High airtight rotary discharger with storing spiral cavity and contact type self-compensating flat surface

A flat contact, self-compensating technology, used in rotary conveyors, conveyors, transportation and packaging, etc., can solve problems such as poor sealing, achieve high air tightness, and achieve the effect of automatically compensating for wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

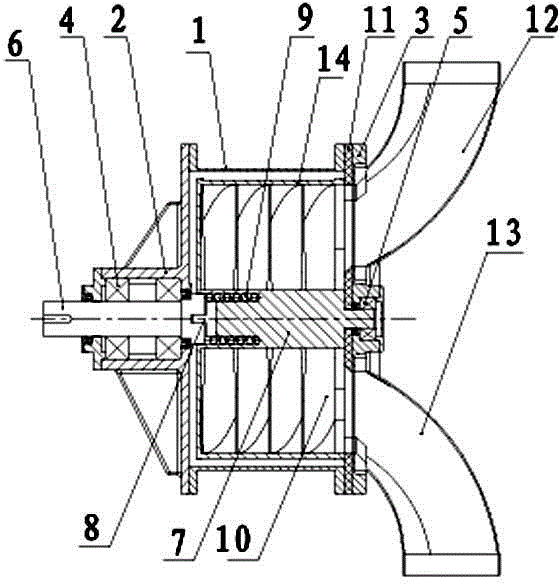

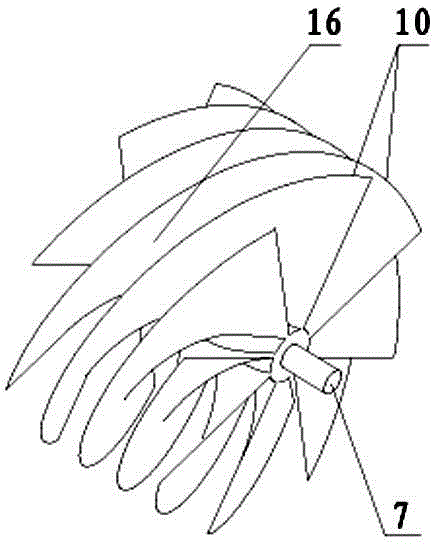

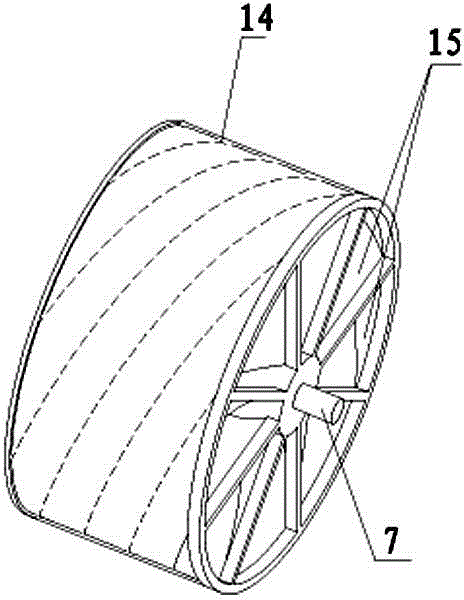

[0011] Such as figure 1 , 2 , 3, the self-compensating plane contact type high-airtight rotary unloader for spiral cavity material storage according to the present invention includes a horizontally arranged cylindrical shell 1 and an impeller assembly horizontally arranged in said cylindrical shell 1, so The two ends of the impeller shaft of the impeller assembly respectively extend out of the left and right end covers 2 and 3 of the shell 1, and pass through the bearing bodies 4 and 5 arranged on the left and right end covers 2 and 3 and the left and right end covers 2, 3 are sealed and rotated connected; the impeller shaft is composed of a power input shaft 6 and a blade installation shaft 7; the power input shaft 6 and blade installation shaft 7 are connected through a cross coupling 8 that can slide in the axial direction An annular groove is axially opened on the end face where the blade installation shaft 7 and the power input shaft 6 are connected, and a pressure sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com