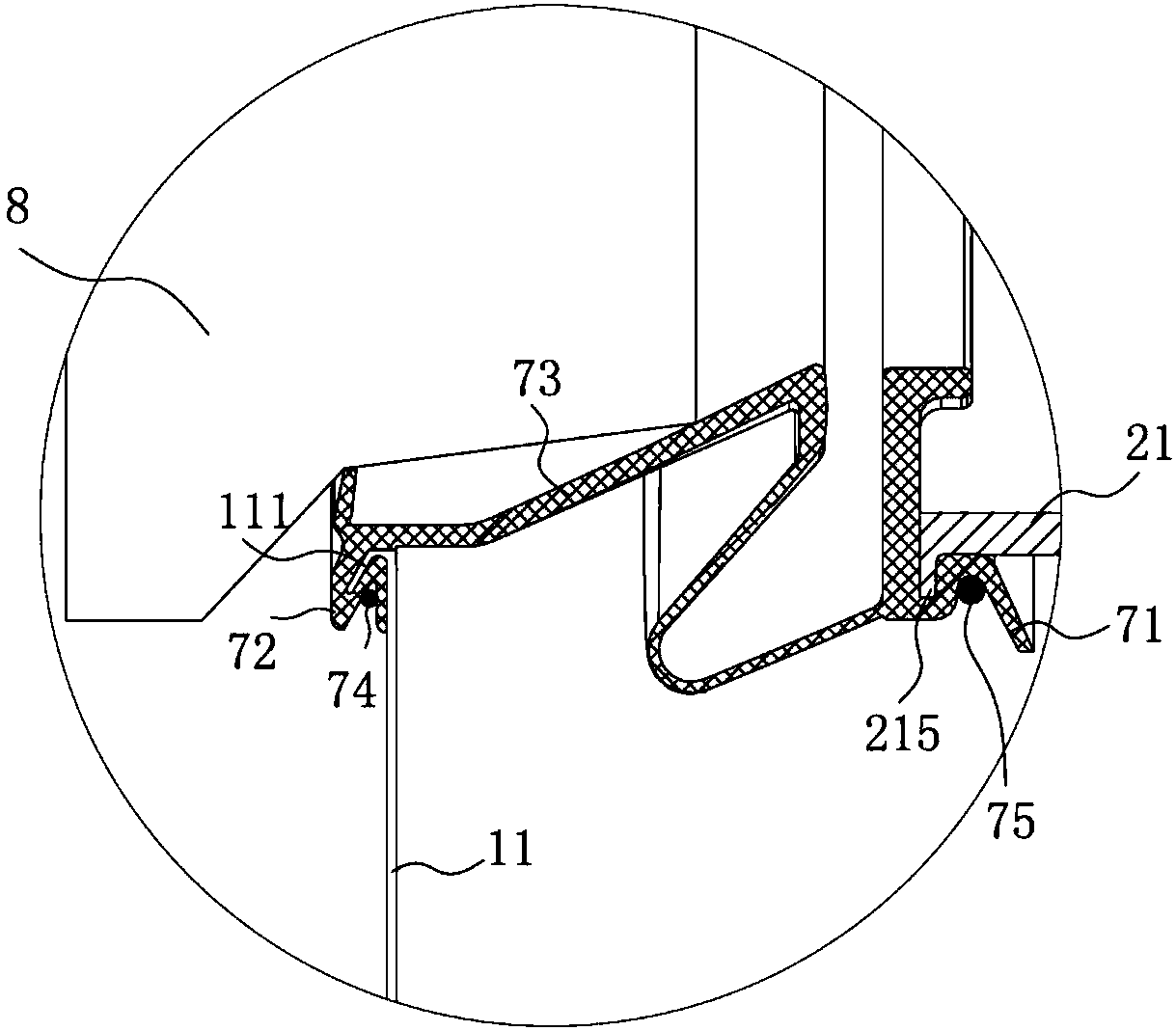

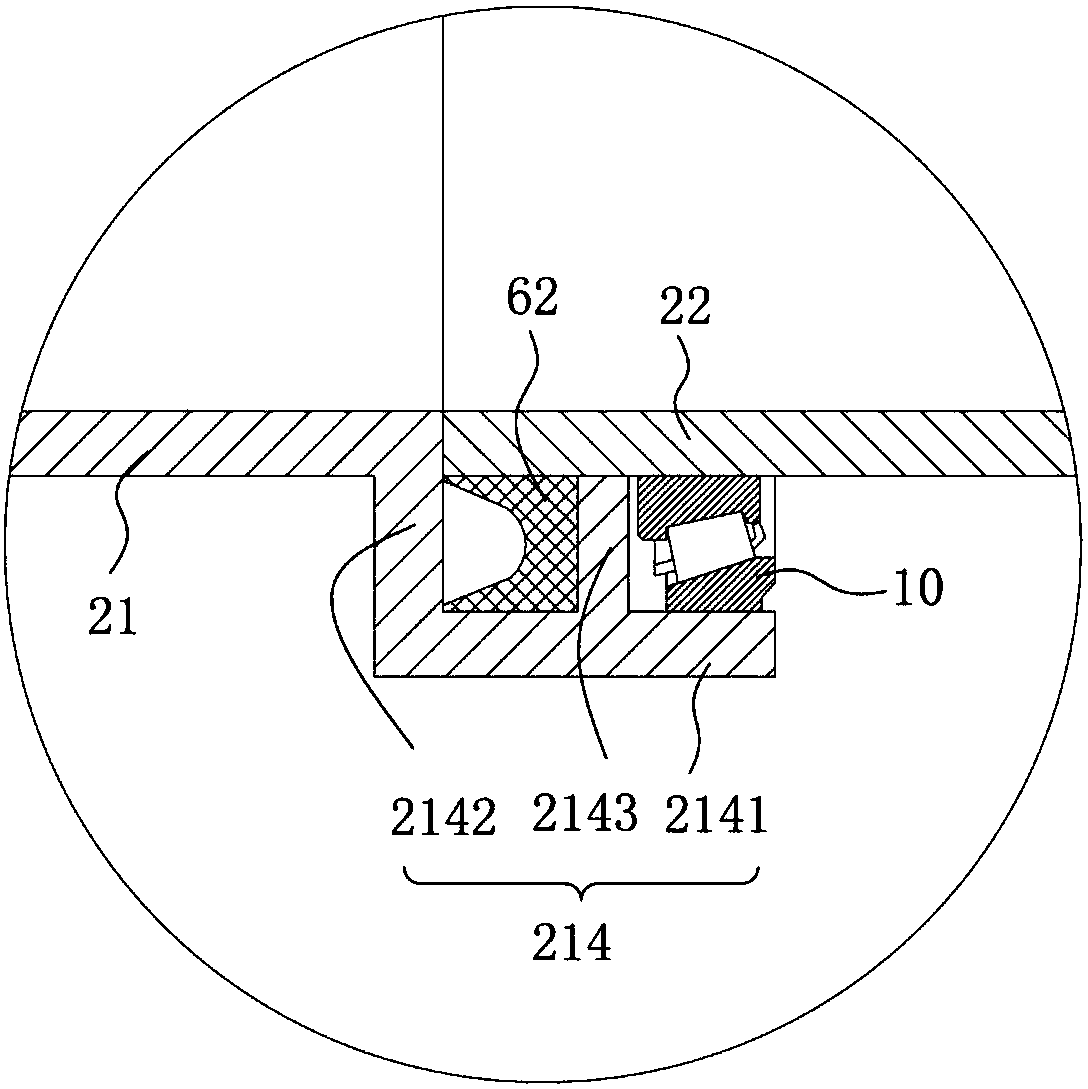

Drum washing machine

ActiveCN108396505ARealize no-cleanAvoid accumulationOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention relates to the technical field of washing machines, in particular to a drum washing machine. The drum washing machine comprises a washing machine shell, wherein a washing drum is arranged in the washing machine shell and comprises a washing front drum and a washing rear drum; the washing front drum is connected with the washing rear drum in a sealed manner; the washing rear drum rotates relative to the washing front drum; the washing rear drum rotates along with a motor; and the washing front drum is fixed relative to the washing rear drum. The washing rear drum rotates relativeto the washing front drum, and water and clothes in the washing drum are driven to rotate so as to wash the clothes. The washing drum is not divided into an inner drum and an outer drum, the circumstance that the outer wall of the washing drum is full of water, particularly water which have been used for washing clothes is avoided, dirt can be prevented from being accumulated on the outer wall ofthe washing drum, the outer wall of the washing drum does not need to be cleaned, meanwhile, water between the inner drum and the outer drum of the washing drum is saved, and the water is saved further.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Magnetic seal

InactiveCN1815067AAutomatically compensates for wearEliminate the effects ofEngine sealsBearing componentsMagnetBasal body

Present invention refers to a magnetism sealing. Said magnetism sealing has a round basal body with magnet, said magnetism sealed basal body made of flexibility material, capable of automatically compensating automatically compensating magnetic sealed surface wearing, automatically eliminating shaft run-out axial float influence to magnetic sealed surface, said magnetism seal structure having fine sealing effect prolonging bearing service life, greatly raising production efficiency and reducing production costs.

Owner:孙荣军

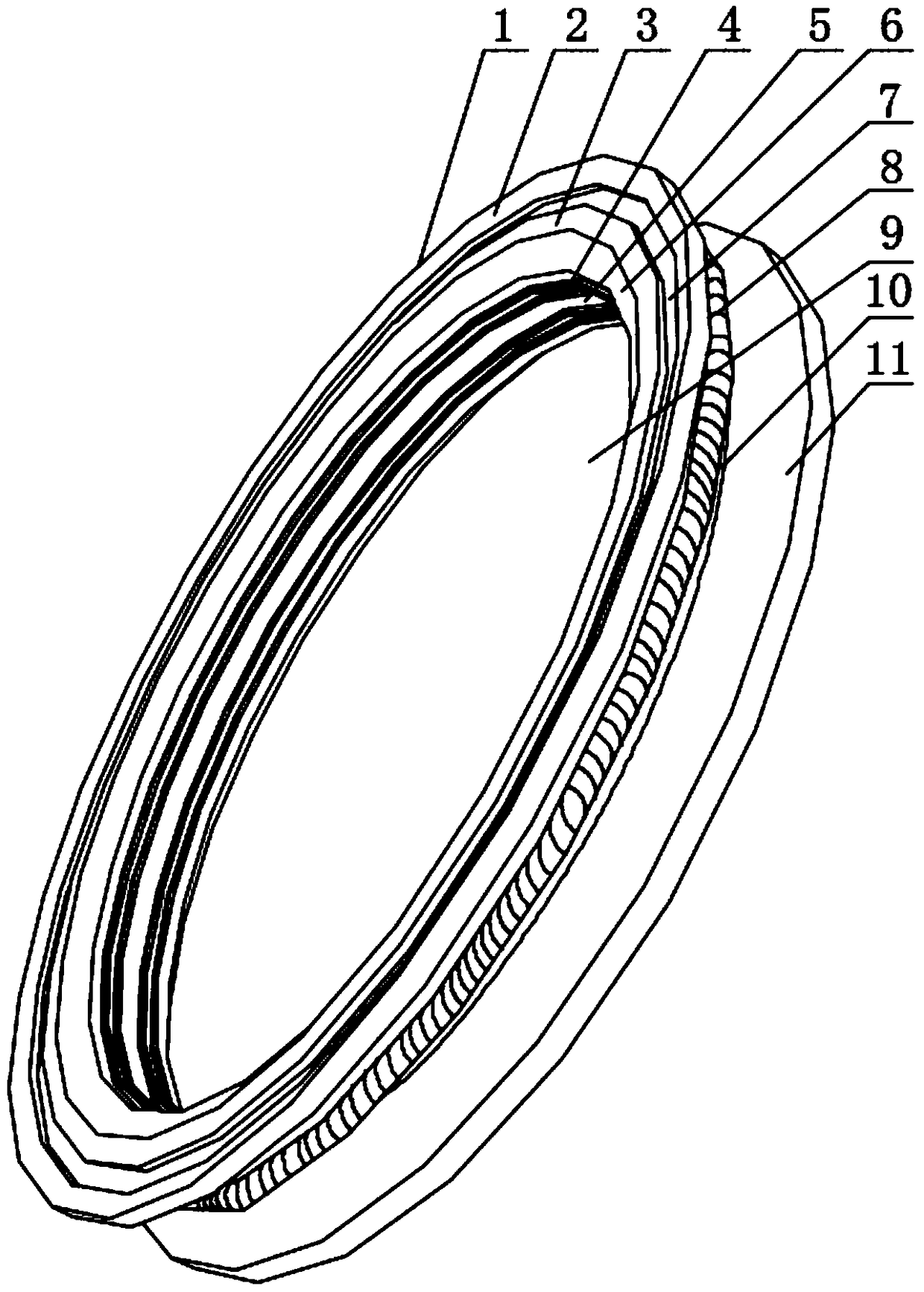

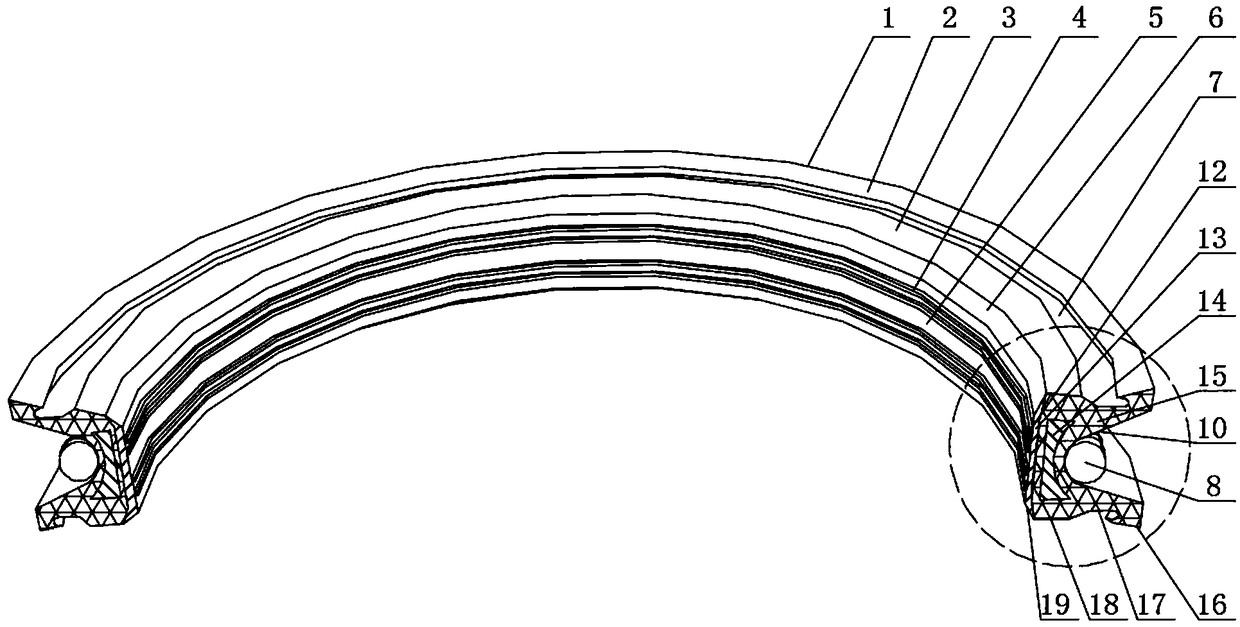

Marine rudderstock double-sided lip seal ring

PendingCN109027239AImprove sealingAutomatically compensates for wearEngine sealsLip sealPolytetrafluoroethylene

The invention relates to a marine rudderstock double-sided lip seal ring which comprises a seal ring body. An upper inner side lip and an upper outer side lip as well as a lower inner side lip and a lower outer side lip are integrally arranged at the upper end and the lower end of the seal ring body in a coaxial opposite-symmetrical outwards-inclined extending way; a sealing surface on which the lip sealing end between the upper inner side lip and the upper outer side lip is located is perpendicular to a seal ring inner hole, and a sealing surface on which the lip sealing end between the lowerinner side lip and the lower outer side lip is located is perpendicular to the seal ring inner hole, so that a double-sided end surface sealing structure is formed; sloping bench ring surfaces are integrally arranged on one sides, close to the seal ring inner hole, of the top parts and the bottom parts of the upper and lower inner side lips; a stainless steel strengthened ring is arranged in themiddle of the peripheral rubber of the seal ring body; and polytetrafluoroethylene seal rings are arranged in the sloping bench ring surfaces. The marine rudderstock double-sided lip seal ring provided by the invention adopts a double-sided lip sealing structure so as to be good in rudderstock sealing effect, less in vibration sensitivity, and less in rudderstock surface wear.

Owner:TIANJIN BAOBOTE SEALING TECH

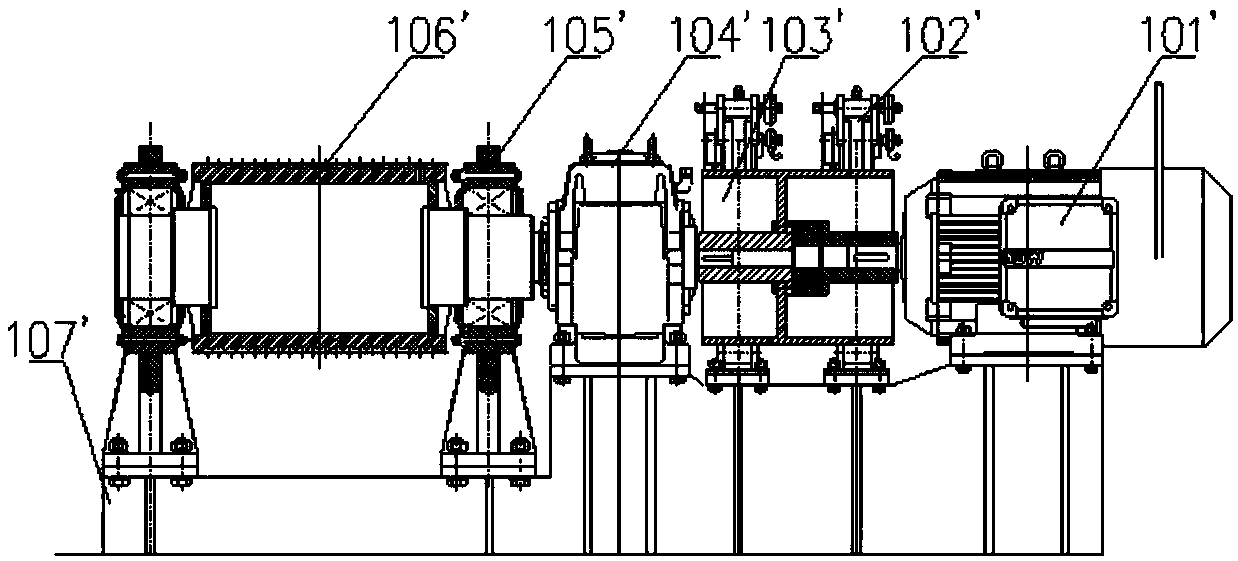

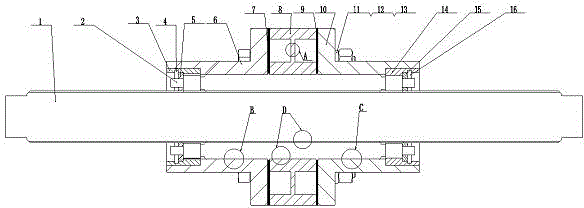

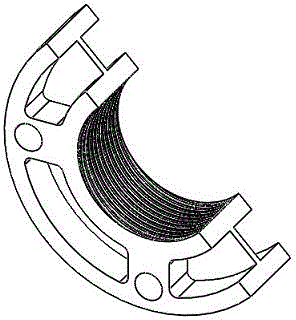

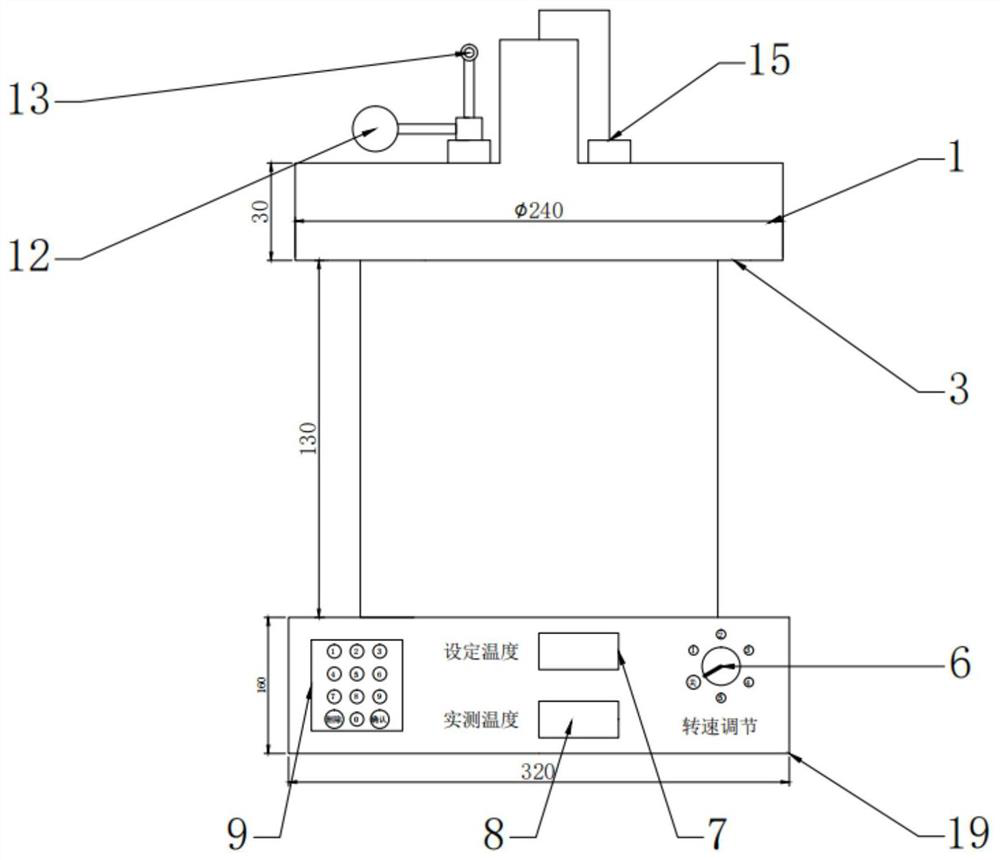

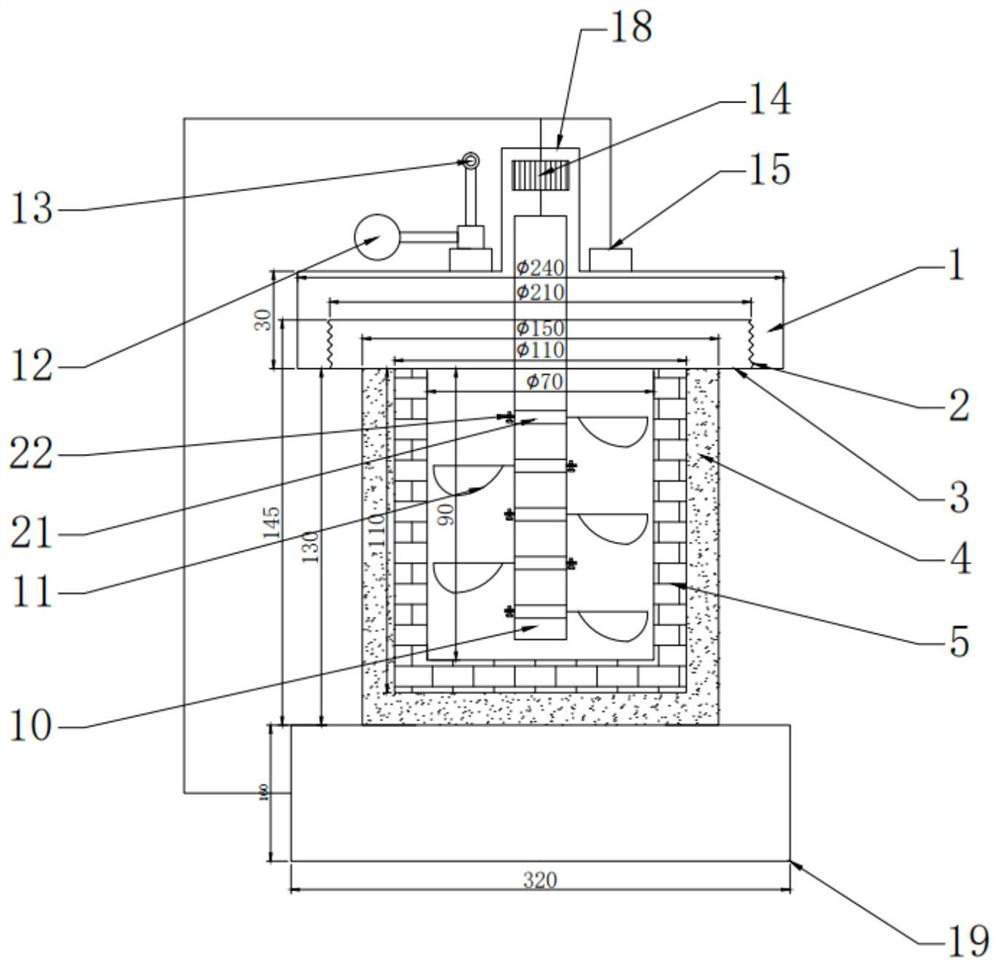

Precise numerically-controlled invertible vertical honing equipment

ActiveCN101811282BAutomatically compensates for wearReal-time monitoring of processing statusHoning machinesEngineeringAutomation

The invention relates to precise numerically-controlled invertible vertical honing equipment, which comprises at least one honing head unit, a rotary driving mechanism for controlling rotary motion of the honing head unit, a stroke driving mechanism for controlling reciprocating stroke motion of the honing head unit, a motion detection device for detecting hole parameters, a control unit for controlling each machining unit and a workbench device for mounting a part to be machined. The rotary driving mechanism and the stroke driving mechanism are connected with the honing head unit; the workbench device can be movably adjusted to match the position of a honing hole of the part to be machined and the honing position of the honing head unit; and the motion detection device detects the honed hole, and compensates the abrasion of a honing strip on line. The honing equipment can detect the machining state in real time, and can compensate the abrasion of the honing strip on line; a workbenchcan move left and right, and precisely locks the current position of the honing hole of the part to be machined by combining an indexing rotary device; and the honing equipment has high automation degree, and can precisely machine various parts.

Owner:SUZHOU XINNENG PRECISE MACHINERY

Low-wear rotary compensator

InactiveCN108386634AGuaranteed tightnessReduce frictionPipeline expansion-compensationAdjustable jointsInternal pressureEngineering

The invention relates to a low-wear rotary compensator. The low-wear rotary compensator comprises an outer cylinder (1) and an inner cylinder (2), wherein the outer wall of the inner cylinder is sleeved with a rubber sleeve (4), and the rubber sleeve is sleeved with a pressure-bearing cylinder (5). Annular surfaces extending inward are correspondingly arranged at the two ends of the pressure-bearing cylinder, and flanges extending outward are correspondingly arranged on the two ends of the rubber sleeve. A baffle ring (3) is arranged on the left side of the rubber sleeve, and a gland (5) is arranged on the right side of the rubber sleeve. A left annular surface of the pressure-bearing cylinder is hermetically connected with a plurality of drainage tubes (8), and the drainage tubes sequentially penetrate through the left flange and the baffle ring of the rubber sleeve. The low-wear rotary compensator is characterized in that the left annular surface of the rubber sleeve is in close contact with the baffle ring and the rubber sleeve and the pressure-bearing cylinder form a closed cavity after compressed by the gland, the pressure of fluid causes the rubber sleeve to cling to the outer wall of the inner cylinder to realize the seal between the inner cylinder and the outer cylinder. The greater the pressure of the fluid of the rubber sleeve, the closer the contact between the rubber sleeve and the inner cylinder. When the inner cylinder rotates relative to the outer cylinder, the friction force borne by the rubber sleeve is small, and the wearing capacity of the rubber sleeve can be automatically compensated under the action of the inner pressure, and the sealing performance is maintained.

Owner:高玉琴

Novel sliver discharging device

InactiveCN105666724AAutomatically compensates for wearGlue cut smoothlyGas supply equipmentEngineering

The invention discloses a novel sliver discharging device which comprises a bracket, a supporting rod, a cutter, an air cylinder and gas supply equipment, wherein the lower end of the supporting rod is rotatably connected with the bracket; the cutter is rotatably arranged at the upper end of the supporting rod; the air cylinder is fixedly connected with the bracket and provided with a piston rod; and the gas supply equipment is connected with the air cylinder. The upper end of the piston rod is rotatably connected with the middle upper portion of the supporting rod. The abrasion loss of a cutting edge of the cutter can be automatically compensated under the action of the air cylinder so that the cutter can be tightly attached to the roller wall of a roller, and accordingly smooth rubber cutting and slice discharging can be guaranteed. The reliability is good, and the structure is simple.

Owner:JIANGYIN XINHAI ROAD CONSTR MATERIAL

An automatic tight packing polished rod sealer

The embodiment of the invention discloses an automatic tight packing polished rod sealer, which belongs to the technical field of oil production equipment in oilfields. It includes a packing gland and a packing box connected to the packing gland. Inside the packing box, there are packing, hydraulic piston and piston gland; the piston gland, hydraulic piston and packing box together form an upper sealing oil A lower sealing oil cavity is provided inside the packing box below the packing, and the pressure oil in the oil well flows into the lower sealing oil cavity and the upper sealing oil cavity through the gap in turn. The invention conveniently realizes that the pressure oil in the lower sealing oil cavity is introduced into the upper sealing oil cavity, and the pressure oil directly acts on the upper surface of the hydraulic piston, and the hydraulic piston automatically pressurizes and seals the packing under the action of the pressure oil, It avoids the excessive wear on the packing usually caused by manually increasing the pre-tightening force, improves the service life of the packing, has a simple structure, low processing and manufacturing costs, and is safe and reliable.

Owner:江天科技有限公司

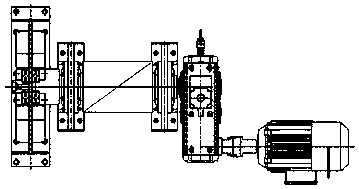

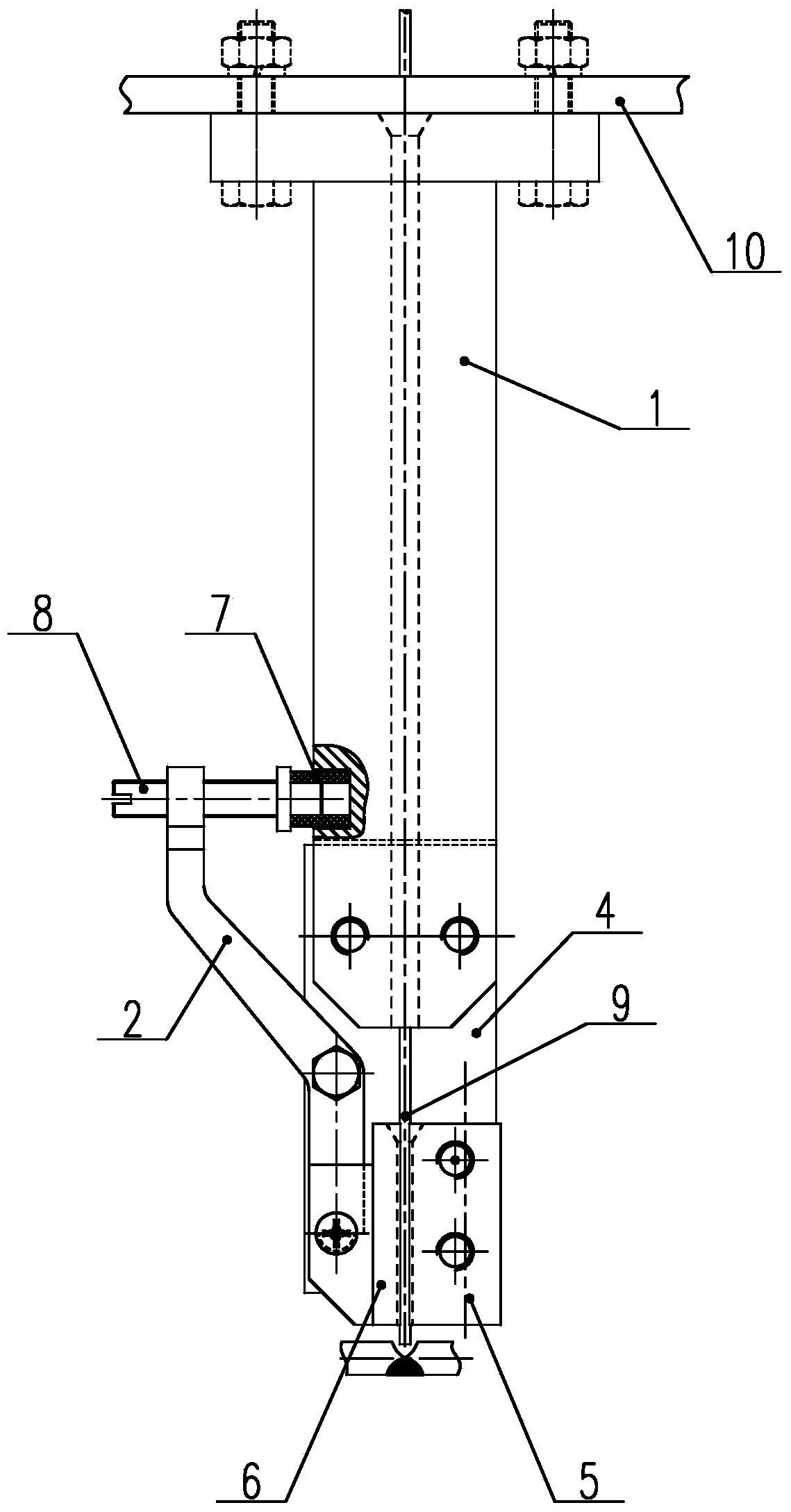

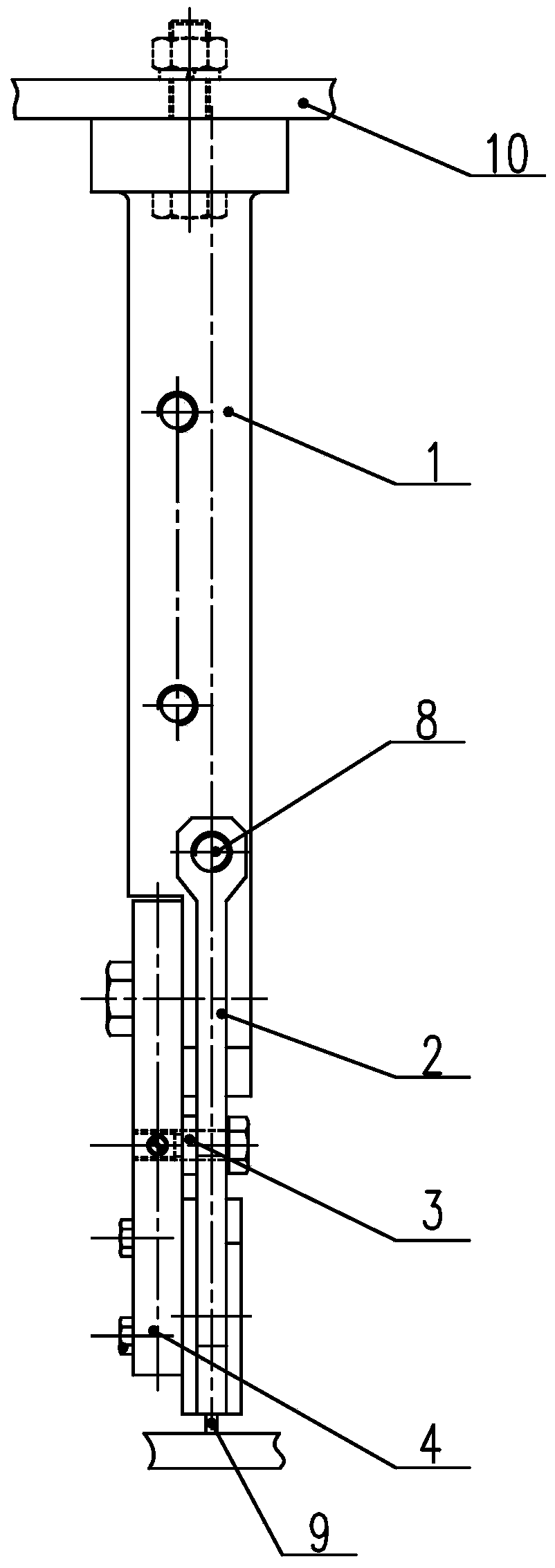

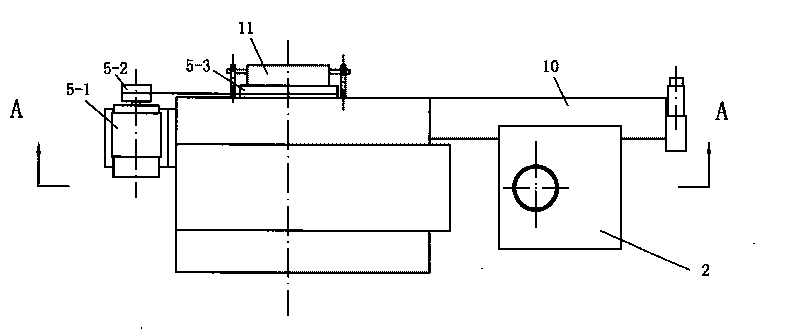

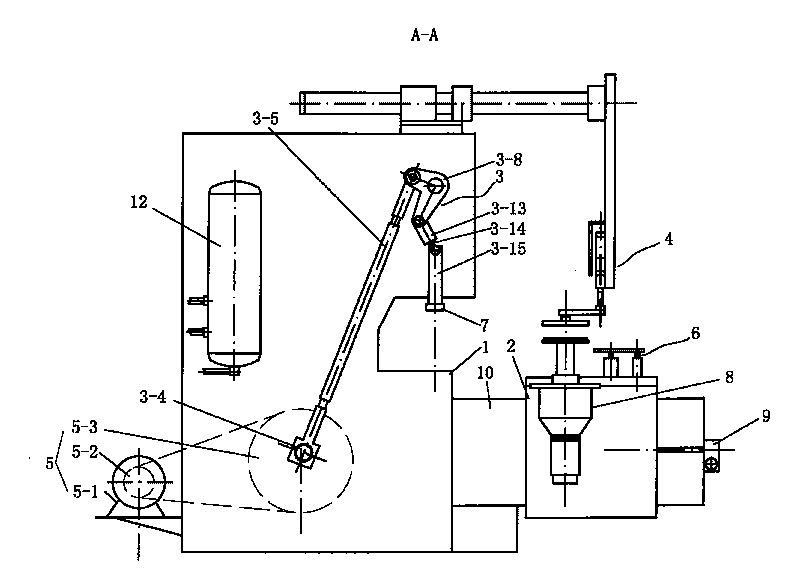

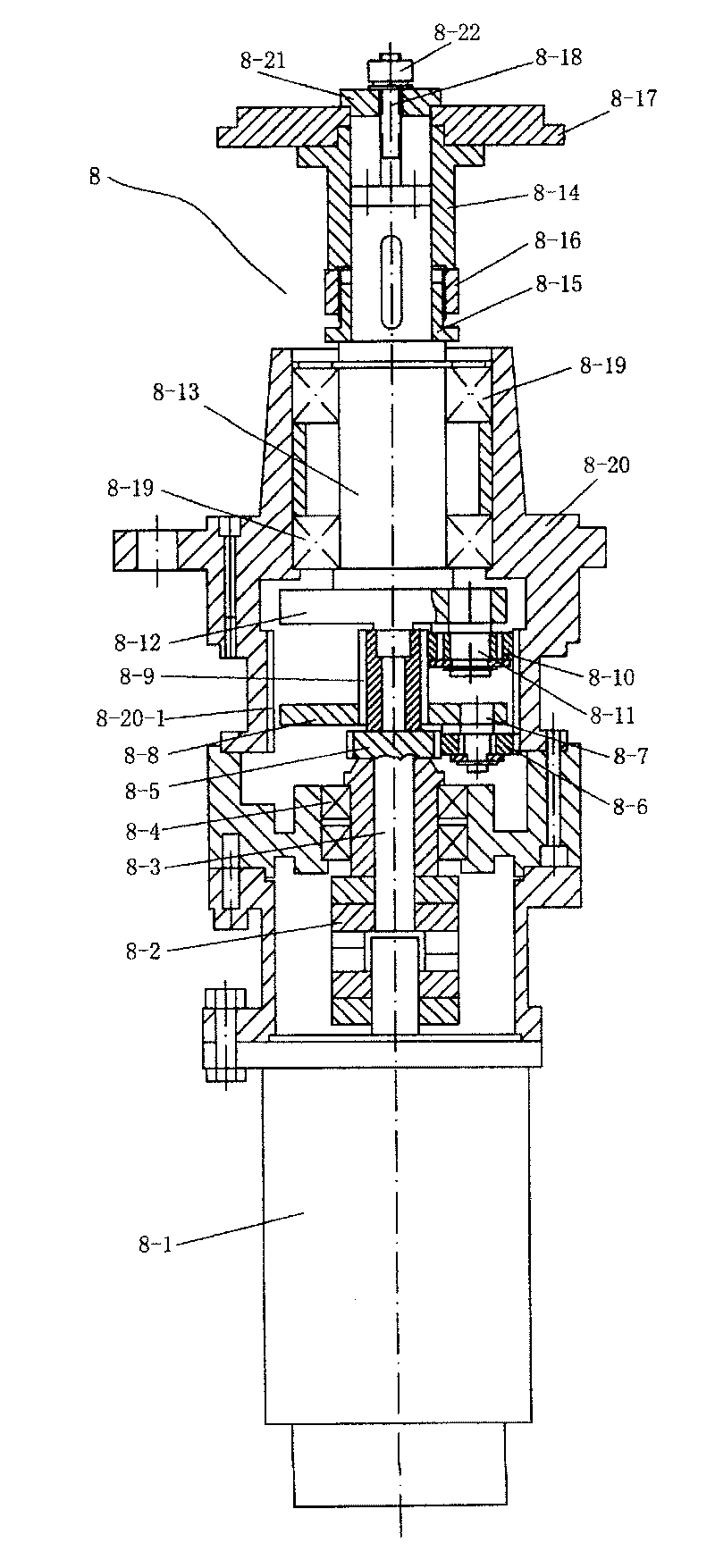

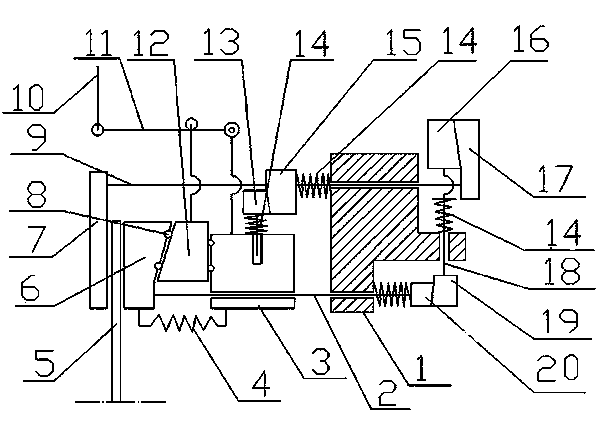

Main unit of numerical control notching press

ActiveCN101244441BSuitable for intelligent controlCompact structureManufacturing dynamo-electric machinesNumerical controlPunching

Owner:常州市耀华电机设备有限公司

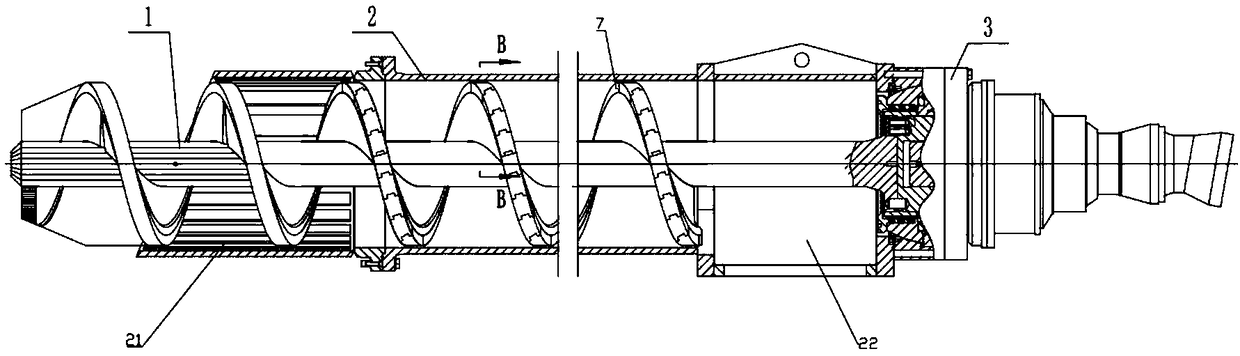

Spiral conveyor with blade wear-resistant layer capable of being compensated

PendingCN109368156AAutomatically compensates for wearImprove transportation capacityPackagingWear resistantSpiral blade

The invention discloses a spiral conveyor with a blade wear-resistant layer capable of being compensated. The spiral conveyor comprises a cylinder body, a screw rod and a driving device, wherein the screw rod is arranged in the cylinder body in a penetrating mode, the driving device is fixed to the outer end of the cylinder body, and spiral blades are fixed on the outer side surface of the screw rod; a plurality of limiting screws are sequentially fixed on the portions, located inside the cylinder body, of the spiral blades and close to the outer end of the cylinder body, each limiting screw is provided with a blade wear-resistant block, each blade wear-resistant block is provided with a movable limiting groove, the inner end of each blade wear-resisting block sleeves outside the corresponding limiting screw of the spiral blade, the limiting screws are arranged in the movable limiting grooves, and a thrust spring is arranged between each blade wear-resistant block and the outer end ofthe corresponding spiral blade. According to the spiral conveyor, when the wear-resistant blocks are abraded, the wear-resistant blocks can automatically exit through the thrust springs, so that the abrasion loss is compensated, and not only is the service life of the spiral blade greatly prolonged and the stable working efficiency can be kept, but also the abrasion-resistant blocks can be directly replaced on the construction site when the wear-resistant blocks are damaged.

Owner:JIANGSU KAIGONG TUNNEL MACHINERY

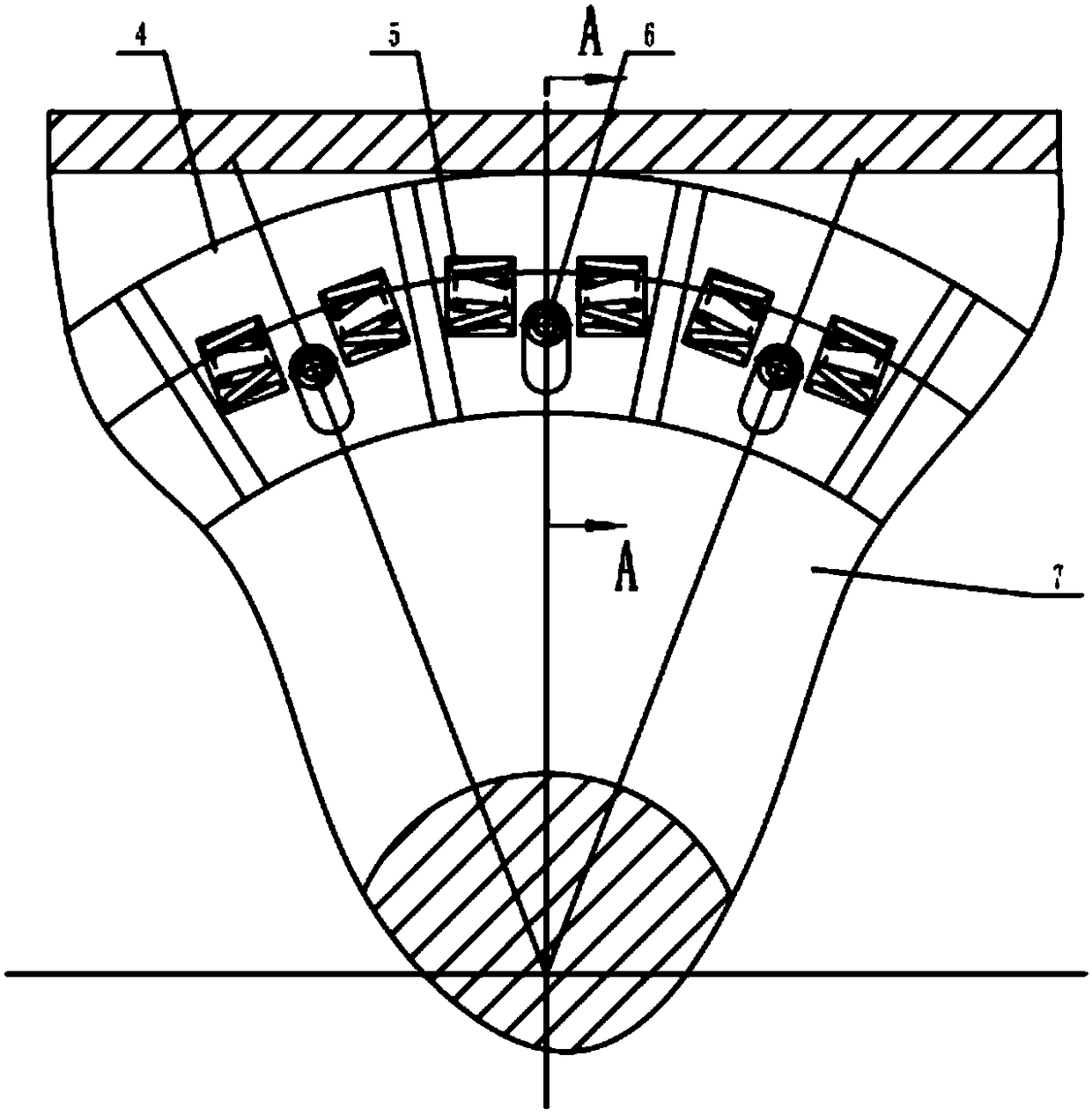

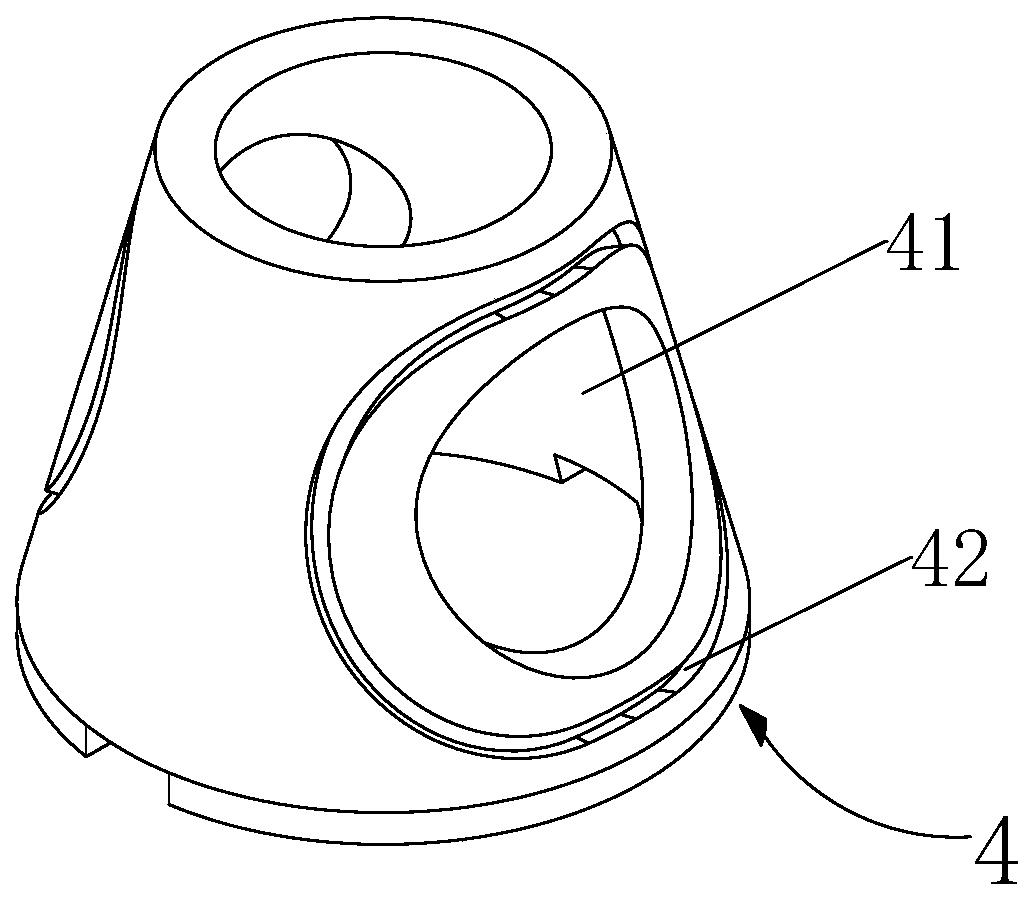

Cock regulating valve with high adjustable ratio

ActiveCN110425297AHas equal percentage flow characteristicsAchieving controllable flow characteristicsPlug valvesValve housingsEngineeringDrop-shaped

The invention relates to a cock regulating valve with a high adjustable ratio, belongs to the technical field of pipeline valves. The cock regulating valve comprises a valve body, a valve body sealingassembly, a valve rod, a valve seat and a cock, wherein the valve body is provided with a longitudinal through hole and a transverse through hole; the valve rod and the cock are arranged in the longitudinal through hole; the valve body sealing assembly is arranged at the bottom of the cock; the valve seat is hollow frustum-shaped, and the cock is frustum-shaped; the valve seat sleeves outside thecock, the outer side of the valve seat is hermetically matched with the valve body, and the inner side of the valve seat is in sliding fit with the cock; the valve seat is provided with a valve seatthrough hole which communicates with the transverse through hole, and the valve seat is fixedly connected with the valve body sealing assembly; the cock is provided with two water drop-shaped windows;and a cock passage is formed between the two drop-shaped windows, and the two drop-shaped windows are symmetrical in the axial direction of the cock. When the regulating valve is small in opening degree, the regulating valve has a linear flow characteristic; when the regulating valve is large in opening degree, the regulating valve has an equal percentage flow characteristic, high flow capacity and a high adjustable ratio; and when the regulating valve is fully opened, the throttling area is equal to the cross section area of inlet and outlet flow channels of the valve, and the flow resistance is extremely small.

Owner:HEFEI GENERAL MACHINERY RES INST

Height adjusting device using in mechanical unit for screening combustible material

InactiveCN103287789AGuaranteed uptimeExtended service lifeConveyorsEngineeringMechanical engineering

The present invention relates to a height adjusting device using in a mechanical unit for screening combustible materials. The device comprises a fixing member, a base frame, at least one guide rod, a movable plate and a driving source. A drive sprocket and a driven sprocket are coupled to the fixing member to form a single unit. The base frame is adapted to be fixed on the top of a main frame. The main frame is adapted to fixedly supporting a mixed material conveyor. The guide rod is adapted to be vertically fixed to the top surface of the base frame. The movable plate is adapted to be fitted to the guide rod, thus moving up and down. The driving source is adapted to be fixed to the base frame and is connected to the lower side of the movable plate, thereby moving the movable plate up and down, wherein the fixing member is adapted to be fixed to the movable plate.

Owner:FORCEBEL +1

Stirrer magnetic fluid sealing device

InactiveCN108413043AAutomatically compensates for wearFix stability issuesEngine sealsAxial displacementEngineering

The invention discloses a stirrer magnetic fluid sealing device. The stirrer magnetic fluid sealing device is composed of an inner ring and an outer ring, a high-speed main shaft is vertically arranged in a shaft table, a belt wheel is arranged at the top of the main shaft, a high-speed bearing block is arranged below the main driving belt wheel, and the upper part of the belt wheel is provided with a magnetic fluid seal III and an electronic slip ring; a bearing press plate under the high-speed bearing block is located on the shaft table, and a magnetic fluid seal II, a gear and a magnetic fluid seal I are sequentially arranged under the bearing press plate; the inner ring is arranged on the high-speed main shaft, an upper bearing and a lower bearing are arranged between the inner ring and the outer ring, and a hollow shaft is used as a mounting carrier; and O-shaped rings are arranged at the bottoms of the magnetic seals, and the sealing rings and the top of the hollow shaft form theseals. Compared with a traditional mechanical sealing structure, the stirrer magnetic fluid sealing device is characterized in that the structural elements are small and compact, installation is convenient, and the elastic force of an elastic element is replaced by the magnetic force, so that influences caused by a manufacturing error, an installation error and the axial displacement during working are avoided; and compared with a common sealing structure, the device is reliable in working, small in abrasion and long in service life.

Owner:SHAOYANG DALI POWER SUPPLY IND CO LTD

High-pressure reaction kettle

InactiveCN112044358AAchieve sealingAutomatically compensates for wearProcess control/regulationChemical/physical/physico-chemical stationary reactorsHeater RodEngineering

The invention discloses a high-pressure reaction kettle which comprises a kettle body and a kettle cover, the kettle cover is connected to the top of the kettle cover, a magnetic sealing assembly is connected between the kettle cover and the kettle body, the kettle body sequentially comprises a heat preservation layer, a heating layer and an inner container from outside to inside, and a stirring shaft is rotatably connected to the central axis in the kettle body. The stirring shaft is driven to rotate by a driving system arranged on the kettle cover, stirring blades are fixed on the stirring shaft, the stirring shaft is an electric heating rod, and the heating layer, the electric heating rod and the driving system are respectively and electrically connected to a control panel. The stirringefficiency and the kettle body sealing performance can be considered at the same time, the integration of temperature measurement and a control device is realized, the heat transfer efficiency in thereaction kettle is enhanced, the reaction efficiency and the experiment safety are further improved, and the innovative significance is realized.

Owner:FUJIAN UNIV OF TECH +1

High airtight rotary discharger with storing spiral cavity and contact type self-compensating flat surface

InactiveCN102942029AHigh air-tightnessAutomatically compensates for wearRotary conveyorsCross-linkImpeller

The invention discloses a high airtight rotary discharger with a storing spiral cavity and a contact type self-compensating flat surface. The high airtight rotary discharger comprises a cylinder shell horizontally arranged and an impeller component arranged in the cylinder shell, wherein two ends of an impeller shaft of the impeller component extend out of a left end cover and a right end cover of the cylinder shell respectively, and are in sealed rotational connection with the left and right end covers through bearings arranged on the left and right end covers; the impeller shaft consists of a power input shaft and a vane mounting shaft which are connected through a cross-linked coupling; a ring groove is axially arranged on the end surface where the vane mounting shaft and the power input shaft are connected, and a pressure spring is mounted in the ring groove; an annular wearable liner plate in tight fit with the vane of the impeller component is fixed on the inner surface of the right end cover; and a feeding barrel and a discharging barrel are communicated with the upper side and lower side of the right end cover. The invention has the advantage that pretty high air locking tightness can be ensured whiling realizing uniform discharge under differential pressure, and the automatic wear compensation can be realized during the discharging process.

Owner:ZHENGZHOU AIRCRAFT EQUIP

Spherical hinged support for opening and closure of door

A spherical hinged support for opening and closure of a door comprises a door frame, a door leaf, a movable hinged support body connected to the door leaf and a fixed hinged support body connected to the door frame, wherein the movable hinged support body is provided with a hinge sleeve, the fixed hinged support body is provided with a hinge sleeve, and the hinge sleeves are hinged to each other. The spherical hinged support for opening and closure of the door is characterized in that notches are formed in the combination portions of the hinge sleeves correspondingly, and a steel ball is placed into each notch. The spherical hinged support for opening and closure of the door further comprises a pressure application structure for applying pressure to the steel balls. The spherical hinged support for opening and closure of the door is simple in structure and small in friction resistance, spherical surface abrasion is automatically compensated, and spherical surface is kept.

Owner:贵州瑞安达人防设备有限公司

Automatic filling sealing structure for high-pressure valve

ActiveCN102313074BUniform deformationUniform pressing forceSpindle sealingsHigh pressureMechanical engineering

The invention relates to an automatic filling sealing structure for a high-pressure valve, which comprises a valve rod filling box body, a valve rod, a filling assembly and a support plate, wherein a difference pressure ring block in a step shaft sleeve structure is coaxially arranged on the valve rod arranged between the support plate and the filling assembly in the filling box body, a gap is formed between the upper plane of the step of the difference pressure ring block and the radial matched surface made in the filling box body, a waveform elastic element is coaxially pressed on the valverod arranged between the difference pressure ring block and the support plate, the filling assembly is coaxially arranged on the valve rod arranged in the filling box body at the inner side of the difference pressure ring block and sequentially comprises a filling pad, woven forming fillings, a filling separation sleeve and forming press ring fillings from top to bottom, the woven forming fillings, the filling separation sleeve and the forming press ring fillings are fixedly assembled. The sealing can be automatically formed under the medium pressure effect, the structure is simple, the effect is obvious, the sealing reliability of the movable sealing position of the valve rod is greatly improved, the filling abrasion can be automatically compensated through the structure, and the sealingpressure of the fillings in the use process is maintained.

Owner:TIANJIN BAILIZHANFA GRP

Self-compensating vacuum valve

PendingCN107461507AAchieving wear resistanceExtended service lifeSpindle sealingsLift valveEngineeringWear resistance

The invention belongs to the technical field of valves, and discloses a self-compensating vacuum valve. The self-compensating vacuum valve comprises a valve body, a valve rod, a valve seat, a flow rate adjusting mechanism and a valve element, wherein the valve body is provided with an air inlet and an air outlet; the valve seat is arranged in an inner cavity of the valve body; the flow rate adjusting mechanism is arranged at the outside of the valve body and is connected to one end of the valve rod; the valve element is arranged in the valve body and is in match with the other end of the valve rod; the valve seat is in sealing connection with the wall of the inner cavity of the valve body; a valve hole is formed in the center of the valve seat; the valve element is a circular platform of which one end is provided with a taper; a guide groove which protrudes from the surface of the valve seat and fits the taper of the valve element is formed in the valve hole; a valve column provided with a concave groove is arranged at a part where the outside of the valve body is in contact with the valve rod; the concave groove is filled with a flexible filler; a pressing plate which is connected to the valve column in a force balancing manner is arranged o the valve rod; the first surface of the pressing plate fits the concave groove, and the second surface of the pressing plate is provided with locking structures which are used for connecting the pressing plate and the valve column; the pressing plate is elastically connected to the locking structures. According to the vacuum valve, the valve element is automatically centered, and the valve rod is extruded by the filler to downwards move, so as to automatically compensate the abrasion loss of the valve element and the guide groove, thus the abrasion resistance of the vacuum valve is improved, and the service life is prolonged.

Owner:郴州万墨环保科技有限公司

Mechanical disc brake with automatic adjustment of shoe clearance

ActiveCN106151330BAutomatically compensates for wearLow costSlack adjustersBrake torqueAgricultural engineering

The invention discloses a mechanical disc brake with the shoe block clearance automatically adjusted. The mechanical disc brake is characterized in that a left shoe block is fixedly connected with one end of a left shaft, the other end of the left shaft penetrates through a base and connected with a left wedge block, and a passive wedge block is fixedly installed in the middle of the left shaft; a right shoe block is fixedly connected with one end of a right shaft, and the other end of the right shaft penetrates through the base and fixedly connected with a right wedge block; a right shaft section between the right shoe block and the base is sleeved with a slide block; an active wedge block is arranged between the slide block and the right shoe block, and the two surfaces of the active wedge block make contact with the right shoe block and the slide block through steel balls; a connection shaft perpendicular to the right shaft and the left shaft is installed on the base, a right stop block and a left stop block are connected to the two ends of the connection shaft, the right stop block is in bevel fit with the right wedge block, and the left stop block is in bevel fit with the left wedge block; and the slide block is provided with a push block which is in prismatic pair fit with the slide block, and the push block is in bevel fit with the passive wedge block. According to the mechanical disc brake with the shoe block clearance automatically adjusted, the shoe block clearance of the mechanical disc brake is automatically adjusted, and the mechanical disc brake has the characteristics of being low in cost and large in braking torque.

Owner:毛琴飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com