Mechanical disc brake with automatic adjustment of shoe clearance

An automatic adjustment and shoe block technology, which is applied in the field of mechanical disc brakes, can solve problems such as insufficient braking torque, jumping, and magnification of influence, and achieve the effects of automatic adjustment of shoe block clearance, large braking torque, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

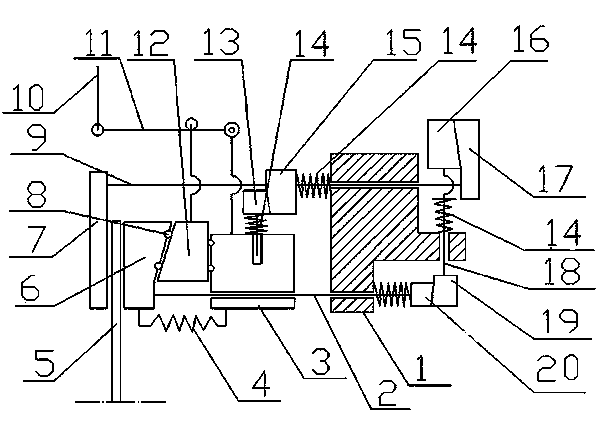

[0009] A mechanical disc brake with automatic adjustment of shoe gaps, comprising base 1, right shoe 6, left shoe 7, steel wire rope 10, pull rod 11, left shoe 7, right shoe 8 installed at the left and right ends of disc 5 , it is characterized in that the left shoe block 7 is fixedly connected with one end of the left shaft 9, the other end of the left shaft 9 passes through the base 1 and is connected with the left wedge block 17, the passive wedge block 15 is fixedly installed in the middle of the left shaft 9, and the passive wedge block 15 A spring 14 is provided on the left shaft section between the base 1; the right shoe block 6 is fixedly connected with one end of the right shaft 2, and the other end of the right shaft 2 passes through the base 1 and is fixedly connected with the right wedge block 20, and the right wedge block 20 is connected with the A spring is arranged on the right shaft section between the bases 1, the slide block 3 is set on the right shaft section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com